Patents

Literature

44results about How to "Spinnable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing conductive polyester fibers

ActiveCN102978744AHas conductive propertiesEasy to processElectroconductive/antistatic filament manufactureFilament/thread formingPolyesterBreaking strength

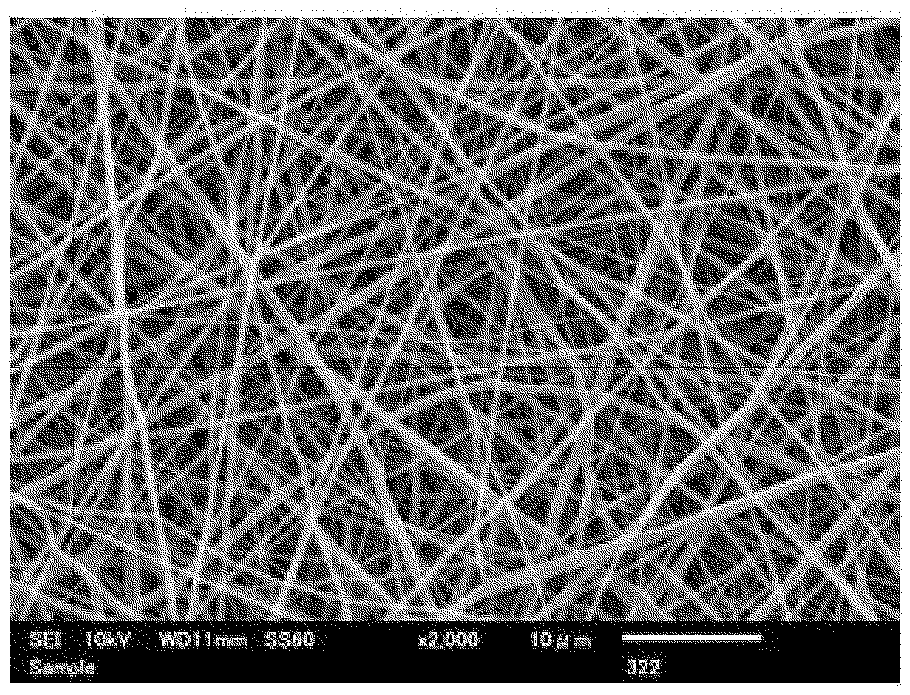

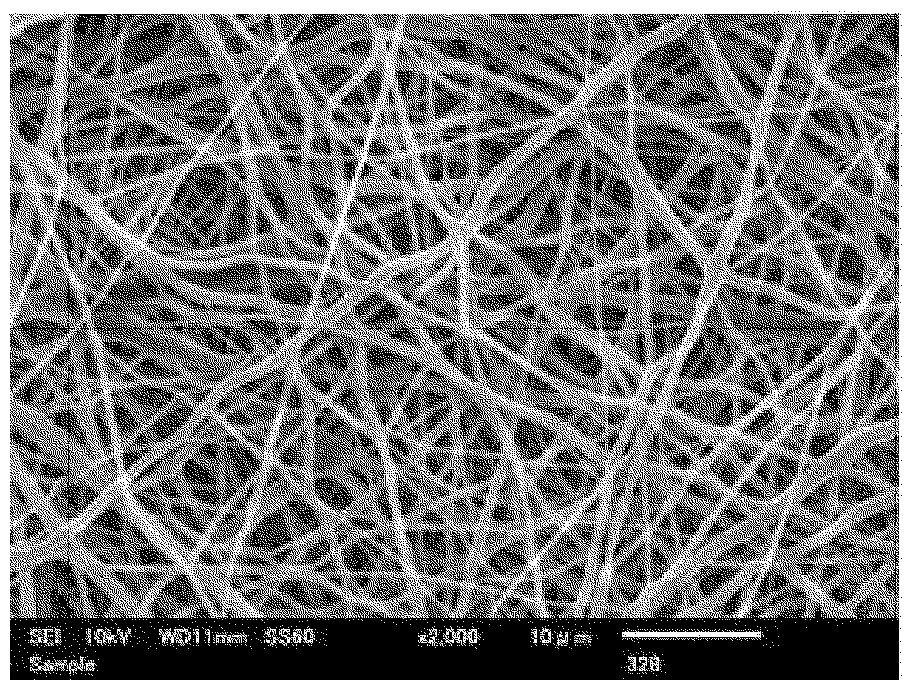

The invention discloses a method for manufacturing conductive polyester fibers. The method comprises the following steps of: adding conductive materials including ATO conductive powder, superconducting carbon black, zinc oxide whiskers, potassium titanate whiskers and the like into polyester to prepare conductive polyester; and taking the conductive polyester as a skin layer to prepare polyester conductive fibers with other polyesters through a composite spinning technology. Through the method, the skin layer part of the fibers contains conductive substances, so that the fibers have excellent physical and processing performance of synthetic fibers while having conductivity, the resistivity of the polyester fibers can be greatly reduced, and the breaking strength of the fibers can also be improved.

