Patents

Literature

41results about How to "With filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bidirectional authentication method of radio frequency identification system

ActiveCN103413109AImprove securityHigh utility valueUser identity/authority verificationSensing record carriersHash functionAttack

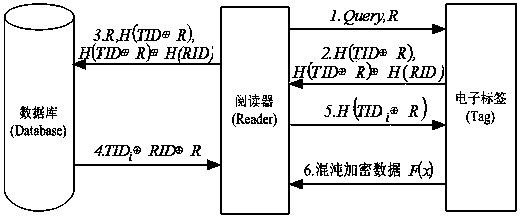

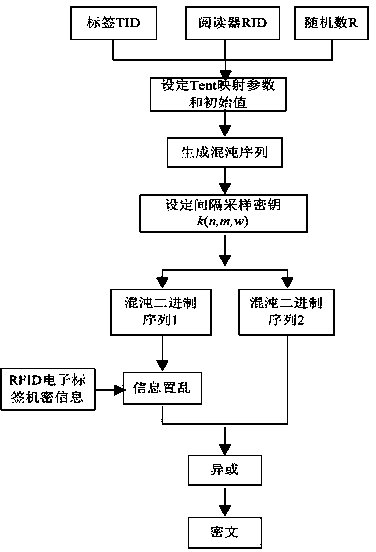

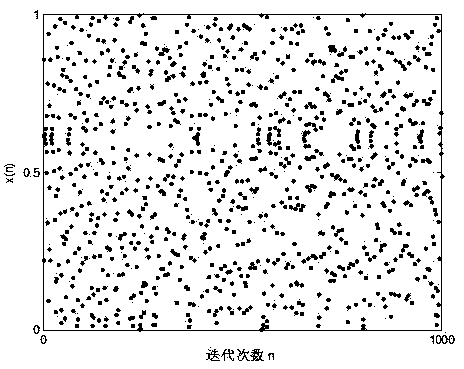

Disclosed is a bidirectional authentication method of a radio frequency identification system. The simple and rapid method with chaotic mapping combined with the Hash function, the exclusive-or operation and the like is adopted, filter operation is conducted together with bidirectional authentication, search and computing loads of a back-end data base are reduced, the safety problems of impersonation, retransmission attack, tracing and the like are avoided, a label of the radio frequency identification system and TID and RID of the unique mark amount of a reader are used as an initial value and parameters of the chaotic mapping, and chaotic scrambling and exclusive-or encryption are performed on confidential information of the label by being combined with the authentication process. On the basis of taking full consideration of saving the cost of the passive radio frequency identification label, data encryption and safety authentication are organically combined, and accordingly the safety problems such as illegal access, counterfeiting and cheating and data leakage in the radio frequency identification system can be solved.

Owner:徐州虹智智能科技有限公司

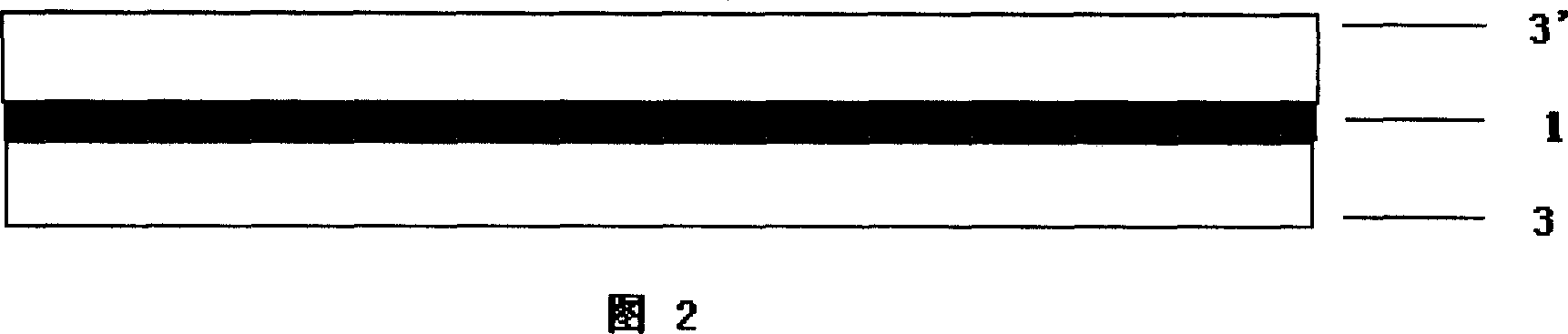

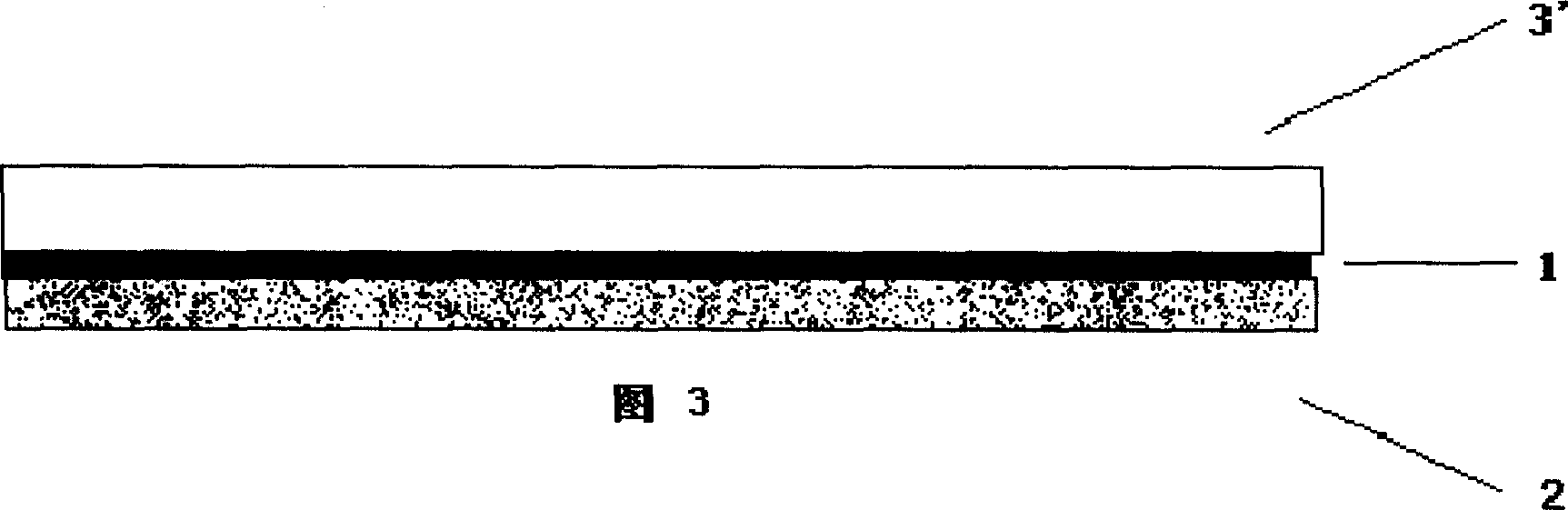

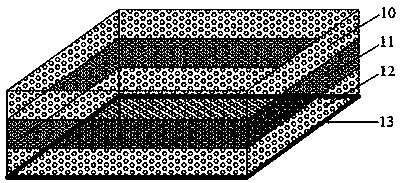

Functional composite face fabric and producing method thereof

The present invention relates to a new-type functional composite face fabric with several functions of resisting static electricity, resisting radiation, resisting bacteria, killing bacteria, filtering toxic material and protecting health, etc. Said composite face fabric includes functional fibre layer, adhered base layer or surface layer face fabric, the above-mentioned all the layers and combined together by means of physical, chemical or mechanical method so as to obtain the invented product.

Owner:上海兰度科技有限公司

Method for preparing tourmaline functional ceramic filter element

The invention discloses a preparation method of a tourmaline functional ceramic filter core, which comprises the steps as follows: (1) 20 to100 parts by weight of the tourmaline, 0 to 80 parts by weight of auxiliary materials, 2 to 20 parts by weight of additive, and 5 to 25 parts by weight of water are mixed and mechanically stirred so as to prepare composite base materials; (2) the composite base materials are pressed and formed in a die so as to prepare the tourmaline functional ceramic filter core green body; (3) the green body is demoulded and dried, sintered under a certain temperature which is preserved, and then cooled so as to prepare the tourmaline functional ceramic filter core. The tourmaline functional ceramic filter core prepared by the method provided by the invention has the functions of filtrating harmful substances such as bacteria and suspended pollutant, etc. just as the porous ceramic filter core has, leads the water to sufficiently contact each tourmaline slit during the filtration process, greatly improves the contact area, and sufficiently makes the effects of the tourmaline, which are beneficial for human body, such as radiating infrared, releasing anion, activating water and generating week alkalescence, etc.

Owner:SOUTH CHINA UNIV OF TECH

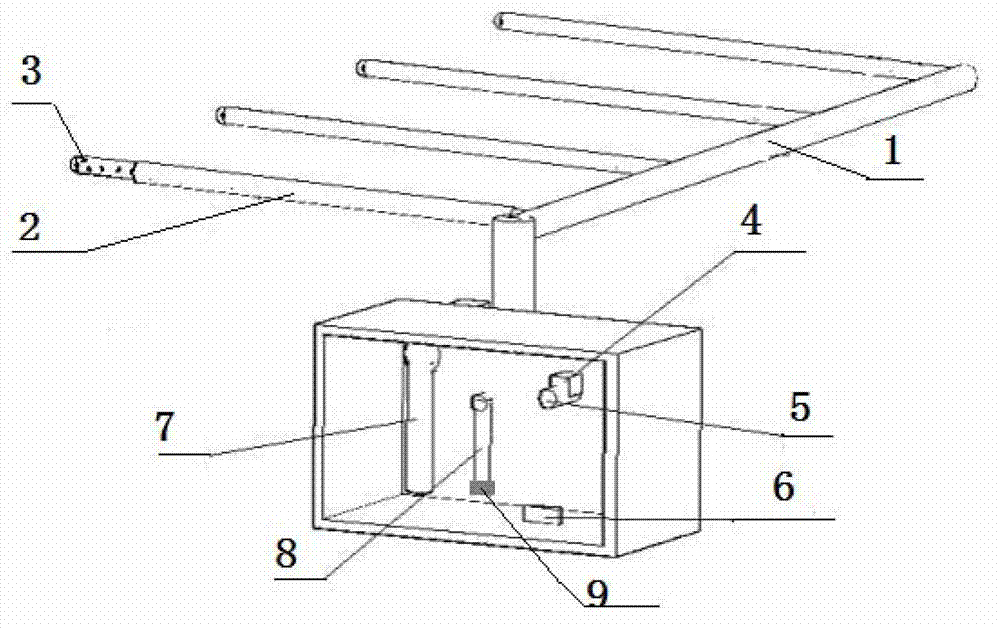

Irrigation and drainage integrated device suitable for underground high water level

InactiveCN102919102AContribute to high and stable productionAchieve drainageConstructionsSoil drainageWater storageSubsurface irrigation

