Preparation method of conductive meta-aramid fiber

A technology of aramid fibers and conductive components, applied in the manufacture of conductive/antistatic filaments, spinning solution preparation, wet spinning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

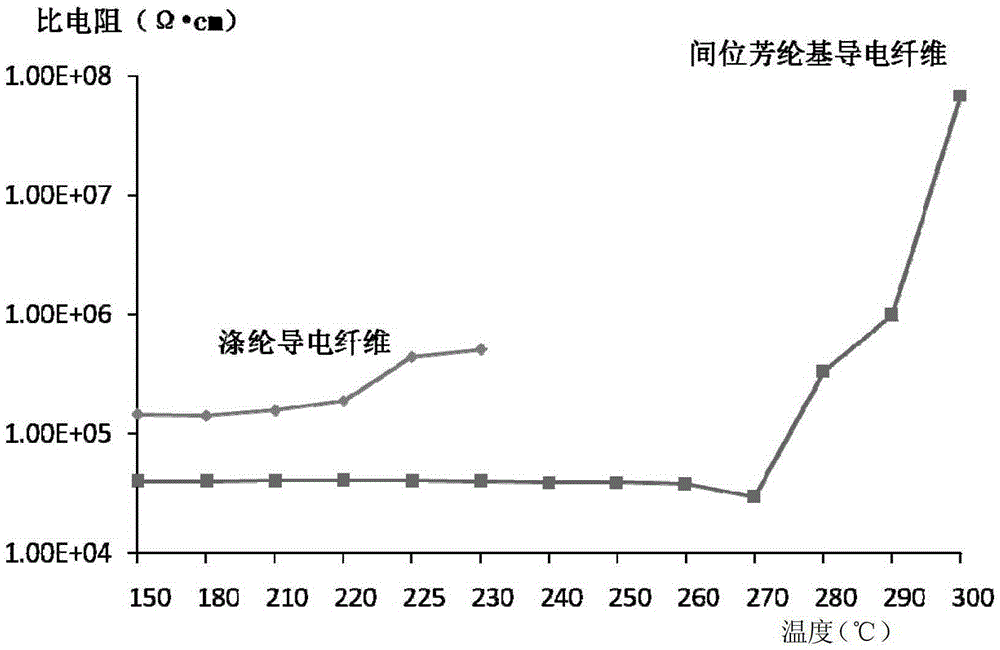

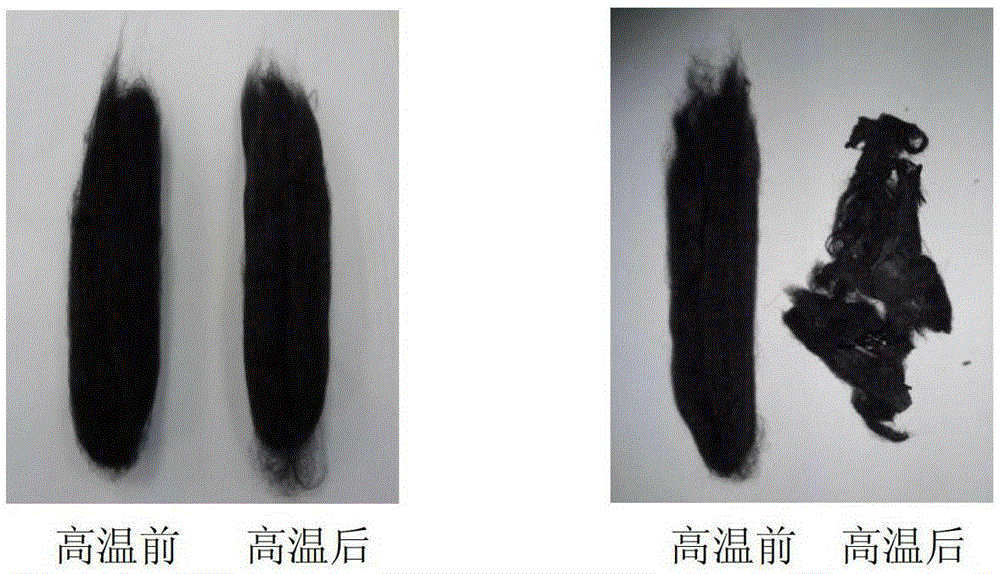

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, heat the carbon nanotubes in a mixture of concentrated nitric acid and concentrated sulfuric acid (volume ratio 2:1) to 60-80°C for 3 hours, then ultrasonically wash them, and dry them at 150°C for later use. The treated conductive components are enhanced and polymer compatibility;

