Ultrafine semi-dull high-strength low-elongation viscose fiber and preparation method thereof

A viscose fiber, high-strength and low-elongation technology, which is applied in the field of ultra-fine semi-matte high-strength and low-elongation viscose fiber and its preparation, can solve the problem that the market share of viscose fiber is reduced, and the development of new downstream textiles cannot be met to a greater extent. and industrial upgrading, etc., to achieve the effect of high product strength, good color fastness and good air permeability of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

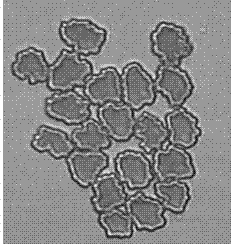

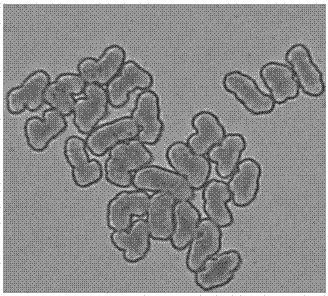

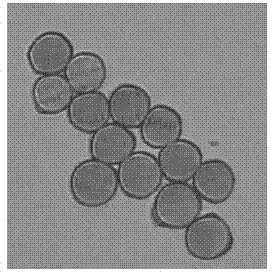

Image

Examples

Embodiment 1

[0063] The pulp raw material is sequentially soaked, ground, crushed, kneaded, depolymerized, yellowed, dissolved, filtered, defoamed, matured, matting agent is added, spinning and drawing, refining and drying to obtain semi-dull viscose. Glue fiber, the semi-dull viscose fiber of the present embodiment has following performance index system:

[0064] The fineness is 1.67 dtex, the dry breaking strength is 3.12 cN / dtex, the wet breaking strength is 1.65cN / dtex,

[0065] The strength required to produce 5% elongation in wet state is 0.55cN / dtex,

[0066] Dry elongation at break is 19.0%, wet elongation at break is 21.0%,

[0067] The crystallinity is 40%, the radial water swelling degree is 22%, and the content of matting agent is 0.10%.

[0068] The linear density deviation rate is -11.0%, the residual sulfur is 8.0mg / 100g,

[0069] The length deviation rate is -11.0%, the ultra-long fiber rate is 0.48%, and the whiteness is 84.1%.

[0070] The double-length fiber is 4.0mg...

Embodiment 2

[0072] The difference between the superfine type semi-dull high-strength low-elongation viscose fiber of the present embodiment and embodiment 1 is: the present embodiment has the following indicators:

[0073] Denier is 1.52 dtex, dry breaking strength is 3.15 cN / dtex, wet breaking strength is 1.67cN / dtex,

[0074] The strength required to produce 5% elongation in wet state is 0.54cN / dtex,

[0075] The dry elongation at break is 18.9%, and the wet elongation at break is 20.8%.

[0076] The crystallinity is 40%, the radial water swelling degree is 22.5%, and the matting agent content is 0.75%.

[0077] The whiteness is 84.6%, the linear density deviation rate is -10.0%, the residual sulfur is 8.0mg / 100g,

[0078] The length deviation rate is +10.0%, and the ultra-long fiber rate is 0.5%,

[0079] The double-length fiber is 4.0mg / 100g, and the defect is 4.0mg / 100g.

Embodiment 3

[0081] In order to better implement the present invention, this embodiment further provides the specific preparation method of the superfine semi-dull high-strength low-elongation viscose fiber of the present invention, and measures the performance index.

[0082] A method for preparing semi-dull viscose fiber: the pulp raw material is soaked and pressed to remove the lye to obtain alkali cellulose; Cellulose; the obtained methyl cellulose is yellowed to obtain cellulose sulfonate; the obtained cellulose sulfonate is dissolved in a solvent, then filtered, matured, defoamed, and the spinning solution is obtained; the obtained spinning After the silk liquid is added with a matting agent, it is sent to a spinning machine for spinning and drawing to obtain a tow, and the tow is refined and dried to obtain the viscose fiber of the present invention. Samples were taken, and each index was measured according to the above-mentioned measurement standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pulverization | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com