Patents

Literature

36results about How to "Has conductive properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

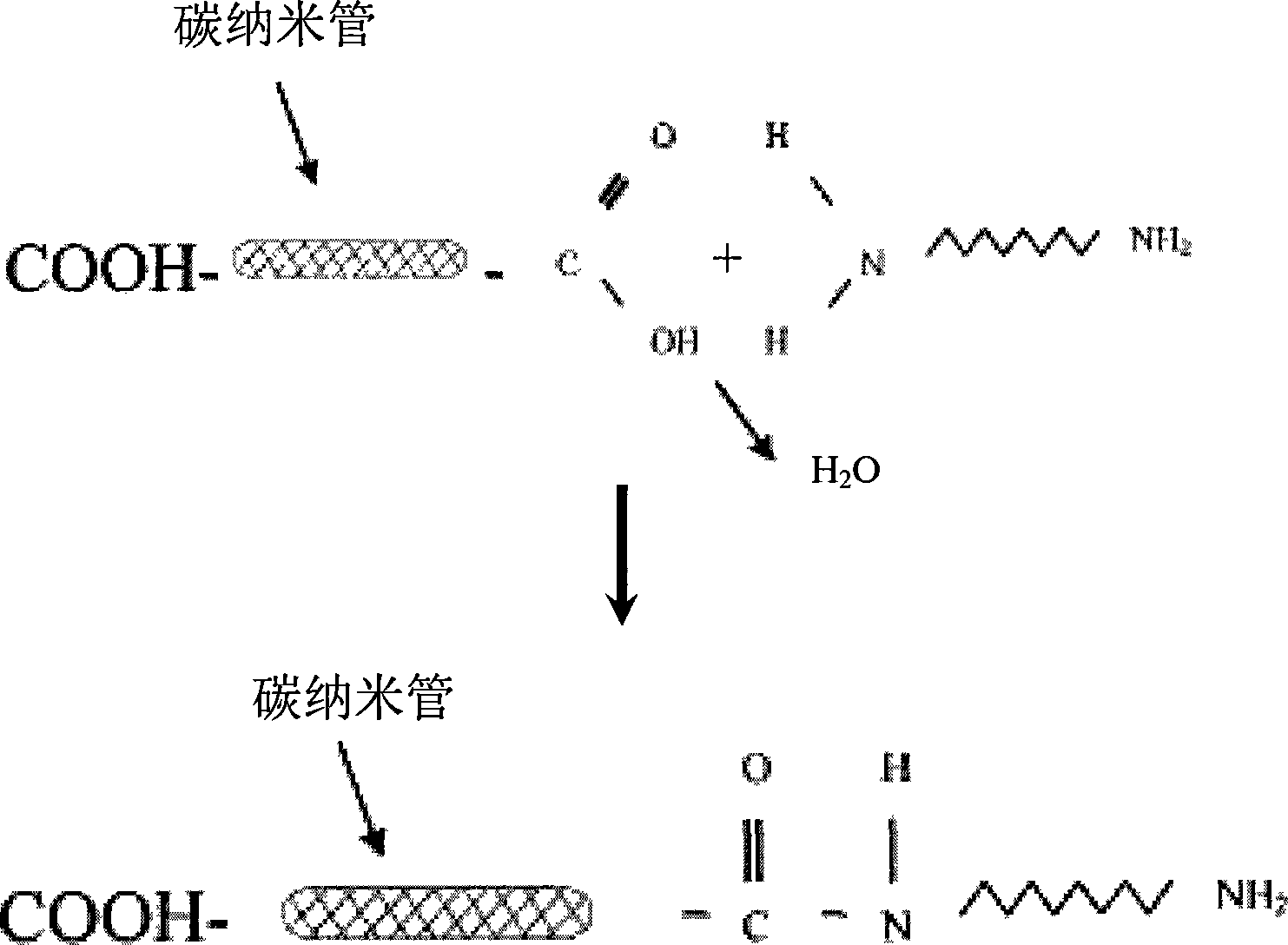

Conducing composite material and preparation method thereof

InactiveCN101085863AImprove conductivityImprove performanceNon-conductive material with dispersed conductive materialCarbon nanotubePolyamide

The invention relates to a conductive complex material, comprising functional carbon nanopipe and polyamide. The weight of said carbon nanopipe is 0.1- 10% of that of polyamide, and said carbon nanopipe is carboxylate carbon nanopipe. The carboxyl in carboxylate carbon nanopipe is reacted with polyamide or amidol in polyamide monomer to generate amido bond. The invention is characterized in that the antistatic property of polyamide is improved, and the conductivity is avaliable, and the application range is enlarged, such as used as nylon rope, nylon bale, pad and nylon braid.