Owner:ZHEJIANG SCI-TECH UNIV

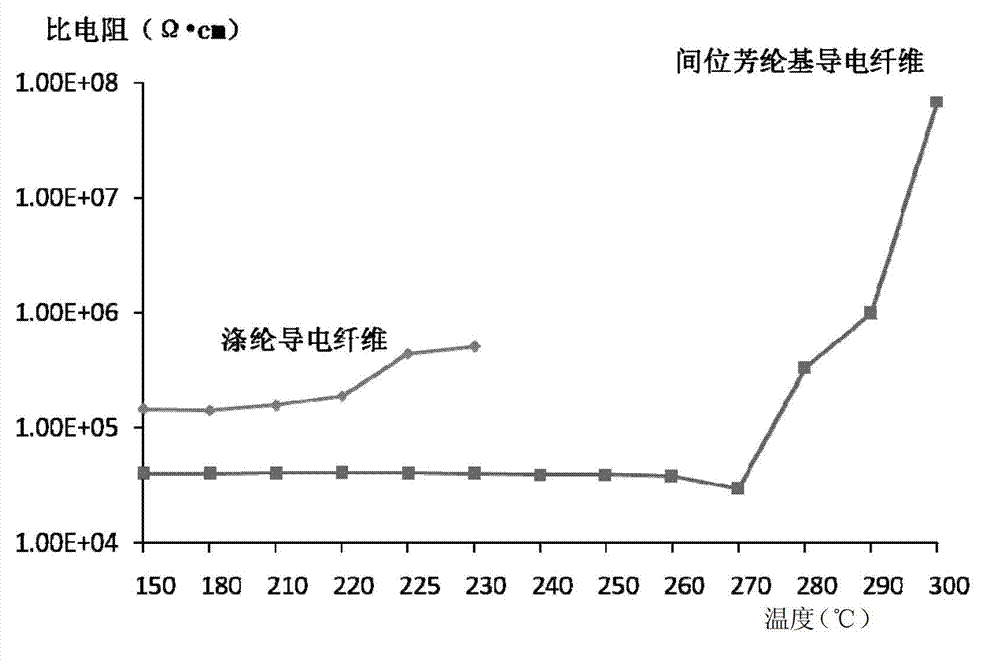

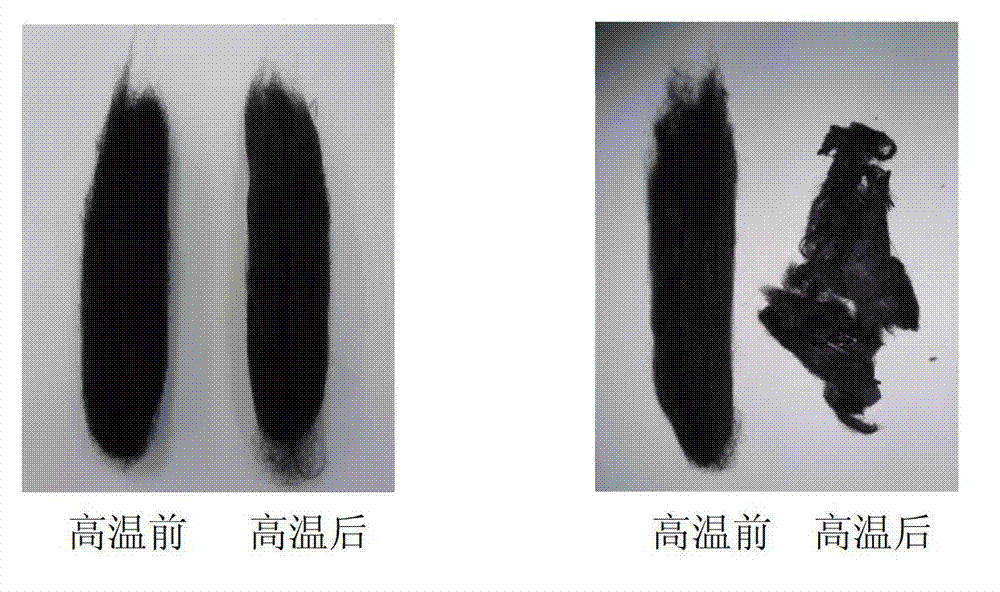

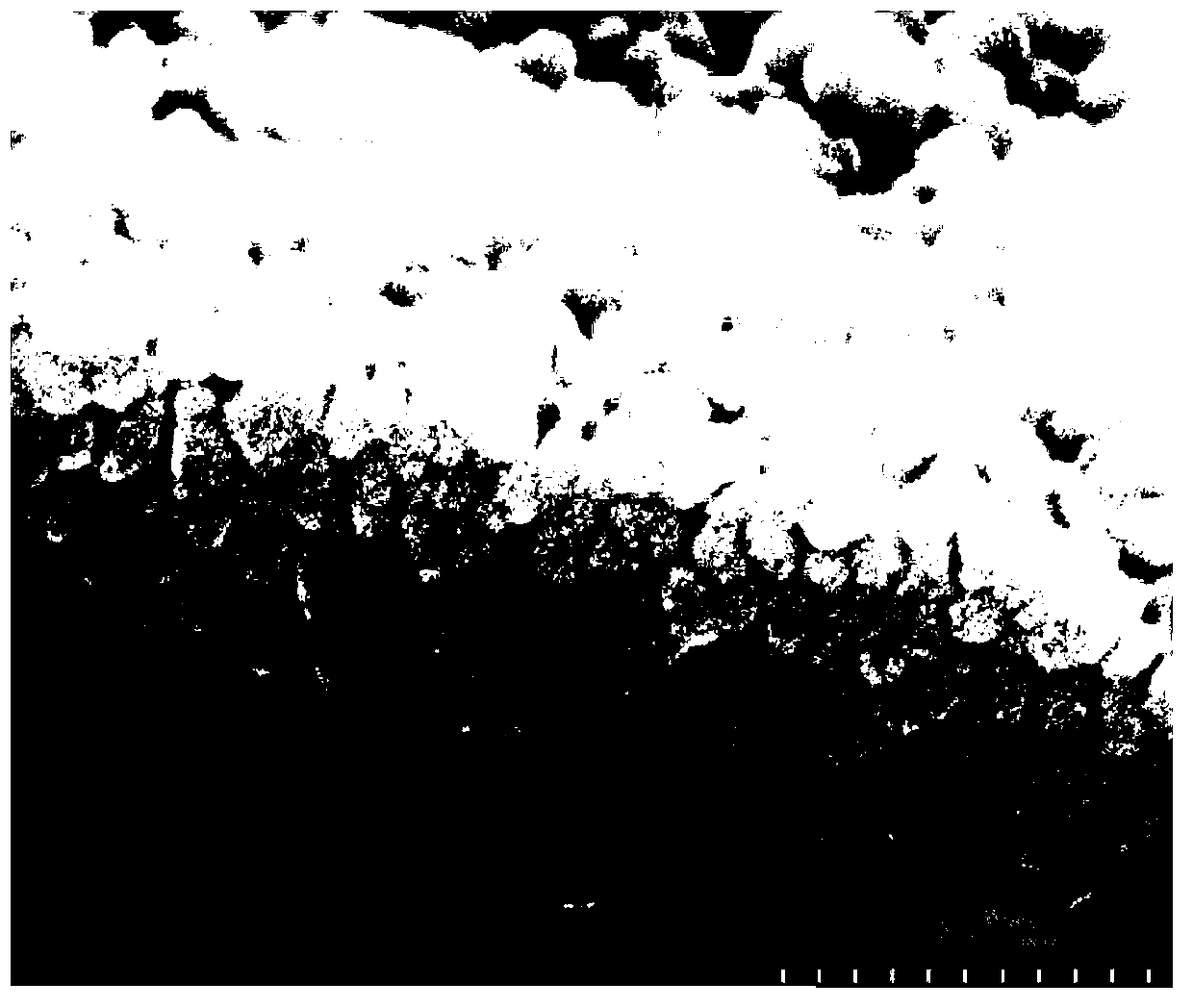

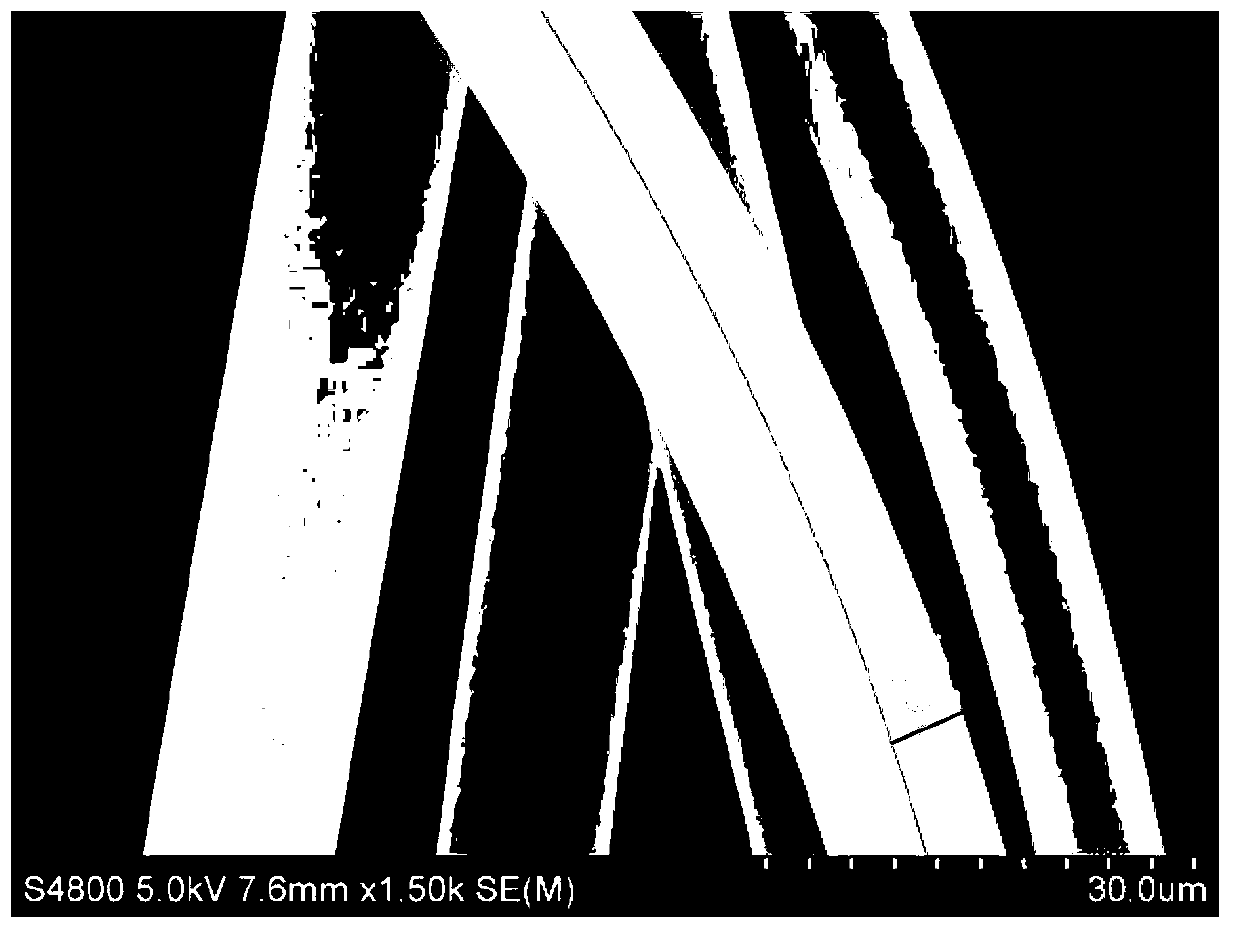

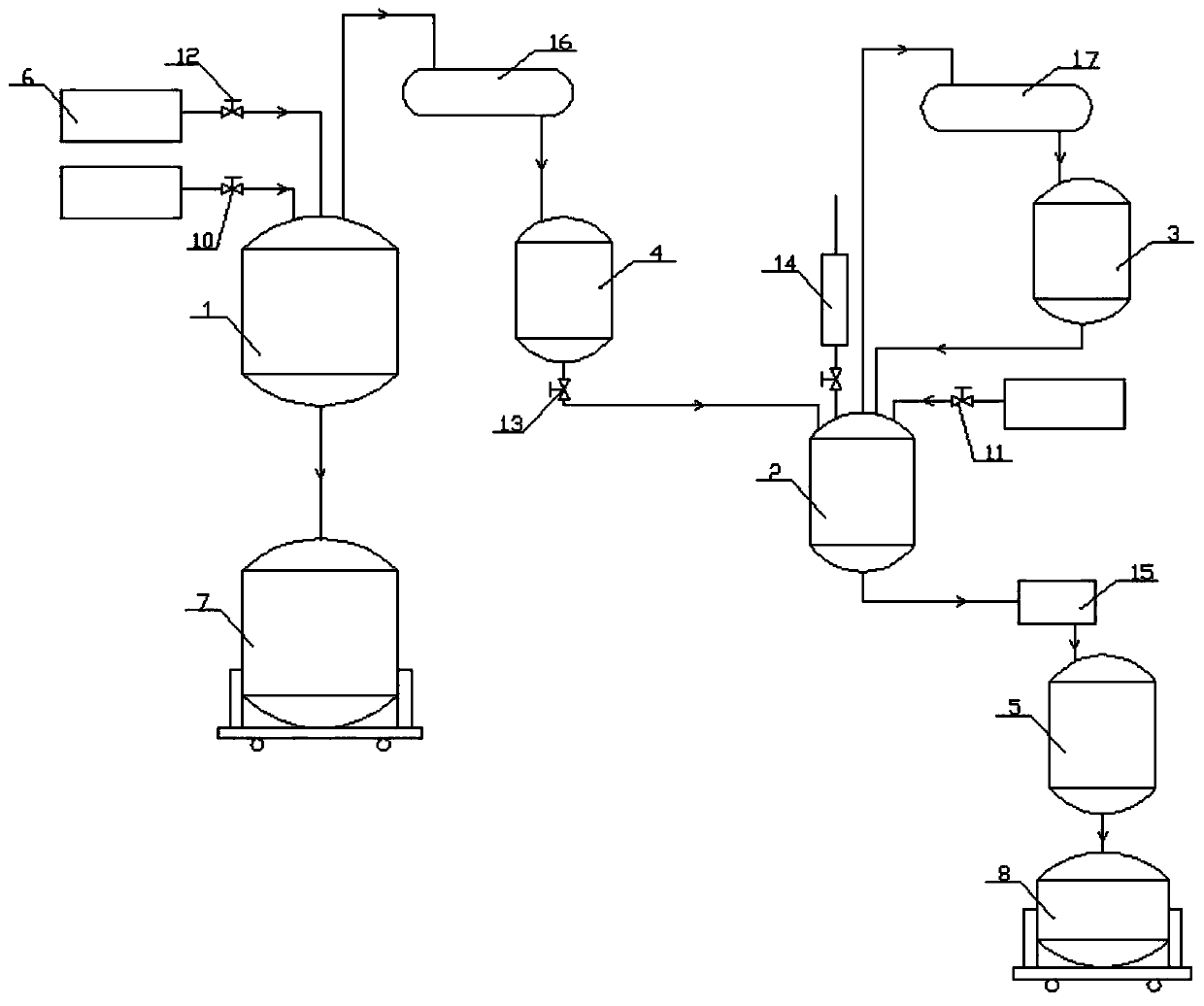

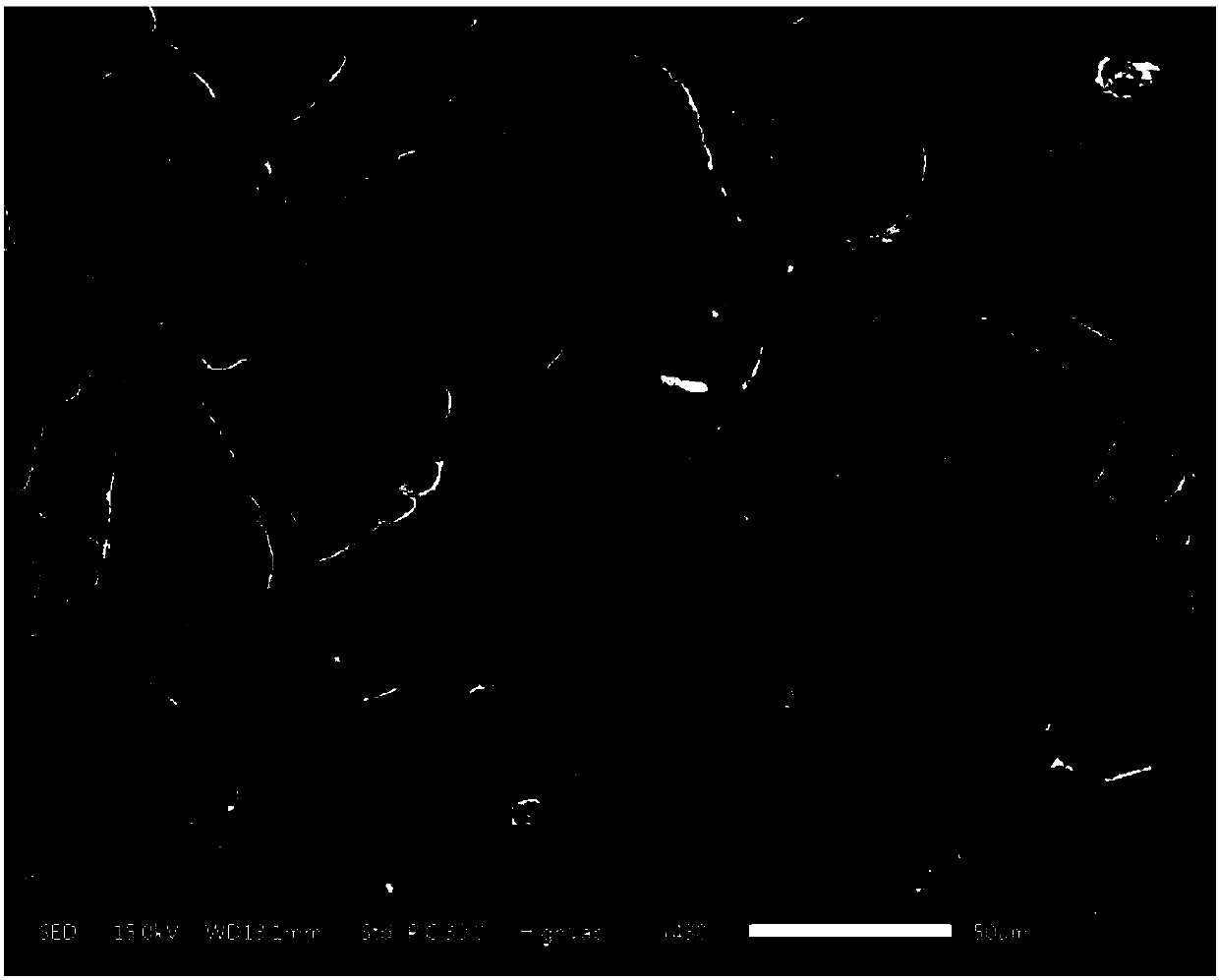

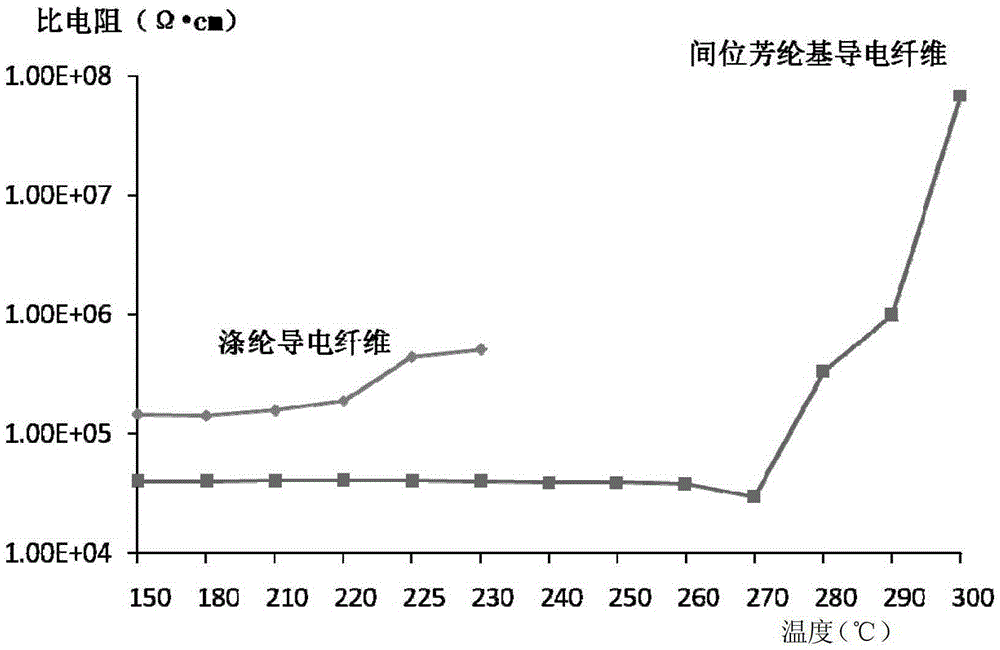

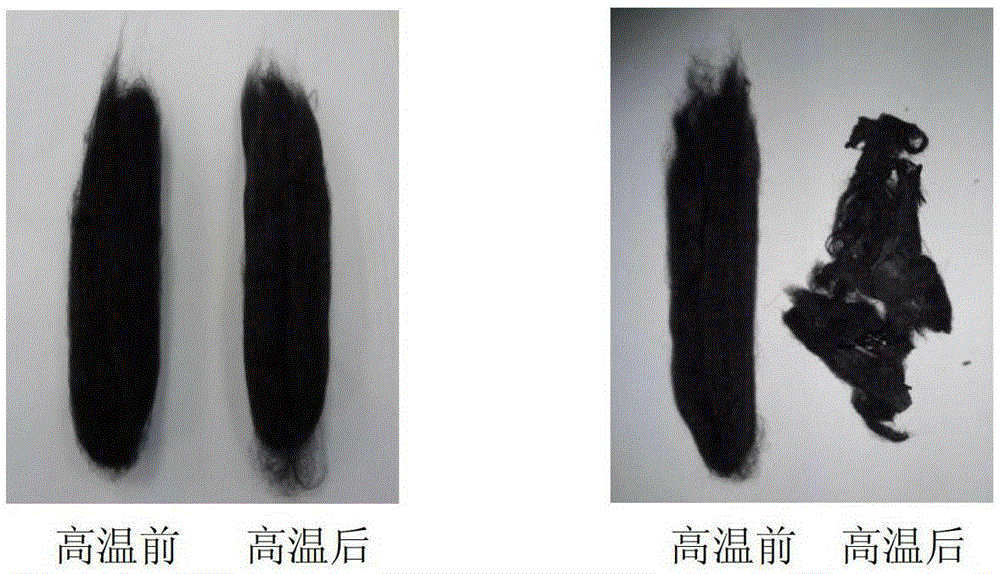

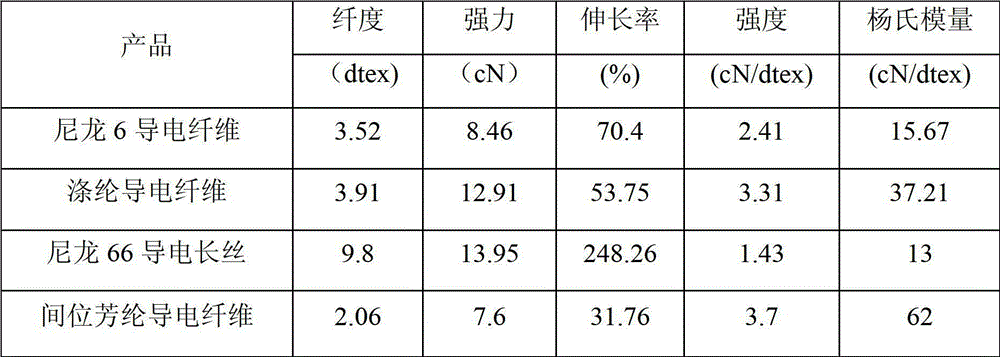

Method for preparing conduction meta-position aramid fibers

ActiveCN103046155AHigh temperature resistantDimensional stabilityElectroconductive/antistatic filament manufactureWet spinning methodsPolymer scienceSolvent

The invention relates to a method for preparing conduction meta-position aramid fibers. The method mainly comprises the following steps: (1) treating conduction components; (2) adding the conduction components, a solvent and a dispersing agent into high-speed mixing equipment in proportion, controlling the temperature by 50-80 DEG C, and fully mixing; and then grinding to reach the reasonable size, wherein the maximum size is below 200 nanometer; (3) adding the ground conduction component solution into a polymer solution, fully and uniformly mixing, and then cooling and deaerating to obtain a conduction fiber spinning solution; and (4) adopting a wet spinning process, carrying out solidification, drawing, washing and heat treating, and finally obtaining the meta-position aramid fibers with conductivity. The conduction meta-position aramid fibers prepared by the method has the good performances of meta-position aramid such as intrinsic inflaming retarding, high temperature resistance, size stability, spinnability and the like and meanwhile has the good conductivity of the resistivity (104-105) omega.cm.