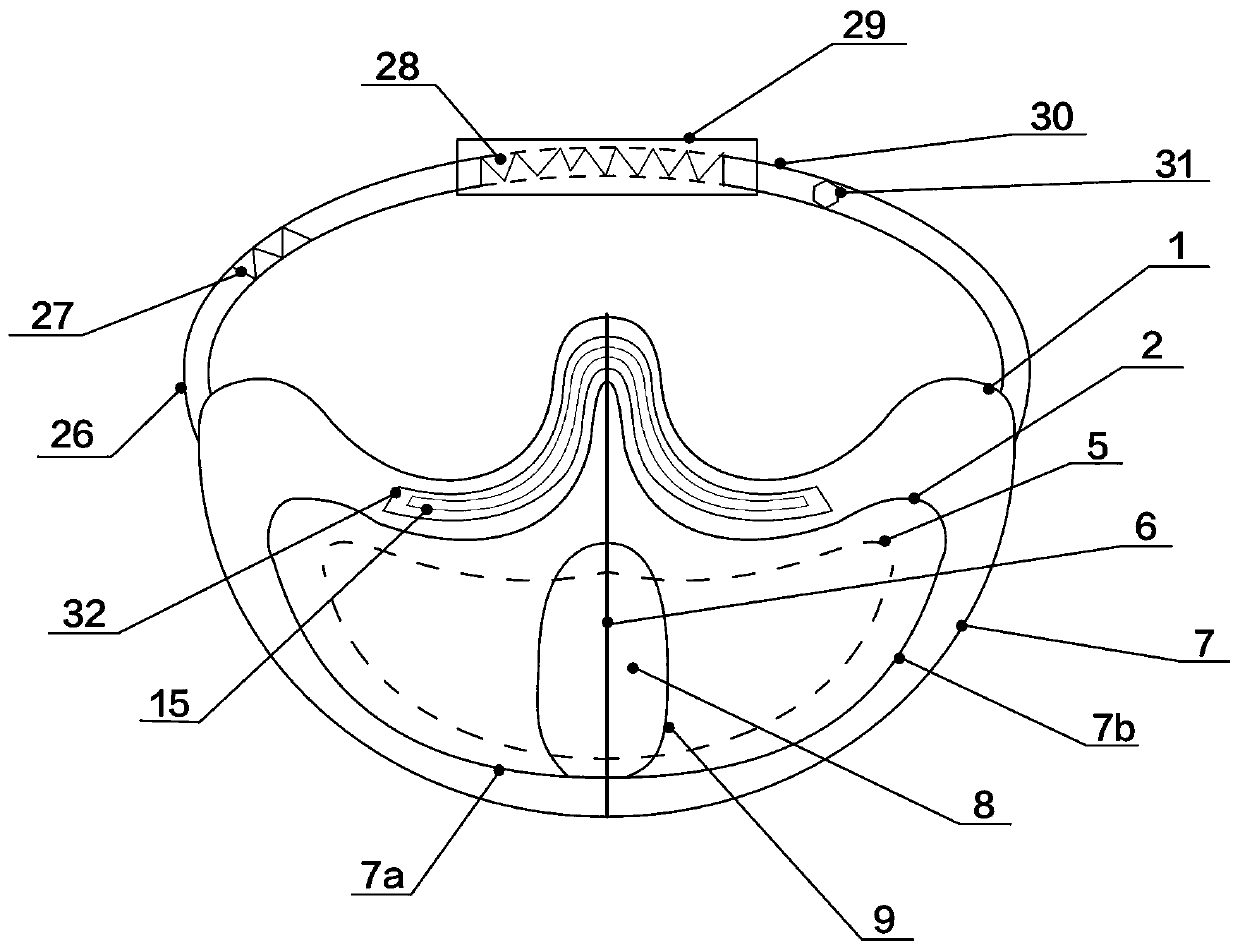

The invention discloses an irrigation and drainage integrated device suitable for a high underground water level. The irrigation and drainage integrated device comprises a set of underground irrigation pipelines, an underground water conveying pipeline, a water storage pool body, a water inlet pipe, a water outlet pipe, a water pump and two automatic control valves of the water pump, wherein one end of each underground irrigation pipeline is connected with the underground water conveying pipeline; a water permeable film is mounted at the other end of each underground irrigation pipeline; the underground water conveying pipeline is connected with the water inlet pipe; the water inlet pipe is connected with the water storage pool body; the first automatic control valve is mounted on the water inlet pipe; one end of the water outlet pipe is connected with one side of the water inlet pipe; the other end of the water outlet pipe is connected with the water storage pool body; and the water pump and the second automatic control valve are respectively mounted on the water outlet pipe. According to the irrigation and drainage integrated device, redundant underground water can be drained under higher underground water level of farmland and is stored in the water storage pool body, and infiltrating irrigation is carried out through the underground irrigation pipelines under lower underground water level, so that the irrigation and drainage functions are achieved, the water resources are saved and high and stable yield of crops can be facilitated.

Owner:HOHAI UNIV

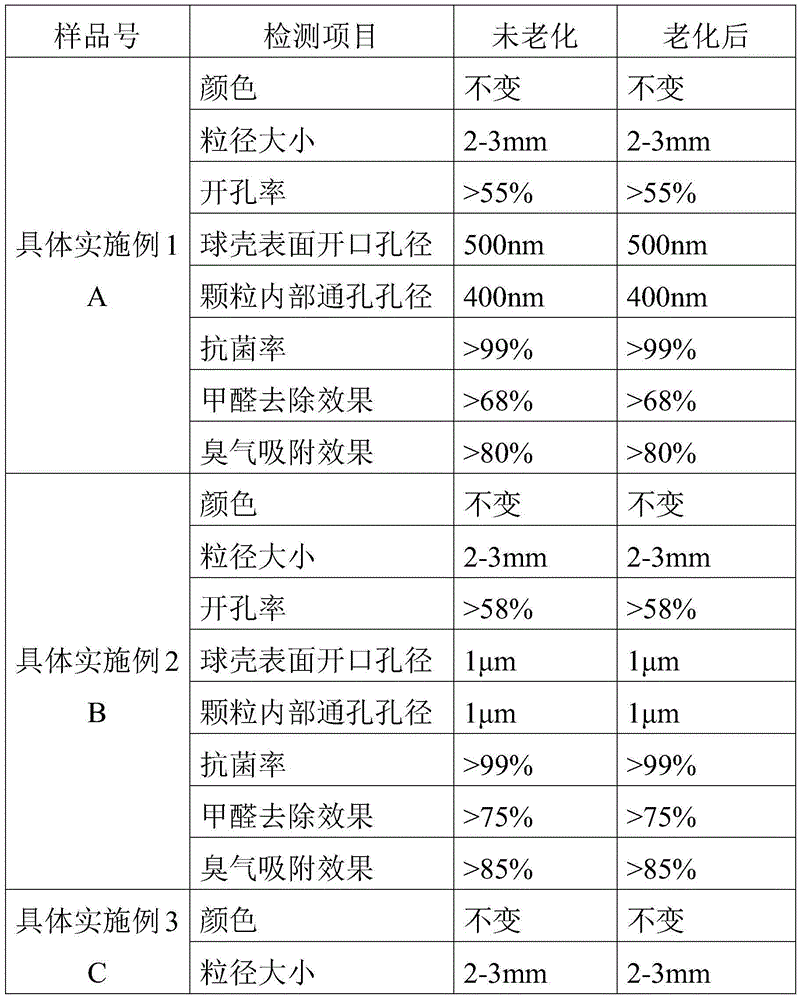

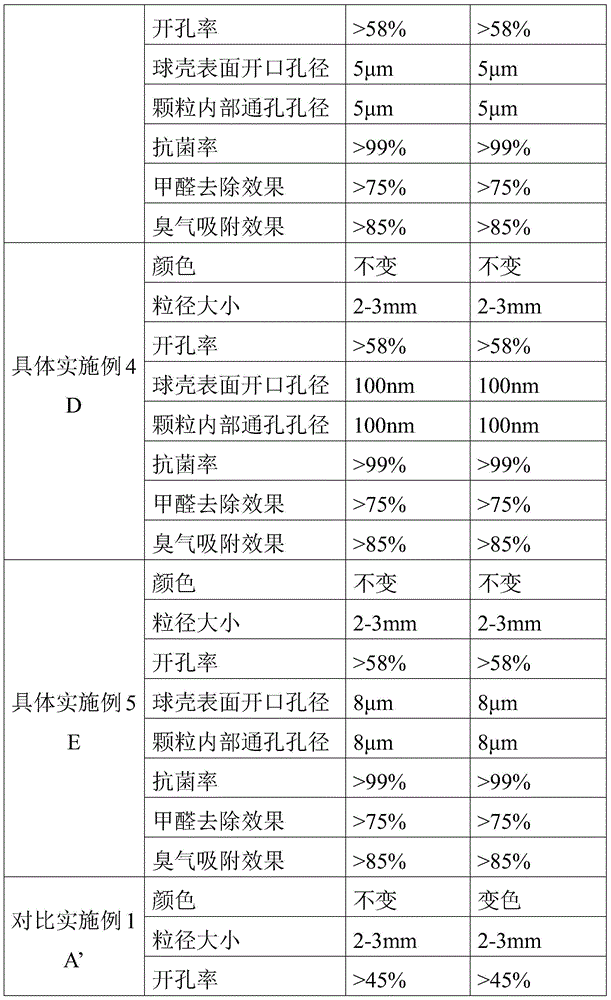

Multifunctional opening foaming polymer particle and preparation method thereof

The invention provides a multifunctional opening foaming polymer particle and a preparation method thereof. The method includes the steps that nano-titanium dioxide or nano-zinc oxide or nano silver powder or nano zinc sulfide is used as a multifunctional auxiliary, an appropriate coupling agent, polymeric dispersant, antioxygen and polymer resin are further adopted, a twin-screw extruder is used for achieving melt blending to conduct extrusion and particle cutting, functional nano powder is wrapped in matrix resin so that polymer particles can be formed, then the polymer particles are foamed by supercritical carbon dioxide gas, the multifunctional opening foaming polymer particle with excellent performance can be prepared, the particle has a surface opening through hole structure and an inner continuous large hole structure, the particle size is 0.5-5 mm, and the opening hole diameter and the inner through hole diameter of the surface of a particle spherical shell both can reach 50 nm-10 microns. The preparation method is simple in technology, convenient and easy to implement. The prepared opening foaming polymer particle has the functions of absorption, filtering, antibacteria and mold prevention, catalysis, odor removal, formaldehyde removal, anti-ultraviolet ageing and the like.

Owner:BILIC FORTUNE TECH

Method for producing conductive geotextile

The invention relates to a production method, in particular to a method for producing conductive geotextile. The method for producing the conductive geotextile comprises the steps of raw material selection, raw material screening, drying, fusion, spinning, cross air blow cooling, airflow drafting, swinging, net laying, mixed even feeding of metal fibers, carbon fibers and other short fibers, ironing conducted by a hot roller, shaping conducted by a pre-needle machine, reinforcing shaping conducted by a first main needle machine, repair shaping conducted by a second main needle machine, cloth containing conducted by a cloth containing machine, trimming and rolling. The geotextile produced according to the method for producing the conductive geotextile has the protective performance, the isolating performance, the waterproof performance, the filtering performance and the like of traditional geotextile, further has the conductive characteristic and is a good electrode material. According to the method for producing the conductive geotextile, the production technology is stable, control over the thickness of a material is good, the control range of the puncture density is large and is 50 to 500 stitches / cm<2>, the controllable range of the permeability performance of the material is large and is (1.0-9.9)*(10<-1>-10<-3>)cm / s, the strength of the product is high, and the thickness reaches 20mm.