Owner:上海扬泽纳米新材料有限公司

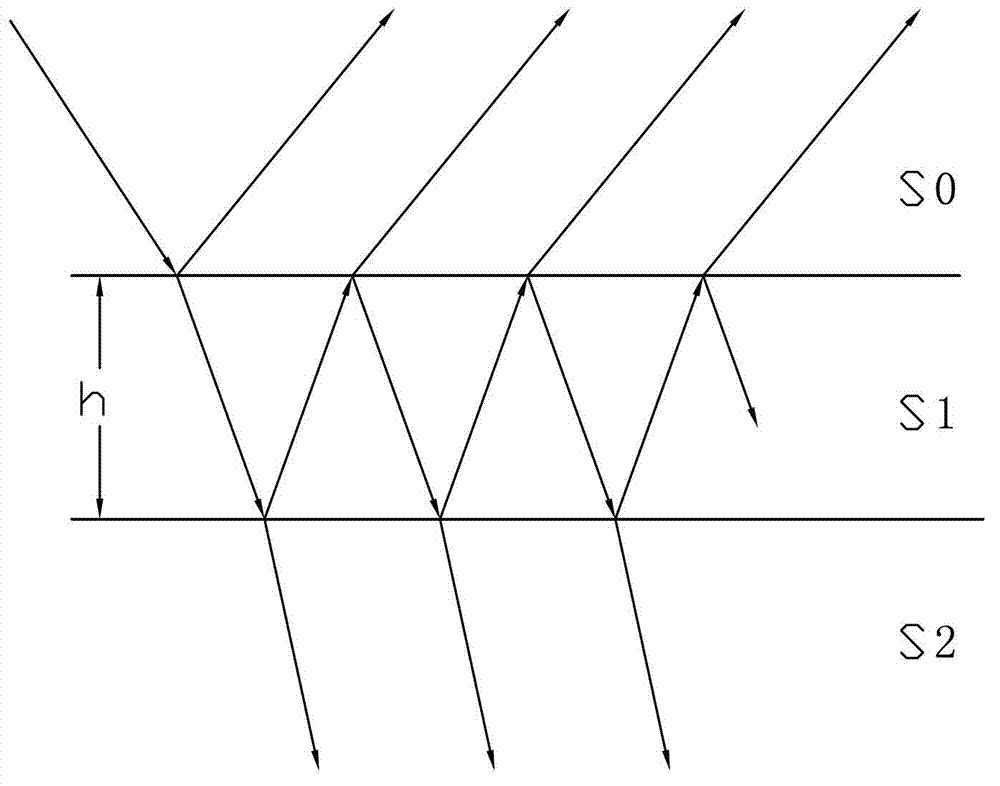

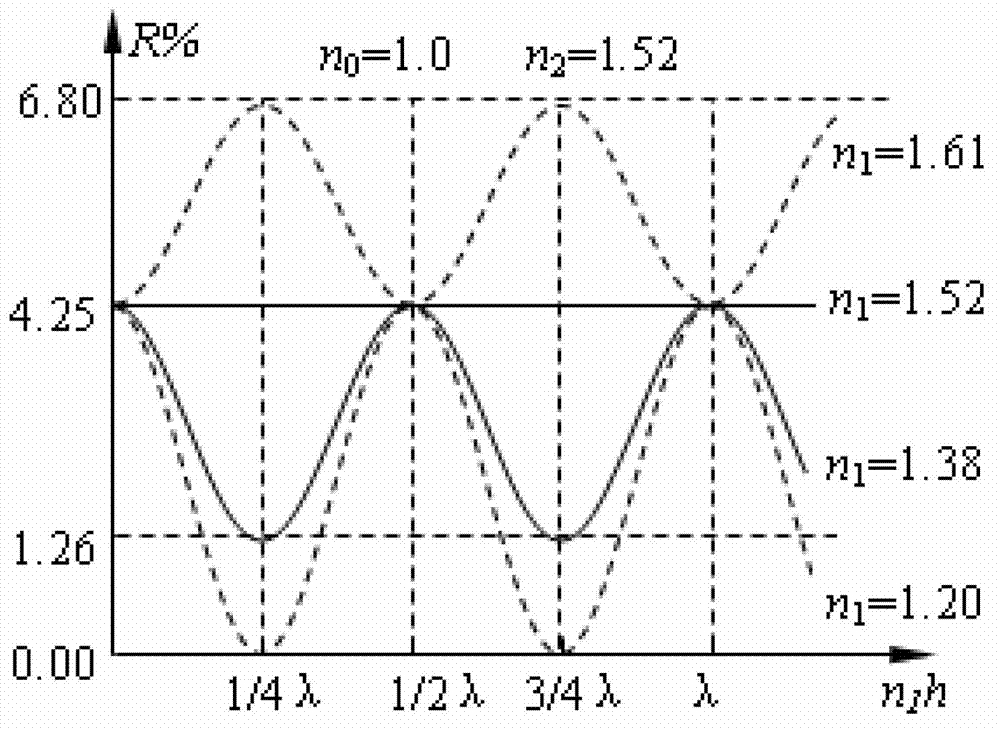

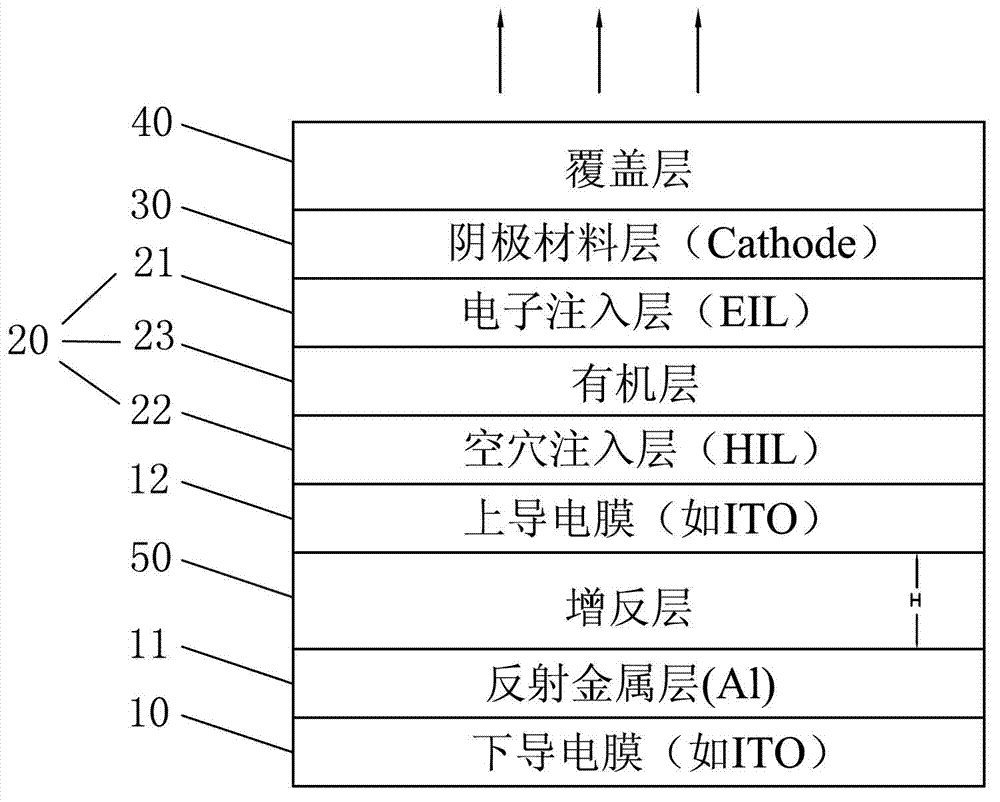

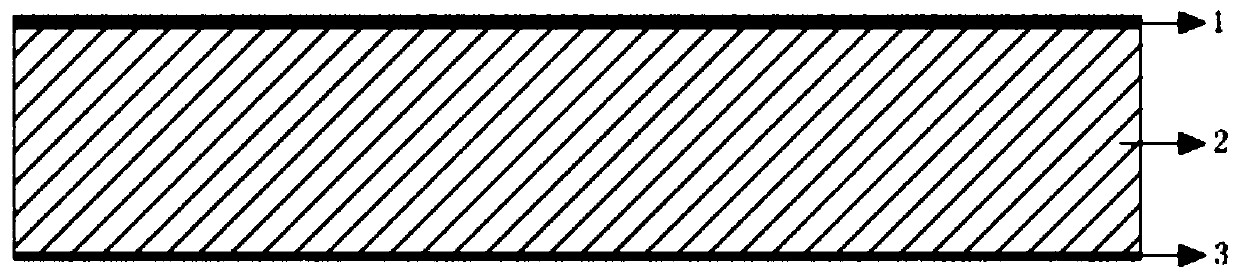

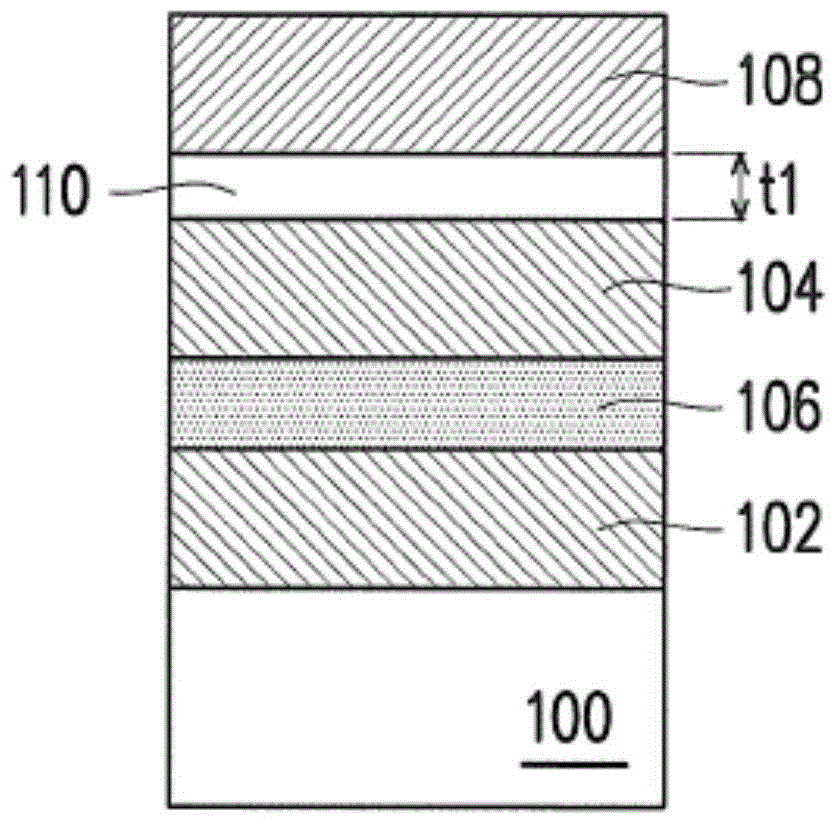

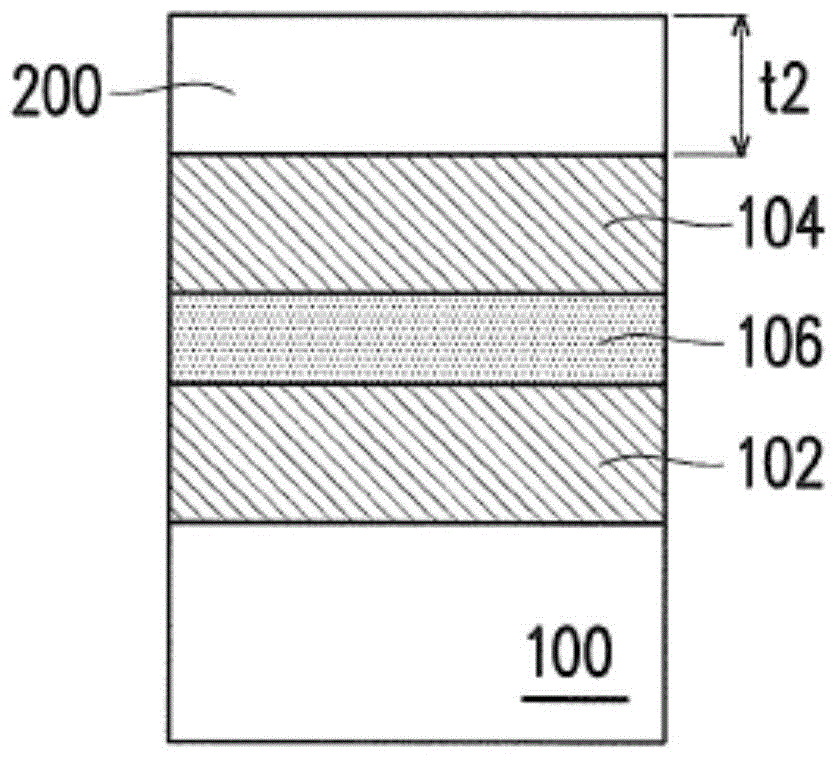

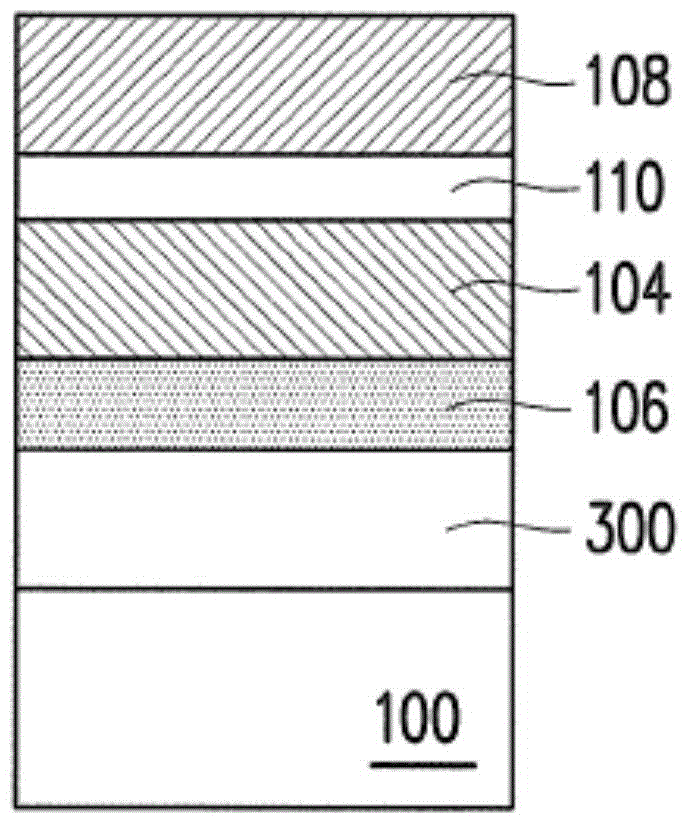

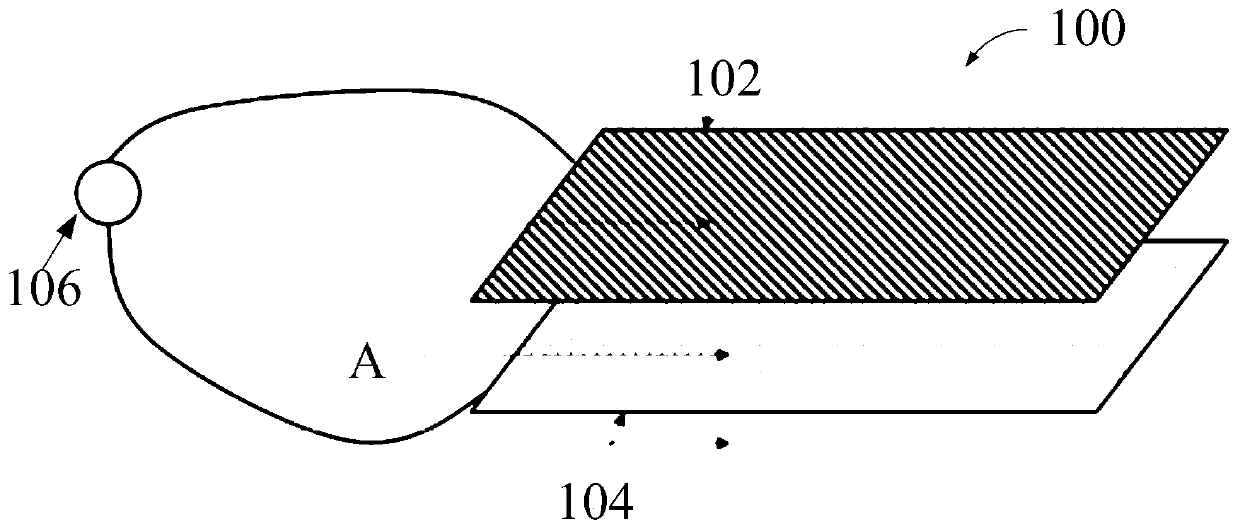

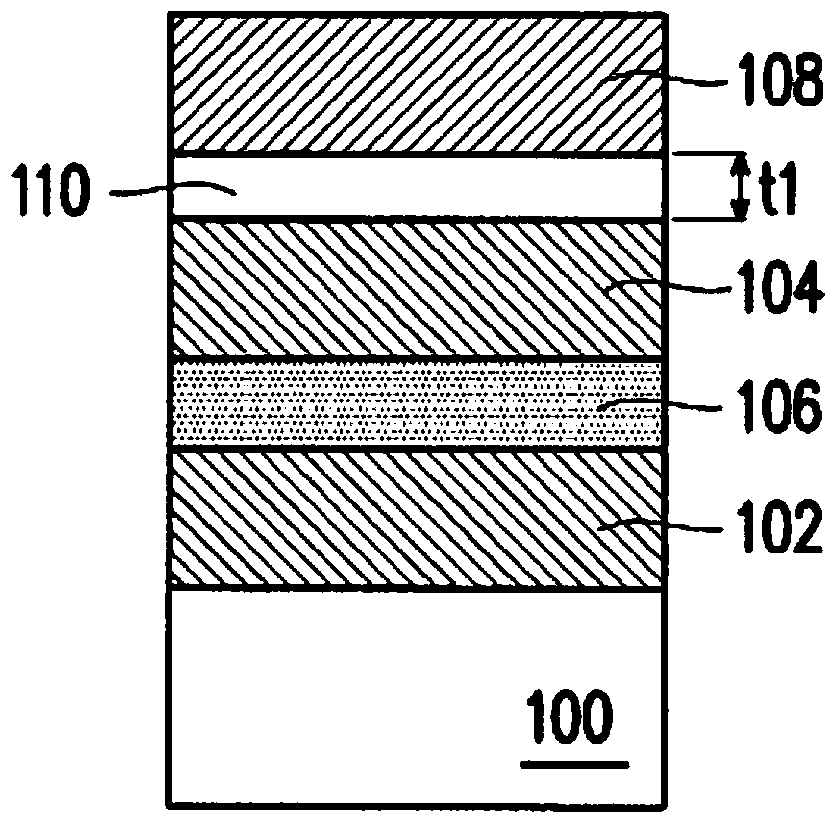

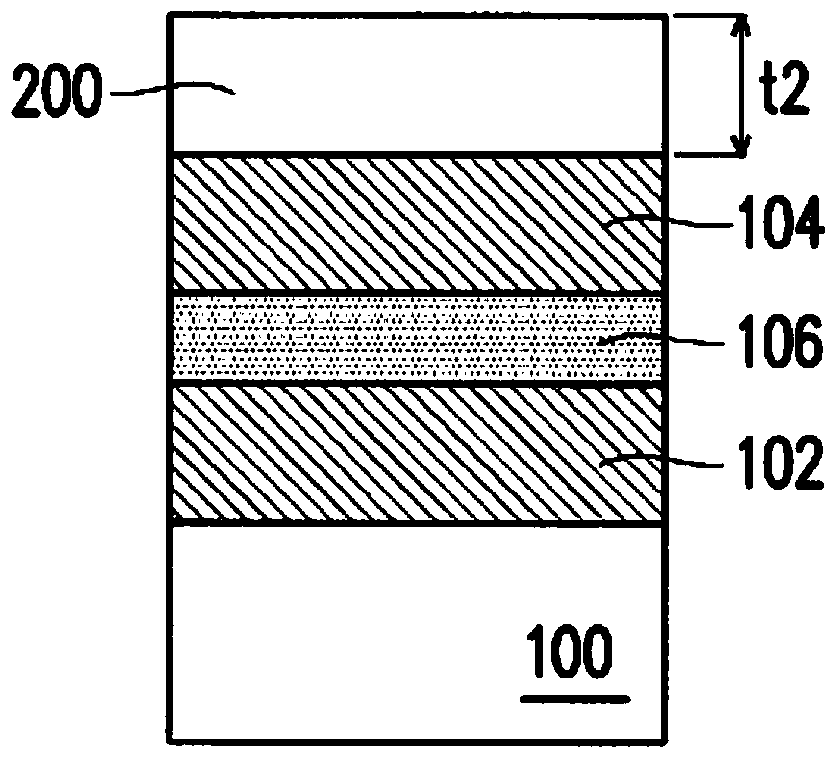

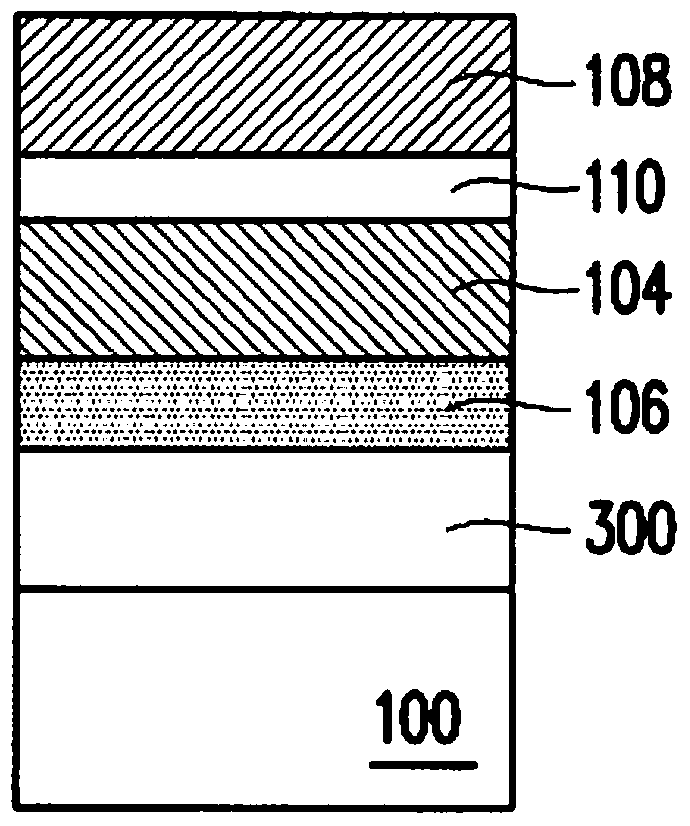

Reflection enhancement structure of OLED (Organic Light Emitting Diode) anode and reflection enhancement structure of OLED cathode

InactiveCN102891265AHas conductive propertiesGood electrical conductivitySolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexLight-emitting diode

The invention provides a reflection enhancement structure of anOLED (Organic Light Emitting Diode) anode and a reflection enhancement structure of an OLED cathode. A reflection enhancement film with electroconductive properties are added in an anode structure or a cathode structure of an OLED, and the refractive index of the reflection enhancement film is more than the refractive rate of the two adjacent material layers, so that a reflection enhancement effect can be achieved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

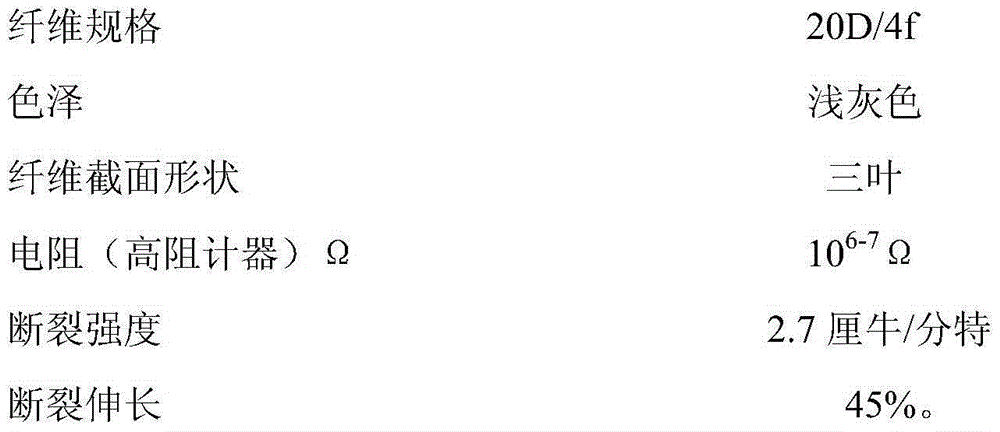

Method for manufacturing conductive polyester fibers

ActiveCN102978744AHas conductive propertiesEasy to processElectroconductive/antistatic filament manufactureFilament/thread formingPolyesterBreaking strength

The invention discloses a method for manufacturing conductive polyester fibers. The method comprises the following steps of: adding conductive materials including ATO conductive powder, superconducting carbon black, zinc oxide whiskers, potassium titanate whiskers and the like into polyester to prepare conductive polyester; and taking the conductive polyester as a skin layer to prepare polyester conductive fibers with other polyesters through a composite spinning technology. Through the method, the skin layer part of the fibers contains conductive substances, so that the fibers have excellent physical and processing performance of synthetic fibers while having conductivity, the resistivity of the polyester fibers can be greatly reduced, and the breaking strength of the fibers can also be improved.

Owner:ZHEJIANG SCI-TECH UNIV

Method for producing conductive geotextile

The invention relates to a production method, in particular to a method for producing conductive geotextile. The method for producing the conductive geotextile comprises the steps of raw material selection, raw material screening, drying, fusion, spinning, cross air blow cooling, airflow drafting, swinging, net laying, mixed even feeding of metal fibers, carbon fibers and other short fibers, ironing conducted by a hot roller, shaping conducted by a pre-needle machine, reinforcing shaping conducted by a first main needle machine, repair shaping conducted by a second main needle machine, cloth containing conducted by a cloth containing machine, trimming and rolling. The geotextile produced according to the method for producing the conductive geotextile has the protective performance, the isolating performance, the waterproof performance, the filtering performance and the like of traditional geotextile, further has the conductive characteristic and is a good electrode material. According to the method for producing the conductive geotextile, the production technology is stable, control over the thickness of a material is good, the control range of the puncture density is large and is 50 to 500 stitches / cm<2>, the controllable range of the permeability performance of the material is large and is (1.0-9.9)*(10<-1>-10<-3>)cm / s, the strength of the product is high, and the thickness reaches 20mm.

Owner:大连格尔迈斯合成材料有限公司

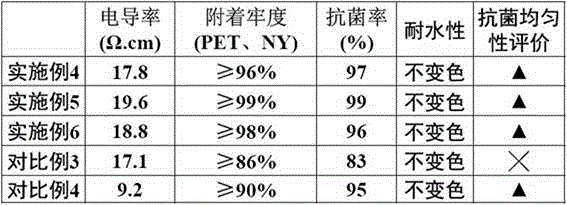

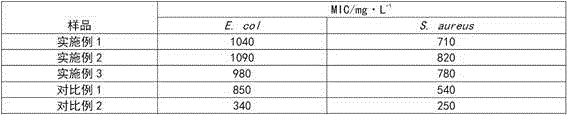

Multifunctional water-based ink and preparing method thereof

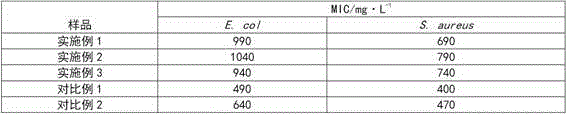

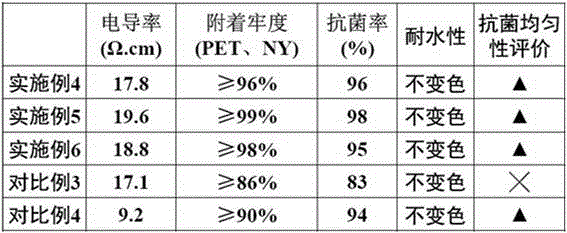

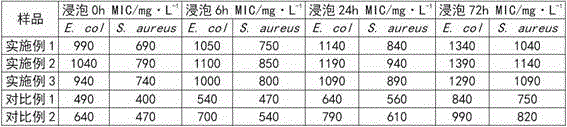

InactiveCN106366767ADense conductive structureImprove antibacterial propertiesInksWater basedPolymer science

The invention discloses a preparing method of multifunctional water-based ink. The preparing method includes the steps that 1, half of waterborne polyurethane resin, an antibacterial composite material and conducting filler are added into a reaction kettle and stirred uniformly, and an emulsifying agent is added dropwise; temperature raising, heat preservation and temperature lowering are carried out, a dispersing agent and water-based pigment are added, and pigment slurry is prepared through grinding after the mixture is stirred uniformly and is filtered; 2, remaining waterborne polyurethane resin, water, neutralizer, cosolvent and a defoaming agent are added into the pigment slurry, the mixture is dispersed through a grinding miller, and when the fineness reaches 5 micrometers or below, the mixture is packaged to obtain water-based ink. The conducting filler and the antibacterial composite material are reasonably matched, and therefore the ink has conductivity and durable antibacterial performance.