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

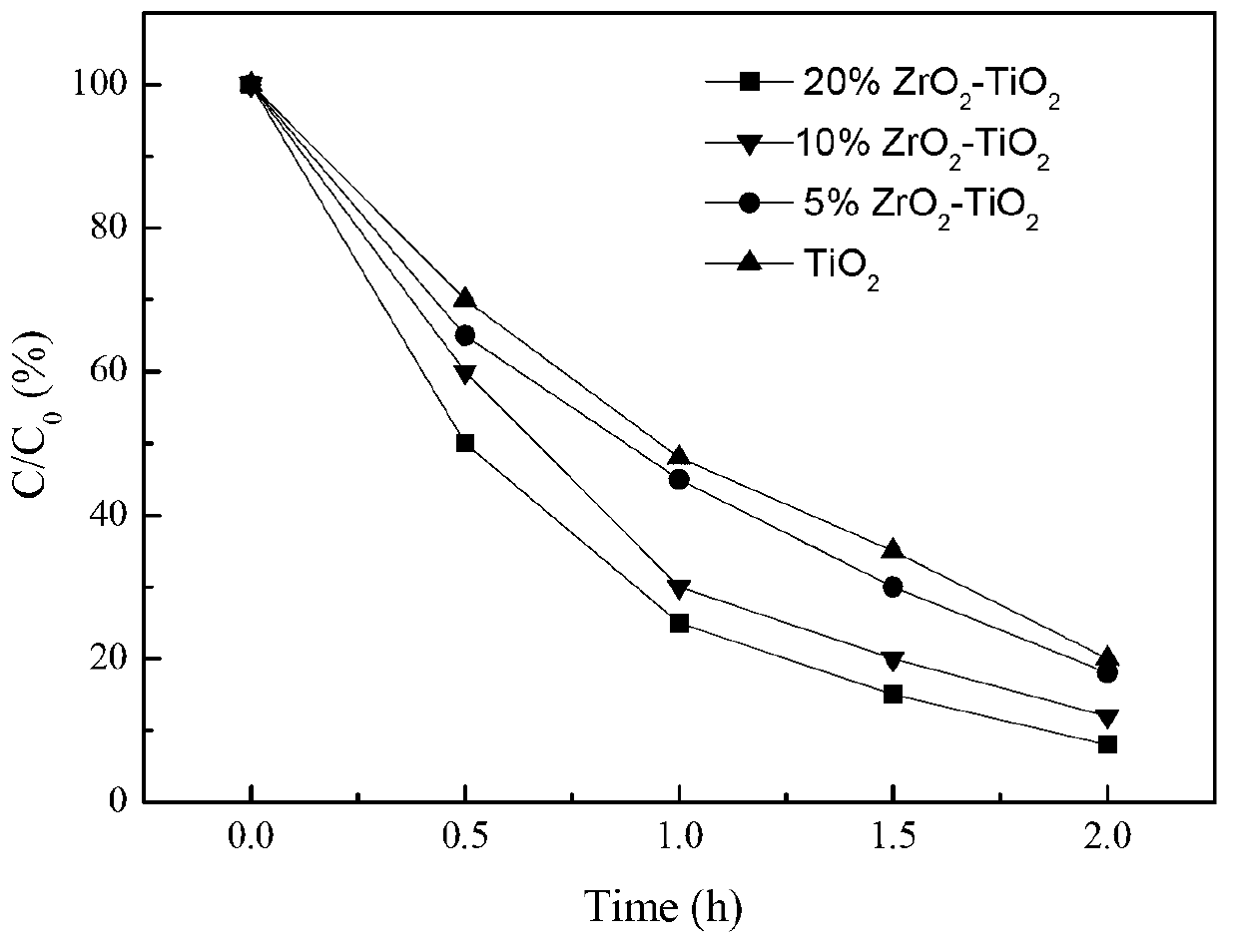

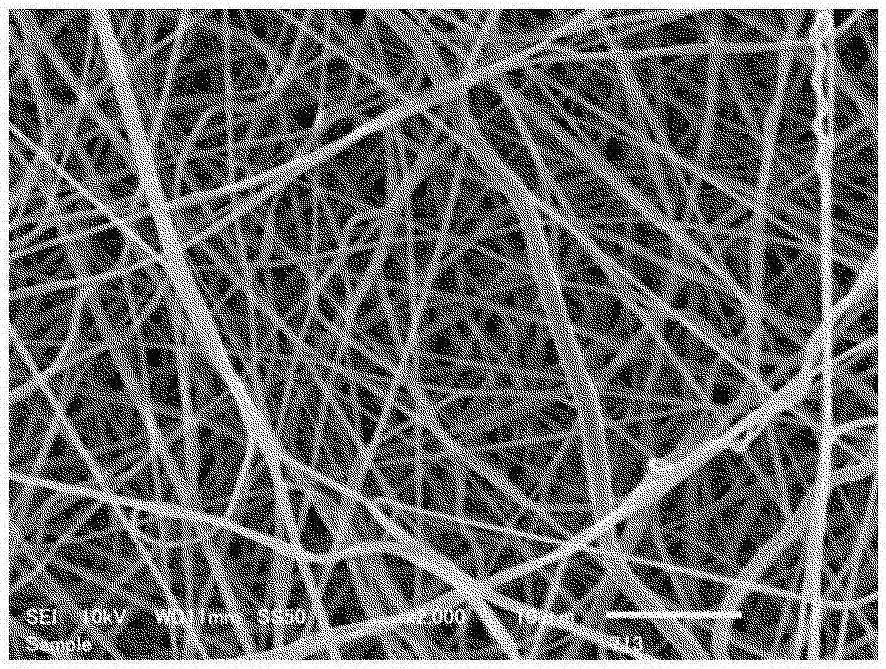

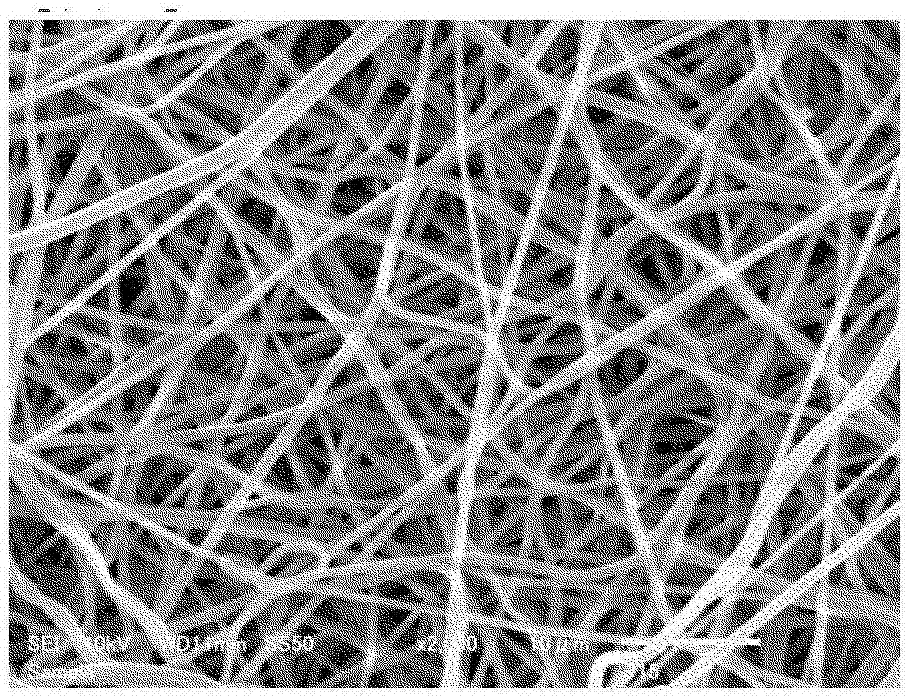

Preparation method of titanium dioxide-zirconium oxide composite fibers

ActiveCN103127923AHigh photocatalytic activityImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationFiberOrganotitanium compound

The invention relates to a preparation method of titanium dioxide-zirconium oxide composite fibers, which comprises the following steps: dissolving polyacetylacetonatozirconium in an alcohol solvent, adding 95-5 mol% of zirconium oxide and 5-95 mol% of titanium dioxide into an organic titanium compound, and concentrating at 32-45 DEG C under reduced pressure until the solution viscosity reaches 10-50 Pa.s, thereby obtaining a spinning solution; and carrying out centrifuging spinning to obtain titanium dioxide-zirconium oxide composite precursor gel fibers, and carrying out high-heat treatment to obtain the high-quality titanium dioxide-zirconium oxide composite fibers. The titanium dioxide-zirconium oxide fibers can be reprocessed into fiber cloth, paper or any other shape; and on the premise of keeping the catalytic activity, the specific area can be fully utilized, and the photocatalysis effect is good.