Owner:大连格尔迈斯合成材料有限公司

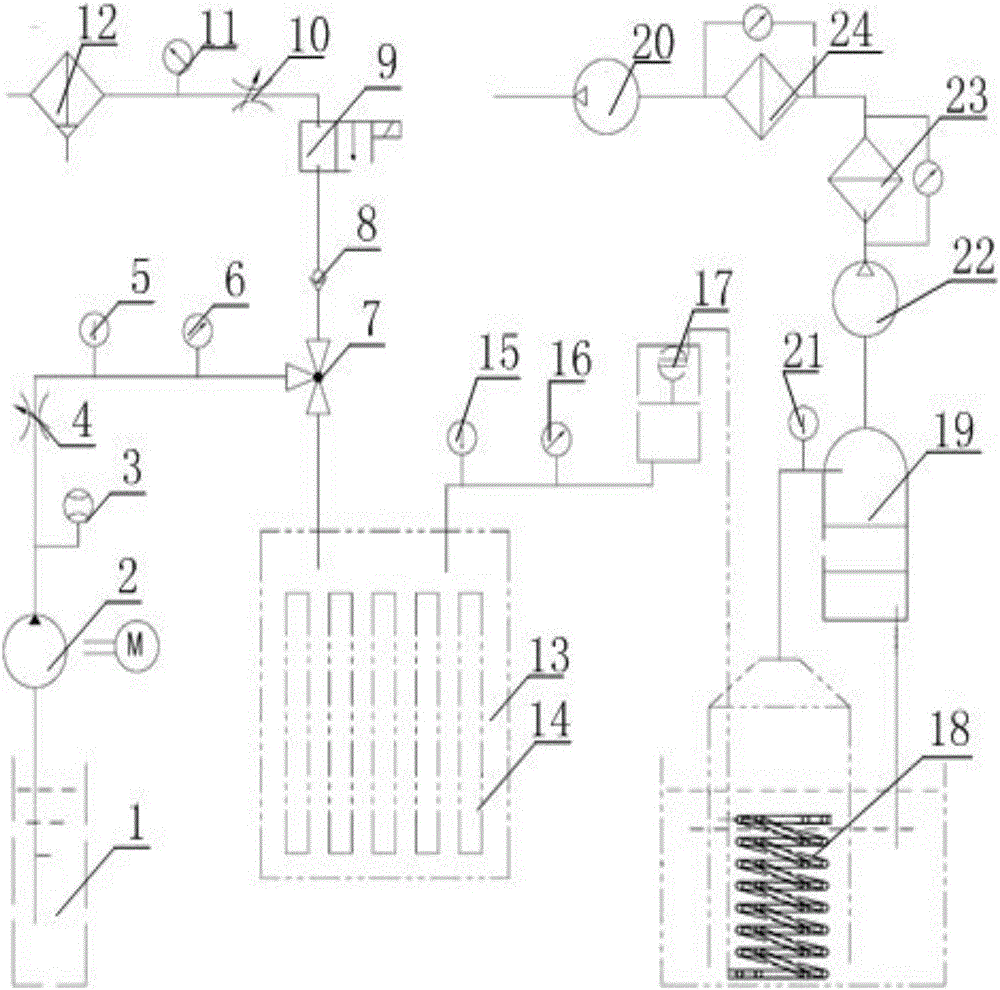

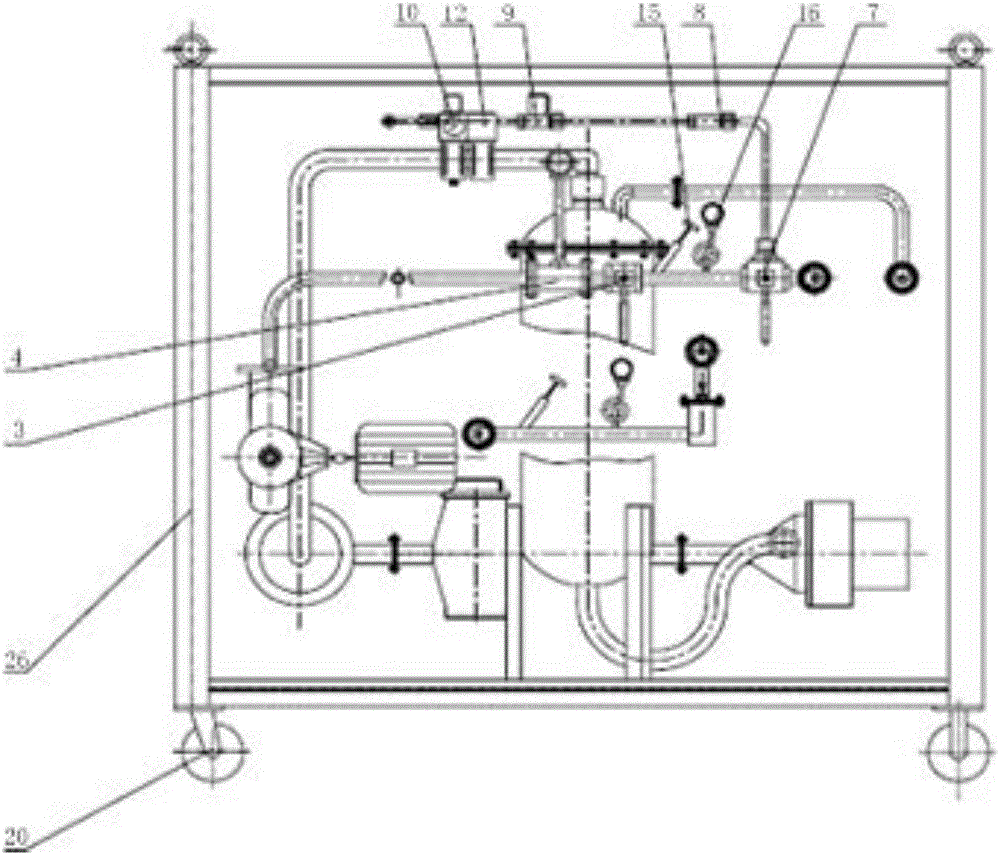

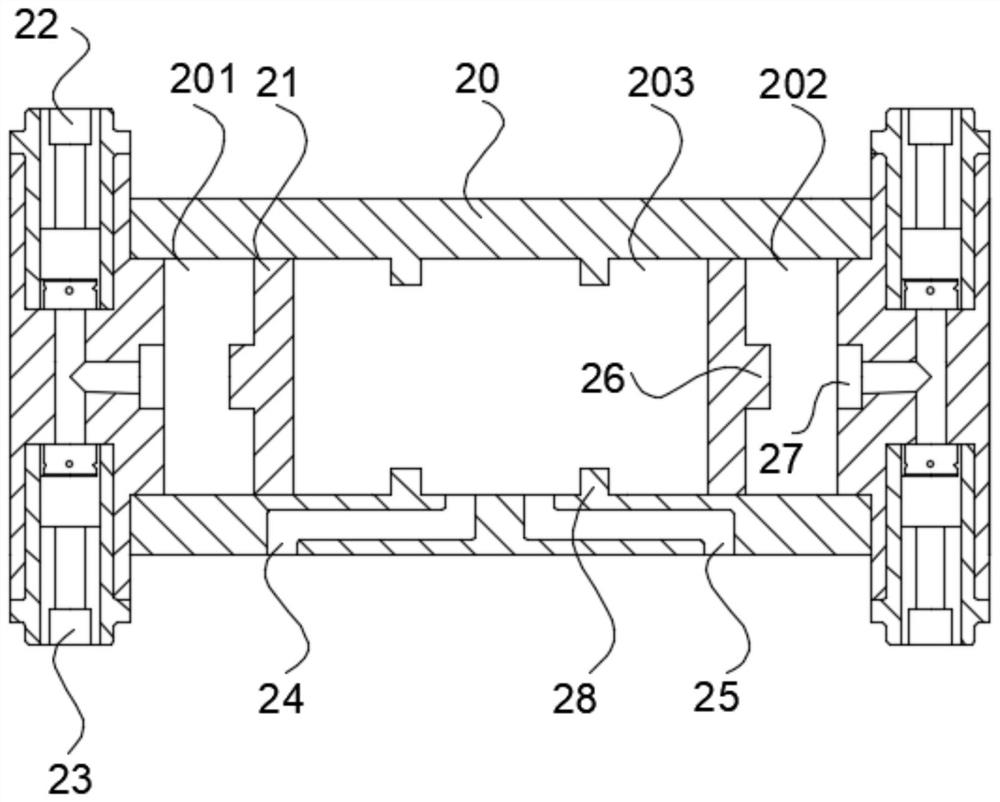

Residual heat removal facility for spent fuel shipping flask

ActiveCN107180661AAvoid damageTimely replacementPortable shielded containersAir filtrationWater discharge

The invention discloses a residual heat removal facility for a spent fuel shipping flask. The residual heat removal facility for the spent fuel shipping flask comprises a water filling loop, an air inflation loop, a gas-water discharging loop, a gas-water separator and a gas exhausting loop, wherein the water filling loop and the air inflation loop share one three-way valve and then are sequentially connected with the gas-water discharging loop, a cooling system, the gas-water separator and the gas exhausting loop by virtue of a pipeline. The residual heat removal facility for the spent fuel shipping flask can independently complete functions such as water filling and boron dissolution, water filling and exhausting, circulation cooling, cooling of exhausted gas, steam-water separation, air filtration and water drainage from a container, and single equipment can meet residual heat removal technological requirements of the spent fuel shipping flask. The residual heat removal facility for the spent fuel shipping flask is added with a water filling and boron dissolution technology in use; and the technology is used for dissolving boron crystals in the loop and preventing the loop from being blocked, so that the technology is more complete. The residual heat removal facility for the spent fuel shipping flask adopts an immersion heat exchange method, a heat exchange component is directly immersed into an immersion heat exchanger, heat exchange effect is good, and structure is simple.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