Owner:佛山市高明区尚润盈科技有限公司

Ceramic flat membrane-separation film layer for sewage treatment and preparation process thereof

ActiveCN107020022AImprove throughputReduce resistanceMembranesSemi-permeable membranesHigh fluxCatalytic oxidation

The invention discloses a ceramic flat membrane-separation film layer for sewage treatment and a preparation process thereof, and belongs to the field of inorganic membranes. The preparation process comprises the specific steps of adding graphite powder and water into ammonia water together, and carrying out ball milling, so as to obtain graphite slurry; adding a binding agent, a pore forming agent, a dispersing agent and water into the obtained graphite slurry, carrying out uniform mixing, and then, carrying out ultrasonic treatment; spraying the slurry, obtained through ultrasonic treatment, to a flat membrane supporting body, and then, carrying out high-temperature sintering, thereby obtaining a product. According to the preparation process disclosed by the invention, graphite is adopted as a main film layer raw material while high flux, low resistance and high filtration of a ceramic membrane material are guaranteed, so that the membrane material has a conductive characteristic; the process is simple, economical and efficient, and a material basis is provided for electric-field-utilized catalytic-oxidation or electric-field-strengthened sewage purification.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

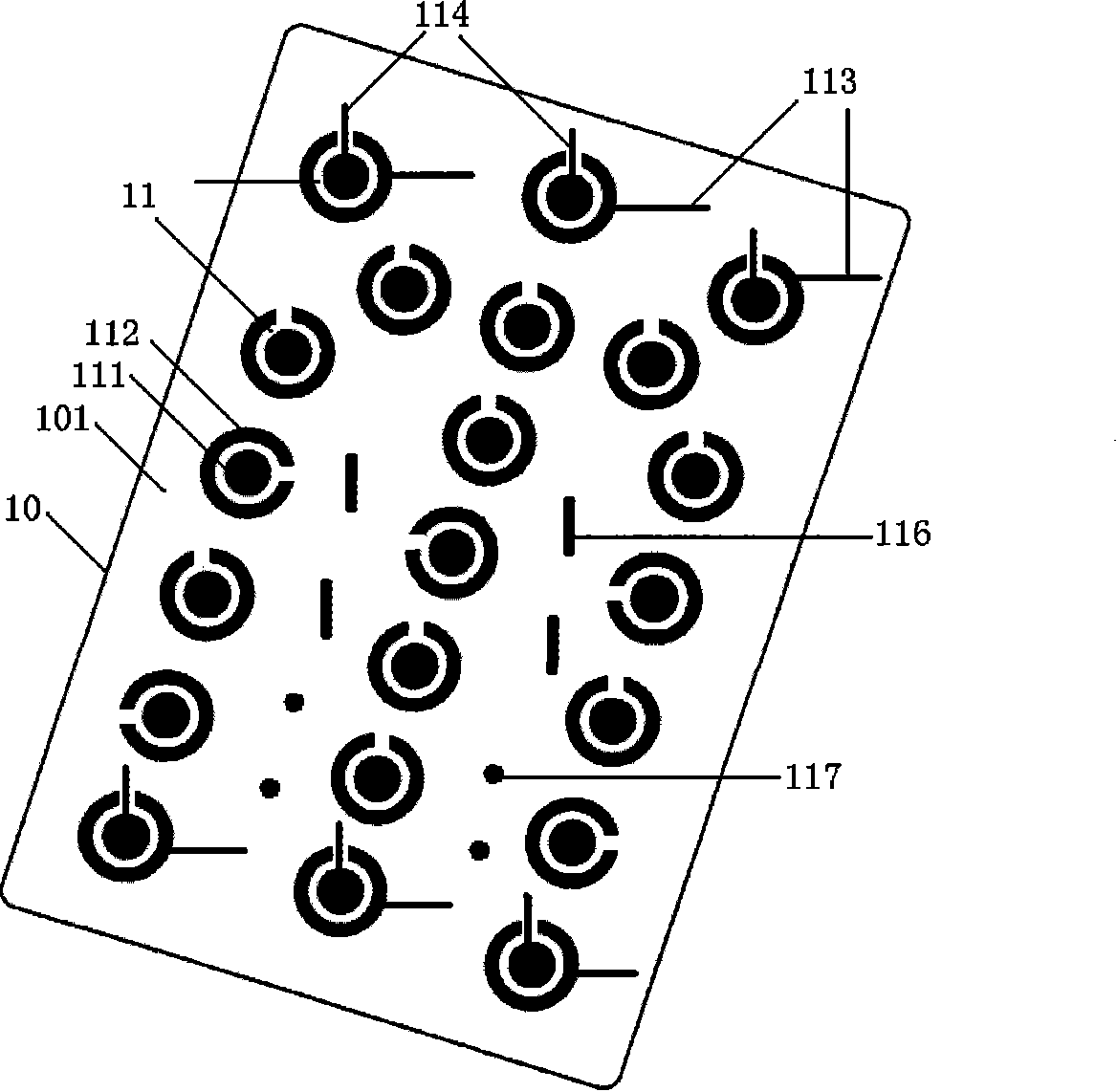

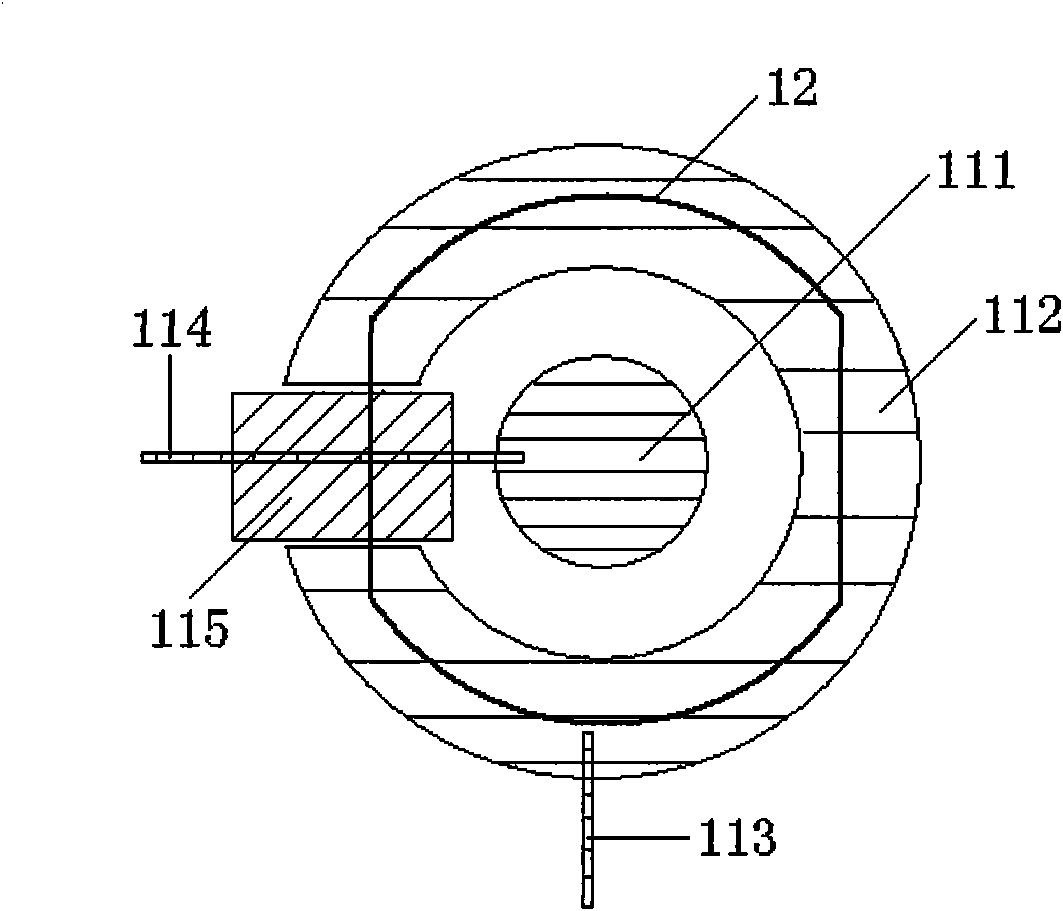

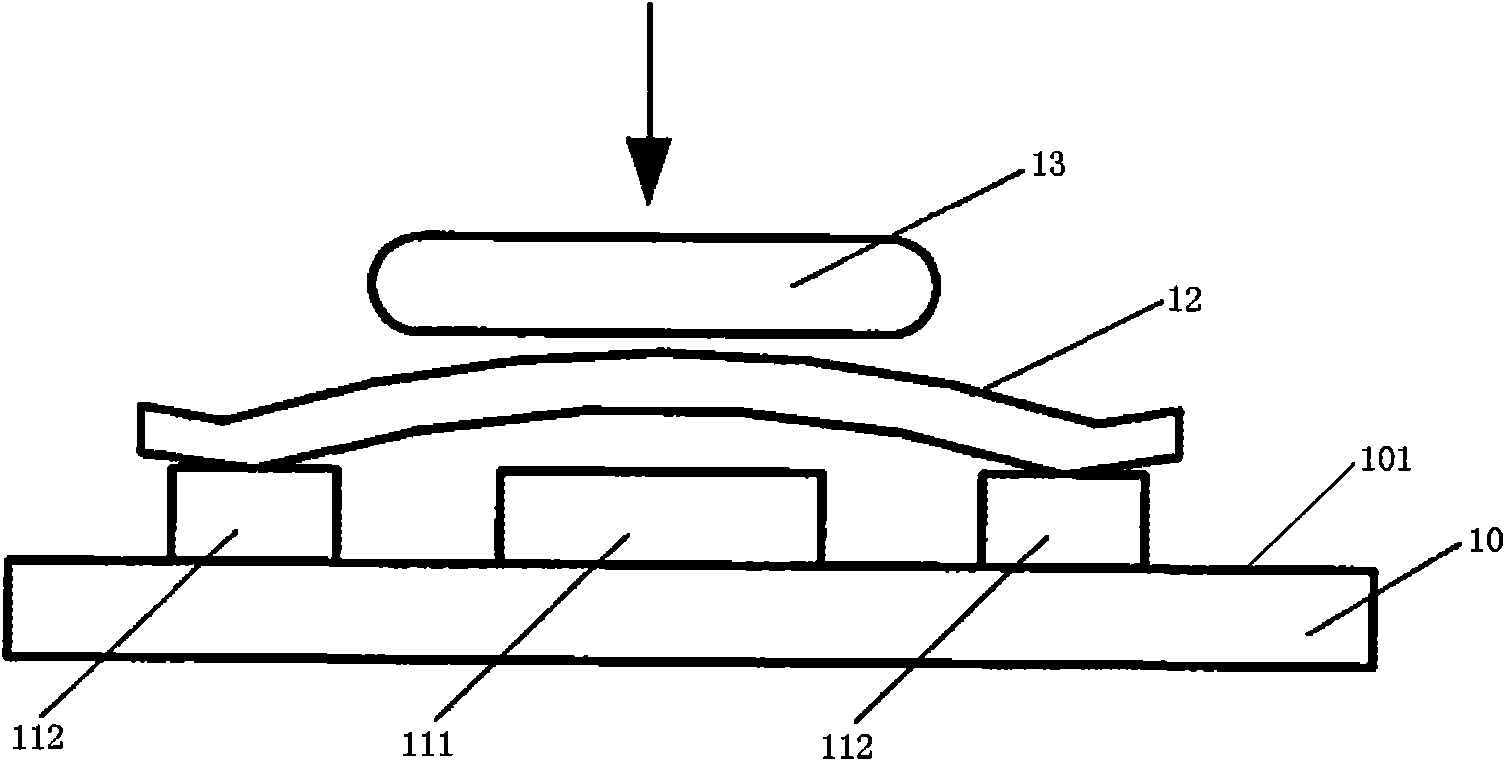

Keyboard panel

InactiveCN101673632AReduce manufacturing costHas conductive propertiesElectric switchesElectrical connection printed elementsTerminal equipmentEngineering

The embodiment of the invention discloses a keyboard panel. The keyboard panel comprises a PCB substrate and a key bonding pad which is arranged on a first surface of the PCB substrate by a carbon membrane printing graph; the key bonding pad comprises an inner ring and an outer ring, and the outer ring is connected by carbon membrane wiring on the first surface of the PCB substrate. The keyboard panel is applicable to terminal equipment.

Owner:HUAWEI DEVICE (SHENZHEN) CO LTD

Method for manufacturing nylon conductive fibers

ActiveCN103173886AHas conductive propertiesEasy to processElectroconductive/antistatic filament manufactureMonocomponent polyamides artificial filamentHydrogen NitrateCarbon nanotube

The invention discloses a method for manufacturing nylon conductive fibers. The method comprises the following steps of: (1) uniformly mixing four-needle type zinc oxide crystal whisker and conductive potassium titanate crystal whisker, roasting, cooling, adding into deionized water, performing ultrasonic dispersion, filtering, and drying, and thus obtaining wrapped crystal whisker mixtures; (2) adding multi-wall carbon nano tubes into a hydrogen nitrate solution, performing ultrasonic dispersion, heating, oxidizing, cooling, filtering, drying and grinding; (3) stirring the crystal whisker mixtures, the multi-wall carbon nano tubes, stibium-doped tin oxide conductive powder, a coupling agent, polymethylene, an antioxidant and nylon sliced powder in a closed manner, and granulating the mixtures through a screw extruder, and thus obtaining nylon conductive mother particles; and (4) respectively putting the nylon conductive mother particles and polyamide 6 into the corresponding screw extruders, spraying from a composite spinneret plate, cooling and winding to obtain the nylon conductive fibers. The nylon conductive fibers have conductive characteristics and are high in processing property and spinning property.

Owner:JIANGSU ZJA NEW MATERIAL

Conductive waterborne ink and preparing method thereof

InactiveCN106118227ADense conductive structureImprove antibacterial propertiesBiocideInksPolymer sciencePigment

The invention discloses a preparing method of conductive waterborne ink. The preparing method includes the following steps that 1, a half of waterborne polyurethane resin, a half of antibacterial composite materials and a half of conductive filler are added into a reaction kettle and stirred to be even, an emulsifying agent is dropwise added, heating, heat preservation and cooling are carried out, a dispersing agent and waterborne pigment are added, the mixture is stirred to be even, and then color paste is grinded, prepared and filtered; 2, the residual waterborne polyurethane resin, water, a neutralizing agent, a solubilizing assistant and an antifoaming agent are added into the color paste, the mixture is dispersed through a grinding miller, and when the fineness is 5 microns or below, packaging is carried out, and the waterborne ink is obtained. According to the preparing method, the conductive filler and the antibacterial composite materials are reasonably matched, and the ink has the conduction characteristic and further has the lasting antibacterial performance.