Owner:山东德艾普节能材料有限公司

Japanese banana fiber and its preparation method and uses

InactiveCN101187068AImprove qualityImprove spin performanceMechanical fibre separationYarnYarnRaw material

The invention relates to a musa fiber, which is prepared from stems of musa plants, which are used as raw materials, wherein the musa fiber comprises the following components: cellulose is 81-95 percent, hemicellulose is 1.0-5.0 percent, lignin is 1.0-2.8 percent, other components are pectin water soluble matter and is based on the dry weight of the musa fiber. The above musa fiber is prepared through the mechanical treatment, acid preimpregnation, washing, soda boil, washing, dehydration and oil supply, the above musa fiber is used to be spun into 10-60 single yarn, the process has low cost, compared with ancient process, the strength and the fineness of the made fiber are improved, and the process of preparing the musa fiber of the invention is also capable of being used to made mulberry fiber. The invention opens a new way for the development and utilization of phloem resources, has an important significance at the present that a part of prior fiber resources are run out, and accords with strategic demands of sustainable development.

Owner:吴苏明 +2

Silicone-modified polyurethane-based fiber and method for manufacturing same

ActiveCN107407011ASoftSlidingMonocomponent polyurethanes artificial filamentElectro-spinningFiberPolymer science

Provided is a fiber formed from a resin containing a silicone-modified polyurethane resin. With the present invention, a characteristic fiber having excellent flexibility, slipping ability, blocking resistance, heat retaining property, water vapor permeability, water repellency, and spinnability can be provided.

Owner:SHIN ETSU CHEM IND CO LTD +2

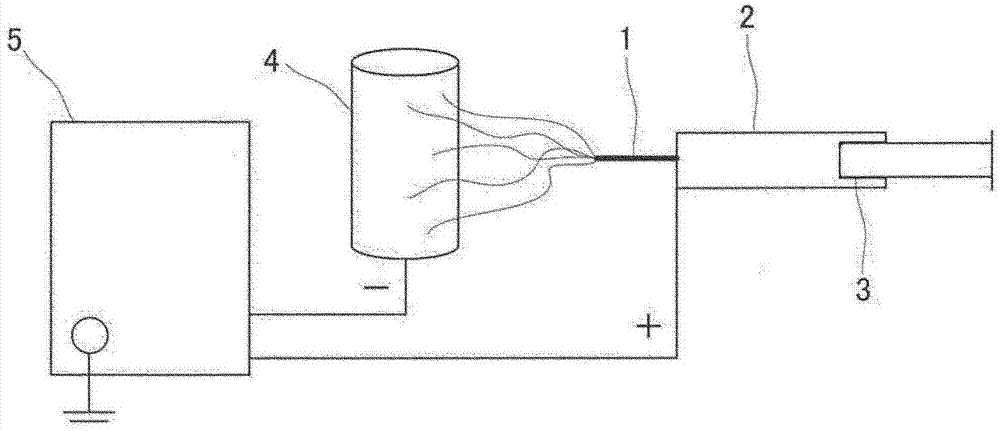

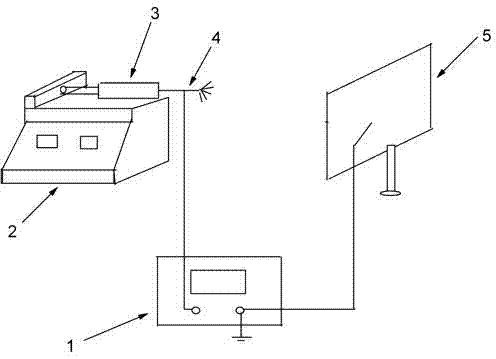

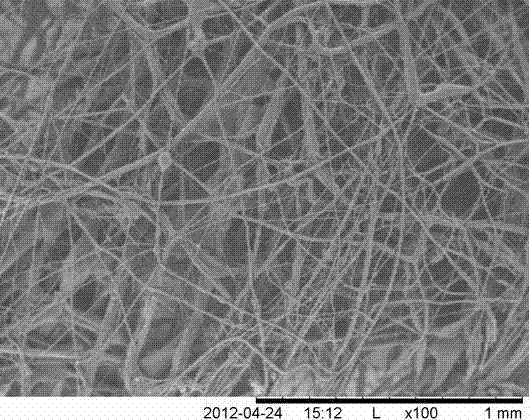

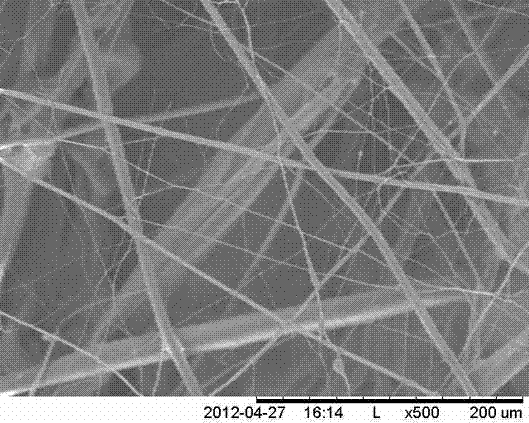

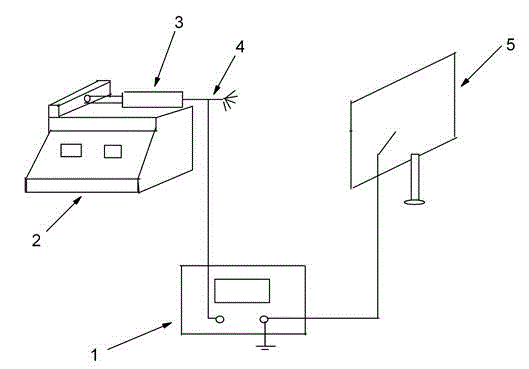

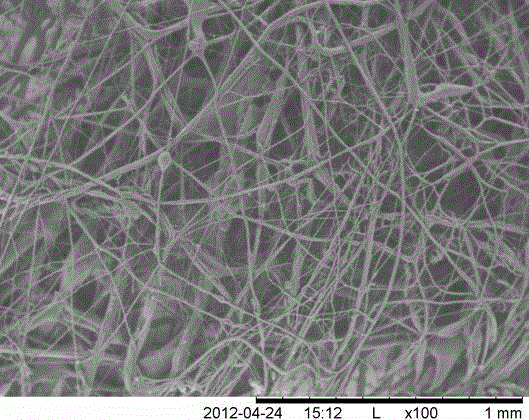

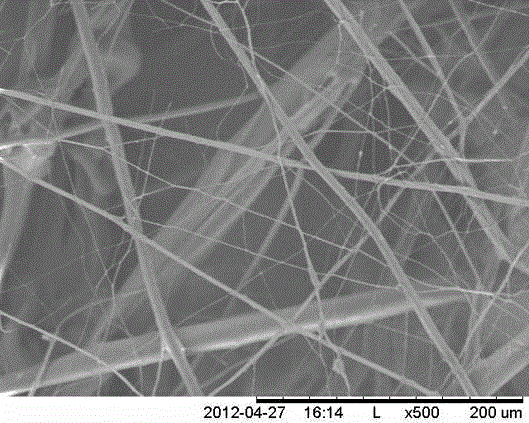

Method for preparing modified konjac glucomannan fiber by electrostatic spinning

InactiveCN102926016AReduce hydrogen bondingImprove heat settingFilament/thread formingMonocomponent synthetic polymer artificial filamentChemical industryElectrospinning

The invention discloses a method for preparing modified konjac glucomannan fiber by electrostatic spinning. The method is characterized by comprising the following steps of: modifying konjac glucomannan, i.e., dissolving the konjac glucomannan in ethanol water solution, carrying out swelling reaction by adding sodium hydroxide, neutralizing by diluted hydrochloric acid, filtering, washing, and drying to obtain acetyl-free konjac glucomannan; mixing and reacting distilled water, acetyl-free konjac glucomannan, methyl acrylate and initiator under the temperature of 10-70DEG C, mixing by adding ethanol, standing for settling, filtering, washing solid with acetone, and drying to obtain modified konjac glucomannan; preparing spinning solution; and carrying out electrostatic spinning to prepare fiber. The method has the characteristics of simple technology, low cost and the like, and is environment-friendly, and the prepared fiber material has good application prospect in the fields of medicine, environmental protection, chemical industry, agriculture and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of spinnable polycarbosilane precursor material

InactiveCN109824906AImprove linearityModerate viscosityFibre chemical featuresInternal pressureNitrogen

The invention discloses a preparation method of a spinnable polycarbosilane precursor material. The preparation method includes the steps: placing polydimethyl silane into a pyrolysis kettle, openinga vacuum valve of the pyrolysis kettle, turning on a vacuum pump, closing the vacuum valve of the pyrolysis kettle when the pyrolysis kettle is vacuumized to be -0.08 to -0.09Mpa, opening a nitrogen valve of the pyrolysis kettle, leading in nitrogen, enabling the internal pressure of the pyrolysis kettle to be 0.04Mpa and maintaining the pressure for 20-24 hours; vacuumizing the pyrolysis kettle to be lower than -0.09Mpa, turning on a stirring device and a heating device of the pyrolysis kettle, heating the inside of the pyrolysis kettle to reach the temperature of 200 DEG C, keeping the temperature for 1-3 hours, continuously stirring the polydimethyl silane in the pyrolysis kettle at high temperature and low pressure to remove residual solvents of the polydimethyl silane, increasing thetemperature for pyrolysis, transferring the polydimethyl silane to a synthesis kettle and performing synthesis at the high temperature and high pressure to obtain polycarbosilane. A molecular chain inthe prepared polycarbosilane is good in linearity, branches on the molecular chain are fewer and less crossed, the polycarbosilane is moderate in viscosity and good in spinnability, the molecular weight of the prepared polycarbosilane is moderately 800-1300, and the polycarbosilane is the most spinnable.

Owner:福建立亚化学有限公司

Preparation method of biomass charcoal/graphene flexible composite film

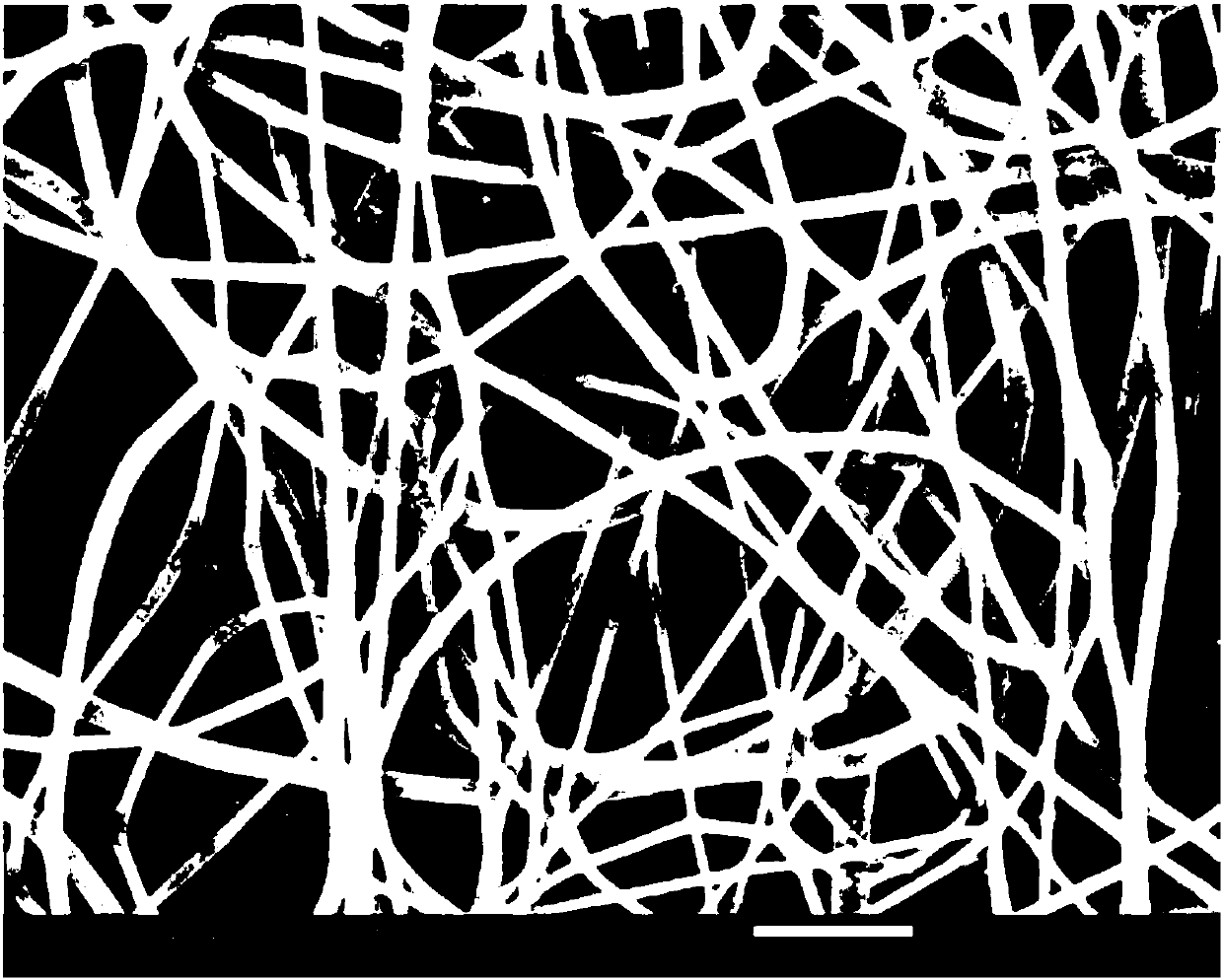

ActiveCN108538630ALow costHigh mechanical strengthHybrid capacitor electrodesCell electrodesCross-linkComposite film

The invention provides a preparation method of a biomass charcoal / graphene flexible composite film. The nitrogen-rich biomass charcoal / graphene flexible composite film is prepared by the blended spinning solution containing the silk fibroin, the graphene oxide and the activator through the electrospinning technology and high temperature one-step carbonization activation. The material has the characteristics of being nitrogen-rich, porous and flexible. According to the method, the silk fibroin is rich in amino acids and can react with the graphene oxide in a cross-linking way through heating and stirring so that the graphene oxide is enabled to be aminated, the graphene oxide can be further reduced in the carbonization process, and the nitrogen atom part of the biomass residues in the composite material. The mass ratio of the biomass charcoal to the graphene in the obtained biomass charcoal / graphene flexible composite film is (0.5-9):1, the specific area is 1850-2740m2 / g and the mitogencontent is 3.6-9.4%. The composite film is applied to the electrode material of the supercapacitor and the sodium ion battery so as to show high specific capacity, long cycle life and excellent rateperformance.

