Preparation method of electromagnetic shielding composite material and the electromagnetic shielding composite material

A composite material and electromagnetic shielding technology, which is applied in the preparation of electromagnetic shielding composite materials and the field of electromagnetic shielding composite materials, can solve the problem of needle tip fracture of four-needle zinc oxide whiskers, poor electromagnetic shielding performance of composite materials, and influence on conductive network components, etc. problem, achieve the effect of overcoming filler crushing, enhancing shielding characteristics, and promoting conductive network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

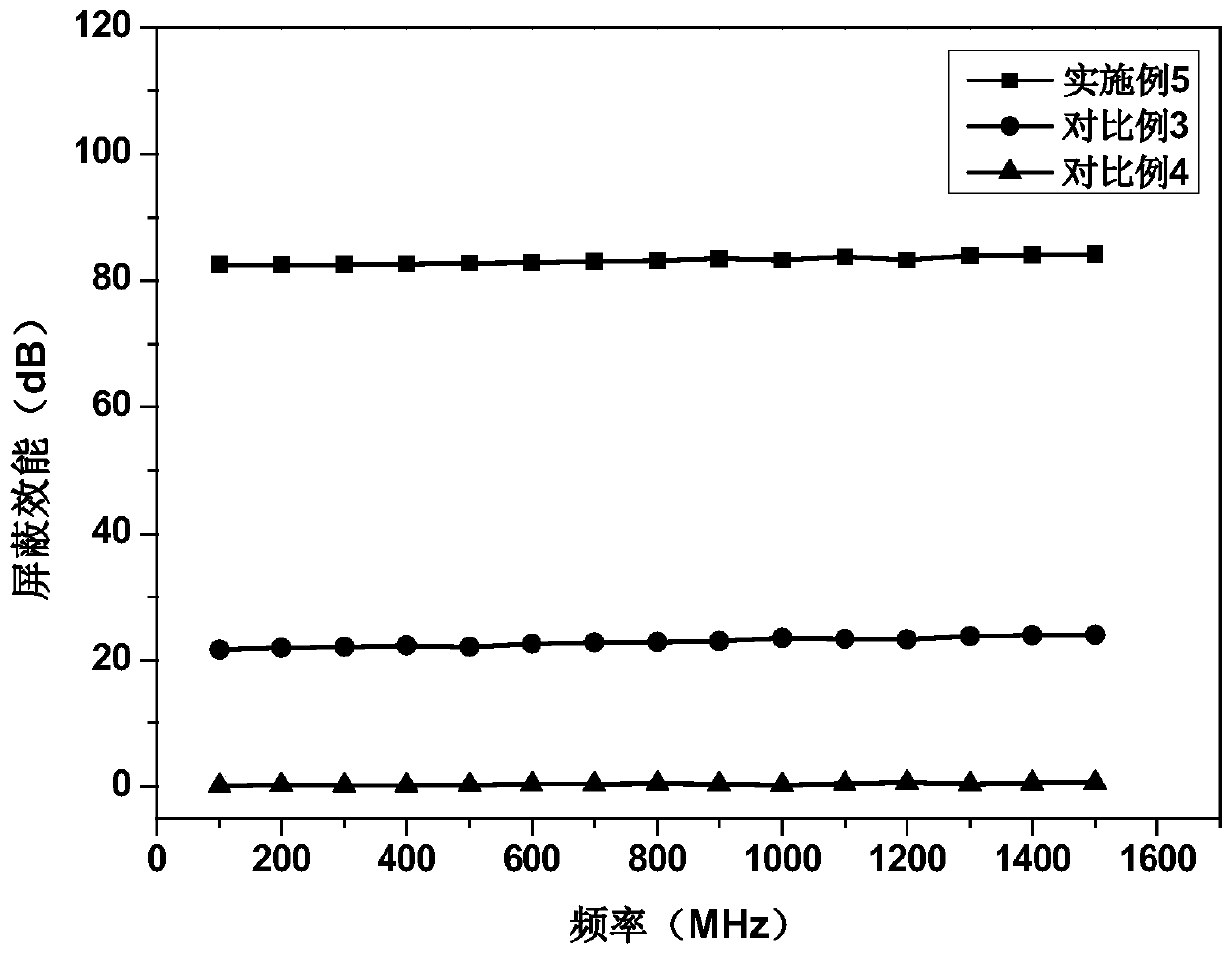

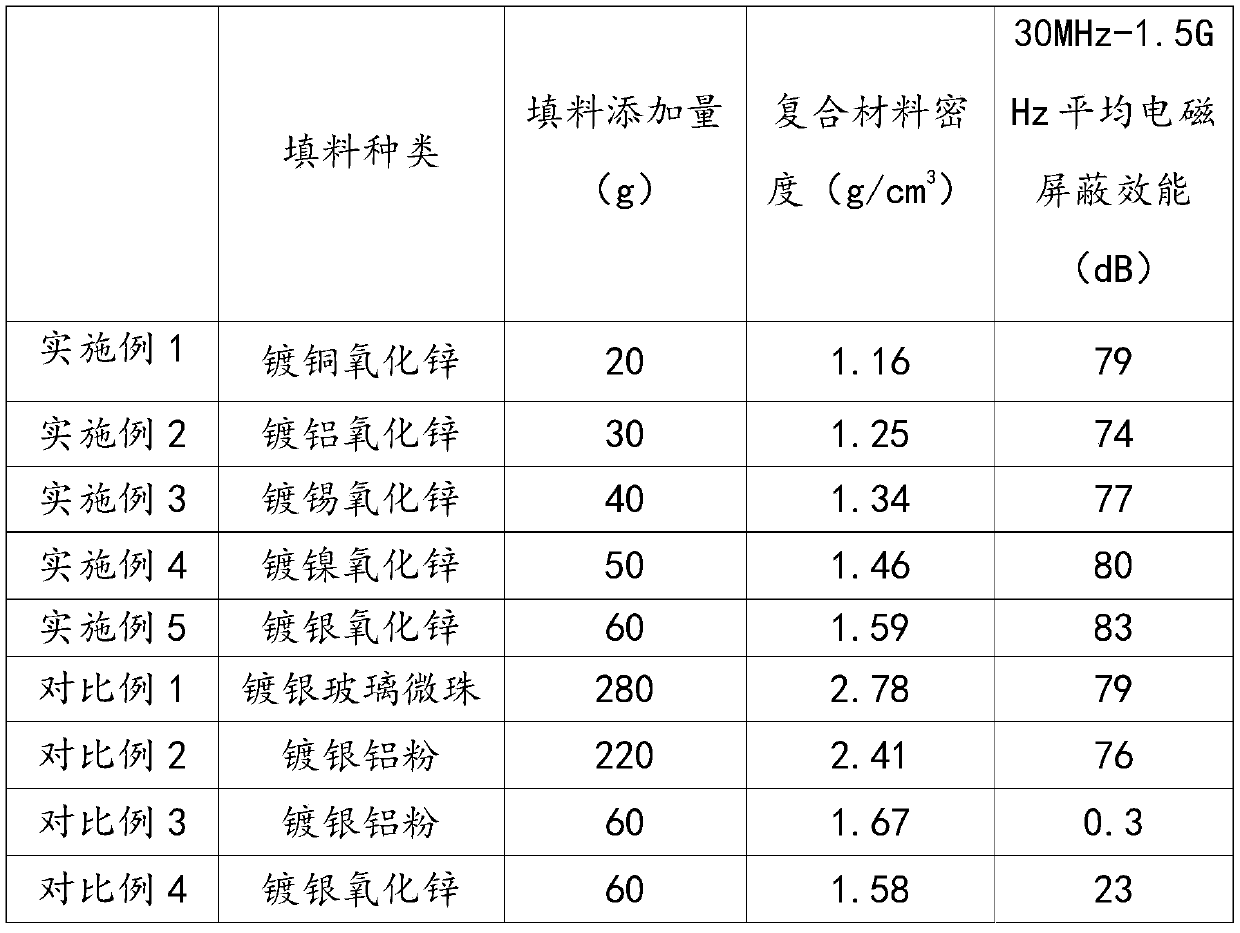

Examples

Embodiment 1

[0035] This embodiment provides an electromagnetic shielding composite material, including the following raw materials: 100 g of silicone rubber matrix (90 g of silicone rubber 3450A and 10 g of silicone rubber 3450B), 2 g of crosslinking agent hydroxyl silicone oil, 2 g of platinum catalyst, and copper-plated four Acicular zinc oxide filler 20g, acetylenic alcohol inhibitor 2g.

[0036] The preparation method of the above-mentioned electromagnetic shielding composite material comprises the following steps:

[0037] 1) Mix silicone rubber 3450A, silicone rubber 3450B, cross-linking agent hydroxy silicone oil, platinum catalyst, and acetylenic alcohol inhibitor to prepare a rubber compound.

[0038] 2), the mixed rubber obtained in step 1) is evacuated in a vacuum box to remove air bubbles in the mixed rubber;

[0039]3), the mixed rubber obtained in step 2) is placed in a polytetrafluoroethylene mold, and the tetrapod zinc oxide coated with copper on the surface is evenly dis...

Embodiment 2

