Method for preparing modified konjac glucomannan fiber by electrostatic spinning

A technology of mannan and electrospinning, applied in the direction of spinning solution preparation, fiber treatment, fiber chemical characteristics, etc., to achieve the effect of environmental friendliness, rich raw materials and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

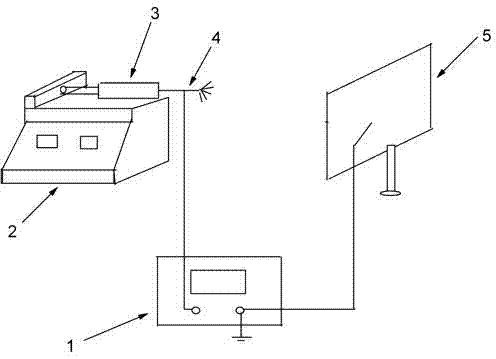

Method used

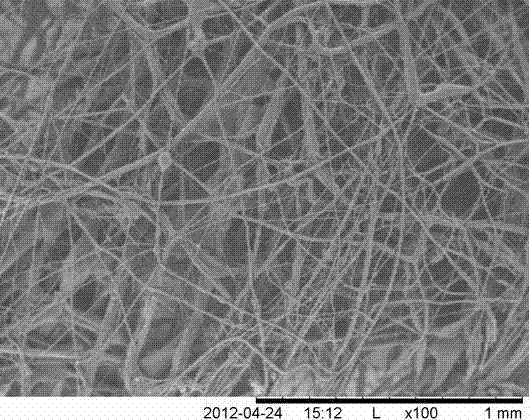

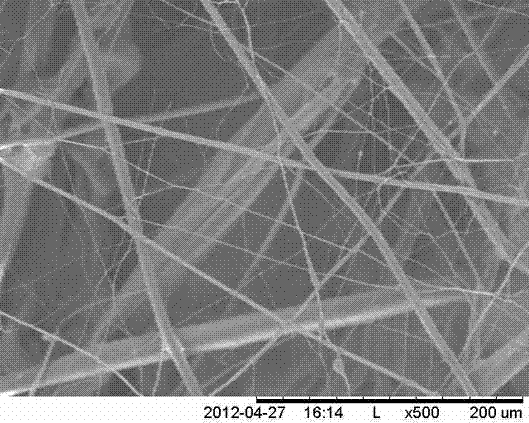

Image

Examples

Embodiment 1

[0024] A method for preparing fiber by electrostatic spinning of modified konjac glucomannan, comprising the following steps:

[0025] a. To modify konjac glucomannan, disperse 40 parts of konjac glucomannan (parts by weight, grams, the same hereinafter) in 240 parts of 40% ethanol aqueous solution, add 3 parts of sodium hydroxide, and heat at 25°C Swell under conditions for 2 hours, stop the reaction, neutralize the reaction with hydrochloric acid, filter the sample, wash it with 30% ethanol aqueous solution several times, put the sample in a drying oven at 100°C and dry it to constant weight. That is, deacetylated konjac glucomannan.

[0026] Put distilled water, deacetylated konjac glucomannan, methyl acrylate, and initiator in a container with a stirring device in a ratio of 300:10:30:0.1 parts by weight, and stir at 60°C for 3 hours, Take out the obtained emulsion, add three times the volume of absolute ethanol to the emulsion to settle for 1 hour, filter and wash repeat...

Embodiment 2

[0030] A method for preparing fiber by electrostatic spinning of modified konjac glucomannan, comprising the following steps:

[0031] Step a is the same as Step a in Example 1, and the following Examples 3 to 15 are the same as Step a in Example 1.

[0032] b. The prepared modified konjac glucomannan is pulverized, and the modified konjac glucomannan and trifluoroacetic acid are weighed according to the mass volume ratio of 4:10, and the modified konjac glucomannan is pulverized and dissolved in three in fluoroacetic acid, stirred until completely dissolved, and placed in an ultrasonic oscillator for 2 minutes to obtain a 4% electrospinning solution.

[0033] c. After extracting the electrospinning solution obtained in step b with a syringe, fix it on the electrospinning device, adjust the voltage to 12kv, the distance between the spinneret and the collection screen is 10cm, and the flow rate of the spinning solution flowing out of the spinneret The spinning temperature was ...

Embodiment 3

[0035] A method for preparing fiber by electrostatic spinning of modified konjac glucomannan, comprising the following steps:

[0036] a step is the same as in Example 1.

[0037] B, the obtained modified konjac glucomannan is pulverized, and the modified konjac glucomannan and trifluoroacetic acid are weighed according to the mass volume ratio of 5:10, and the modified konjac glucomannan is pulverized and dissolved in three In fluoroacetic acid, stir until completely dissolved, place in an ultrasonic oscillator and sonicate for 1 minute to obtain a 5% electrospinning solution.

[0038] c. After extracting the electrospinning solution obtained in step b with a syringe, fix it on the electrospinning device, adjust the voltage to 15kv, the distance between the spinneret and the collection screen is 12cm, and the flow rate of the spinning solution flowing out of the spinneret The spinning temperature was 1 mL / h, and the spinning ambient temperature was 20° C. After the electrosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com