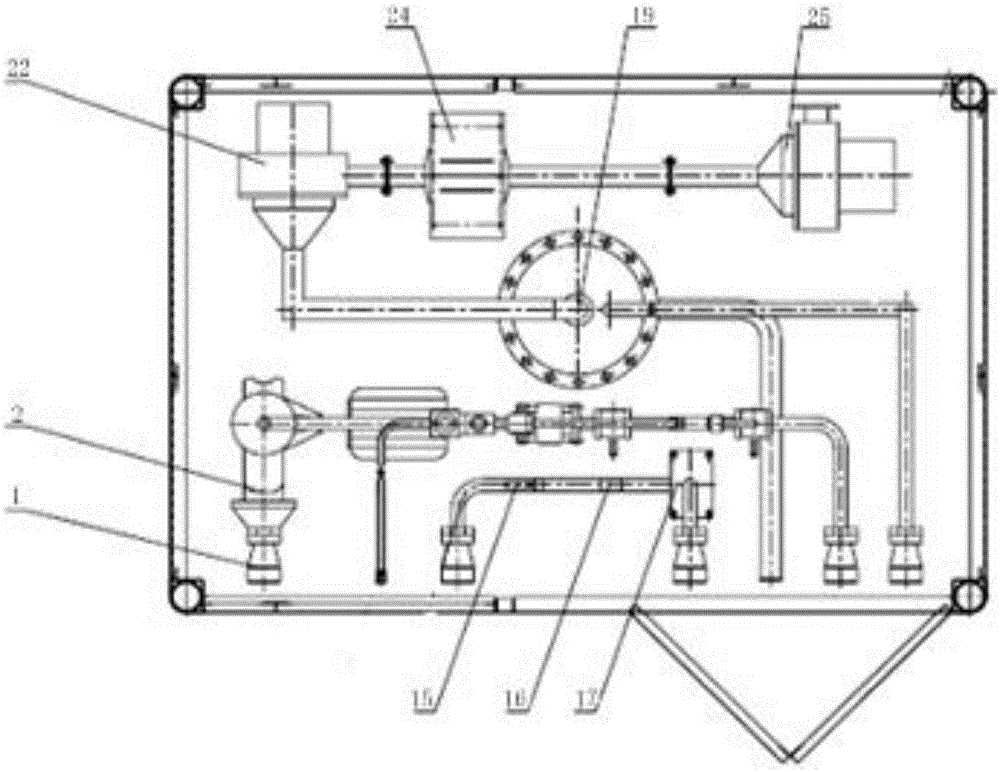

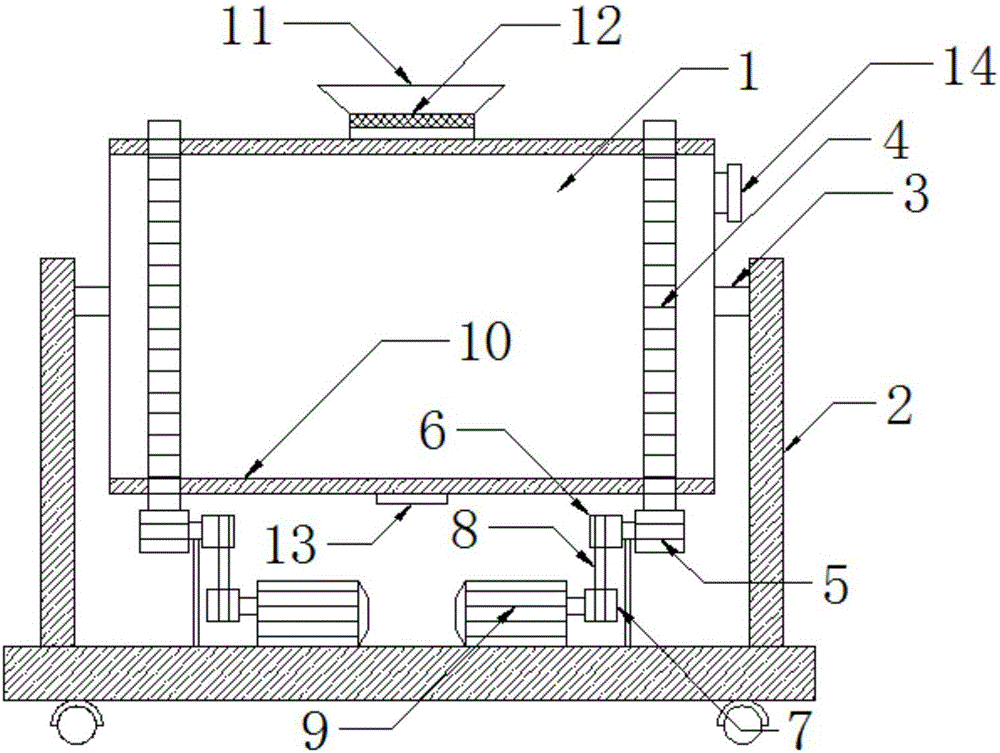

Material stirring device for compound fertilizer production

InactiveCN106179050AVersatileSimple structureRotating receptacle mixersTransportation and packagingDrive wheelExhaust valve

The invention provides a material stirring device for compound fertilizer production. The material stirring device comprises a stirring drum, a workbench, a rotating shaft, gear rings, gears, driven wheels, driving wheels, conveying belts, servo motors, an infrared-heating lining plate, a feed inlet, a vibrating screen, a discharge outlet and an exhaust valve; two ends of the stirring drum are arranged on the support of the workbench through the rotating shaft, and a sealing pair is arranged between the rotating shaft and the stirring drum; the gear rings are arranged on the outer side of the stirring drum and are meshed with the gears, the gears are connected with the driven wheels through the connecting shaft, and the driven wheels are in transmission connection with the driving wheels of the servo motors through the conveying belts; the feed inlet and the discharge outlet are arranged in the drug wall of the stirring drum, the vibrating screen is arranged on the inner side of the stirring drum, the infrared-heating lining plate is arranged on the inner wall of the stirring drum, and the exhaust valve is arranged on the side wall of the stirring drum. The material stirring device has the advantages of functional diversities of stirring, drying and screening.

Owner:TIANJIN SHIYIDE FERTILIZER

Ultraviolet (UV) curing ink screen printing technology for UV highlight veneer

The invention discloses ultraviolet (UV) curing ink screen printing technology for a UV highlight veneer, which relates to UV ink screen printing technology. Ink is printed on the surface of the UV highlight veneer, and a UV curing measure of ink is adopted, so that a pattern is firm and durable. The technology is characterized by comprising the following process steps of: stretching a screen; sizing; drying; printing down; developing; drying; cleaning and drying the UV highlight veneer; printing; and performing UV curing. The technology has the advantages that: environmentally-friendly high-polymer UV resin ink has the properties of fresh color, difficult breakage, acid resistance and alkali resistance; after the UV highlight veneer which is subjected to screen printing is used, a clear pattern, high adhesion, surface wear and flexible and plain tone are realized; and impurities in resin can be filtered better through the screen in the printing process, so that a printed pattern has a bright and flexible color, and the problems of unavailable UV ink printing on the UV highlight plate in the prior art and making of UV on a UV surface are solved.

