Emulsion-based heat storage fiber and preparation method thereof

A heat storage and fiber technology, applied in the chemical characteristics of fibers, cellulose/protein conjugated rayon, wet spinning, etc., can solve the problems of cumbersome preparation process of heat storage fibers, low heat storage efficiency, etc. The effect of high heat storage density and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

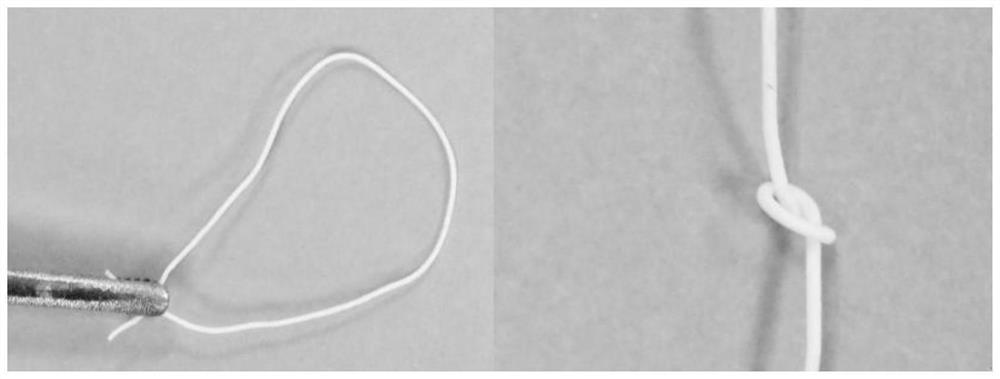

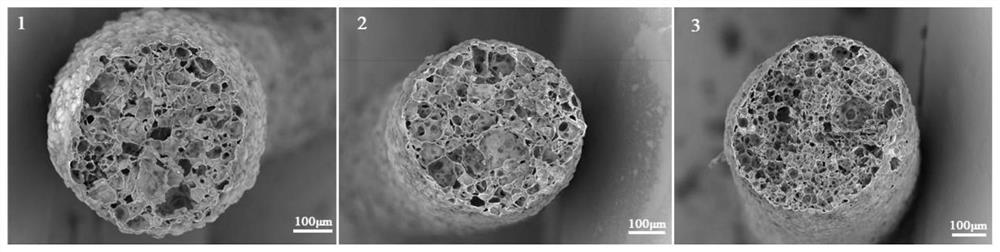

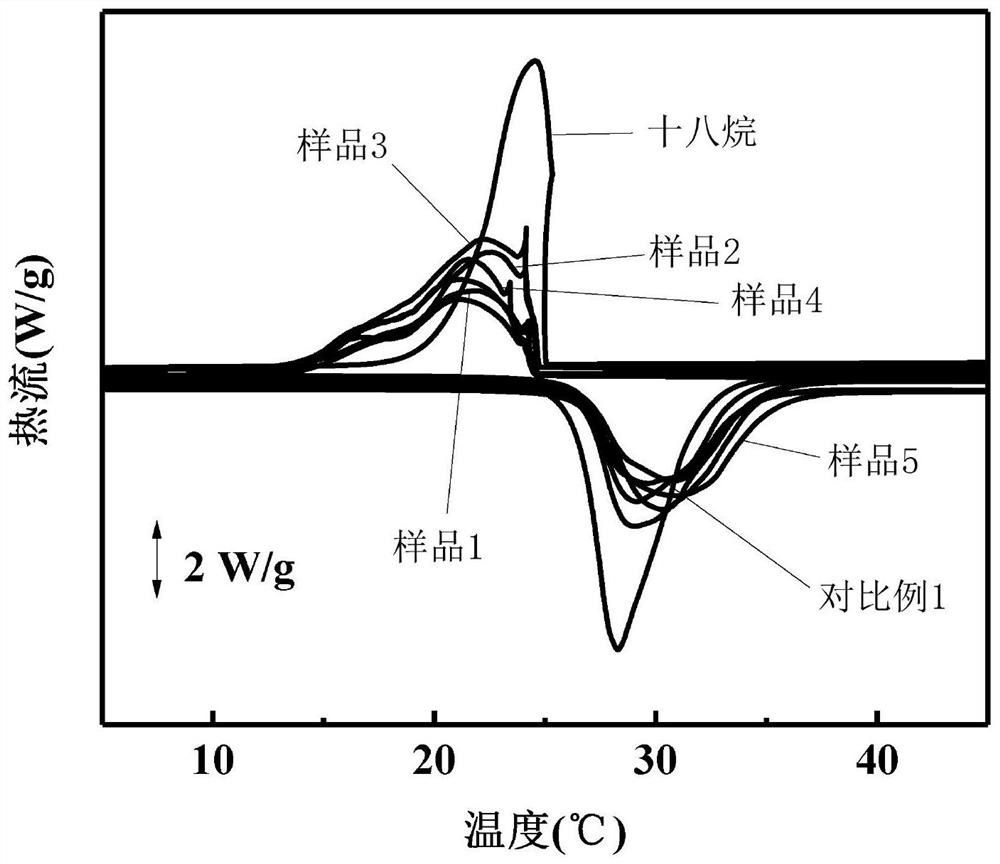

[0038] An emulsion-based heat storage fiber and a preparation method thereof, specifically comprising the following steps:

[0039] (1) Dissolve 0.5g of sodium alginate in 9.5g of water, 0.4g of polyvinyl alcohol in 4.6g of water, and 0.5g of cellulose nanocrystals in 4.5g of water, and stir for 5 minutes at 1500rpm mechanical speed until completely dissolved, An aqueous phase is obtained. Under the condition of maintaining mechanical stirring, 4 g of octadecane was dropped dropwise into the above water phase, and after mixing uniformly, an oil-in-water emulsion was obtained, which was used as a spinning dope.

[0040] (2) Spinning using a wet spinning device, the size of the wet spinning syringe is 50 mL, the needle is a flat head, the diameter of the needle is 0.6 mm, the spinning speed is 500 μL / h, and the coagulation bath is a 5wt% calcium ion solution, Its temperature was 30°C. The collected primary fibers were placed in a calcium ion solution for 20 minutes, solidified...

Embodiment 2

[0042] An emulsion-based heat storage fiber and a preparation method thereof, specifically comprising the following steps:

[0043] (1) Dissolve 0.5g of sodium alginate in 9.5g of water, 0.4g of polyvinyl alcohol in 4.6g of water, and 0.5g of cellulose nanocrystals in 4.5g of water, and stir for 5 minutes at 1500rpm mechanical speed until completely dissolved, An aqueous phase is obtained. Under the condition of maintaining mechanical stirring, 6 g of octadecane was dropped dropwise into the above water phase, and after mixing uniformly, an oil-in-water emulsion was obtained, which was used as the spinning dope.

[0044] (2) Spinning using a wet spinning device, the size of the wet spinning syringe is 50 mL, the needle is a flat head, the diameter of the needle is 0.6 mm, the spinning speed is 500 μL / h, and the coagulation bath is a 5wt% calcium ion solution, Its temperature was 30°C. The collected primary fibers were placed in a calcium ion solution for 20min, solidified co...

Embodiment 3

[0046] An emulsion-based heat storage fiber and a preparation method thereof, specifically comprising the following steps:

[0047] (1) Dissolve 0.5g of sodium alginate in 9.5g of water, 0.4g of polyvinyl alcohol in 4.6g of water, and 0.5g of cellulose nanocrystals in 4.5g of water, and stir for 5 minutes at 1500rpm mechanical speed until completely dissolved, An aqueous phase is obtained. Under the condition of maintaining mechanical stirring, 8 g of octadecane was dropped dropwise into the above water phase, and after mixing uniformly, an oil-in-water emulsion was obtained, which was used as the spinning stock solution.

[0048] (2) Spinning using a wet spinning device, the size of the wet spinning syringe is 50 mL, the needle is a flat head, the diameter of the needle is 0.6 mm, the spinning speed is 500 μL / h, and the coagulation bath is a 5wt% calcium ion solution, Its temperature was 30°C. The collected primary fibers were placed in a calcium ion solution for 20min, sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com