[0042] This embodiment provides an electromagnetic shielding composite material, including the following raw materials: 100 g of silicone rubber matrix (90 g of silicone rubber 3450A and 10 g of silicone rubber 3450B), 1 g of crosslinking agent hydroxyl silicone oil, 1 g of platinum catalyst, and four Acicular zinc oxide filler 30g, acetylenic alcohol inhibitor 1g.

[0043] The preparation method of the above-mentioned electromagnetic shielding composite material comprises the following steps:

[0044] 1) Mix silicone rubber 3450A, silicone rubber 3450B, cross-linking agent hydroxy silicone oil, platinum catalyst, and acetylenic alcohol inhibitor to prepare a rubber compound.

[0045] 2), the mixed rubber obtained in step 1) is evacuated in a vacuum box to remove air bubbles in the mixed rubber;

[0046] 3), the mixed rubber obtained in step 2) is placed in a polytetrafluoroethylene mould, and the four-acicular zinc oxide coated with aluminum on the surface is evenly disperse...

Embodiment 3

[0049] This embodiment provides an electromagnetic shielding composite material, including the following raw materials: 100 g of silicone rubber matrix (90 g of silicone rubber 3450A and 10 g of silicone rubber 3450B), 3 g of crosslinking agent hydroxyl silicone oil, 3 g of platinum catalyst, and four Needle-shaped zinc oxide filler 40g, acetylenic alcohol inhibitor 3g.

[0050] The preparation method of the above-mentioned electromagnetic shielding composite material comprises the following steps:

[0051] 1) Mix silicone rubber 3450A, silicone rubber 3450B, cross-linking agent hydroxy silicone oil, platinum catalyst, and acetylenic alcohol inhibitor to prepare a rubber compound.

[0052] 2), the mixed rubber obtained in step 1) is evacuated in a vacuum box to remove air bubbles in the mixed rubber;

[0053] 3), the mixed rubber obtained in step 2) is placed in a polytetrafluoroethylene mold, and the tetraacicular zinc oxide coated with tin on the surface is evenly dispersed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com