Owner:BEIJING UNIV OF CHEM TECH +3

Semi-dull high-strength low-elongation viscose fiber as well as preparation method and application thereof

InactiveCN104846458AGood skin affinityHigh strengthArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceSpinning

The invention provides a semi-dull high-strength low-elongation viscose fiber as well as a preparation method and application thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, directional polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has an index system that the dry fracture strength is more than or equal to 3.20cN / dtex, the wet fracture strength is more than or equal to 1.70cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.6cN / dtex, the dry elongation at break is 13.0-16%, and the wet elongation at break is 16.0-21.0%. The semi-dull high-strength viscose fiber provided by the invention is prepared by virtue of technical innovation, and is a novel fiber variety which has an index system different from that of ordinary viscose fibers and Modal fibers, and a product of the fiber shows high and strong fiber characteristics and also shows skin affinity stronger than that of cotton fibers, so that the semi-dull high-strength low-elongation viscose fiber can effectively replace the existing differentiation viscose fiber, the development and the industrial upgrading of downstream novel textiles can be promoted while the processability of the downstream process of the viscose fiber is improved, and the semi-dull high-strength low-elongation viscose fiber can be well applied to the field of producing underclothes and high-grade woven fabrics.

Owner:YIBIN GRACE GROUP CO LTD +2

Process for antistatic and antibacterial polyamide 6DTY high elastic filament

InactiveCN102766920AWith mechanical propertiesSpinnableElectroconductive/antistatic filament manufactureFilament/thread formingPolymer scienceSpinning

The present invention relates to a process for an antistatic and antibacterial polyamide 6DTY high elastic filament, which is prepared from raw materials comprising polyamide 6 chips and additives by a POY-DTY process on high-speed spinning equipment. The prepared DTY high elastic filament has antistatic and antibacterial function and good stability, and can meet different requirements of post-weaving finishing.

Owner:WUJIANG YATAI CHEM TEXTILE

Method for manufacturing polyvinyl acetal conductive fibers

ActiveCN102978731ALow resistivityHigh breaking strengthElectroconductive/antistatic filament manufactureFilament/thread formingCarbon blackZinc

The invention relates to a method for manufacturing polyvinyl acetal conductive fibers. The method comprises the following steps of: adding conducting materials including ATO conductive powder, superconducting carbon black, zinc oxide whiskers, potassium titanate whiskers and the like into a fiber-grade polyvinyl alcohol spinning solution, and mixing, filtering and defoaming to prepare a conductive polyvinyl alcohol spinning solution; and ensuring that one part of the fibers becomes composite polyvinyl acetal conductive fibers containing conductive substances through a composite spinning technology. The polyvinyl acetal conductive fibers have low resistivity, high strength, durability and conductivity even the humidity is low.

Owner:浙江枫翎新材料科技有限公司

Wire production process

InactiveCN106057362AEasy to bendImprove folding resistanceApparatus for heat treatmentFlexible cablesWater immersionChemical corrosion

The invention discloses a wire production process which comprises the following steps of (1) monofilament drawing, (2) monofilament annealing, (3) surface treatment, (4) stranding, and (5) coating. The process is reasonable and simple, the mechanical strength of a wire is raised, and the ability of chemical corrosion prevention, moisture prevention, water immersion prevention and wire burning prevention is improved.

Owner:HEFEI JIARUILIN ELECTRONICS TECH

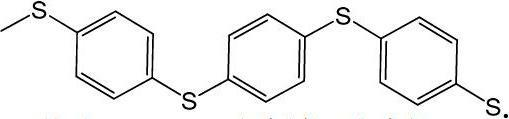

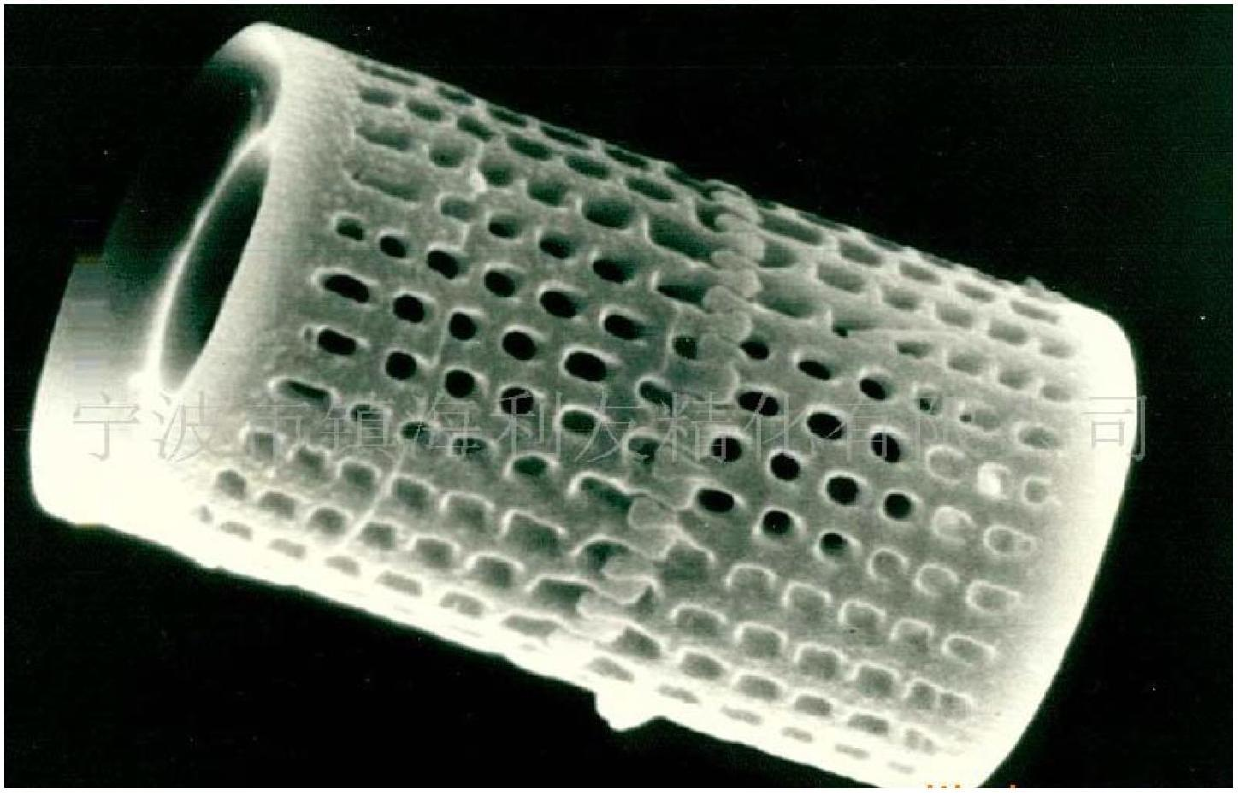

Heat-proof PPS (polyphenylene sulfide) filament adopting copper-loaded bergmeal as filling material and preparation and application of heat-proof PPS filament

ActiveCN102677219AReduce manufacturing costReduce usageDispersed particle filtrationFilament forming substance formingMicro nanoHeat resistance

The invention relates to a heat-proof PPS (polyphenylene sulfide) filament adopting copper-loaded bergmeal as a filling material and the preparation and the application of the heat-proof PPS filament. In the heat-proof PPS filament, the mass content of the copper-loaded bergmeal composite filling material is 5 to 30 percent. A preparation method of the heat-proof PPS filament comprises the following steps: (1) mixing bergmeal with deionized water to preparing a turbid liquid, adding reductant, copper ion contained lyotrope and copper protecting agent, performing reaction, and then performing ball-milling to obtain the micro-nano powdered copper-loaded bergmeal filling material; (2) premixing the micro-nano powdered copper-loaded bergmeal filling material with PPS chips through kneading to obtain premix, then extruding out the premix, and finally palletizing to obtain heat-proof PPS master batches; and (3) drying and crystallizing the heat-proof PPS master batches, performing melt spinning for forming, cooling, applying oil, performing preliminary reeling, and then drawing for shaping to obtain the heat-proof PPS filament. The PPS filament provided by the invention has the advantages of favorable spinnability, excellent heat resistance and wide application prospect.

Owner:DONGHUA UNIV

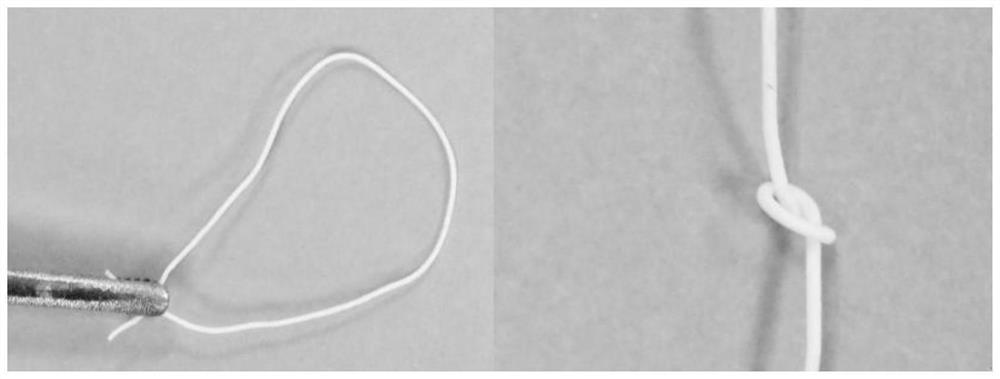

Preparation method of collagenous fiber, collagenous fiber and application

ActiveCN114182381AFast curingSpinnableMonocomponent protein artificial filamentWet spinning methodsFiberSpinning

The invention relates to the technical field of new materials, in particular to a preparation method of collagenous fibers, the collagenous fibers and application, the preparation method of the collagenous fibers comprises the following steps: (1) preparing a spinning solution, soaking a glue raw material in a dissolving solution with the pH value of 3.5-5.5 for dissolving, and then adjusting the pH value to 9.9-12.5 to form the spinning solution; (2) preparation of nascent fibers: putting the spinning solution into a coagulating bath with the pH value of 4.4-6.8, and carrying out coagulating spinning to form the nascent fibers; according to the method, a collagen salting-out environment is formed through multiple times of pH adjustment, and the collagenous fiber with spinnability is prepared through wet spinning.