Owner:佛山市高明区尚润盈科技有限公司

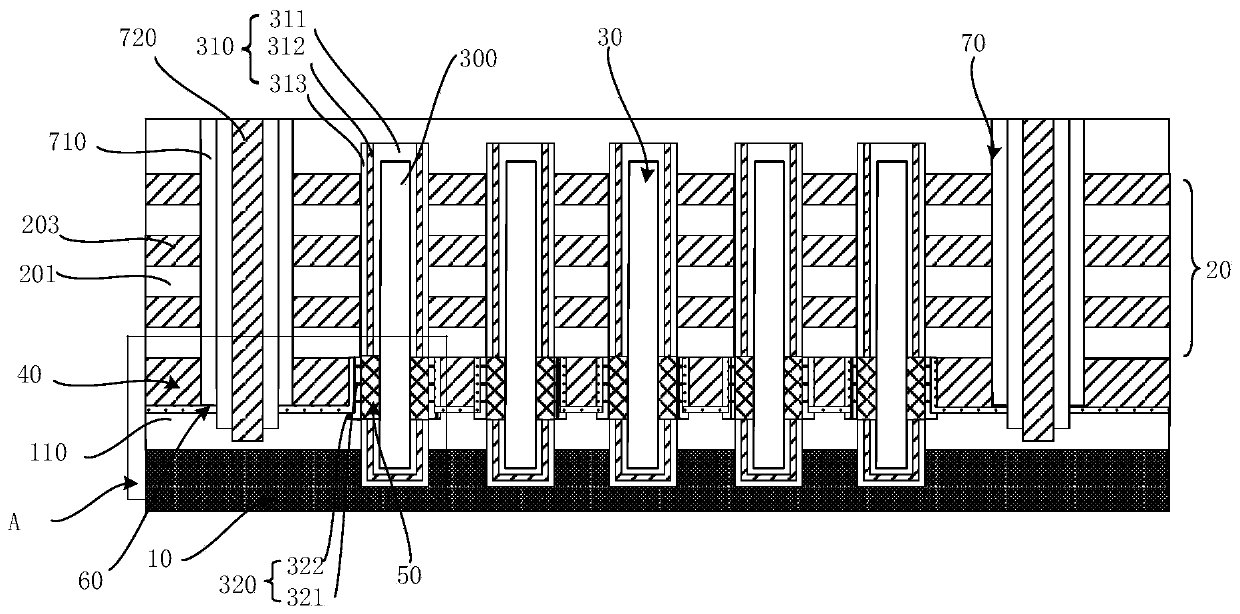

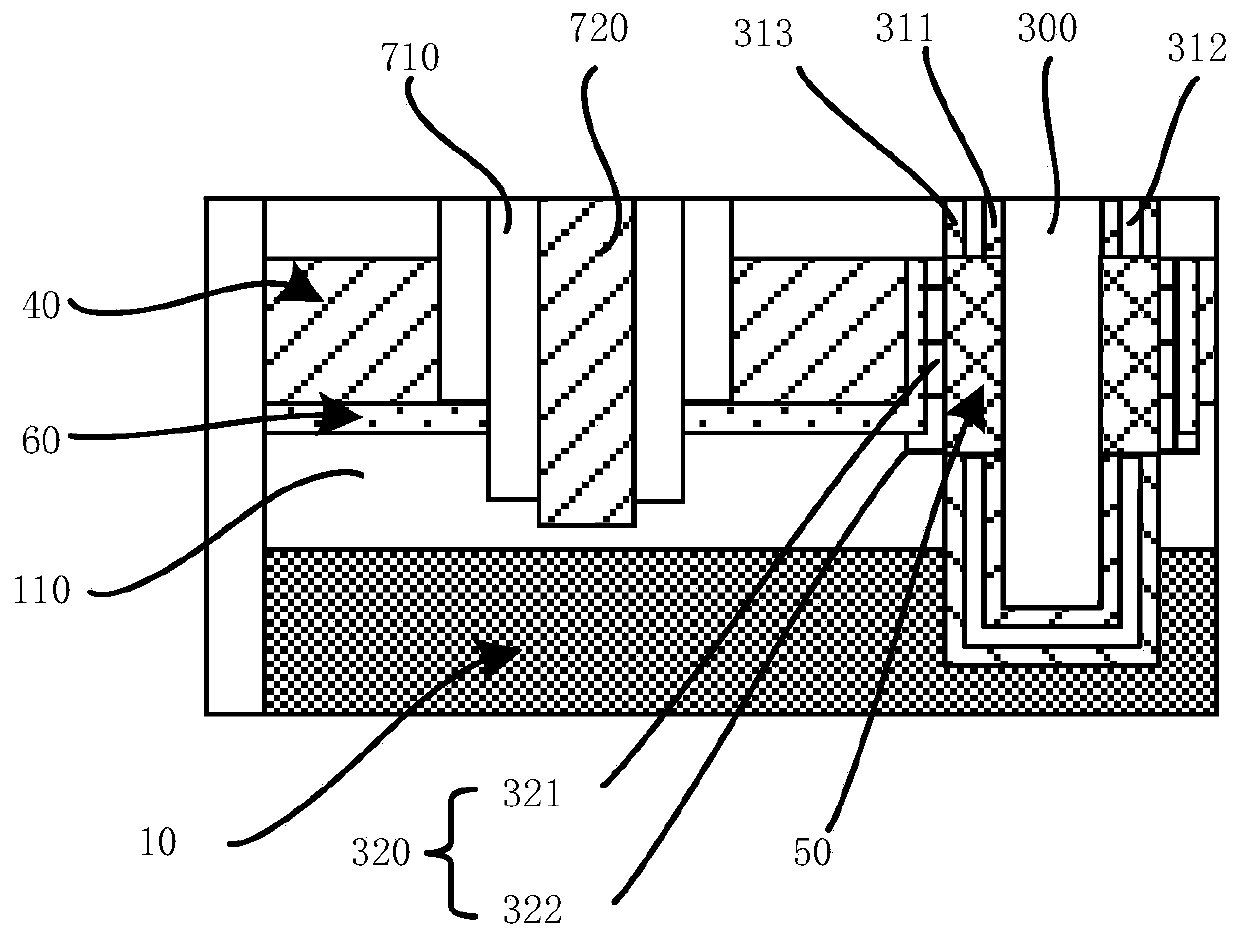

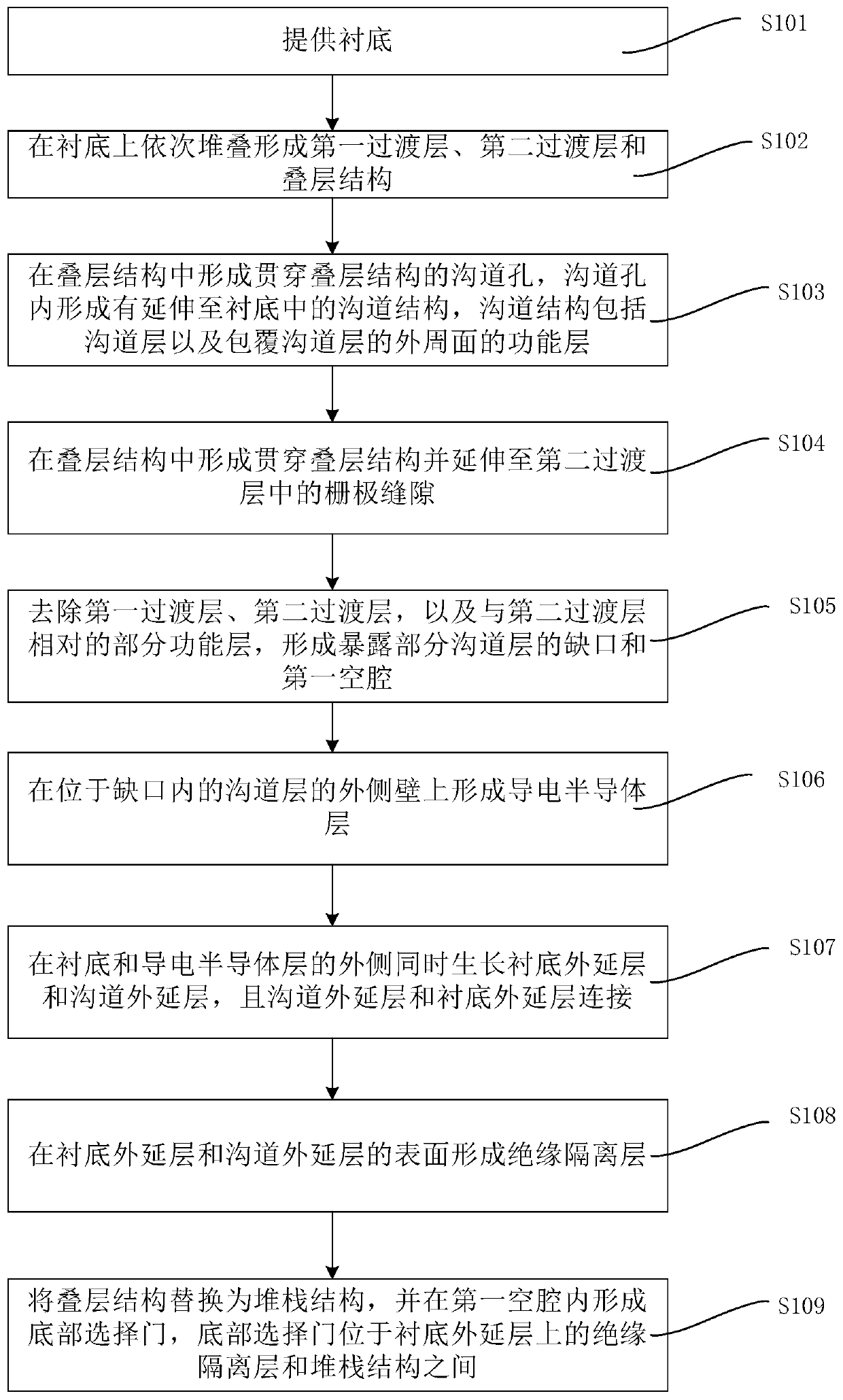

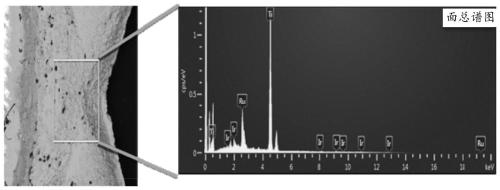

Three-dimensional memory and preparation method thereof

ActiveCN111430359AAvoid the risk of disconnectionHas conductive propertiesSolid-state devicesEnergy efficient computingCondensed matter physicsSemiconductor

The invention belongs to the technical field of memory equipment, and particularly relates to a three-dimensional memory and a preparation method of the three-dimensional memory. The three-dimensionalmemory comprises a substrate, a stack structure arranged on the substrate, and a channel structure penetrating through the stack structure and extending into the substrate. A substrate epitaxial layer is arranged between the substrate and the stack structure; the functional layer is provided with a gap, and the side wall of part of the channel layer exposed in the gap is provided with a conductive semiconductor layer; and a channel epitaxial layer is arranged on the conductive semiconductor layer and is connected with the substrate epitaxial layer. The risk of channel disconnection caused bythe fact that the channel layer is easily etched by hydrochloric acid when the channel layer is prepared by adopting a silicon epitaxial growth method in the prior art is overcome.

Owner:YANGTZE MEMORY TECH CO LTD

Method for manufacturing polyvinyl acetal conductive fibers

ActiveCN102978731ALow resistivityHigh breaking strengthElectroconductive/antistatic filament manufactureFilament/thread formingCarbon blackZinc

The invention relates to a method for manufacturing polyvinyl acetal conductive fibers. The method comprises the following steps of: adding conducting materials including ATO conductive powder, superconducting carbon black, zinc oxide whiskers, potassium titanate whiskers and the like into a fiber-grade polyvinyl alcohol spinning solution, and mixing, filtering and defoaming to prepare a conductive polyvinyl alcohol spinning solution; and ensuring that one part of the fibers becomes composite polyvinyl acetal conductive fibers containing conductive substances through a composite spinning technology. The polyvinyl acetal conductive fibers have low resistivity, high strength, durability and conductivity even the humidity is low.

