Preparation method of collagenous fiber, collagenous fiber and application

A technology of collagen fibers and primary fibers, applied in the fields of application, preparation of collagen fibers, and collagen fibers, can solve problems such as lack of spinnability, and achieve the effect of wide application and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

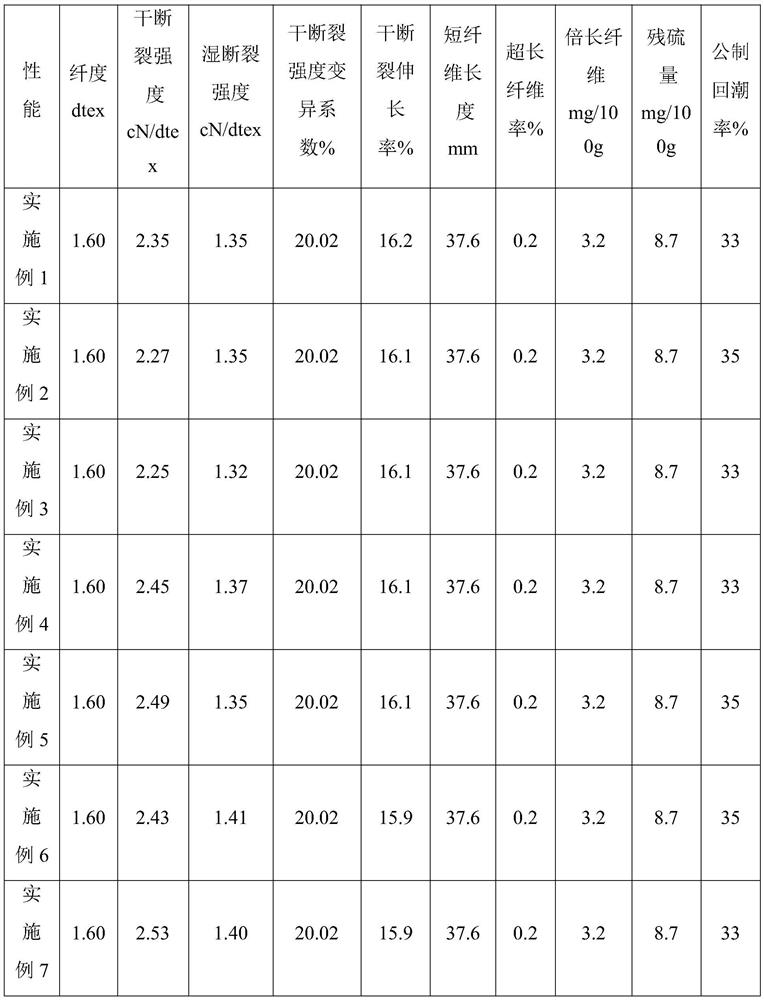

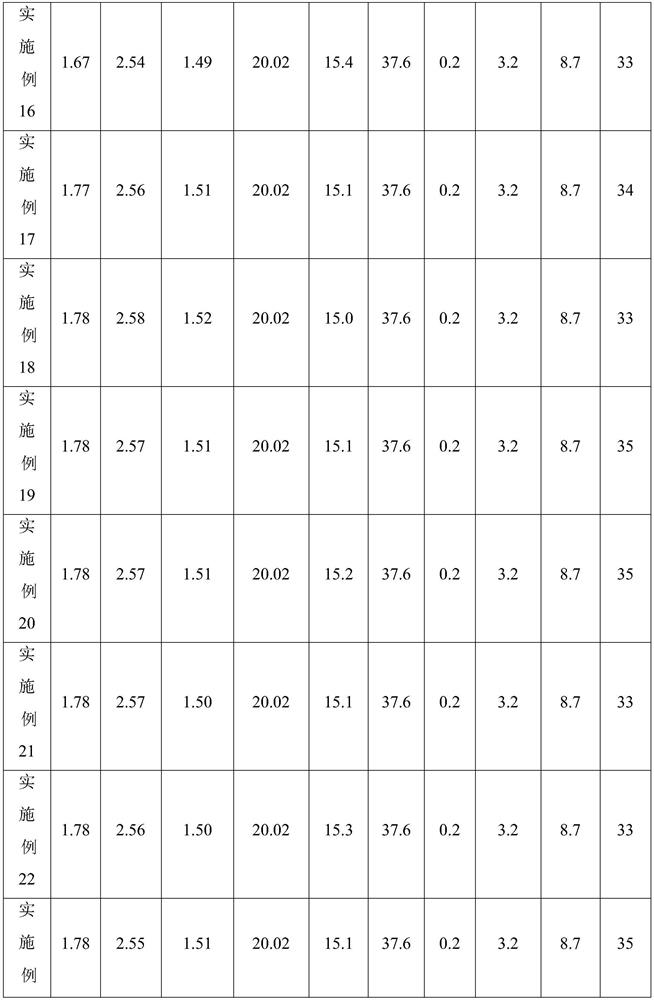

[0068] As shown in Table 1, the main difference of Examples 1-11 is that the pH of the solution, the pH of the spinning solution, and the pH of the coagulation bath are different.