Owner:ZHEJIANG HEURISTIC NEW MATERIAL TECH LLC

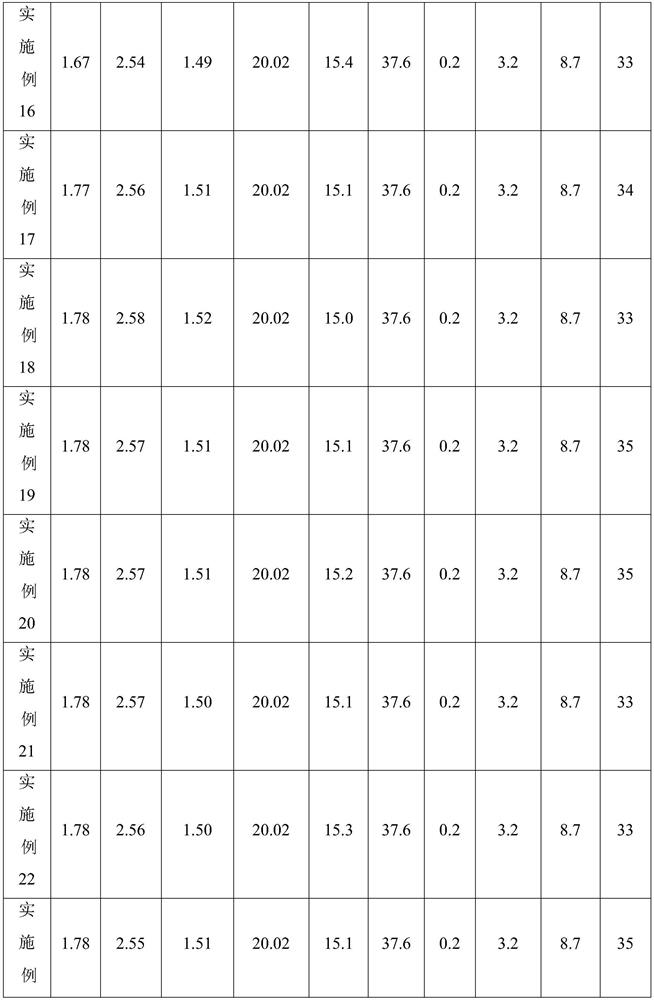

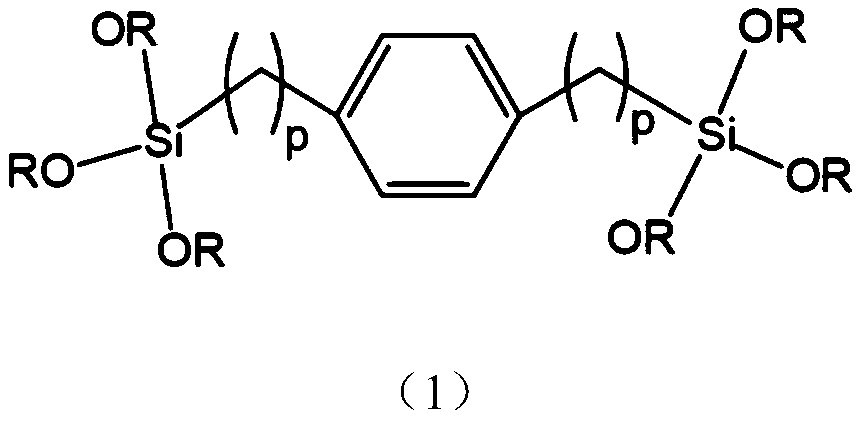

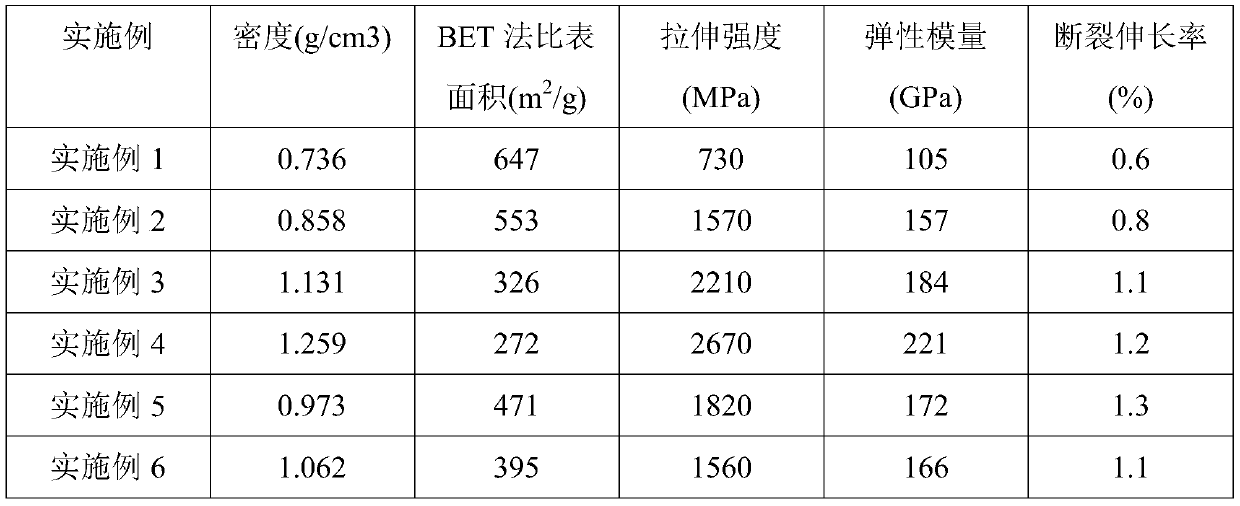

Preparation method of carbon/silicon hybrid fiber and carbon/silicon hybrid fiber

ActiveCN111172624ASpinnableLow densityInorganic material artificial filamentsDimethyl formamideSilane coupling

The invention belongs to the technical field of fibers, and particularly relates to a preparation method of a carbon / silicon hybrid fiber. The preparation method comprises the following steps of carrying out hydrolytic condensation on an alkoxy-containing silicon-based benzene compound and a silane coupling agent in a mixed solvent of N,N-dimethylformamide and deionized water to obtain wet gel, crushing the wet gel, adding the crushed wet gel into a polyacrylonitrile solution, and carrying out spinning, pre-oxidation and high-temperature carbonization to obtain the carbon / silicon hybrid fiber.The carbon / silicon hybrid fiber has the characteristics of spinnability, low density, high specific surface area, high strength, conductivity and the like, and is suitable for the fields of aerospace, chemical engineering, machinery, electronics and the like.

Owner:福建拓烯新材料科技有限公司

Semi-dull low-extensibility viscose fiber as well as preparation method and application thereof

InactiveCN104846456AGood air permeabilityImprove dye uptakeArtificial filament washing/dryingArtificial filaments from viscoseWoven fabricViscose fiber

The invention provides a semi-dull low-elongation viscose fiber as well as a preparation method and application thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, directional polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has an index system that the dry fracture strength is more than or equal to 3.10cN / dtex, the wet fracture strength is more than or equal to 1.60cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.55cN / dtex, the dry elongation at break is 12-14.5%, and the wet fracture extensibility is 16.0-21.0%. The semi-dull high-strength viscose fiber provided by the invention is prepared by virtue of technical innovation, is a novel fiber variety which has an index system different from that of ordinary viscose fibers and Modal fibers, shows high and strong fiber characteristics, and also shows skin affinity stronger than that of cotton fibers, so that the viscose fiber can effectively replace the existing differentiation viscose fiber, the development and the industrial upgrading of downstream novel textiles can be promoted while the processability of the downstream process of the viscose fiber is improved, and the semi-dull low-elongation viscose fiber can be well applied to the field of production of jean fabrics.

Owner:YIBIN GRACE GROUP CO LTD +2

Silicone-modified polyurethane fiber and method for manufacturing same

ActiveCN108884597ASoftSlidingMonocomponent polyurethanes artificial filamentElectro-spinningFiberPolyol

A fiber formed from a resin including a silicone-modified polyurethane resin comprising the reaction products of a polyol (A), a chain extender (B), an active-hydrogen-group-containing organopolysiloxane (C), and a polyisocyanate (D), wherein the active-hydrogen-group-containing organopolysiloxane (C) contains an active-hydrogen-group-containing organopolysiloxane (C-1) having a carbinol group atonly one terminal.

Owner:SHIN ETSU CHEM CO LTD +2

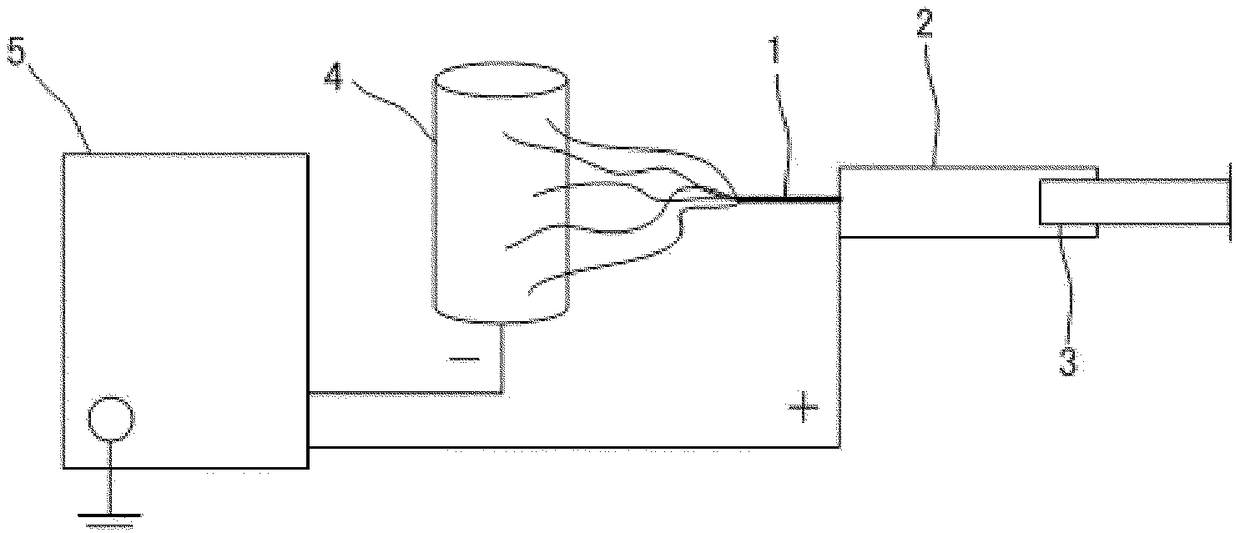

Electrostatic spinning process of brominated butyl rubber

ActiveCN107663716ASimple processEasy to implementElectro-spinningNon-woven fabricsFiberPolymer science

The invention discloses an electrostatic spinning process of brominated butyl rubber. The process comprises the following steps that 1, the brominated butyl rubber is added in an organic solvent, andstirring is conducted to obtain a brominated butyl rubber solution; 2, a surfactant is added into the brominated butyl rubber solution obtained in the step 1, and stirring is conducted to obtain a spinning solution; 3, electrostatic spinning is conducted to obtain an initial product of fiber thin film; 4, extraction and post-treatment are conducted on the initial product of the fiber thin film toobtain brominated butyl rubber fiber thin film. In the process, firstly, the spinnability of the brominated butyl rubber is improved by adding the surfactant; secondly, by spraying a release agent and / or liquid paraffin and / or zinc stearate on a receiving screen before electrostatic spinning, the obtained fiber thin film has self-support performance; thirdly, the extraction and the post-treatmentare conducted after electrostatic spinning, so that the shape and appearance of the obtained fiber thin film are controllable; moreover, the process is simple and easy to implement.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Preparation method of conductive meta-aramid fiber

ActiveCN103046155BHigh temperature resistantDimensional stabilityElectroconductive/antistatic filament manufactureWet spinning methodsPolymer sciencePolymer solution

The invention relates to a method for preparing conduction meta-position aramid fibers. The method mainly comprises the following steps: (1) treating conduction components; (2) adding the conduction components, a solvent and a dispersing agent into high-speed mixing equipment in proportion, controlling the temperature by 50-80 DEG C, and fully mixing; and then grinding to reach the reasonable size, wherein the maximum size is below 200 nanometer; (3) adding the ground conduction component solution into a polymer solution, fully and uniformly mixing, and then cooling and deaerating to obtain a conduction fiber spinning solution; and (4) adopting a wet spinning process, carrying out solidification, drawing, washing and heat treating, and finally obtaining the meta-position aramid fibers with conductivity. The conduction meta-position aramid fibers prepared by the method has the good performances of meta-position aramid such as intrinsic inflaming retarding, high temperature resistance, size stability, spinnability and the like and meanwhile has the good conductivity of the resistivity (104-105) omega.cm.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Antibacterial antistatic composite Fe-Cr-Al fiber

The invention relates to the technical field of metal wires, and especially relates to an antibacterial antistatic composite Fe-Cr-Al fiber, comprising a fiber body. The fiber body is formed by winding two Fe-Cr-Al fibers, a brass fiber, and a nano-silver fiber. The surfaces of the Fe-Cr-Al fibers, the brass fiber, and the nano-silver fiber are coated with an active agent kind antistatic agent. The antibacterial antistatic composite Fe-Cr-Al fiber effectively improves strength and hardness of the Fe-Cr-Al fiber, and the surfaces are coated with the active agent kind antistatic agent, so antistatic property of the Fe-Cr-Al fiber is greatly improved, and toughness, electrical conductivity, weldability, and temperature resistance and rotproofness of metal are maintained, and the fiber has flexibility and spinnability of common fibers. The fiber has effects of effective sterilization and deodorization, and the fiber is used to manufacture a plurality of kinds of metal fiber products.