Owner:浙江枫翎新材料科技有限公司

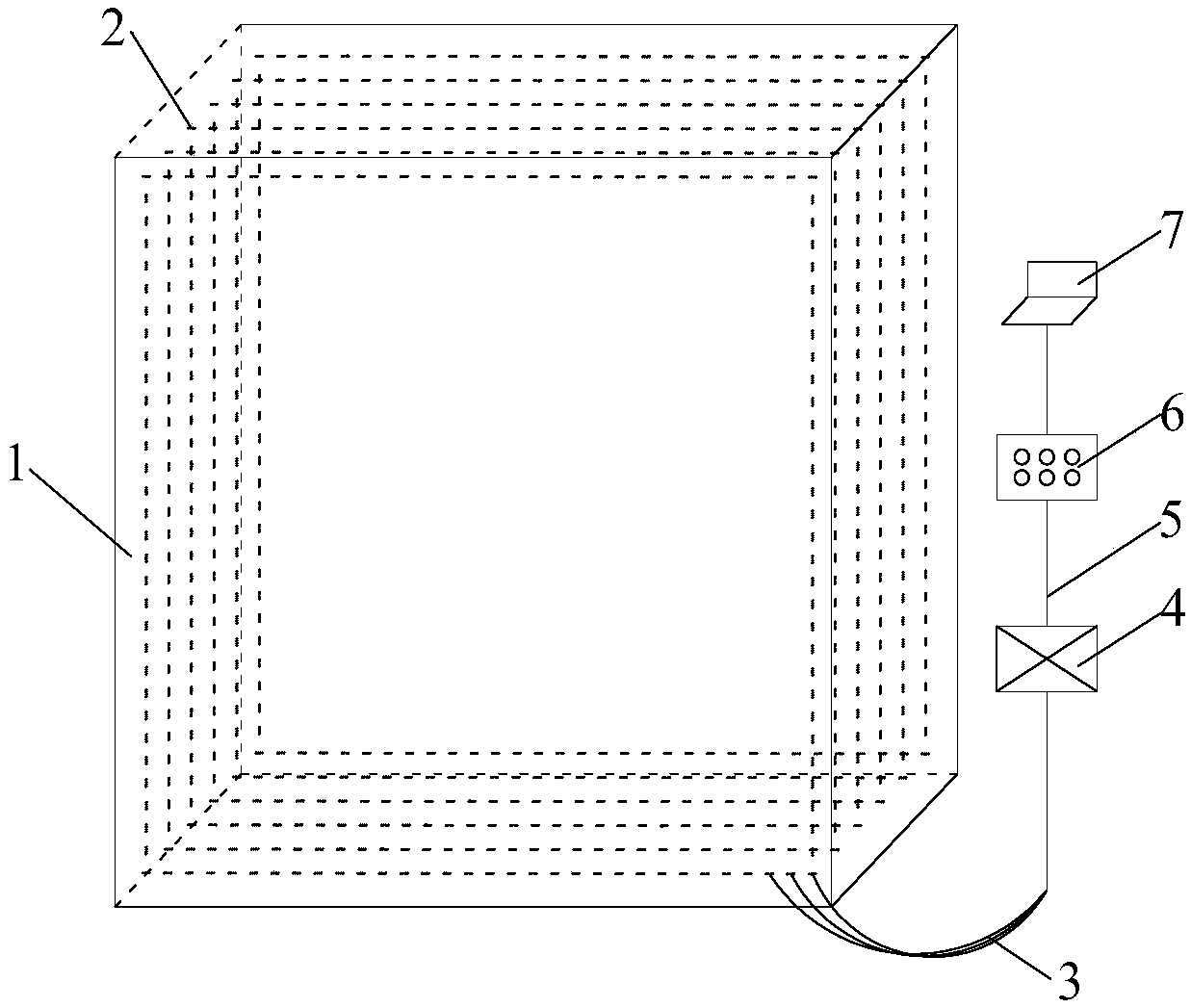

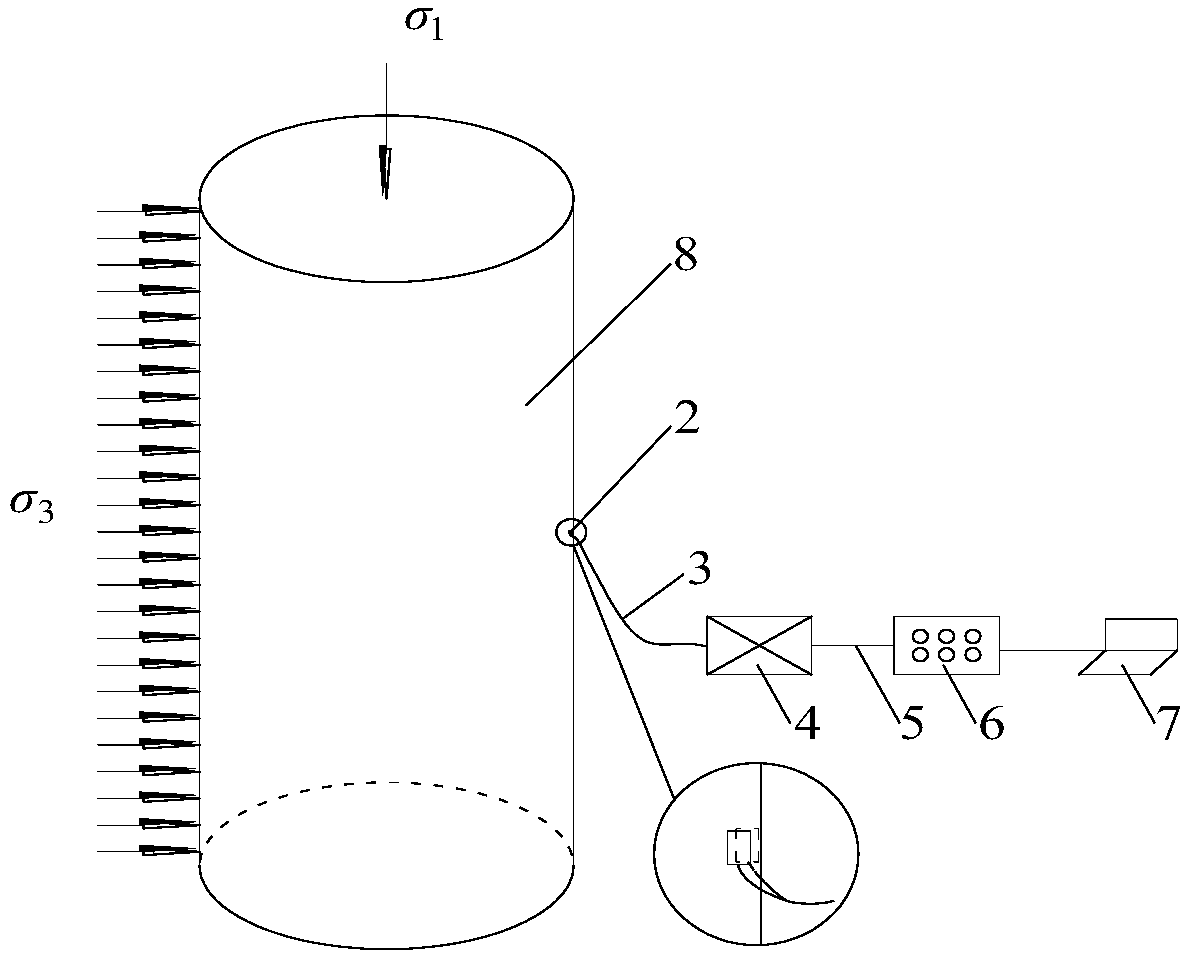

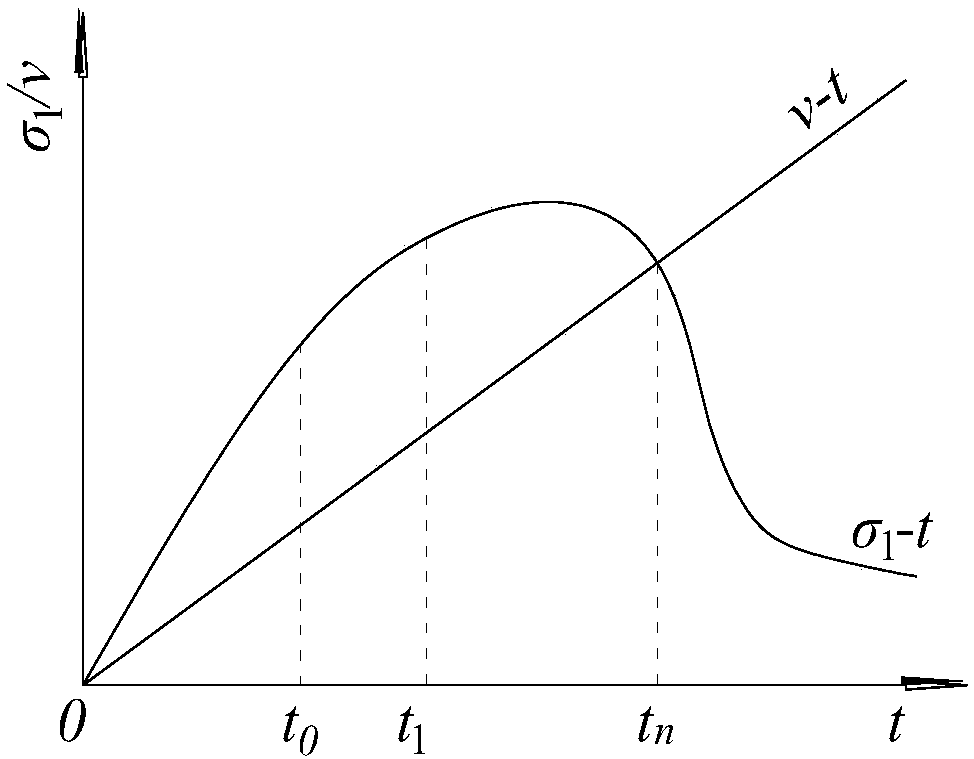

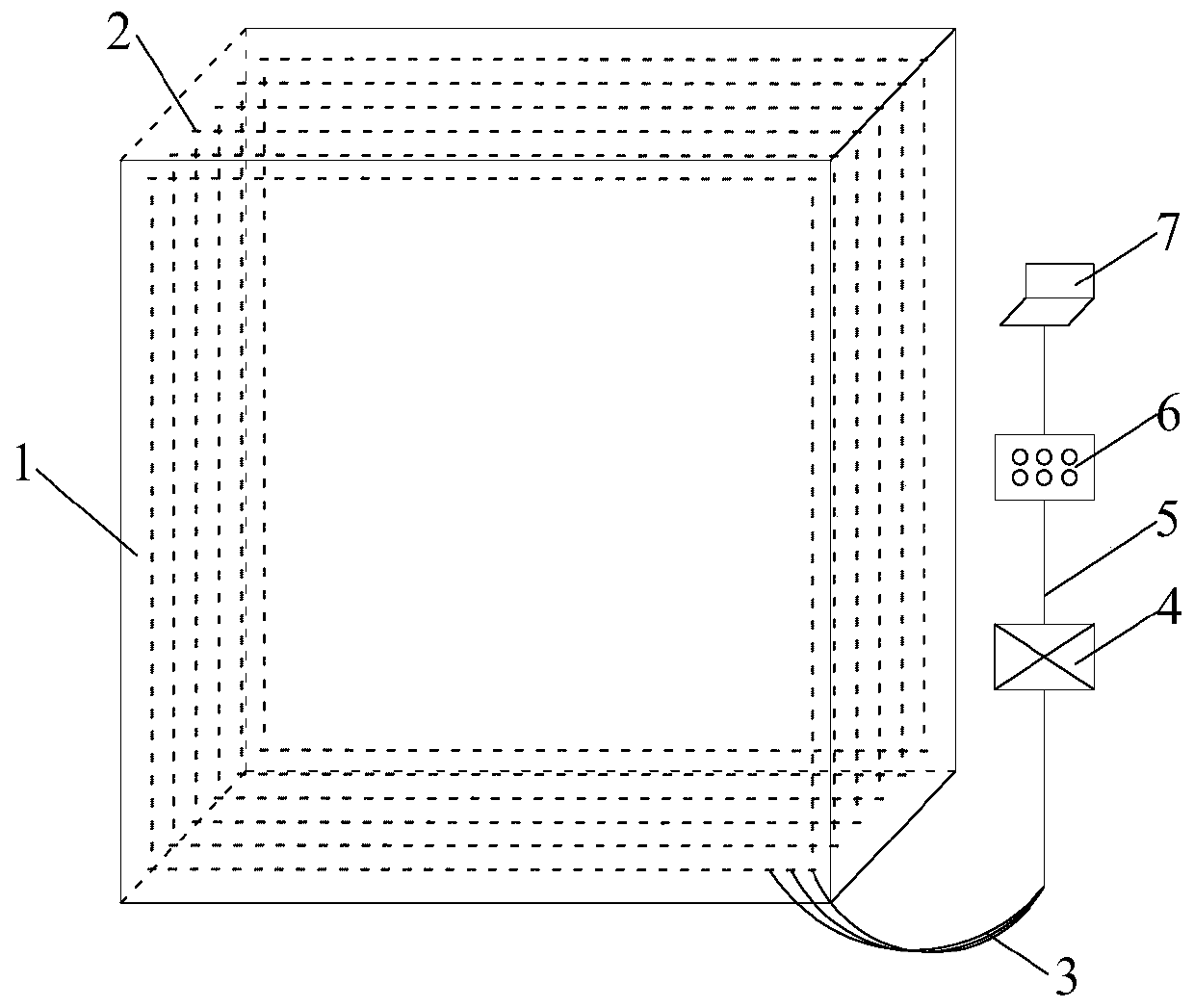

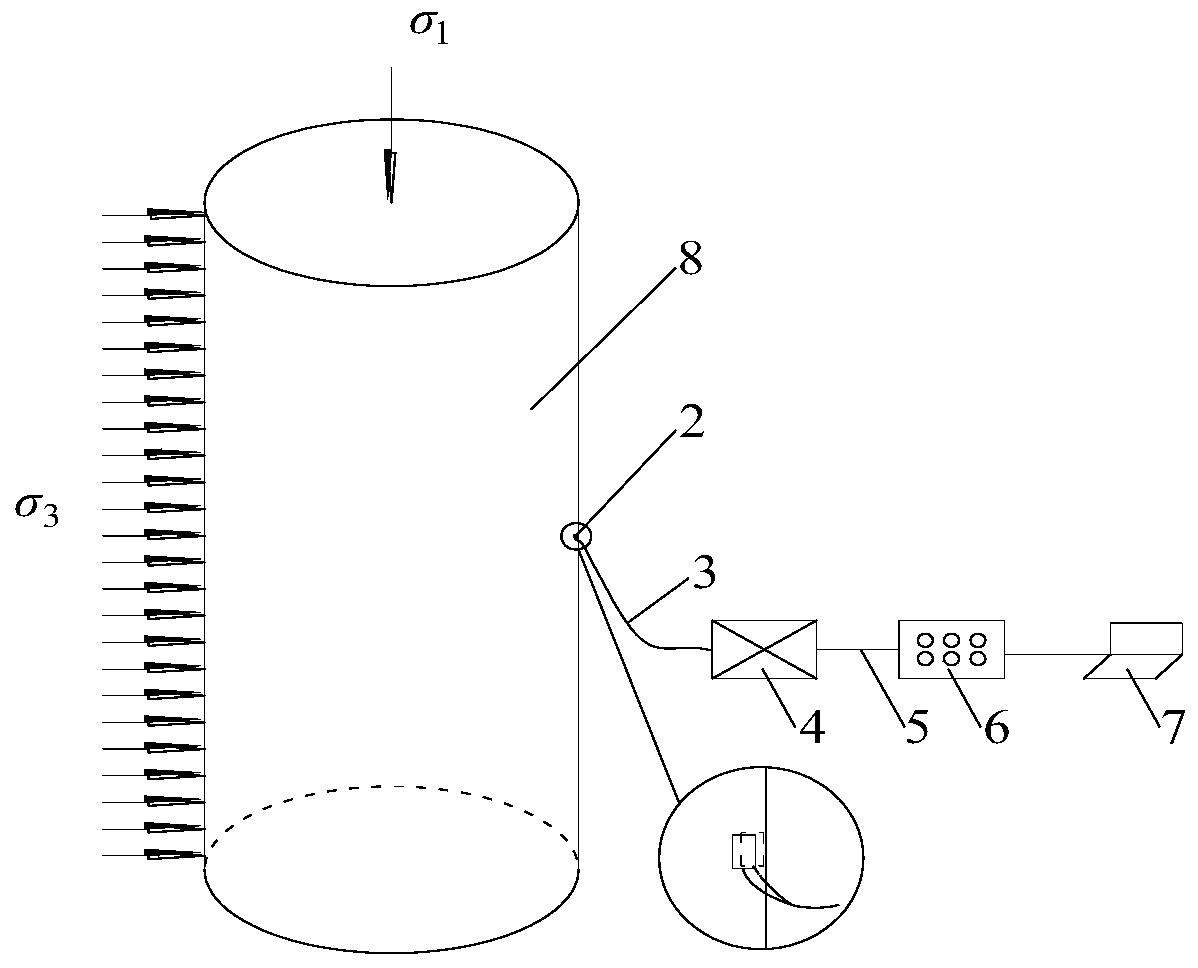

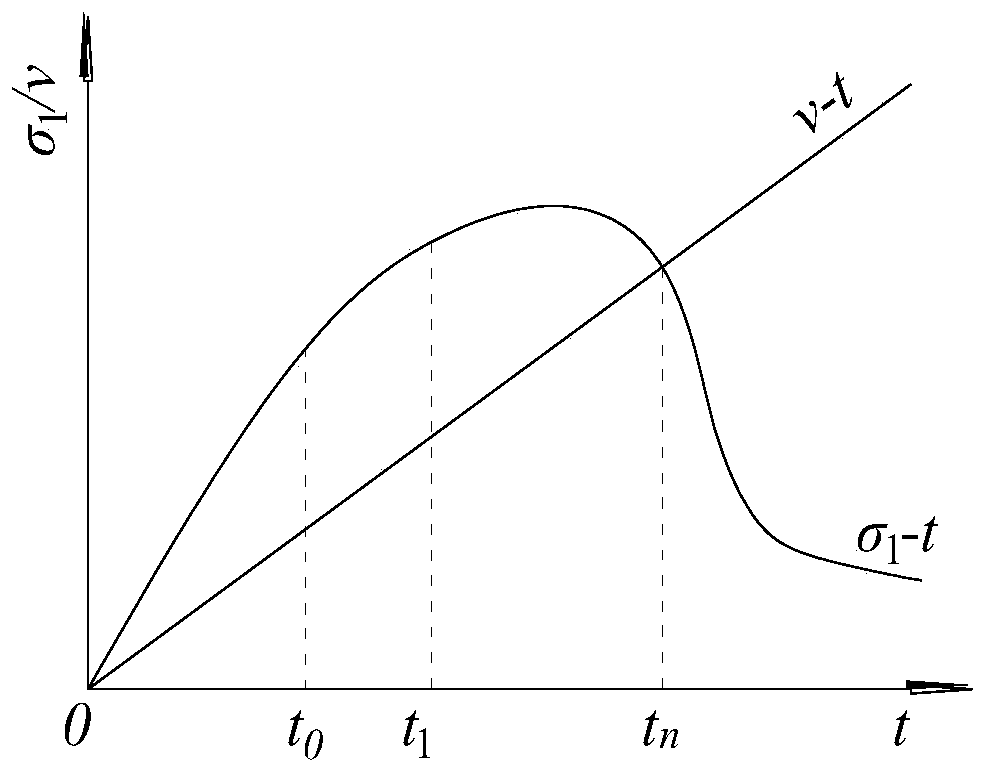

Similar-expansibility model test material with conductivity, and use method

ActiveCN109238804AHas conductive propertiesSwellability with conductive propertiesPreparing sample for investigationMaterial strength using tensile/compressive forcesTest materialVolume expansion

The invention discloses a similar-expansibility model test material with the conductivity, and a use method. The similar-expansibility model test material comprises a main body material and an additional material, wherein the main body material is a mixture of an aggregate material and a cementing material; the additional material comprises an expanding agent and a conductive agent; the volume expansion rate of the additional material is 10-30%; the aggregate material is a main material of the similar-expansibility model test material; the cementing material is a cementing and curing materialof the similar-expansibility model test material; the expanding agent enables the aggregate material and the cementing material to have a certain volume expansion after being mixed; and the conductiveagent enables the similar-expansibility model test material to have the conductivity. The invention provides a novel test material having the expansibility and the conductivity and used for testing asurrounding rock stress in a wide range (full field) in a full matching mode, and a test method.

Owner:CHINA UNIV OF MINING & TECH

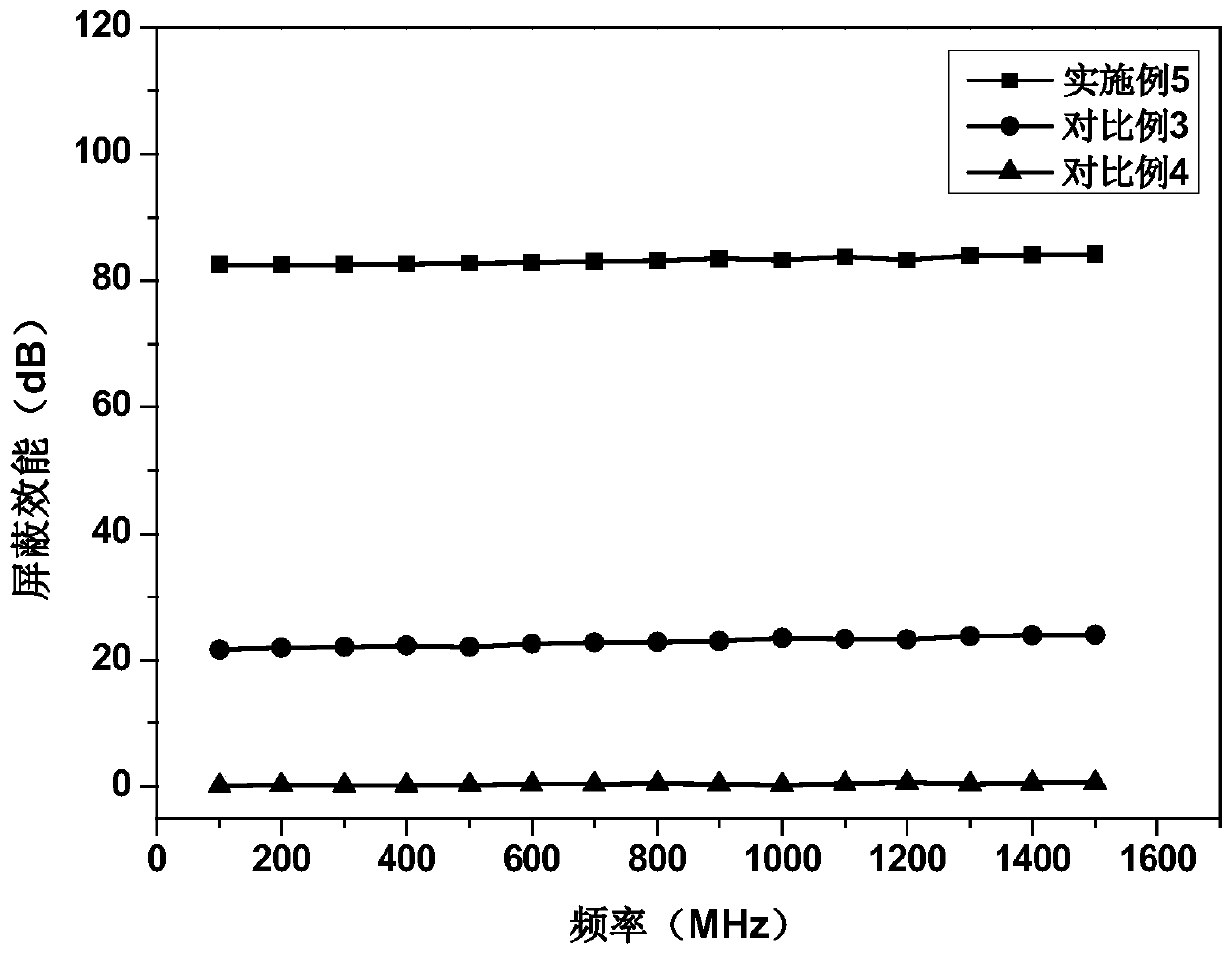

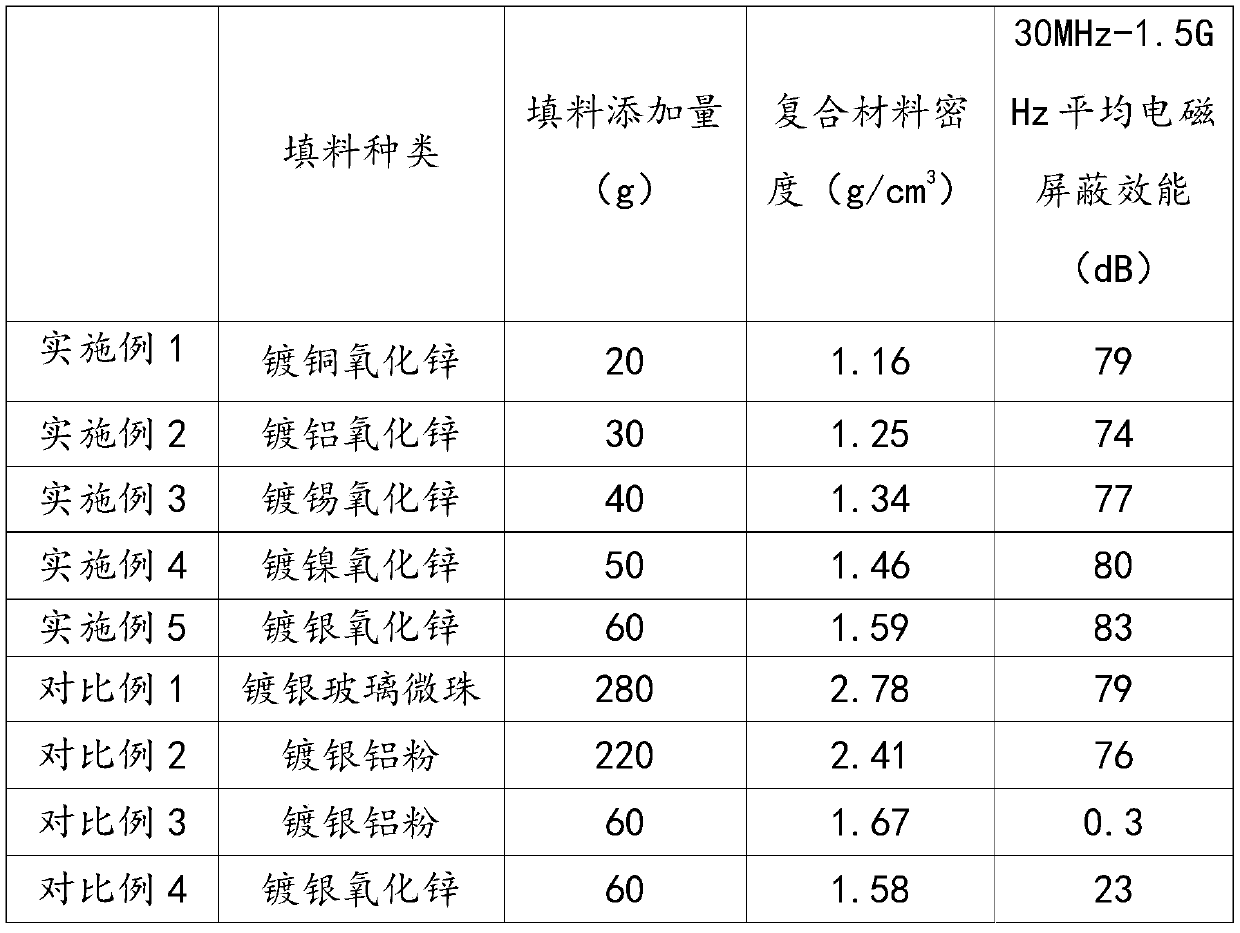

Preparation method of electromagnetic shielding composite material and the electromagnetic shielding composite material

InactiveCN110791097AHas conductive propertiesGood electrical conductivityElectrically conductiveElectrical field strength

The invention relates to the field of electromagnetic shielding materials, and particularly relates to a preparation method of an electromagnetic shielding composite material and the electromagnetic shielding composite material. The method comprises the steps that tetrapod-shaped zinc oxide plated with metal is dispersed into silicone rubber under the action of a high-voltage electric field, thenhigh-temperature vulcanization forming is conducted, wherein the high-voltage electric field is an alternating-current electric field, and the electric field intensity is 10 kV / cm to 50 kV / cm. According to the preparation method provided by the invention, the surface of tetrapod-shaped zinc oxide is plated with metal to form tetrapod-shaped zinc oxide plated with metal on the surface and having aconductive characteristic; by utilizing conductive properties of the tetrapod-shaped zinc oxide plated with metal, the tetrapod-shaped zinc oxide plated with metal can be dispersed under the functionof the electric field in a proper high-voltage electric field, a problem that a filler is broken due to conventional mechanical force is solved, the tetrapod-shaped zinc oxide can play a role of a special spatial three-dimensional structure in the silicon rubber, so that the tetrapod-shaped zinc oxide plated with metal can be promoted to form a good conductive network in the silicon rubber, and the shielding characteristic of the composite material is enhanced.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