[0031] Then add the surface-treated carbon nanotubes, hexadecyltrimethylammonium bromide, and dimethylacetamide into the high-speed mixing equipment at a mass ratio of 1:1:8, and control the temperature at 60-80°C. Make it fully mixed for 60 minutes; then grind it, the maximum size is less than 200 nanometers; add the ground carbon nanotubes in an amount of 5% to the meta-aramid spinning solution, mix well, then cool, filter, Degassing to obtain conductive fiber spinning solution;

[0032] Using wet spinning process, the polymer spinning solution is pressurized by the spinning pump and extruded through the spinneret hole with a diameter of 0.01-0.3mm, and the fiber is formed by the ...

Embodiment 2

[0035] Add the surface-treated conductive components carbon nanotubes, cetyltrimethylammonium bromide, and dimethylacetamide into the high-speed mixing equipment at a mass ratio of 2:1:7, and control the temperature at 50-70 ℃, make it fully mixed for 30 minutes; then grind it, the maximum size is less than 200 nanometers; add the ground carbon nanotubes in an amount of 8% to the meta-aramid spinning solution, mix well, and then cool, Filtration and defoaming to obtain conductive fiber spinning solution;

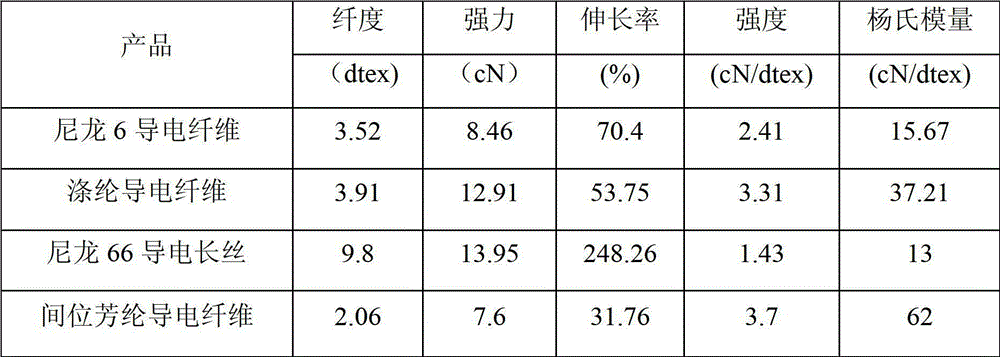

[0036] The meta-aramid fiber with electrical conductivity is obtained through wet spinning process, after coagulation, stretching, water washing, heat treatment and other post-treatments. The fiber density of the obtained meta-aramid conductive fiber is 2.2dtex, the breaking strength is 4.2cN / dtex, the breaking elongation is 31%, and the resistivity is 9.6×10 4 Ω·cm.

Embodiment 3

[0038] Add the surface-treated conductive component carbon nanotubes and conductive carbon black (mass ratio 1:1), and polyethylene glycol octylphenyl ether, methyl pyrrolidone in a ratio of 3:1:6 to the high-speed In the mixing equipment, control the temperature at 60-80°C, make it fully mixed for 60 minutes; then grind it, the maximum size is less than 200 nanometers; add the ground carbon nanotubes and conductive carbon black in the amount of 5% to the meta In the aramid spinning solution, fully mix evenly, then cool, filter, and defoam to obtain the conductive fiber spinning solution;

[0039] The meta-aramid fibers with conductive properties are obtained through wet spinning process and post-treatments such as coagulation, stretching, water washing, and heat treatment.

[0040] The linear density of the obtained meta-aramid conductive fiber is 2.2dtex, the breaking strength is 3.9cN / dtex, the breaking elongation is 31%, and the resistivity is 2.3×10 4 Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com