Owner:陈增金

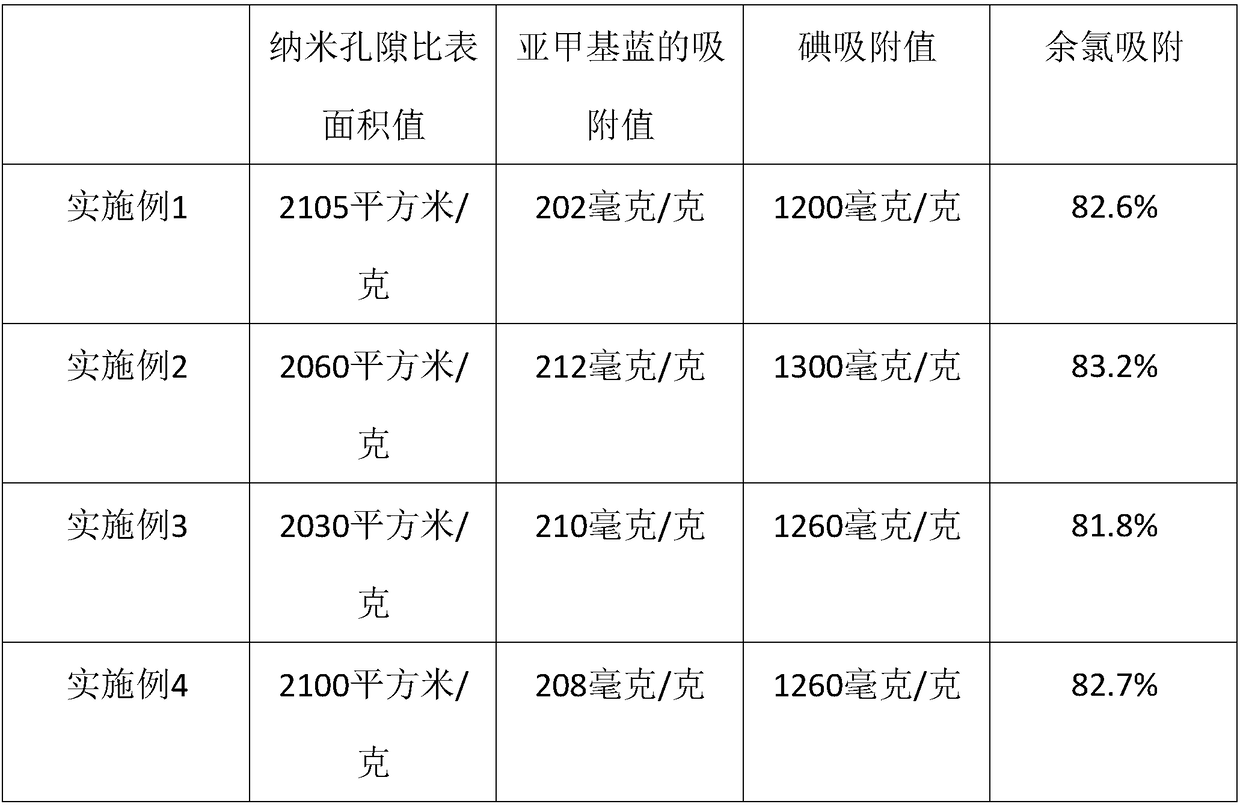

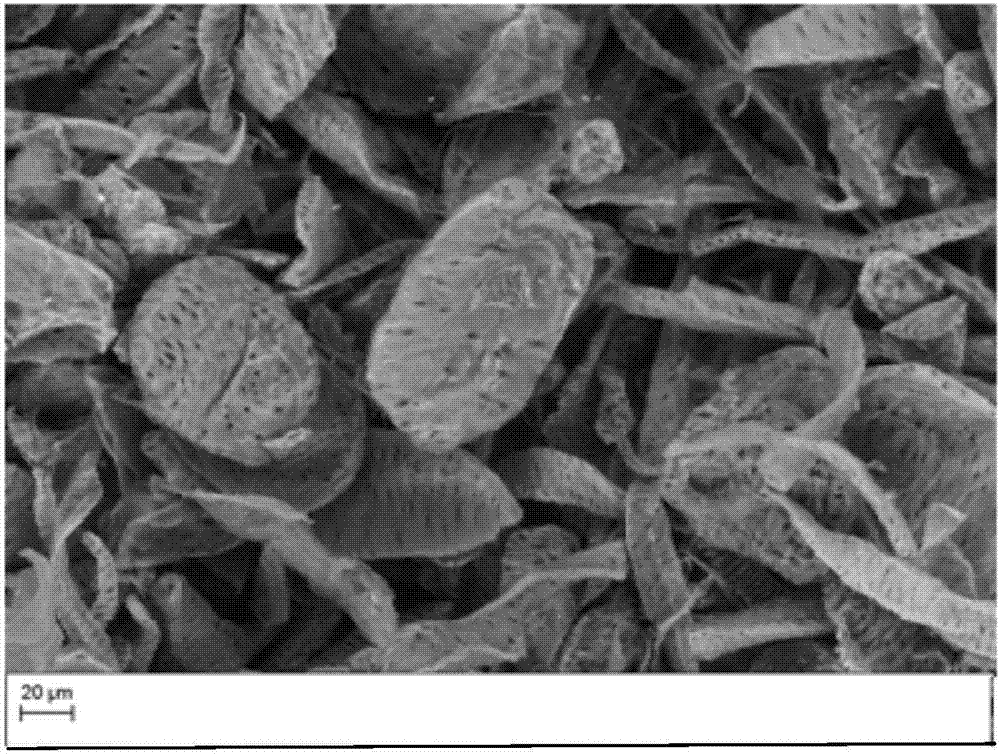

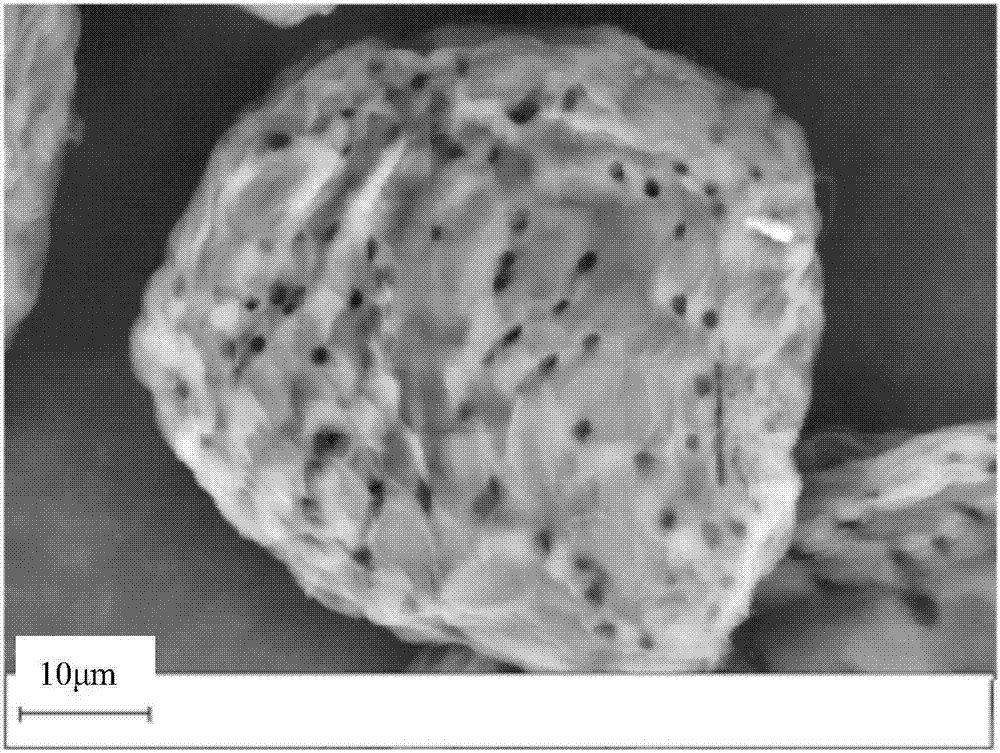

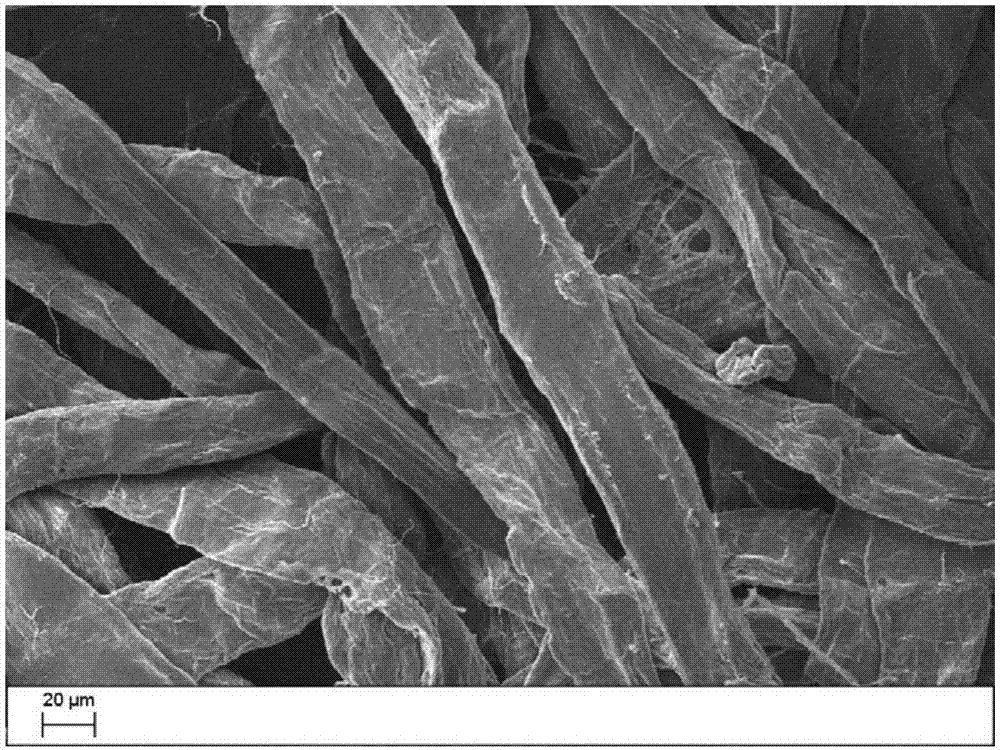

Nano carbon fiber composite water purification material and preparation method and application thereof

InactiveCN109292836AImprove adsorption capacityReduce weightCosmetic preparationsWater treatment compoundsPorosityFiber