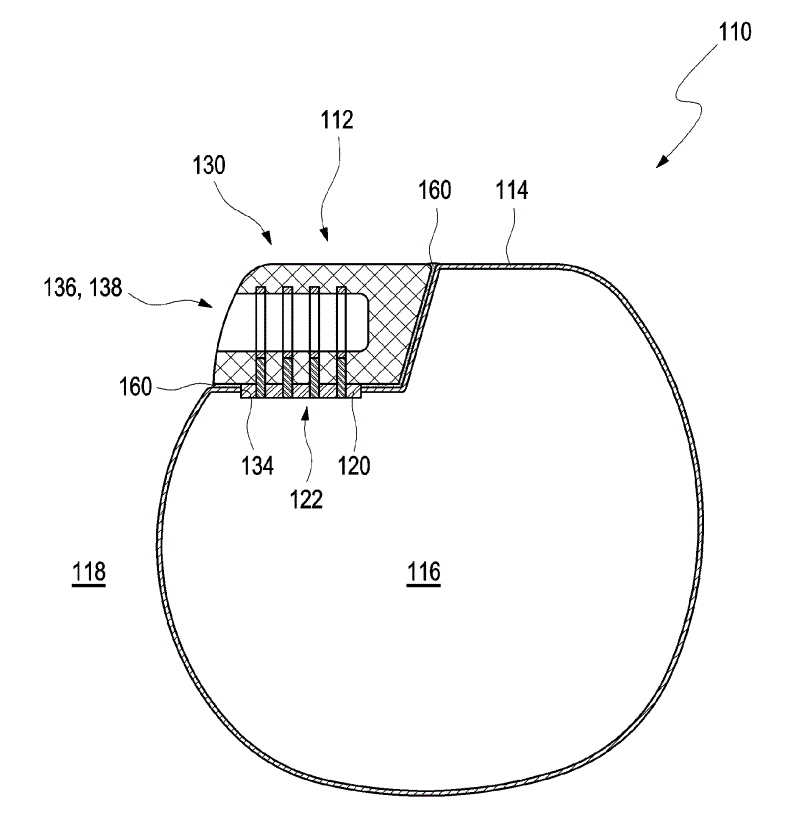

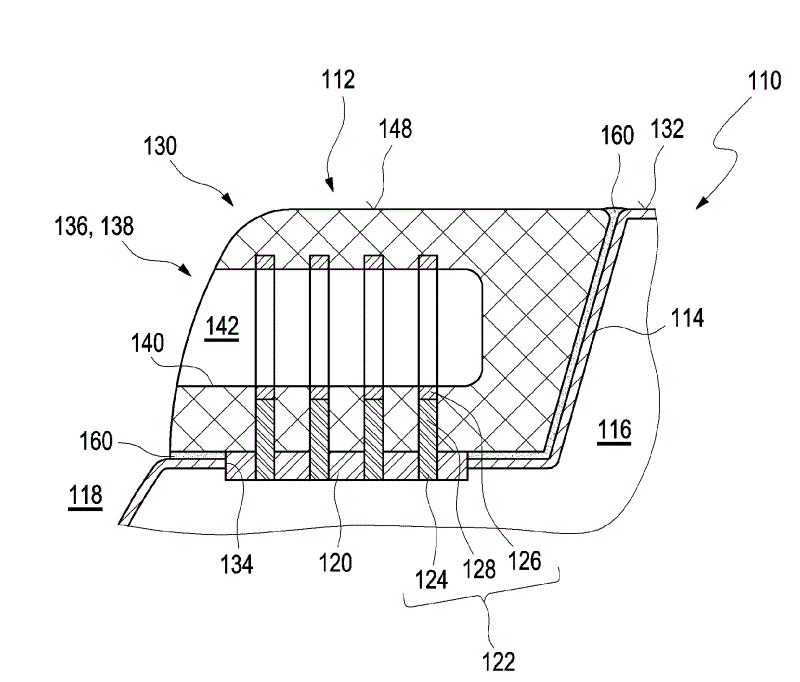

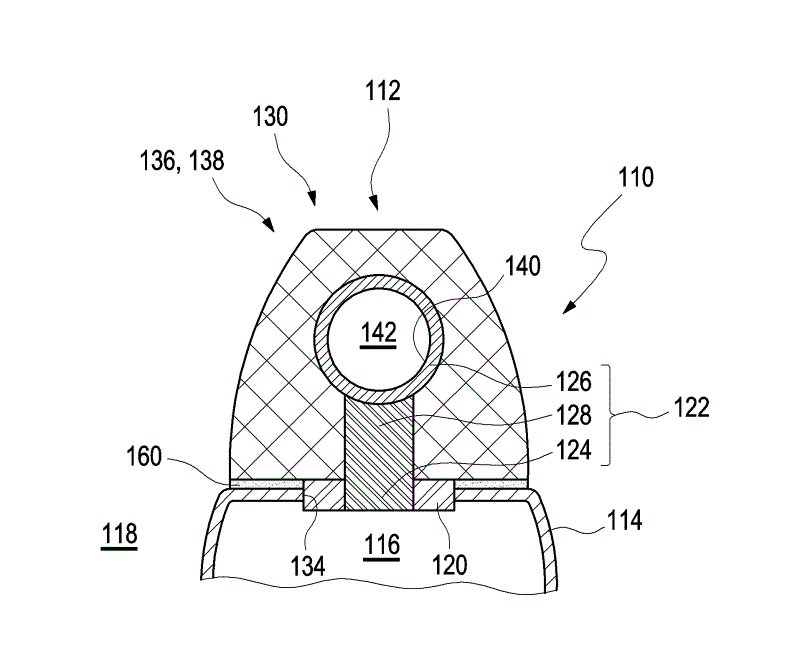

Electrical bushing with cermet-containing connecting element

ActiveCN102614585AAchieving Hermetic SealingReduce the number of soldered connectionsElectrotherapyElectrical bondingMedical device

One aspect relates to an electrical bushing for use in a housing of an active implantable medical device. The electrical bushing includes an electrically insulating base body and an electrical conducting element. The conducting element is set up to establish, through the base body, a electrically conducting connection between an internal space of the housing and an external space. The conducting element is hermetically sealed with respect to the base body, and the conducting element includes a cermet. The electrical bushing includes a head part, the head part includes a plug connector element, the conducting element includes a feedthrough element, and the feedthrough element and the plug connector element are connected in an electrically conductive manner through a connecting element, and the connecting element and the feedthrough element are provided as a single part and are made of the same material.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

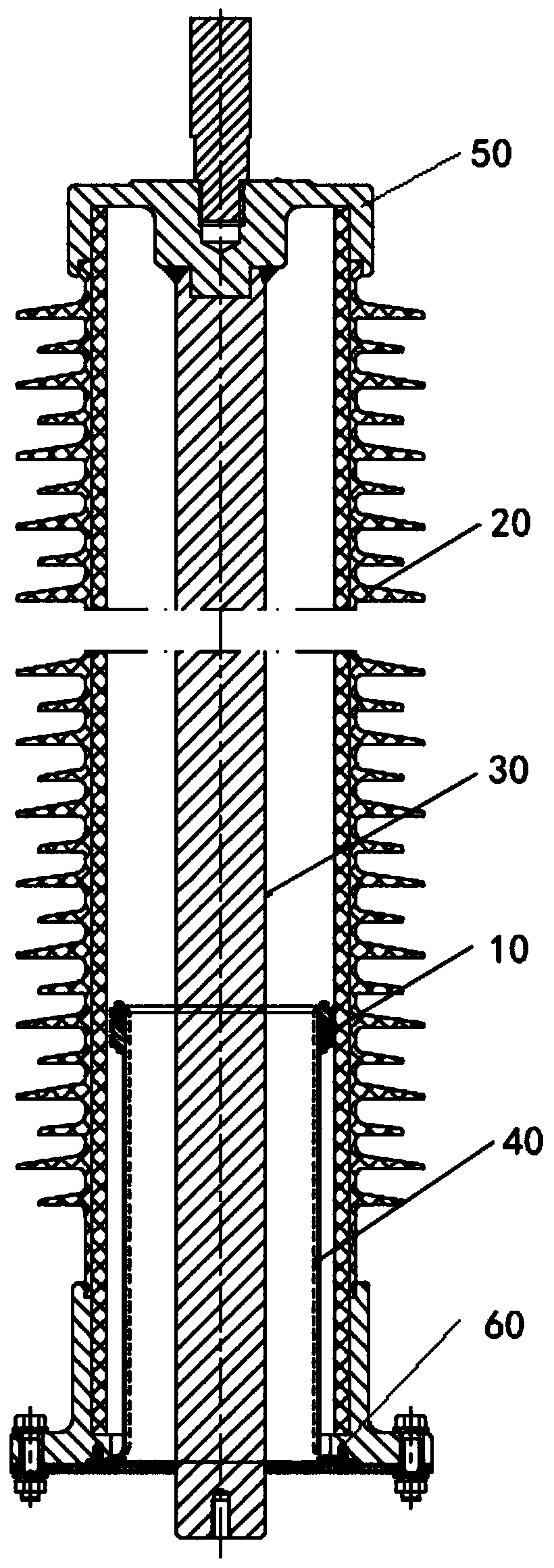

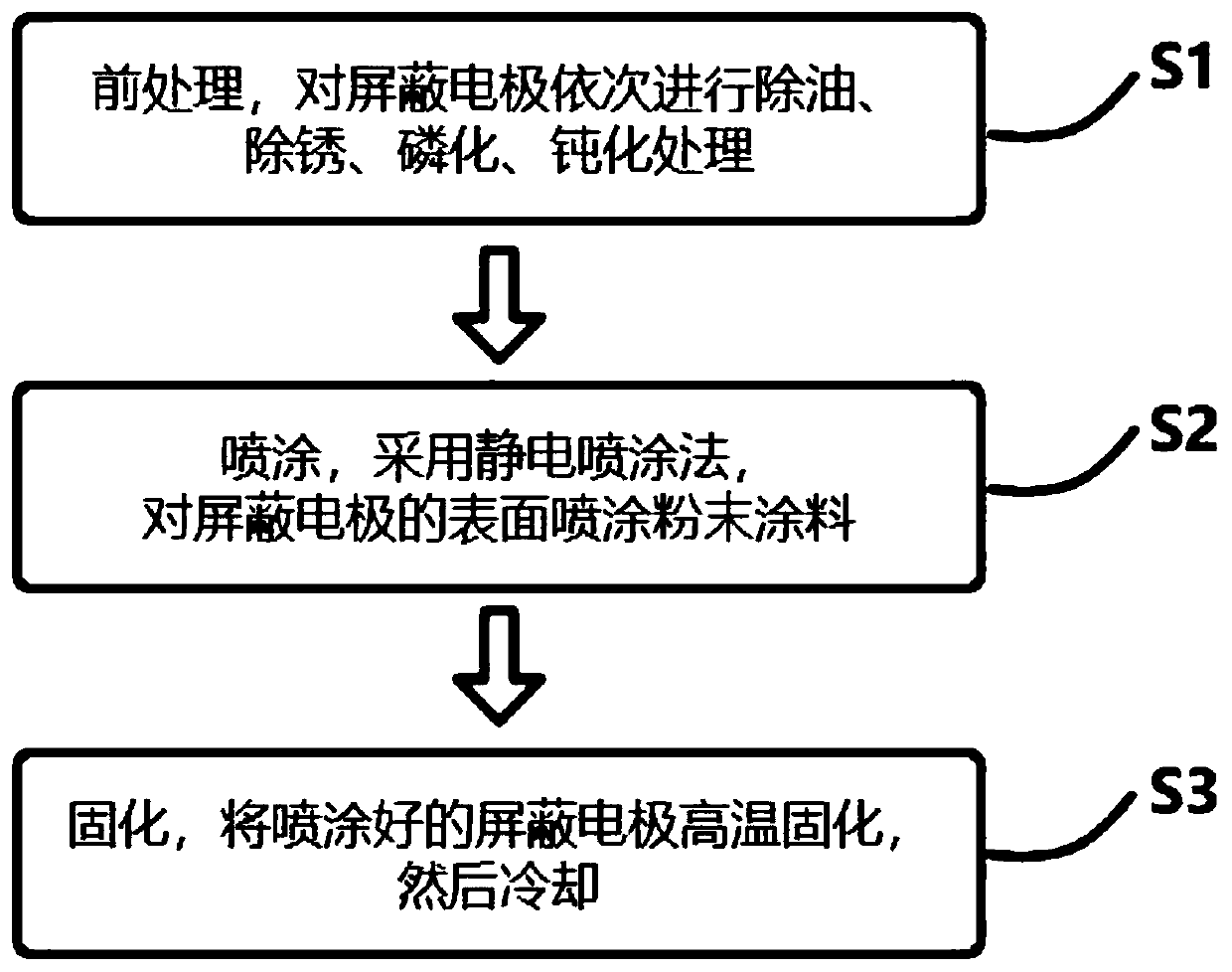

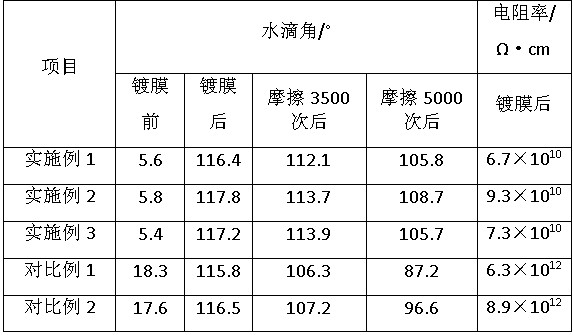

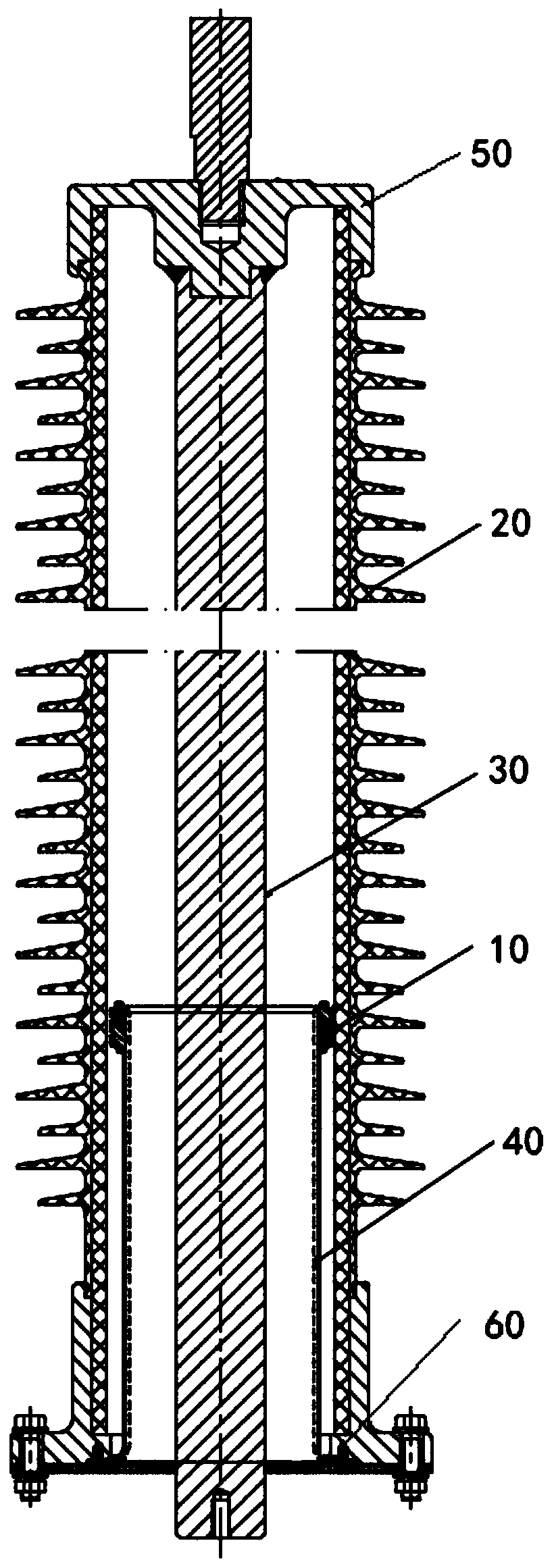

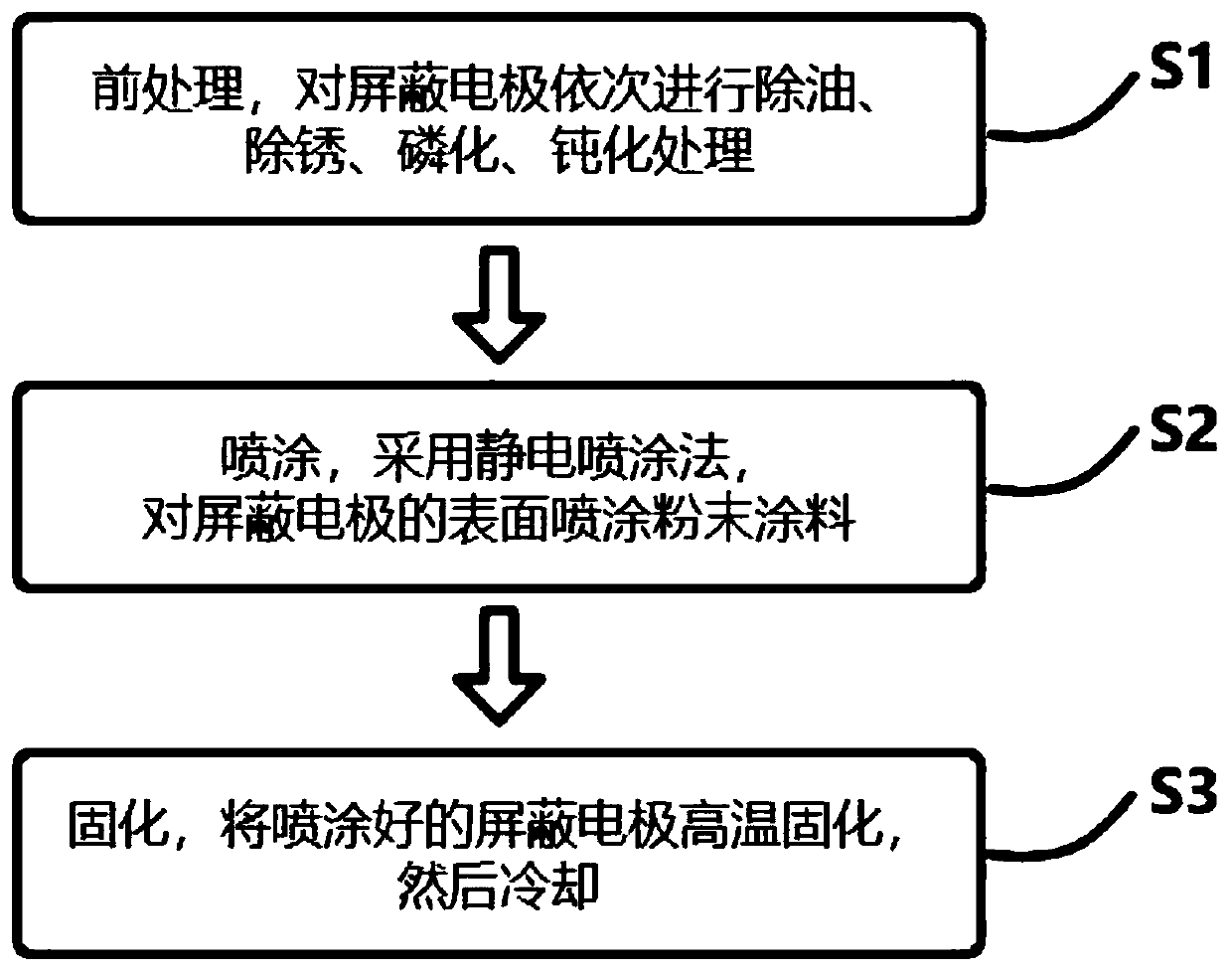

Shielding electrode for corona prevention of gas bushing and preparation process thereof

