Backlight module and display panel

A backlight module and backplane technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems affecting the light quality of the backlight module and inconsistent brightness, so as to improve the quality of light emitted, avoid chromatic aberration, and improve brightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

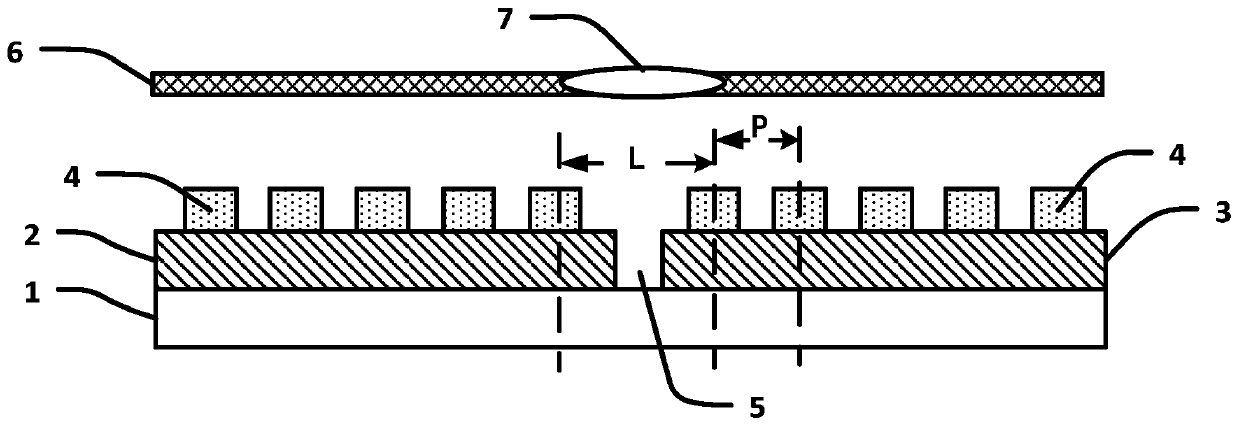

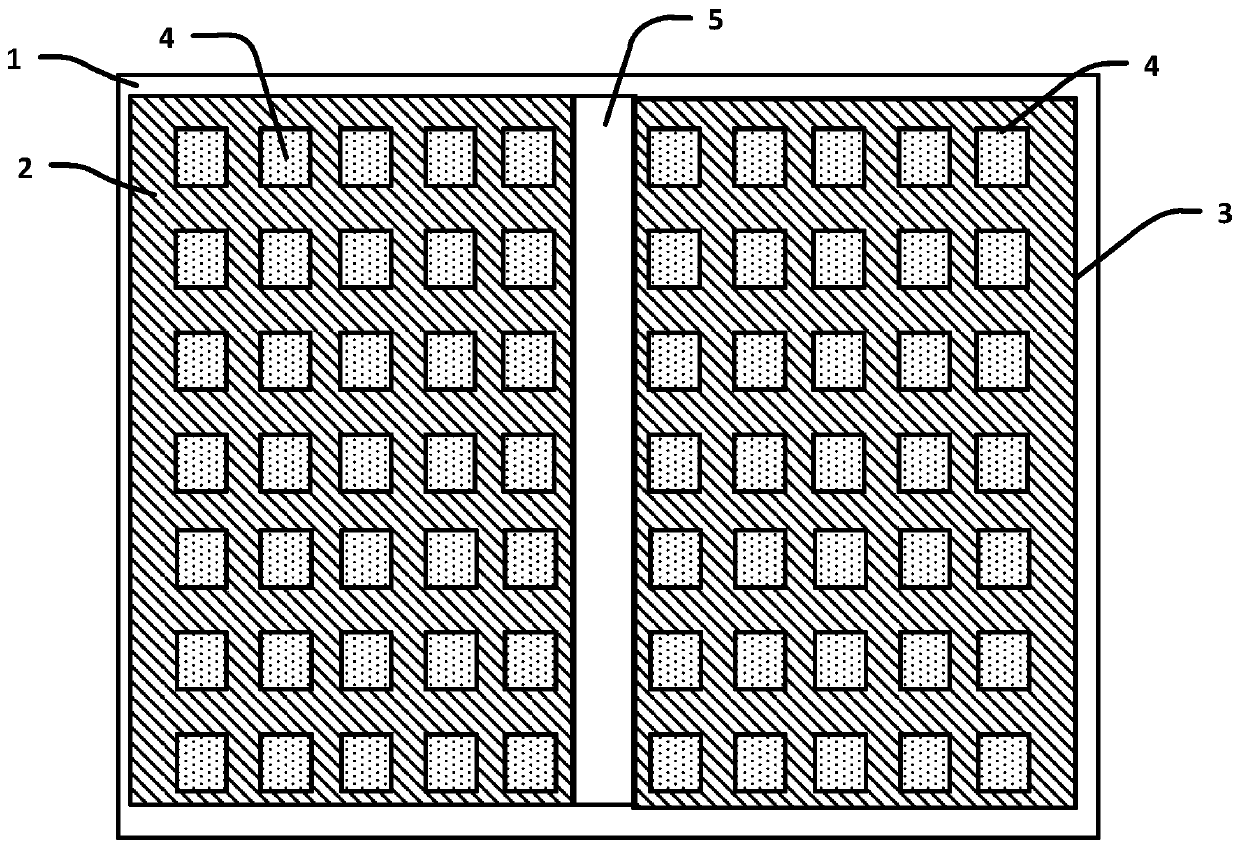

[0046] Such as image 3 As shown, this embodiment provides a backlight module, including a backplane 10 , a lamp panel 20 and a reflective layer 30 .