Owner:GUANGZHOU LANQUAN HOME APPLIANCES CO LTD

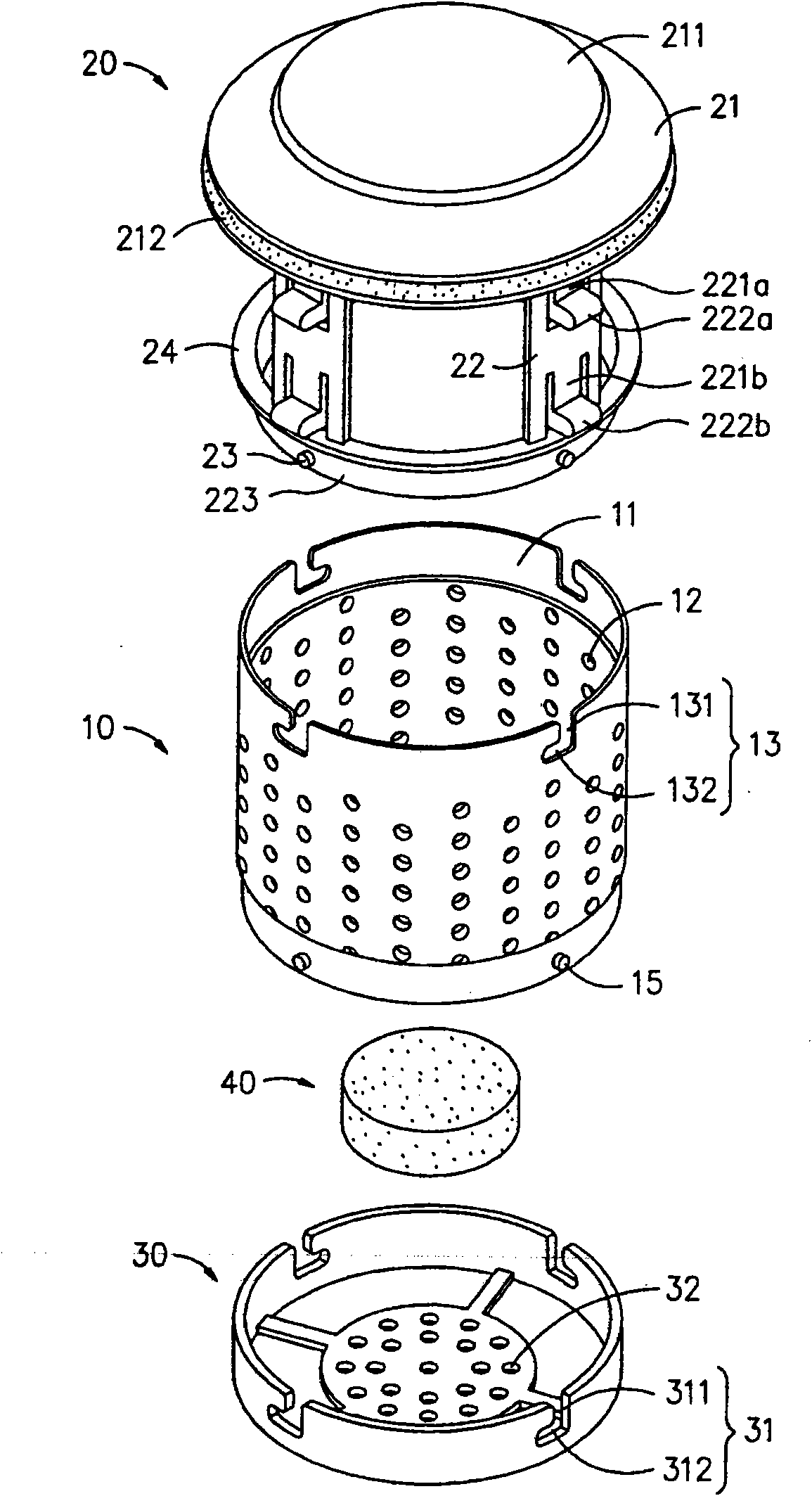

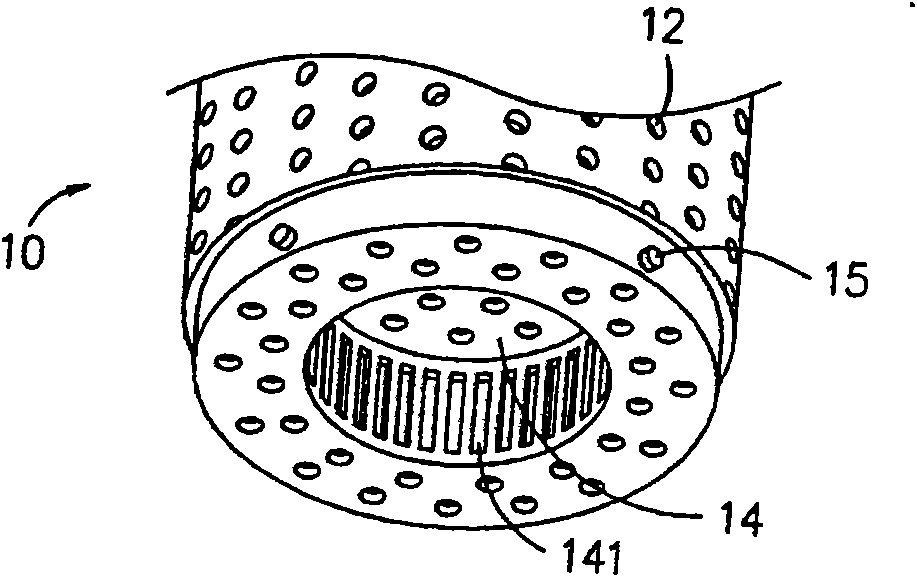

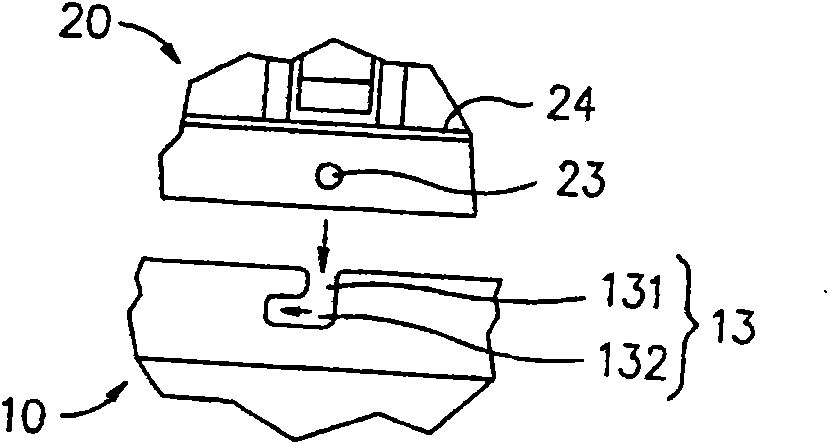

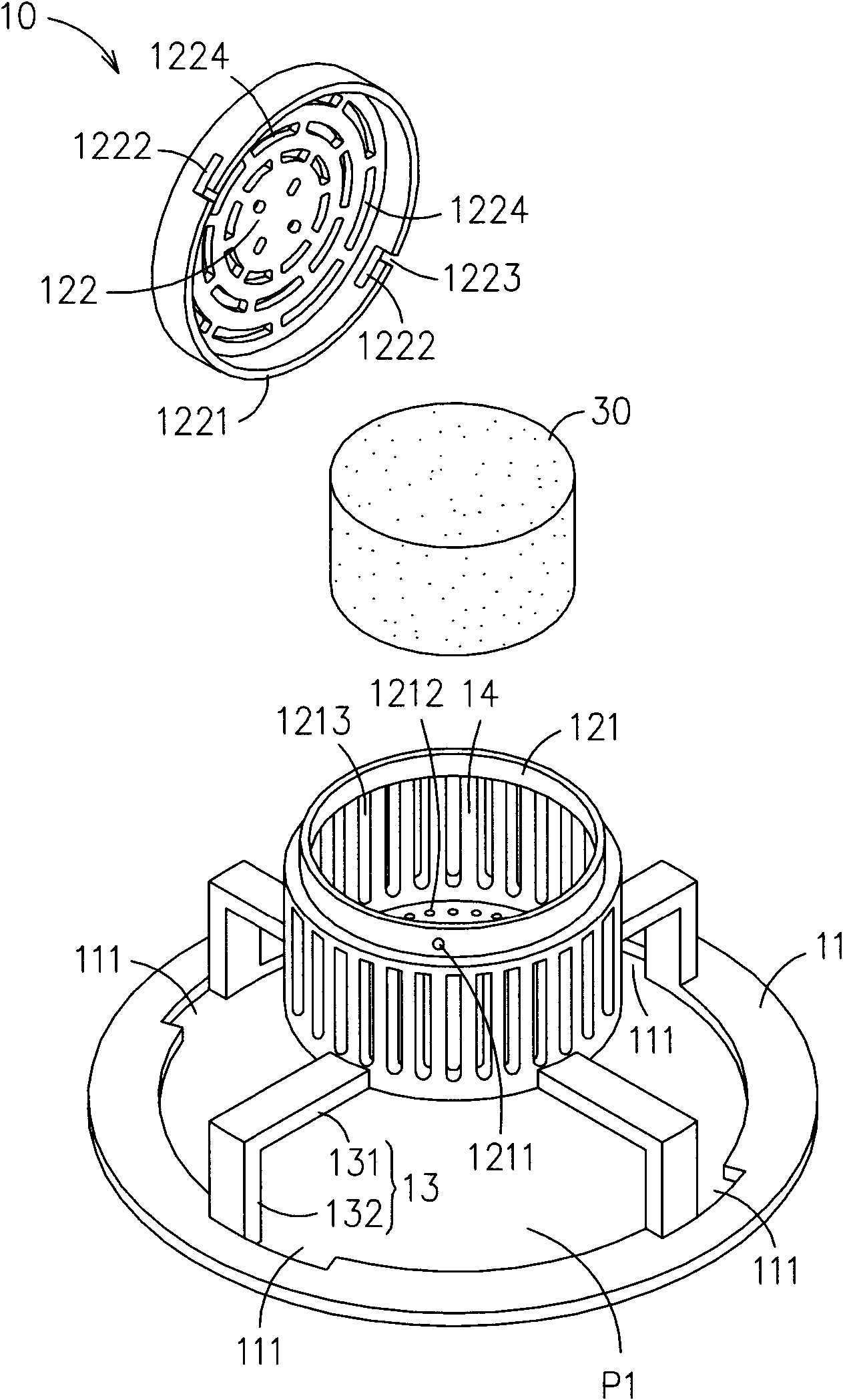

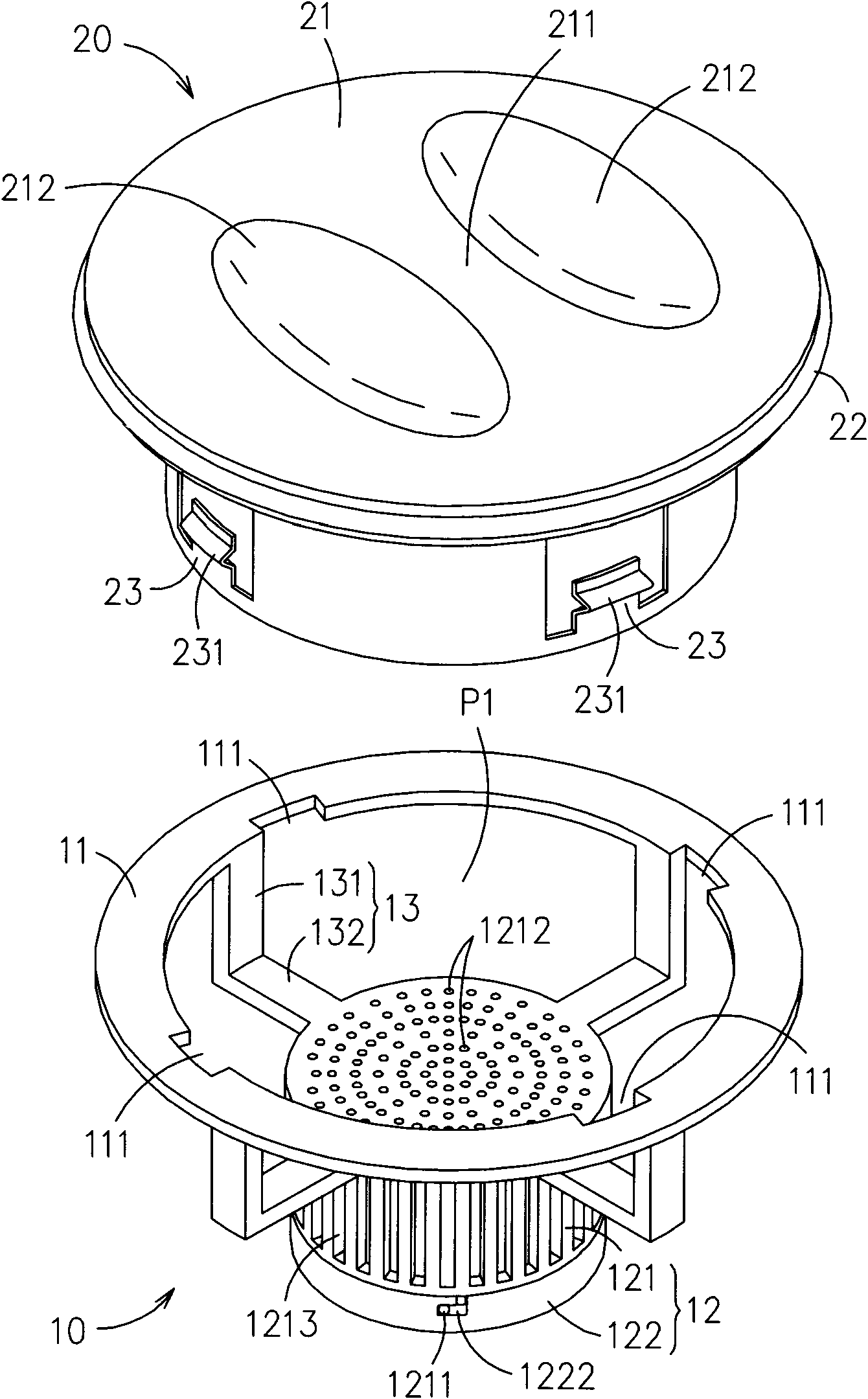

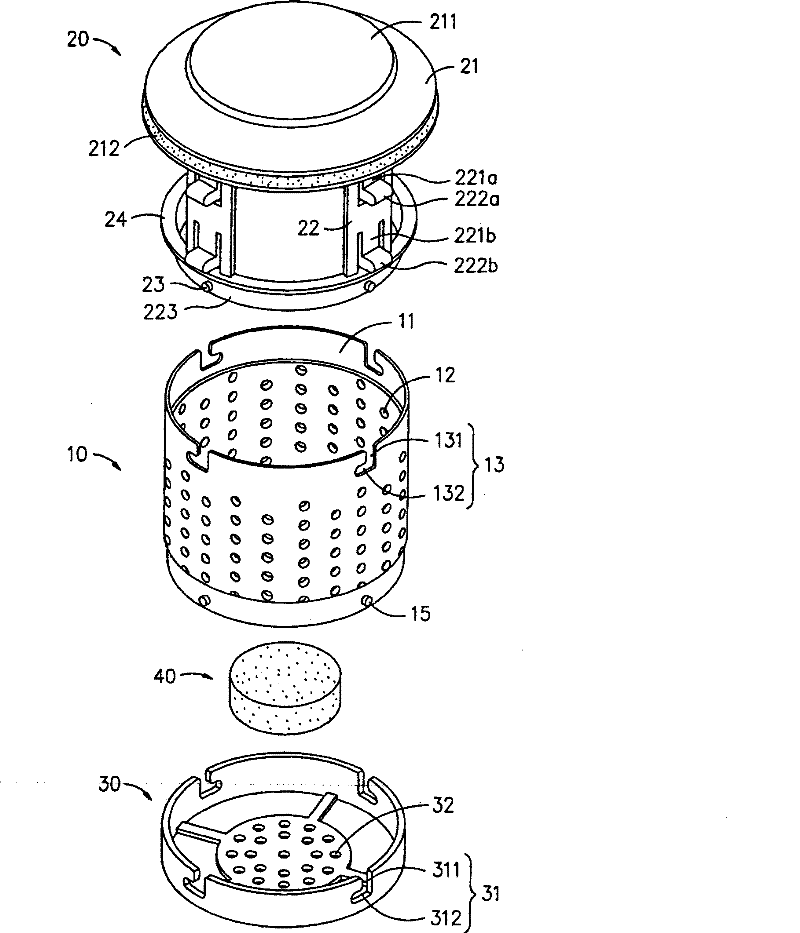

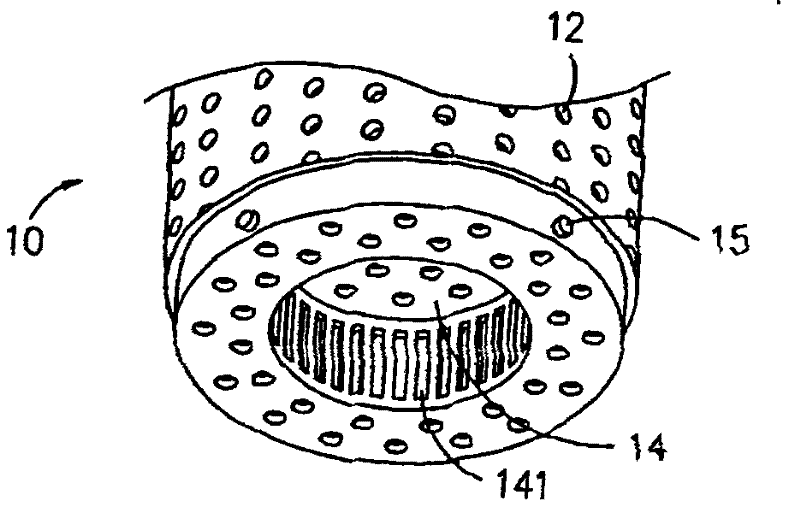

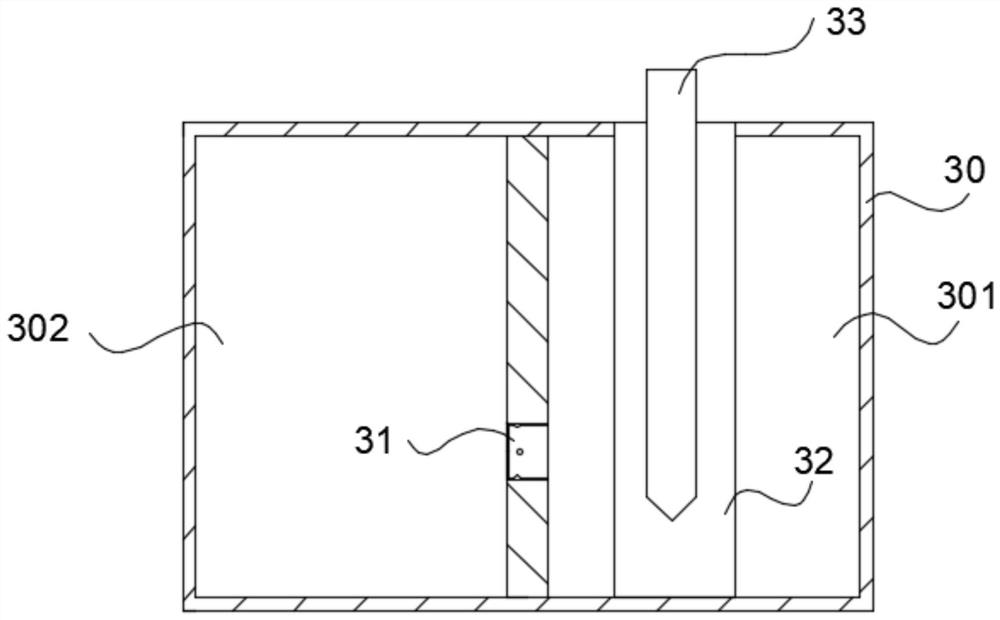

Drain device

The invention relates to a drain device, which comprises a body, a top cover assembly and a bottom cover. The body is provided with an inner space, and a plurality of permeable parts running through the inner space. The top cover assembly is separably arranged on the top of the body and comprises a top cover and a plurality of connecting pieces. The connecting pieces extend a certain length from the bottom of the top cover. The bottoms of the connecting pieces are connected with each other. Each connecting piece is provided with an upper elastic sheet and a lower elastic sheet. The elastic sheets are provided with convex parts towards the outside of the top cover. The bottom cover is separably arranged on the bottom of the body. A certain space is formed between the bottom cover and the body. The bottom cover is provided with a permeable part. Due to the combination of the components, an outer edge of each convex part protrudes out of the body and an outer side wall of the bottom cover, and can be applied with a force so that the convex part inwards contracts toward the inside of the top cover, and the convex part can be automatically popped up when the external force is eliminatedso that the outer edge of the convex part protrudes out of the body and the outer side wall of the bottom cover again.