[0069] Embodiment 1 is taken as an example below for description.

[0070] The preparation method of the collagen fiber that embodiment 1 provides, comprises the following steps:

[0071] (1) Preparation of spinning dope

[0072] Take 100g of cowhide, soak it in 1000mL of sodium carbonate solution with a concentration of 1mg / mL for 2 hours, rinse it with distilled water and dry it in the air, adjust the pH of the solution to 4.5 with acetic acid, keep the solution at 34°C, put the cowhide into the solution fully dissolved in

[0073] Wherein, the dissolving liquid is specifically pepsin solution, and the mass ratio of pepsin and deionized water is 0.2:10, more specifically, the mass ratio of cowhide, pepsin, and deionized water is 1:0.2:10, specifically , cowhide 100g, pepsin 20g, deionized wate...

Embodiment 11-16

[0085] The difference between Examples 11-16 and Example 7 is that the ratio of the coagulation bath is different, see Table 2 for details.

[0086] Table 2 Example 8-13 coagulation bath ratio table

[0087] Protein curing agent% Dehydrating agent% pH adjuster% water% Example 7 8 36 0.8 55.2 Example 11 10 36 0.8 53.2 Example 12 12 36 0.8 51.2 Example 13 10 42 0.8 47.2 Example 14 10 47 0.8 42.2 Example 15 10 42 1 47 Example 16 10 42 3 45

Embodiment 17-18

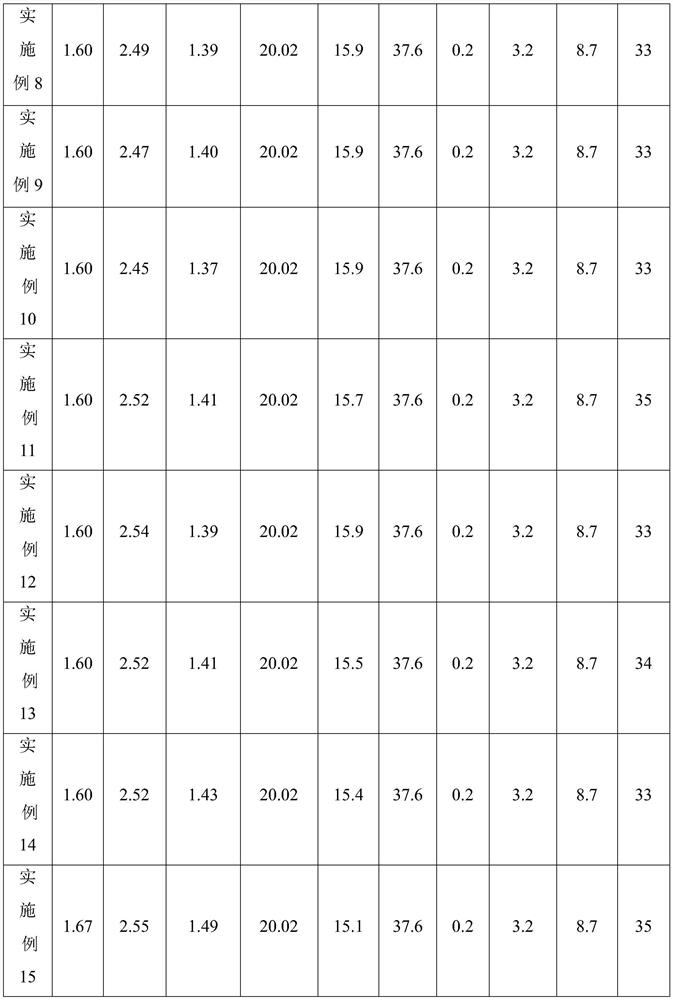

[0089] The difference between Examples 17-19 and Example 15 is that the ratio of the coagulation bath is different, and the coagulation bath also includes a zinc salt. The zinc salt is zinc sulfate as an example for illustration below, see Table 3 for details.

[0090] Table 3 Example 14-16 coagulation bath ratio table

[0091] Protein curing agent% Dehydrating agent% pH adjuster% Zinc salt% water% Example 15 10 42 1 0 47 Example 17 10 42 1 1.2 45.8 Example 18 10 42 1 2 45 Example 19 10 42 1 5 42

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com