Owner:夏鹤鸣

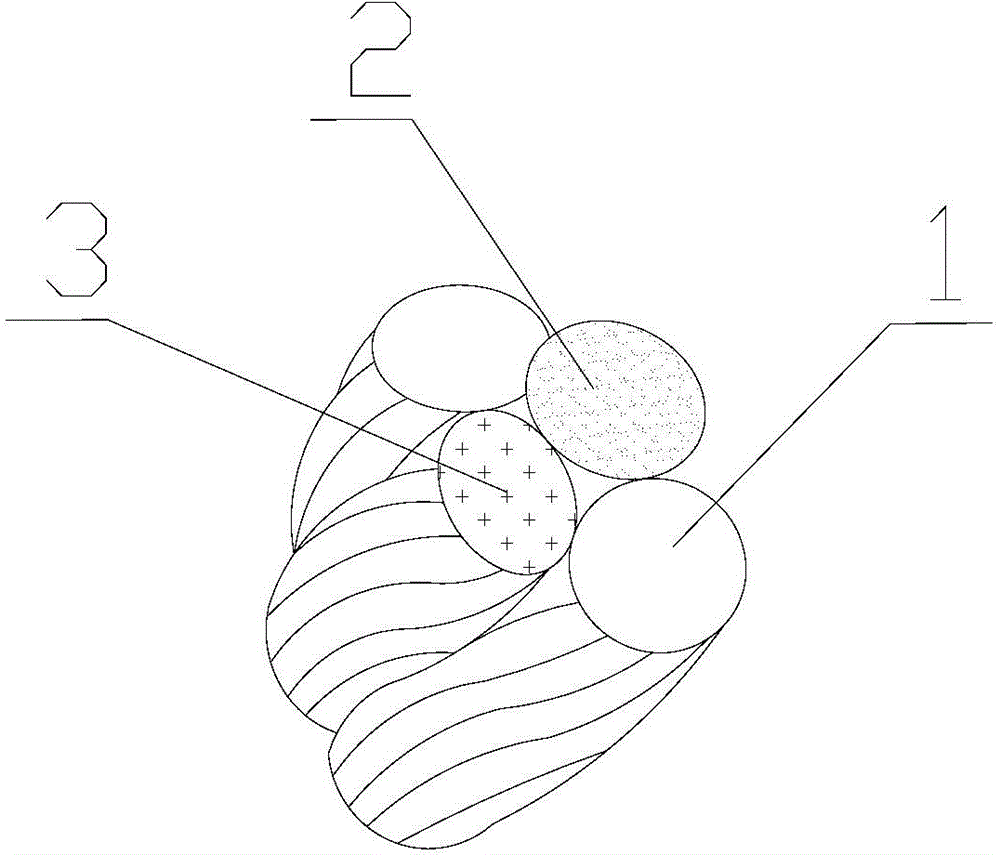

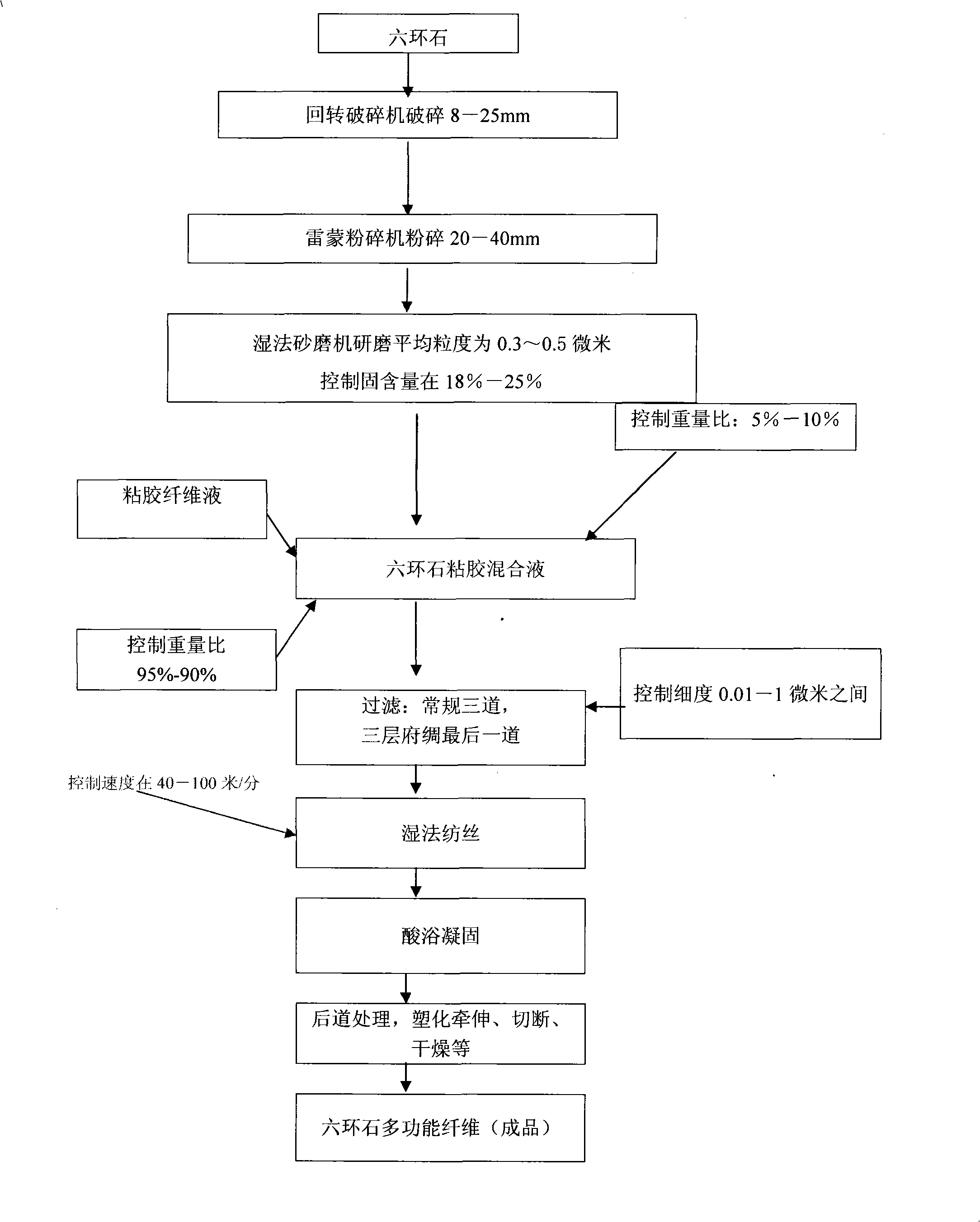

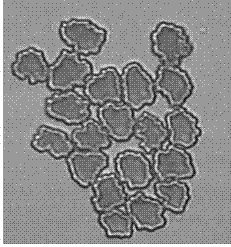

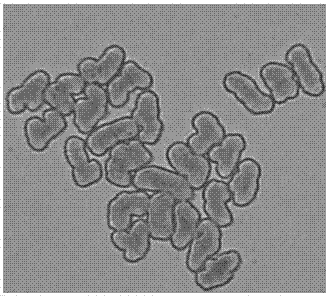

Multifunctional fibre containing Liuhuan stone and manufacturing method thereof

The invention relates to a multifunctional fiber containing six-ring stones, which is characterized in that: the fiber at least contains six-ring stone microparticles the particle diameter of which is between 0.3 and 0.5 micrometer, and the weight ratio of the six-ring microparticles to the viscose fiber is 5-10 percent to 95-90 percent. The multifunctional fiber has the function of emitting far infrared rays, and the emissivity of the multifunctional fiber is over 88 percent as shown through tests. Moreover, the multifunctional fiber has the function of releasing anions, and the release amount of the multifunctional fiber is 4,700 per second per gram (powder) and 1,173 per second per square centimeter (plate) as shown through tests. Therefore, textile fabrics which are processed by the fiber and worn and used by people can generate a plurality of efficacies of environmental protection and health care. The multifunctional fiber can be applied in the fields such as costume, bed clothes, indoor and interior ornamental articles, handcrafts and so on.

Owner:SHANGHAI HONGKANG SCI TECH +1

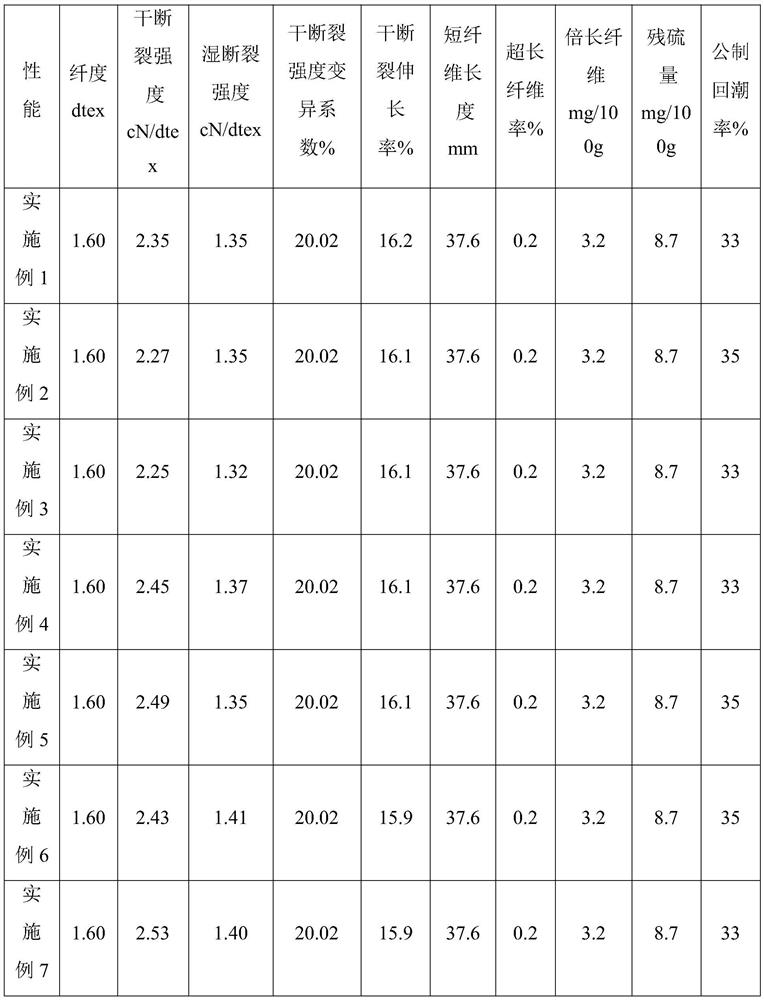

Semi-dull high-intensity low-elongation viscose fiber and preparing method thereof

ActiveCN104846460AGood skin affinityHigh strengthMonocomponent cellulose artificial filamentBleaching apparatusFiberPolymer science

The invention provides semi-dull high-intensity low-elongation viscose fiber and a preparing method of the semi-dull high-intensity low-elongation viscose fiber. The viscose fiber is obtained through sequentially carrying out soaking, grinding, pressing and crushing, kneading, polymerization reduction, yellowing, dissolution, filtering, defoaming, aging, spinning traction and post treatment on pulp raw materials. The viscose fiber has the following indexes that the fiber number is 1.11 to 1.67 dtex, the dry fracture intensity is greater than or equal to 3.10cN / dtex, the wet fracture intensity is higher than or equal to 1.60cN / dtex, the intensity required for generating the 5-percent elongation rate in the wet state is higher than or equal to 0.55N / dtex, and the dry fracture elongation rate is 11.0 to 19.0 percent. The high-intensity low-elongation viscose fiber related by the invention is a novel fiber variety realized through technical innovation, an index system is different from that of ordinary viscose fiber and modal fiber; a product shows the high-intensity and low-elongation fiber features of the modal fiber, and also shows the higher skin affinity than cotton fiber; the existing differentiated viscose fiber can be effectively replaced; the downstream work procedure processing performance of the viscose fiber is improved; meanwhile, the development and the industrial updating of downstream novel textiles can also be promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

Ultrafine semi-dull high-strength low-elongation viscose fiber and preparation method thereof

ActiveCN104846462AGood skin affinityHigh strengthMonocomponent cellulose artificial filamentWet spinning methodsPolymer scienceSpinning

The invention provides an ultrafine semi-dull high-strength low-elongation viscose fiber and a preparation method thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has the following indexes that the fineness is 0.8-1.11dtex, the dry fracture strength is more than or equal to 3.10cN / dtex, the wet fracture strength is more than or equal to 1.60cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.55cN / dtex, and the dry elongation at break is 11.0-19.0%. The ultrafine high-strength low-elongation viscose fiber is a novel fiber variety realized by virtue of technical innovation, and has an index system which is different from that of ordinary viscose fibers and Modal fibers, and a product of the fiber shows the fiber characteristics of high strength and low elongation of the Modal fibers and also shows skin affinity stronger than that of cotton fibers, so that the ultrafine semi-dull high-strength low-elongation viscose fiber can effectively replace the existing differentiation viscose fiber, and while the processability of the downstream process of the viscose fiber is improved, the development and the industrial upgrading of downstream novel textiles are promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

A kind of preparation method of biochar/graphene flexible composite film

ActiveCN108538630BLow costHigh mechanical strengthHybrid capacitor electrodesCell electrodesBiomass carbonSpinning

The invention provides a preparation method of a biomass charcoal / graphene flexible composite film. The nitrogen-rich biomass charcoal / graphene flexible composite film is prepared by the blended spinning solution containing the silk fibroin, the graphene oxide and the activator through the electrospinning technology and high temperature one-step carbonization activation. The material has the characteristics of being nitrogen-rich, porous and flexible. According to the method, the silk fibroin is rich in amino acids and can react with the graphene oxide in a cross-linking way through heating and stirring so that the graphene oxide is enabled to be aminated, the graphene oxide can be further reduced in the carbonization process, and the nitrogen atom part of the biomass residues in the composite material. The mass ratio of the biomass charcoal to the graphene in the obtained biomass charcoal / graphene flexible composite film is (0.5-9):1, the specific area is 1850-2740m2 / g and the mitogencontent is 3.6-9.4%. The composite film is applied to the electrode material of the supercapacitor and the sodium ion battery so as to show high specific capacity, long cycle life and excellent rateperformance.