ActiveCN109830892AReduce electric field strengthSolve electrical agingSparking plugsSpark gap detailsSmooth surfaceSurface resistivity

The invention discloses a shielding electrode for corona prevention of a gas bushing. The shielding electrode is disposed inside the gas bushing. The shielding electrode is fixedly disposed on a lowerflange around a conductive rod. The surface of the shielding electrode is provided with a semi-conductive layer. The surface resistivity of the semi-conductive layer is 103 [omega] to 1011 [omega]. The invention further provides a preparation process for obtaining the shielding electrode for corona prevention of the gas bushing, specifically including the following steps of S1: preprocessing: de-oiling, de-scaling, phosphating, and passivating the shielding electrode successively; S2: spraying: spraying the surface of the shielding electrode with a powder coating by an electrostatic sprayingmethod; S3: solidifying: solidifying the sprayed the shielding electrode at a high temperature and then cooling the shielding electrode. The shielding electrode ensures a solidified smooth surface byelectrostatic spraying of the semi-conductive molding powder. Due to the conductive property, the problem is solved that a conventional sprayed insulating paint is liable to electrical aging, and theelectrical performance of the gas bushing can be obviously improved, and the process is difficult and low in cost.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

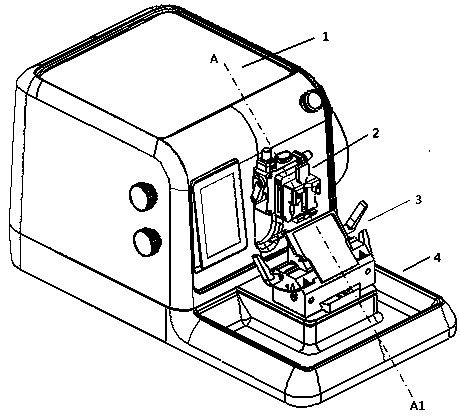

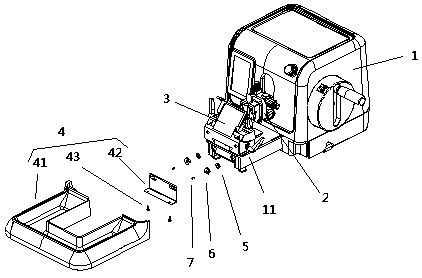

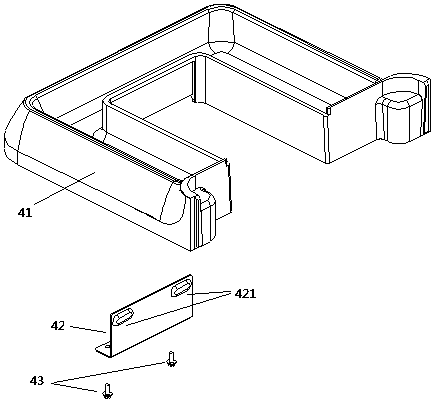

Collecting disc and slicing machine with same

PendingCN111579275AHas conductive propertiesLong-term effective anti-static adsorption capacityWithdrawing sample devicesMetal working apparatusEngineeringMechanical engineering

The embodiment of the invention provides a collecting disc (4). The collecting disc comprises a body (41) and a conductive plate (42), wherein conductive medium is uniformly distributed in the body (41), the conductive plate (42) is fixed on the body (41) through a conductive fastener, the conductive plate (42) can be connected with a base (11) of a main body (1) of the slicing machine, and the base (11) is grounded. The collecting disc is advanaged in that the conductive medium is doped into the body of the collecting disc, so the collecting disc has the conductive characteristic, the body ofthe collecting disc is connected with a grounding base of the slicing machine through the conductive plate, an electrostatic discharge channel is constructed, the collecting disc has the long-term effective anti-static adsorption capacity, and a problem that paraffin chippings adhere to the collecting disc due to the electrostatic adsorption effect is solved.

Owner:RWD LIFE SCI

Highly flame-retardant destatic type butyl rubber composite damping material and preparation method thereof

InactiveCN109957185AHas conductive propertiesEliminate static electricityPetroleum resinCarbon nanotube

The invention relates to a highly flame-retardant destatic type butyl rubber composite damping material and a preparation method thereof. By using brominated butyl rubber as the composite damping basematerial and by the utilization of high-temperature resistant and flame-retardant property of polytetrafluoroethylene powder, the product has extremely high flame retardance. Meanwhile, by adding carbon nanotube for coating ceramic powder, the product has the destaticizing effect. Then, carbon black, polyisobutylene, petroleum resin, light calcium carbonate and naphthenic oil are subjected to mixing. After uniform mixing, tabletting is carried out. Finally, the tabletting product is compounded with a bound layer Kevlar and an isolated layer release paper in a tablet press to obtain the damping material for vehicles.

Owner:天津市浩迪橡塑科技有限公司

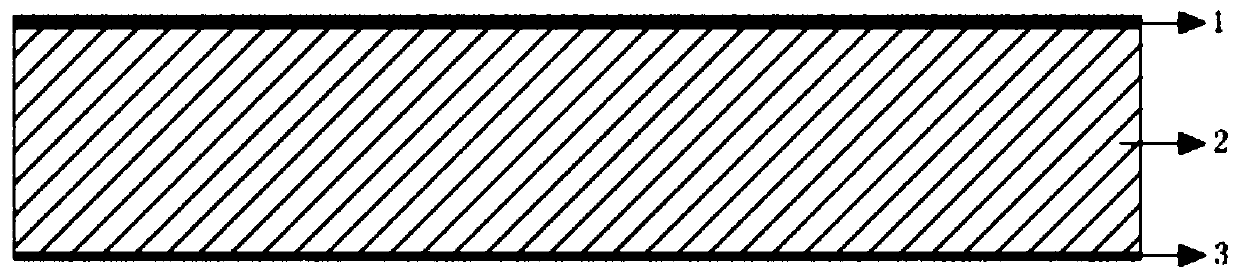

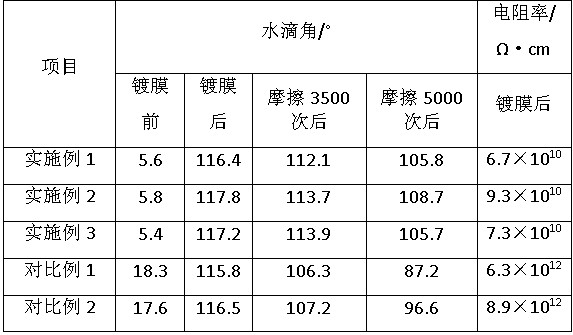

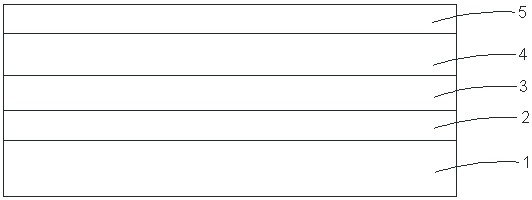

Anti-fingerprint film, glass product and preparation method of glass product

ActiveCN112877642AHas conductive propertiesExcellent abrasion resistanceVacuum evaporation coatingSputtering coatingSilicon oxideMaterials science

The invention provides an anti-fingerprint film, a glass product and a preparation method of the glass product. The anti-fingerprint film comprises a conductive film layer, a transition layer, a silicon dioxide layer and an anti-fingerprint film layer, all of which are sequentially stacked. The conductive film layer comprises one or more kinds of In, oxide of In, Sn and oxide of Sn, and the transition layer comprises Si3N4, SiON and SiO2. The glass product comprises a glass substrate and the anti-fingerprint film. The substrate is adjacent to the conductive film layer. The preparation method of the glass product comprises the step of sequentially preparing the conductive film layer, the transition layer, the silicon dioxide layer and the anti-fingerprint film layer on the glass substrate by using a magnetron sputtering method. The anti-fingerprint film has excellent friction resistance, waterproof performance and anti-fingerprint performance, and is long in service life.

Owner:LENS TECH CHANGSHA

Resistance-type random access memory

ActiveCN105448948AInhibited DiffusionHas conductive propertiesTransistorSolid-state devicesStatic random-access memoryRandom access memory

The invention provides a resistance-type random access memory which comprises an upper electrode, a lower electrode and a transformation metal oxide layer between the upper electrode and the lower electrode. The resistance-type random access memory further comprises a metal cover layer arranged above the upper electrode and a transparent conductive oxide layer arranged between the metal cover layer and the upper electrode.

Owner:WINBOND ELECTRONICS CORP

Manufacturing method of polyamide conductive fibres

ActiveCN103046159BHas conductive propertiesHigh strengthElectroconductive/antistatic filament manufactureFilament/thread formingAntioxidantFiltration

The invention discloses a manufacturing method of polyamide conductive fibres, which comprises the following steps of: A) uniformly mixing tetrapod-like zinc oxide whiskers and conductive potassium titanate whiskers, then calcining in a vacuum furnace; after cooling, stirring and dispersing by using sodium hexametaphosphate in anhydrous ethanol, then carrying out a plasma treatment at the normal temperature, carrying out ultrasonic dispersion and cleaning by reusing deionized water containing a calcium stearate dispersion liquid, taking solution upper suspension whiskers to be filtered by 150 meshes, taking a modified whisker mixed liquid, and repeating the operation until the filtration, drying in a vacuum oven after filtration to obtain a modified whisker mixture; B) stirring the modified whisker mixture obtained in the step A) with antimony-doped tin oxide conductive powder, superconducting super-conductive carbon black, a titanate coupling agent, an aluminate coupling agent and polyethylene wax in a mixer to obtain a modified whisker conductive comixture; C) blending and melting the modified whisker conductive comixture obtained in the step B) with polyamide powder, a PE-g-MAH phase flux and a 1010 antioxidant in the presence of trace sodium hexametaphosphate to be prepared into conductive polyamide slices; and D) preparing conductive polyamide and conventional polyamide to be sheath-core polyamide conductive fibers through a composite spinning technology.

Owner:嘉兴貂帅服饰有限公司

A kind of manufacturing method of conductive polyester fiber

ActiveCN102978744BHas conductive propertiesEasy to processElectroconductive/antistatic filament manufactureFilament/thread formingBreaking strengthPolyester

The invention discloses a method for manufacturing conductive polyester fibers. The method comprises the following steps of: adding conductive materials including ATO conductive powder, superconducting carbon black, zinc oxide whiskers, potassium titanate whiskers and the like into polyester to prepare conductive polyester; and taking the conductive polyester as a skin layer to prepare polyester conductive fibers with other polyesters through a composite spinning technology. Through the method, the skin layer part of the fibers contains conductive substances, so that the fibers have excellent physical and processing performance of synthetic fibers while having conductivity, the resistivity of the polyester fibers can be greatly reduced, and the breaking strength of the fibers can also be improved.