[0047] A plurality of lamp panels 20 are spliced and arranged on the upper surface of the back panel 10 in an array. Mini-LEDs 200 are arranged in an array on the upper surface of each lamp board 20 .

[0048] The splicing area 40 is located between the adjacent first lamp board 201 and the second lamp board 202 , the splicing area 40 has a splicing seam 401 , and the filling light material is filled in the splicing seam 401 . Wherein, the supplementary light material includes white polycarbonate (Polycarbonate, PC) and / or white titanium dioxide (TiO2). The distance between the nearest Mini-LEDs 200 between the adjacent first lamp board 201 and the second lamp board 202 is L (equivalent to the width of the splicing area 40 ), the Mini-LEDs 200 in the first lamp board 201 and the second lamp board 202 The pitch (Pitch) is P. ...

Embodiment 2

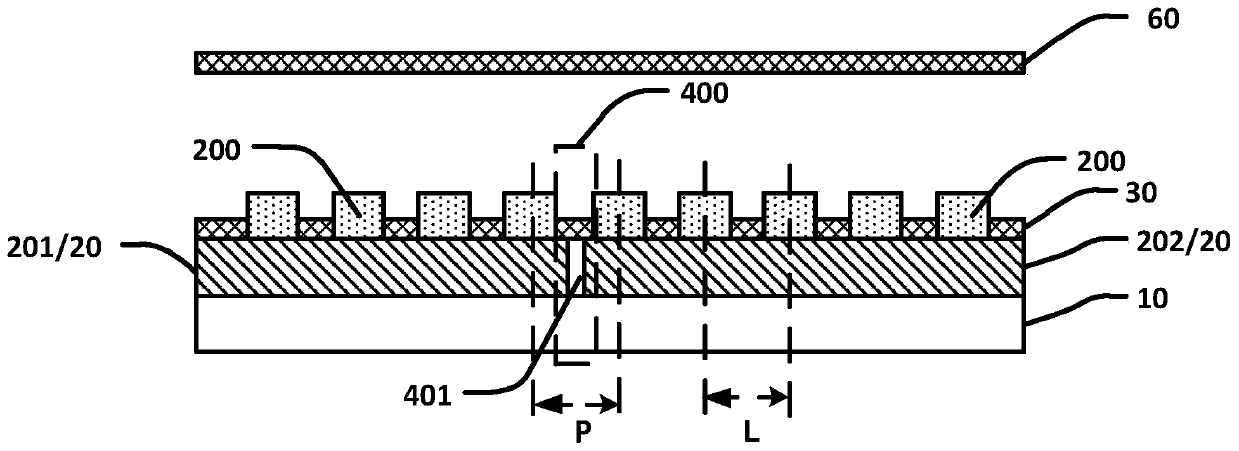

[0054] This embodiment provides a backlight module and a display panel, including most of the technical solutions in Embodiment 1, the difference being that L>P, and the backlight module further includes a reflective sheet.

[0055] Such as Figure 4-8 As shown, the two adjacent lamp panels 20 are the first lamp panel 201 and the second lamp panel 202 respectively.

[0056] Mini-LEDs 200 are arranged in an array on the upper surface of each lamp board 20, including N columns and M rows, wherein N and M are both positive integers. Wherein, the Mini-LEDs 200 in the Nth column and / or the 1st column are adjacent to one of the splicing regions 40 .

[0057] Such as Figure 4-5 As shown, the reflection sheet 50 can be disposed between the Nth column and the N−1th column of the first lamp panel 201 , or between the first column and the second column of the second lamp panel 202 .

[0058] Such as Figure 6-7 As shown, the reflection sheet 50 may also be disposed between the Nth c...

Embodiment 3

[0067] This embodiment provides a backlight module and a display panel, including most of the technical solutions of Embodiment 2. The difference is that the lamp panels in Embodiment 2 are spliced vertically, while the lamp panels in this embodiment are spliced horizontally.

[0068] Such as Figure 9-12 As shown, the adjacent two lamp panels are the third lamp panel 203 and the fourth lamp panel 204 respectively. Mini-LED200 is arranged in an array on the upper surface of each light board, including N columns and M rows, where N and M are both positive integers; the Mini-LEDs in the M row and / or the 1st row are adjacent to it A stitching area.

[0069] Such as Figure 9-10 As shown, the reflection sheet 50 is disposed between the Mth row and the M-1th row of the third lamp panel 203 , or between the first row and the second row of the fourth lamp panel 204 .

[0070] Such as Figure 11-12 As shown, the reflection sheet 50 is disposed between the Mth row and the M-1th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com