Owner:BEIJING UNIV OF CHEM TECH +3

Method for preparing modified konjac glucomannan fiber by electrostatic spinning

InactiveCN102926016BImproves heat stylingReduce hydrogen bondingFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberChemical industry

The invention discloses a method for preparing modified konjac glucomannan fiber by electrostatic spinning. The method is characterized by comprising the following steps of: modifying konjac glucomannan, i.e., dissolving the konjac glucomannan in ethanol water solution, carrying out swelling reaction by adding sodium hydroxide, neutralizing by diluted hydrochloric acid, filtering, washing, and drying to obtain acetyl-free konjac glucomannan; mixing and reacting distilled water, acetyl-free konjac glucomannan, methyl acrylate and initiator under the temperature of 10-70DEG C, mixing by adding ethanol, standing for settling, filtering, washing solid with acetone, and drying to obtain modified konjac glucomannan; preparing spinning solution; and carrying out electrostatic spinning to prepare fiber. The method has the characteristics of simple technology, low cost and the like, and is environment-friendly, and the prepared fiber material has good application prospect in the fields of medicine, environmental protection, chemical industry, agriculture and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of manufacturing method of conductive polyester fiber

ActiveCN102978744BHas conductive propertiesEasy to processElectroconductive/antistatic filament manufactureFilament/thread formingBreaking strengthPolyester

The invention discloses a method for manufacturing conductive polyester fibers. The method comprises the following steps of: adding conductive materials including ATO conductive powder, superconducting carbon black, zinc oxide whiskers, potassium titanate whiskers and the like into polyester to prepare conductive polyester; and taking the conductive polyester as a skin layer to prepare polyester conductive fibers with other polyesters through a composite spinning technology. Through the method, the skin layer part of the fibers contains conductive substances, so that the fibers have excellent physical and processing performance of synthetic fibers while having conductivity, the resistivity of the polyester fibers can be greatly reduced, and the breaking strength of the fibers can also be improved.

Owner:ZHEJIANG SCI-TECH UNIV

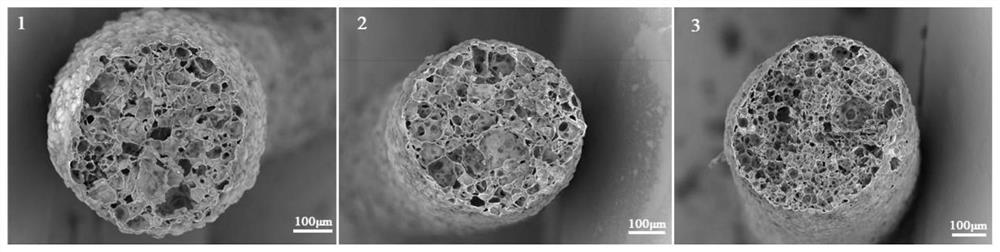

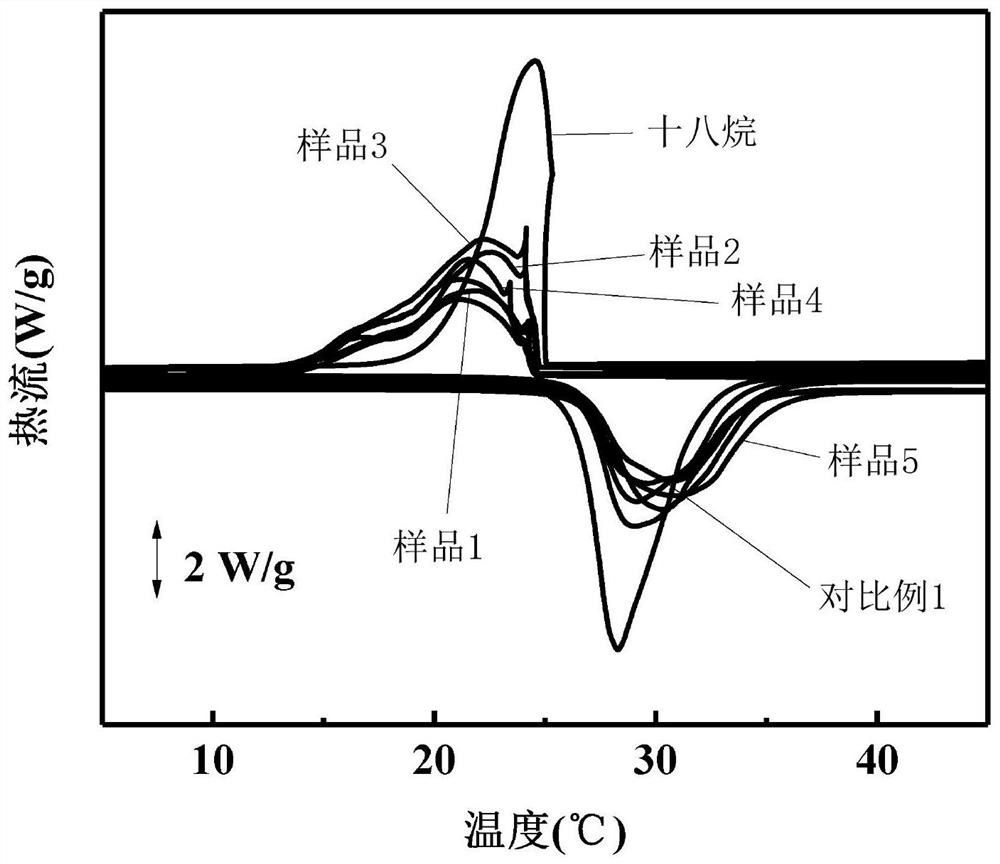

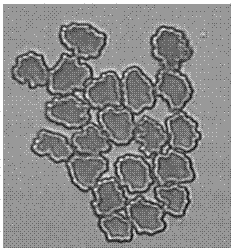

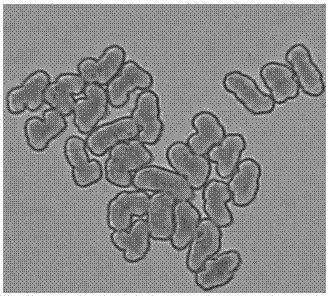

Emulsion-based heat storage fiber and preparation method thereof

ActiveCN114808192AHigh porosityIncrease the areaConjugated cellulose/protein artificial filamentsWet spinning methodsFiberPolymer science

The invention relates to an emulsion-based heat storage fiber and a preparation method thereof, and relates to the technical field of heat storage fibers. The preparation method comprises the following steps: firstly, adding an oil phase into a water phase, and uniformly mixing and stirring to obtain an oil-in-water emulsion; the oil phase is a phase change material; the water phase is a mixed solution of a particle stabilizer, a water-soluble polymer and water; the water-soluble polymer comprises one or more of sodium alginate, polyvinyl alcohol, acrylamide, polyethyleneimine, polyvinyl acetal, polyvinyl methyl ester, polyoxyethylene, polyacrylic acid, polymethylacrylic acid and polyethylene glycol; and extruding the oil-in-water emulsion into a coagulating bath, carrying out wet spinning, and after the reaction is completed, freezing and drying to obtain the emulsion-based heat storage fiber, a calcium ion solution is adopted in the coagulating bath. The heat storage fiber disclosed by the invention has the advantages of high heat storage density, high specific surface area, flexibility, spinnability, stretchability and the like, and has a great application prospect in the field of heat regulation textiles.

Owner:SUZHOU UNIV

A semi-dull high-strength low-elongation viscose fiber and its preparation method

ActiveCN104846457BGood skin affinityHigh strengthArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceSpinning

The invention provides a semi-dull, high-strength, low-elongation viscose fiber and a preparation method thereof. The viscose fiber is prepared by impregnating pulp raw materials, grinding, crushing, kneading, depolymerizing, yellowing, dissolving, and filtering in sequence. , defoaming, ripening, spinning and drawing and post-treatment, the viscose fiber has the following indicators: dry breaking strength ≥ 3.10 cN / dtex, wet breaking strength ≥ 1.60 cN / dtex, 5% elongation in wet state The strength required for elongation is ≥0.55cN / dtex, and the dry elongation at break is 11.0-19.0%. The high-strength and low-elongation viscose fiber involved in the present invention is a new type of fiber achieved through technological innovation. It has an index system different from ordinary viscose fiber and modal fiber, and its products not only show the high-strength, low-elongation fiber characteristics of modal fiber , it also shows stronger skin-friendly properties than cotton fibers, which can effectively replace the existing differentiated viscose fibers. While improving the processing performance of viscose fibers in downstream processes, it can also promote the development and industrialization of downstream new textiles upgrade.

Owner:YIBIN GRACE GROUP CO LTD +2

Clutch cover for forklift

ActiveCN104165196BHigh strengthLow densityLifting devicesFriction clutchesField transformationTitanium alloy

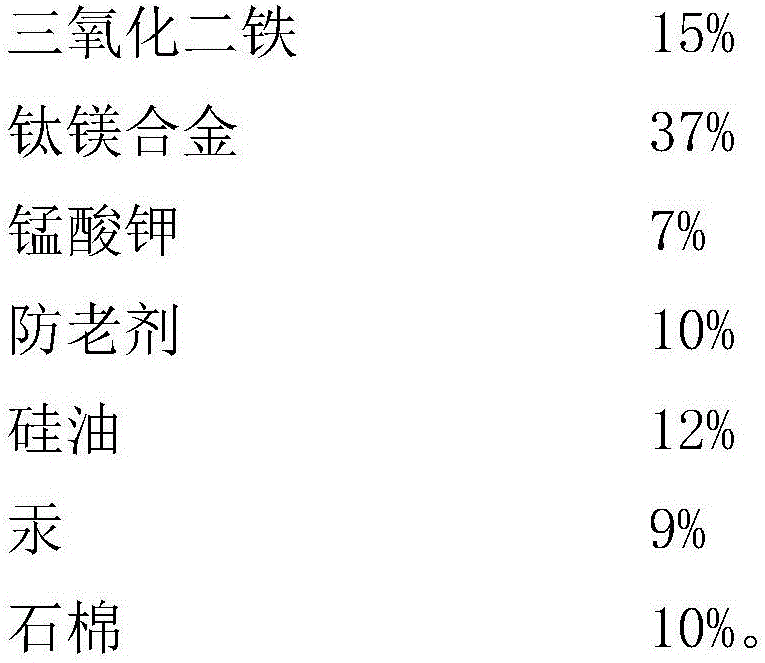

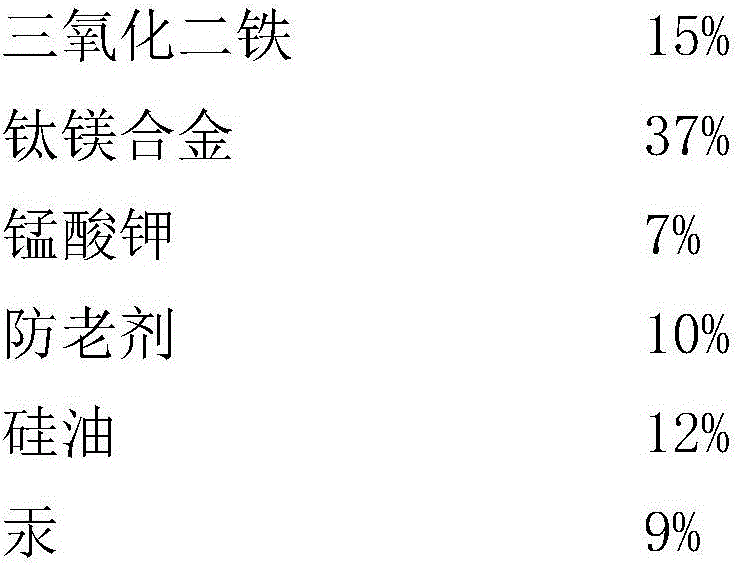

A clutch cover for a forklift, which relates to the technical field of forklift parts processing and modification, is characterized in that it comprises the following components: 15% of ferric oxide, 37% of titanium-magnesium alloy, 7% of potassium manganate, 10% of anti-aging agent, and 12% of silicone oil , mercury 9%, asbestos 10%. The invention has reasonable configuration, high strength and long service life.

Owner:HANSHAN QUANXING INTERNAL COMBUSTION ENGINE FITTING CO LTD

Raw material of non-woven fabric and its preparation method and preparation method of non-woven fabric

ActiveCN105524351BNo residueGood compatibilityNon-woven fabricsBulk chemical productionPolymer scienceEthylene Homopolymers

The invention discloses a non-woven fabric raw material, a preparation method of the non-woven fabric raw material and a preparation method of a non-woven fabric. The non-woven fabric raw material comprises 60-100wt% of a polymer composition and 0-40wt% of a first propylene homopolymer. The polymer composition contains 70-95wt% of crystalline polypropylene A and 5-30wt% of an ethylene-propylene elastic copolymer B. At a temperature of 230 DEG C, under load of 2.16kg, a ratio of a melt index of the polymer composition to a melt index of the crystalline polypropylene A is in a range of 0.7-1.3. The non-woven fabric raw material has spinnability and can be used for preparing the non-woven with high flexibility and high strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com