Owner:THANK GOD ENTERPRISE

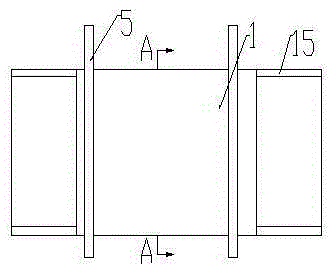

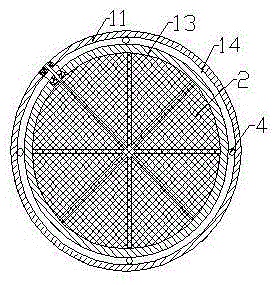

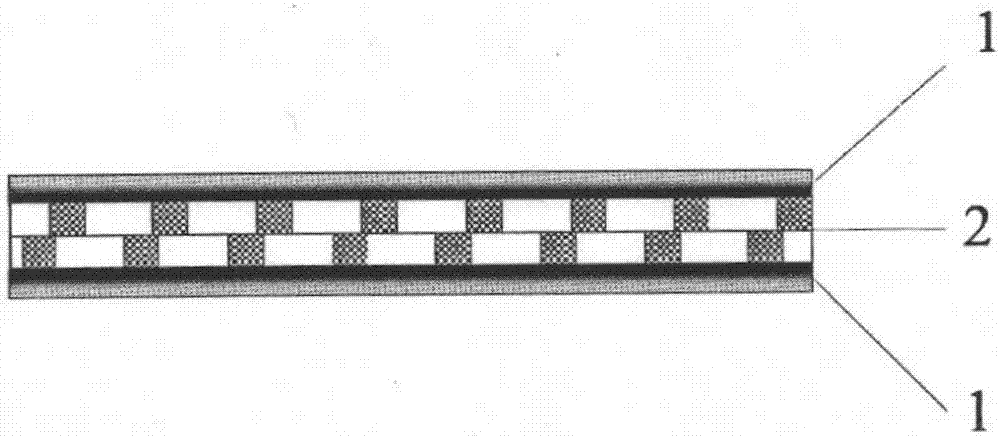

Multifunctional polyethylene (PE) water supply pipe

InactiveCN105351663AWith sterilizationWith filterPipe heating/coolingPipe elementsAnti freezingEngineering

The invention discloses a multifunctional polyethylene (PE) water supply pipe. The multifunctional PE water supply pipe comprises a PE pipe. The PE pipe comprises an outer layer, middle supporting frames and an inner layer. The middle supporting frames are supported between the outer layer and the inner layer in the mode that plastic strips intersect to form a star-shaped structure; an interval of 4-6 mm is formed between the inner layer and the outer layer; the multiple middle supporting frames are arranged in the length direction of the PE pipe; a filtering net is arranged in the center of the middle supporting frames and connected to one sides of the middle supporting frames through thread structures. In this way, the multifunctional PE water supply pipe has various functions of sterilization, filtering and heating, is suitable for secondary filtering of domestic drinking water and has the anti-freezing and anti-cracking functions at the same time.

Owner:SUZHOU XINLICHANG ELECTRONICS MATERIAL CO LTD

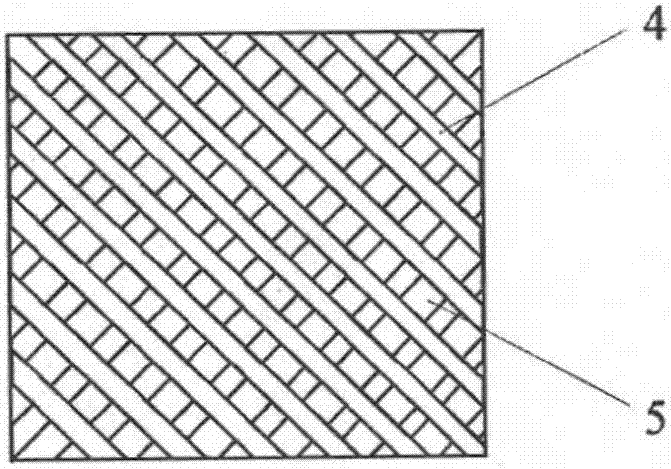

Method for preparing polypropylene fiber earthwork cloth composite drainage net having anti-filtration drainage function

InactiveCN106968051AWith filterWith drainage performanceRoadwaysLiquid repellent fibresAntioxidantWater capacity

The invention provides a preparation method of a polypropylene geotextile composite drainage net with reverse filtration and drainage function, which is characterized by comprising: mixing high melt index isotactic polypropylene chips with anti-aging agent and cooling masterbatch and then pouring into the material The silo is fed into the screw extruder. After melting, extrusion, filtration and metering, it is ejected from the spinneret hole. After cooling by side blowing, it enters the drafting system for drafting. Under the action of downward suction, it is evenly adsorbed on the mesh curtain, and then reinforced by pre-needling and main needling to obtain a polypropylene geotextile; the above-mentioned polypropylene geotextile is treated with hydrophobicity on one side to obtain unidirectional water-conducting performance; The polypropylene geotextile with hydrophobic treatment on one side is combined with the geonet core to obtain the polypropylene geotextile composite drainage net with the function of reverse filtration and drainage. The composite of the geotextile with unidirectional water-conducting ability and the geonet core can accelerate the drainage of the water retained in the roadbed and the bottom groundwater.

Owner:DONGHUA UNIV

Corncob cellulose foaming material as well as preparation method and application thereof

The invention provides a corncob cellulose foaming material as well as a preparation method and application of the corncob cellulose foaming material. The corncob cellulose foaming material comprises the following raw materials which are taken as components: a corncob cellulose and enhanced cellulose solution, a foaming agent and a pore-forming agent. The preparation method of the corncob cellulose foaming material comprises the following steps: (1) mixing the foaming agent and the pore-forming agent in a formula ratio with the corncob cellulose and enhanced cellulose solution to obtain a mixture; (2) injecting the mixture into a mould to be foamed and molded, so as to obtain a molding material; (3) washing the molding material and drying to obtain the corncob cellulose foaming material. The corncob cellulose foaming material has the functions of buffering, shock absorption, heat preservation, filtration and the like and has outstanding elasticity, and can be widely used in industries of furniture, automobiles, packaging and the like; furthermore, the corncob cellulose foaming material is non-toxic and degradable, and has no toxicity to soil or air, and further is simple in preparation method, capable of being used in a large scale and favorable to rural economic development.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

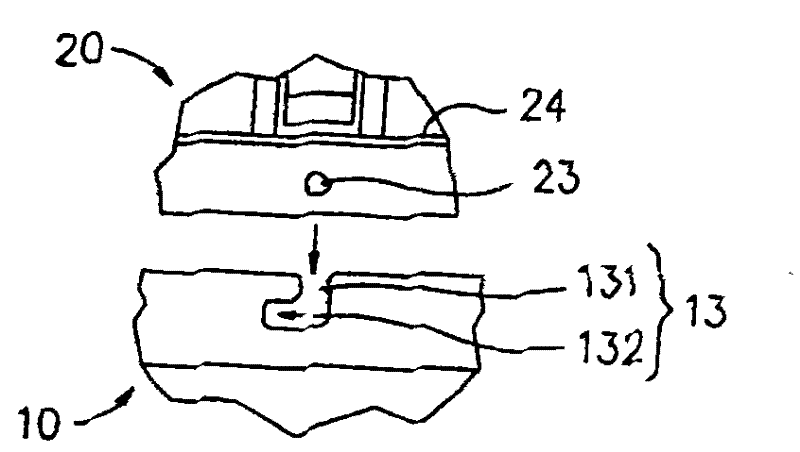

Dropping head apparatus

The invention relates to a dropping head apparatus, which comprises a body and a first cover body, the body is composed of an erection part and an accommodation part, a connection part is provided between the erection part and the accommodation part, at least a groove is provided at the erection part, at least a first hollowed part is provided between the erection part and the accommodation part, at least a second hollowed part is provided at the accommodation part, an accommodation space is provided at the accommodation part, a water inlet end of a drainpipe is provided at the erection part, the accommodation part and the connection part are suspended at the water inlet end; a first cover body has at least a clamping structure, the first cover body is arranged on a first position and a second position of the body, when the first cover body is positioned at the first position, the clamping structure is embedded in the groove and the first cover body is imbedded in the water inlet end, when the first cover body is positioned at the second position, the clamping structure is provided at the erection part and the first cover body is protruded outside the water inlet end.