Owner:ZHEJIANG SCI-TECH UNIV

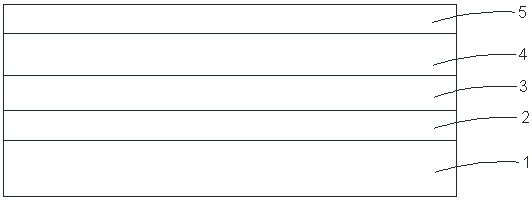

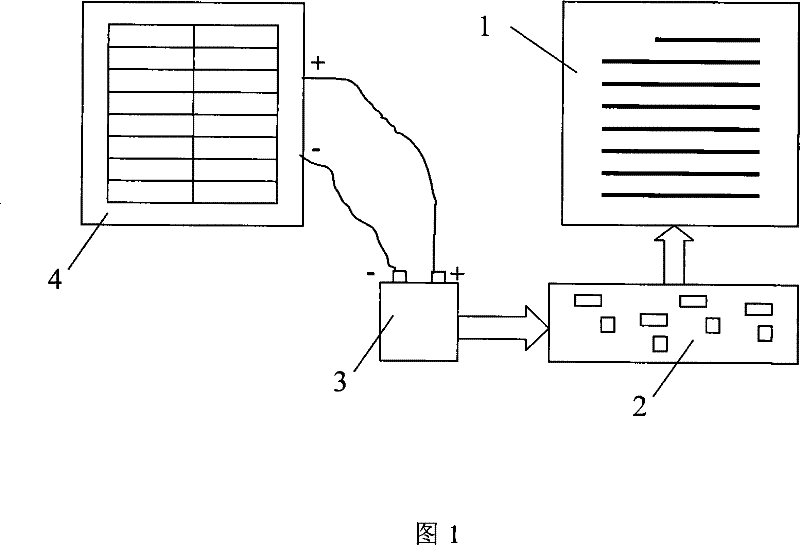

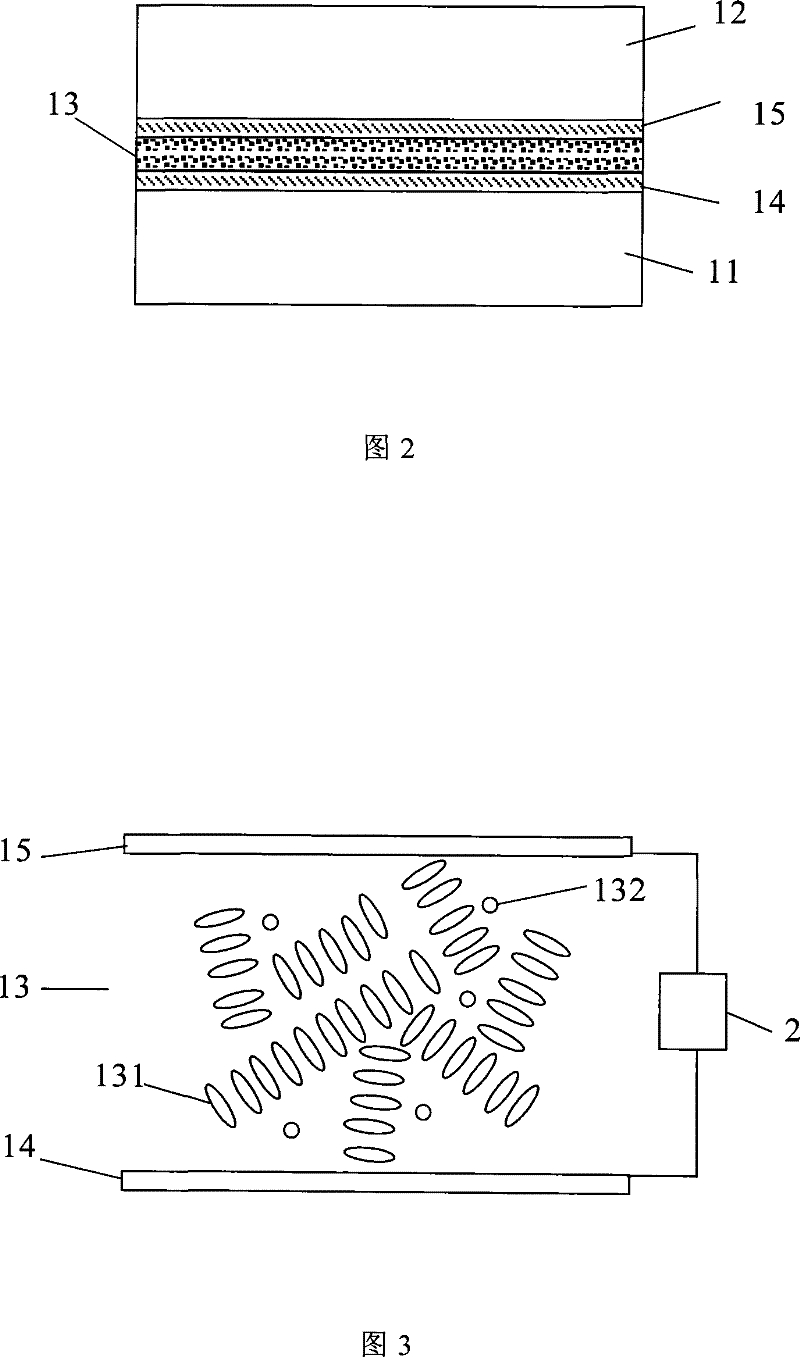

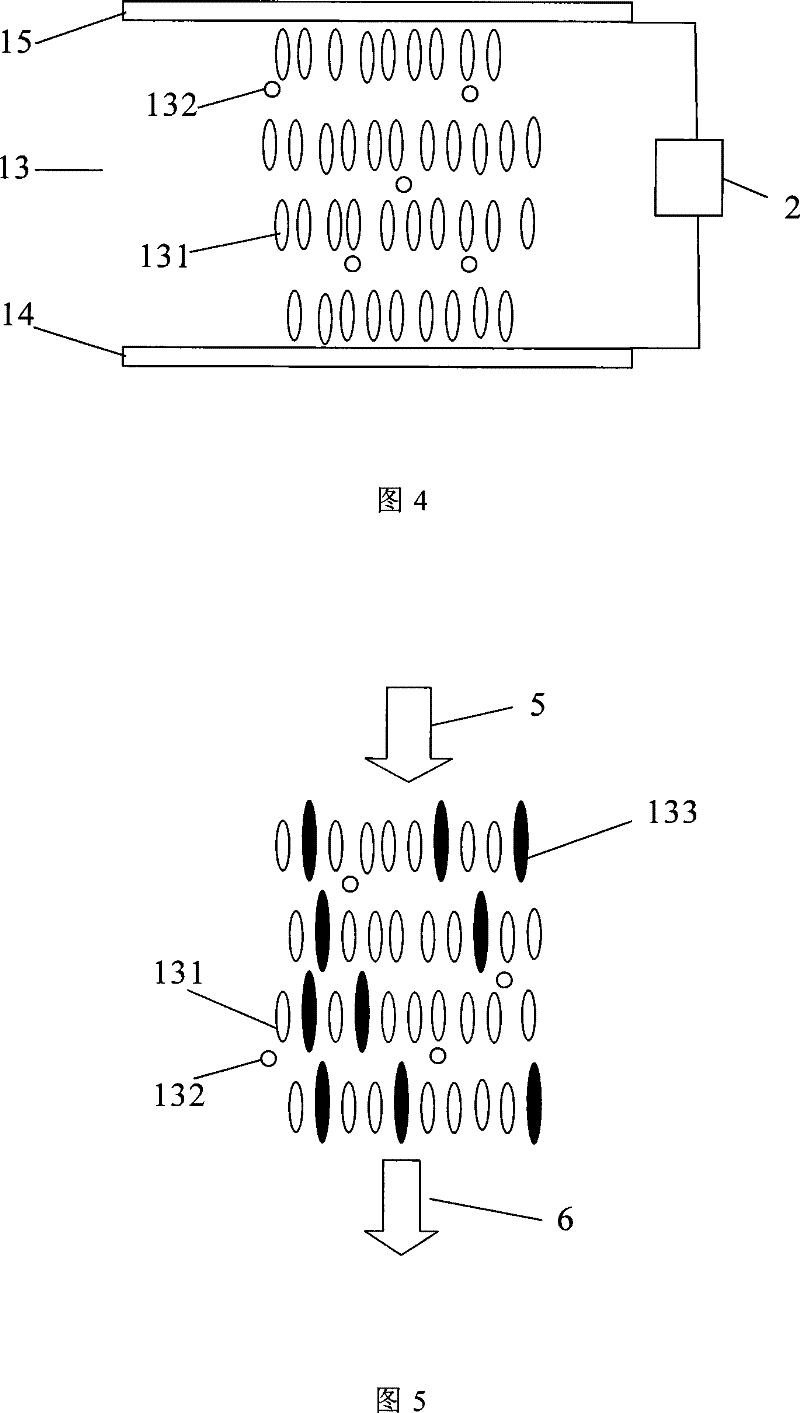

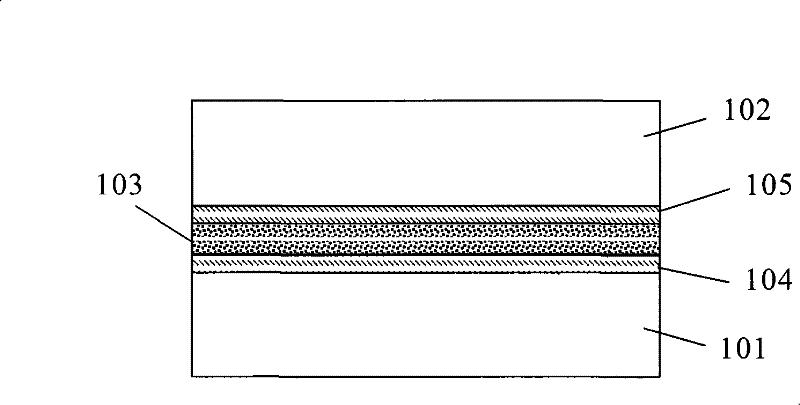

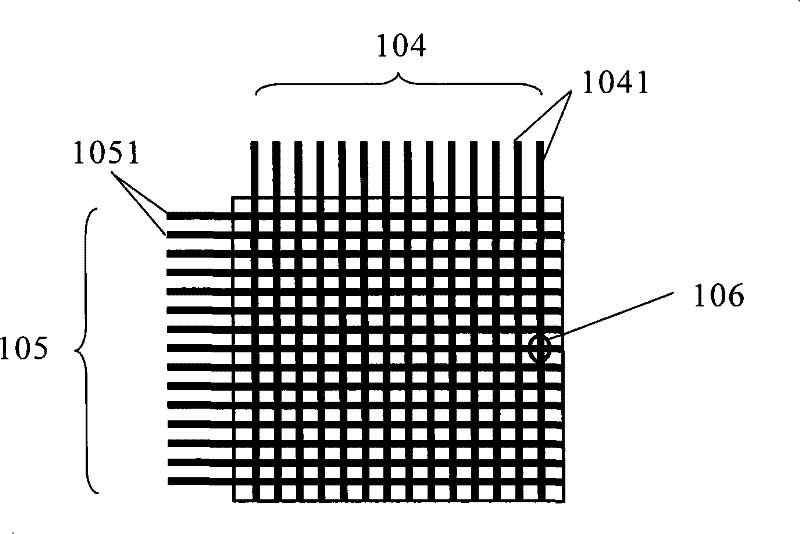

A smectic liquid crystal display device

InactiveCN101470286BHas conductive propertiesNon-toxicLiquid crystal compositionsStatic indicating devicesLiquid-crystal displayEngineering

The invention discloses a smectic liquid crystal display device, which comprises a smectic liquid crystal display, a drive control device, a storage battery and a solar receiving device, the smectic liquid crystal display, a drive control device, a storage battery, and a solar receiving device connected. The smectic liquid crystal display includes a first base layer and a second base layer, and a mixed layer is arranged between the first base layer and the second base layer, and the mixed layer is formed by mixing smectic liquid crystals and additives , the first and second conductive electrode layers are respectively provided on the side of the first and second matrix layers facing the mixed layer, the first and second conductive electrode layers are composed of a plurality of strip electrodes arranged in parallel, and the two conductive electrodes The strip electrodes of the layers are vertical to form a pixel point array, and the first and second conductive electrode layers are connected with the driving control device. The solar receiving device is at least one solar panel. The invention has low energy consumption, no radiation, is charged by solar panels, and is suitable for outdoor use.

Owner:HALATION PHOTONICS CORP

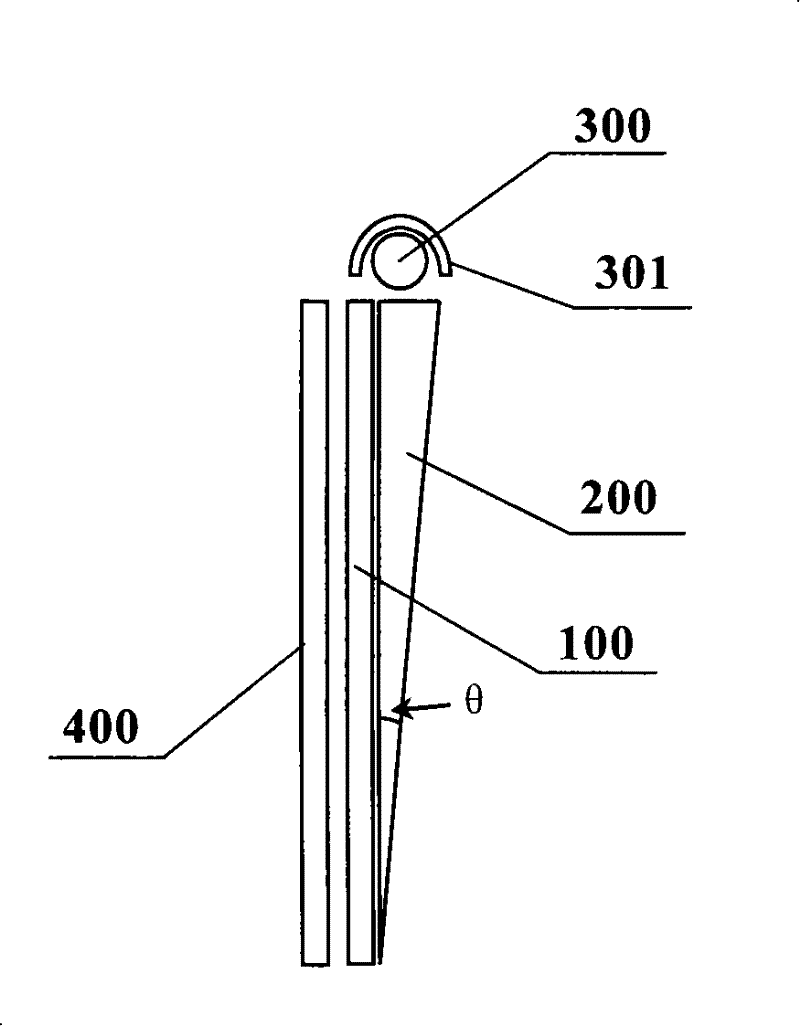

Liquid crystal display screen

InactiveCN101571652BDoes not affect transmittanceStable astigmatismLiquid crystal compositionsNon-linear opticsDisplay contrastEffect light

The invention relates to a liquid crystal display screen comprising a liquid crystal display module; the front side of the liquid crystal display module is provided with a wedged photoconductive layer; a lighting source is arranged above the liquid crystal display module and the photoconductive layer; the liquid crystal display module comprises a first matrix layer and a second matrix layer between which a mixed layer is arranged, and the mixed layer is formed by mixing smectic liquid crystal and additives; the side of the first matrix layer, facing to the mixed layer, is provided with a first conductive electrode layer, and the side of the second matrix layer, facing to the mixed layer, is provided with a second conductive electrode layer; the first conductive electrode layer comprises M parallel stripped electrodes, and the second conductive electrode layer comprises N parallel stripped electrodes; and the M stripped electrodes and the N stripped electrode are orthogonal to form a MxN pixel array. The invention has low energy consumption, no radiation and strong display contrast and can be used as a traffic indication display device and an outdoor or military field display device.

Owner:HALATION PHOTONICS CORP

Electrolysis device and kitchen appliance

InactiveCN111453817AHas conductive propertiesReduce usageWater/sewage treatmentKitchen equipmentElectrolytic agentIridium

The invention provides an electrolysis device and a kitchen appliance. The electrolysis device comprises: at least one first electrode; at least one second electrode, wherein a gap is formed between the second electrode and the first electrode; and a power supply, wherein a first power supply end of the power supply is connected with the first electrode, a second power supply end of the power supply is connected with the second electrode, and the power supply is configured to provide electric energy for the first electrode and the second electrode. The first electrode is manufactured from oneor more materials selected from a group consisting of antimony metal, ruthenium metal, tin metal, iridium metal and platinum metal. Under the action of the power supply, the electrolysis electrode manufactured from materials selected from antimony metal, ruthenium metal, tin metal, iridium metal and platinum metal electrolyzes an electrolyte, and substances with a strong oxidizing property can begenerated, so the electrolysis device can be used for disinfecting and sterilizing vegetables, meat and other food materials, and avoids the problem of secondary pollution to the vegetables, the meatand other food materials when conventional cleaning agents are used for cleaning.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG

RRAM

ActiveCN105448948BInhibited DiffusionHas conductive propertiesTransistorSolid-state devicesStatic random-access memoryRandom access memory

The invention provides a resistive random access memory, which includes an upper electrode, a lower electrode and a transition metal oxide layer between the upper electrode and the lower electrode. The above resistive random access memory also includes a metal cap layer located above the upper electrode and a transparent conductive oxide layer located between the metal cap layer and the upper electrode.

Owner:WINBOND ELECTRONICS CORP

A kind of manufacture method of nylon conductive fiber

ActiveCN103173886BHas conductive propertiesEasy to processElectroconductive/antistatic filament manufactureMonocomponent polyamides artificial filamentHydrogen NitrateCarbon nanotube

The invention discloses a method for manufacturing nylon conductive fibers. The method comprises the following steps of: (1) uniformly mixing four-needle type zinc oxide crystal whisker and conductive potassium titanate crystal whisker, roasting, cooling, adding into deionized water, performing ultrasonic dispersion, filtering, and drying, and thus obtaining wrapped crystal whisker mixtures; (2) adding multi-wall carbon nano tubes into a hydrogen nitrate solution, performing ultrasonic dispersion, heating, oxidizing, cooling, filtering, drying and grinding; (3) stirring the crystal whisker mixtures, the multi-wall carbon nano tubes, stibium-doped tin oxide conductive powder, a coupling agent, polymethylene, an antioxidant and nylon sliced powder in a closed manner, and granulating the mixtures through a screw extruder, and thus obtaining nylon conductive mother particles; and (4) respectively putting the nylon conductive mother particles and polyamide 6 into the corresponding screw extruders, spraying from a composite spinneret plate, cooling and winding to obtain the nylon conductive fibers. The nylon conductive fibers have conductive characteristics and are high in processing property and spinning property.

Owner:JIANGSU ZJA NEW MATERIAL

A kind of production method of conductive geotextile

The invention relates to a production method, in particular to a method for producing conductive geotextile. The method for producing the conductive geotextile comprises the steps of raw material selection, raw material screening, drying, fusion, spinning, cross air blow cooling, airflow drafting, swinging, net laying, mixed even feeding of metal fibers, carbon fibers and other short fibers, ironing conducted by a hot roller, shaping conducted by a pre-needle machine, reinforcing shaping conducted by a first main needle machine, repair shaping conducted by a second main needle machine, cloth containing conducted by a cloth containing machine, trimming and rolling. The geotextile produced according to the method for producing the conductive geotextile has the protective performance, the isolating performance, the waterproof performance, the filtering performance and the like of traditional geotextile, further has the conductive characteristic and is a good electrode material. According to the method for producing the conductive geotextile, the production technology is stable, control over the thickness of a material is good, the control range of the puncture density is large and is 50 to 500 stitches / cm<2>, the controllable range of the permeability performance of the material is large and is (1.0-9.9)*(10<-1>-10<-3>)cm / s, the strength of the product is high, and the thickness reaches 20mm.

Owner:大连格尔迈斯合成材料有限公司

A kind of expansion similar to conductive characteristics, similar model test materials and how to use

ActiveCN109238804BHas conductive propertiesSwellability with conductive propertiesPreparing sample for investigationMaterial strength using tensile/compressive forcesTest materialModel test

The invention discloses a similar-expansibility model test material with the conductivity, and a use method. The similar-expansibility model test material comprises a main body material and an additional material, wherein the main body material is a mixture of an aggregate material and a cementing material; the additional material comprises an expanding agent and a conductive agent; the volume expansion rate of the additional material is 10-30%; the aggregate material is a main material of the similar-expansibility model test material; the cementing material is a cementing and curing materialof the similar-expansibility model test material; the expanding agent enables the aggregate material and the cementing material to have a certain volume expansion after being mixed; and the conductiveagent enables the similar-expansibility model test material to have the conductivity. The invention provides a novel test material having the expansibility and the conductivity and used for testing asurrounding rock stress in a wide range (full field) in a full matching mode, and a test method.

Owner:CHINA UNIV OF MINING & TECH

Anti-fingerprint film, glass product and preparation method thereof

ActiveCN112877642BHas conductive propertiesExcellent abrasion resistanceVacuum evaporation coatingSputtering coatingSilicon oxideSILICONE DIOXIDE

The invention provides an anti-fingerprint film, a glass product and a preparation method thereof. The anti-fingerprint film includes a conductive film layer, a transition layer, a silicon dioxide layer, and an anti-fingerprint film layer that are stacked in sequence; the conductive film layer includes one of In, In oxides, Sn, Sn oxides, or Various, the transition layer includes Si 3 N 4 , SiON and SiO 2 . The glass product includes a glass substrate and the anti-fingerprint film; the substrate is adjacent to the conductive film layer. The method for preparing glass products includes: sequentially preparing the conductive film layer, the transition layer, the silicon dioxide layer and the anti-fingerprint film layer on a glass substrate by magnetron sputtering. The anti-fingerprint film provided by the present application has excellent friction resistance, waterproof and anti-fingerprint properties, and has a long service life.

Owner:LENS TECH CHANGSHA

A kind of shielding electrode used for gas sleeve anti-corona and its preparation process

ActiveCN109830892BSolve the problem of high roughnessHas conductive propertiesSparking plugsSpark gap detailsSurface resistivityElectrical aging

The invention discloses a shielding electrode for corona prevention of a gas bushing. The shielding electrode is disposed inside the gas bushing. The shielding electrode is fixedly disposed on a lowerflange around a conductive rod. The surface of the shielding electrode is provided with a semi-conductive layer. The surface resistivity of the semi-conductive layer is 103 [omega] to 1011 [omega]. The invention further provides a preparation process for obtaining the shielding electrode for corona prevention of the gas bushing, specifically including the following steps of S1: preprocessing: de-oiling, de-scaling, phosphating, and passivating the shielding electrode successively; S2: spraying: spraying the surface of the shielding electrode with a powder coating by an electrostatic sprayingmethod; S3: solidifying: solidifying the sprayed the shielding electrode at a high temperature and then cooling the shielding electrode. The shielding electrode ensures a solidified smooth surface byelectrostatic spraying of the semi-conductive molding powder. Due to the conductive property, the problem is solved that a conventional sprayed insulating paint is liable to electrical aging, and theelectrical performance of the gas bushing can be obviously improved, and the process is difficult and low in cost.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com