Owner:THANK GOD ENTERPRISE

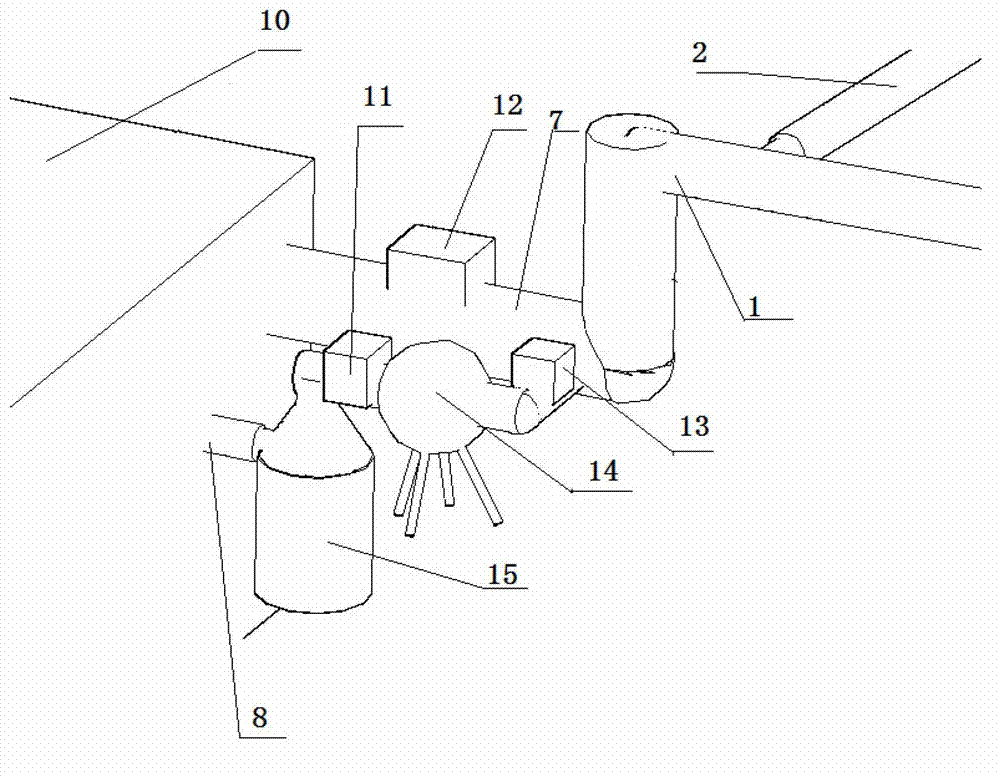

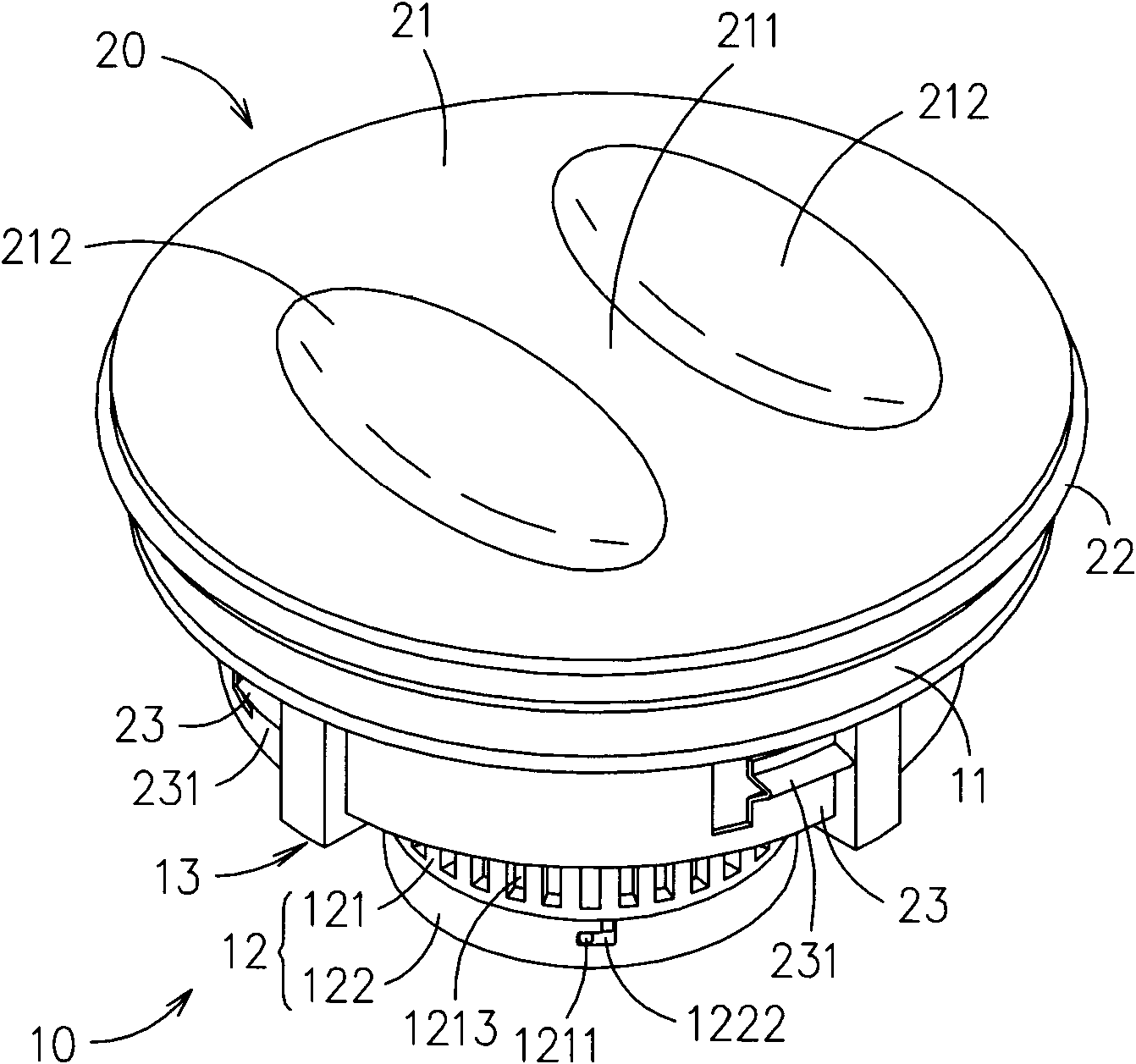

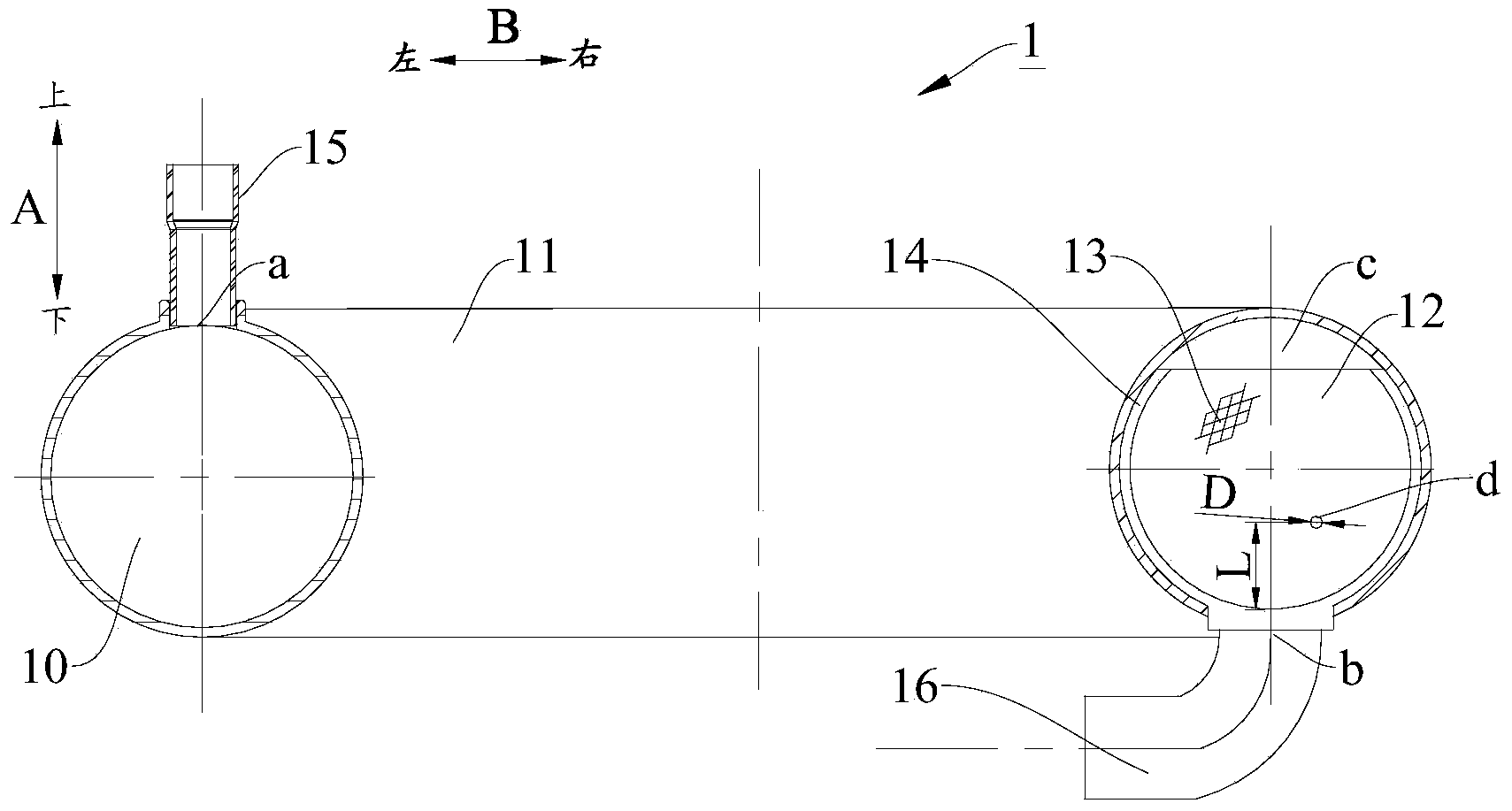

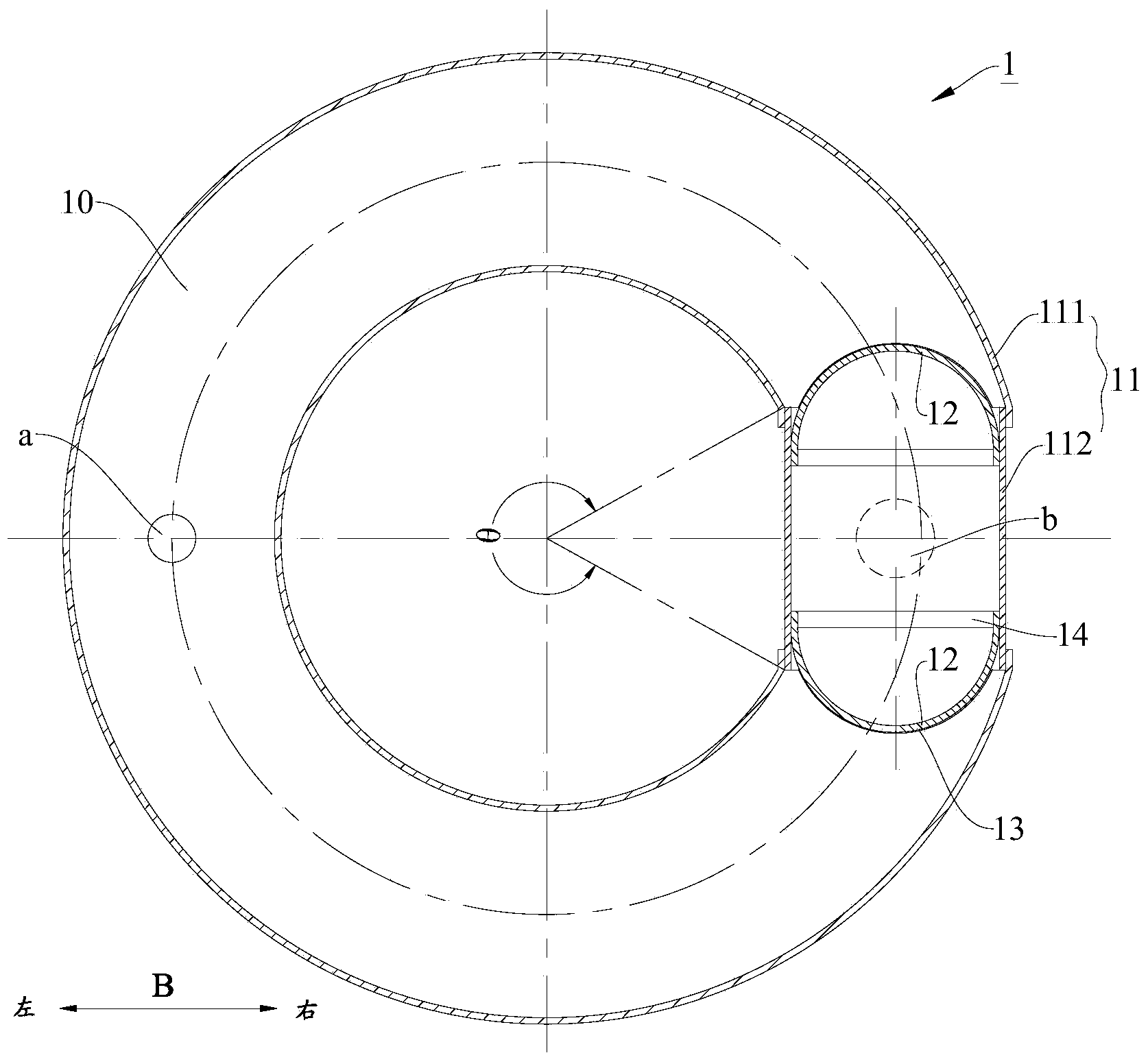

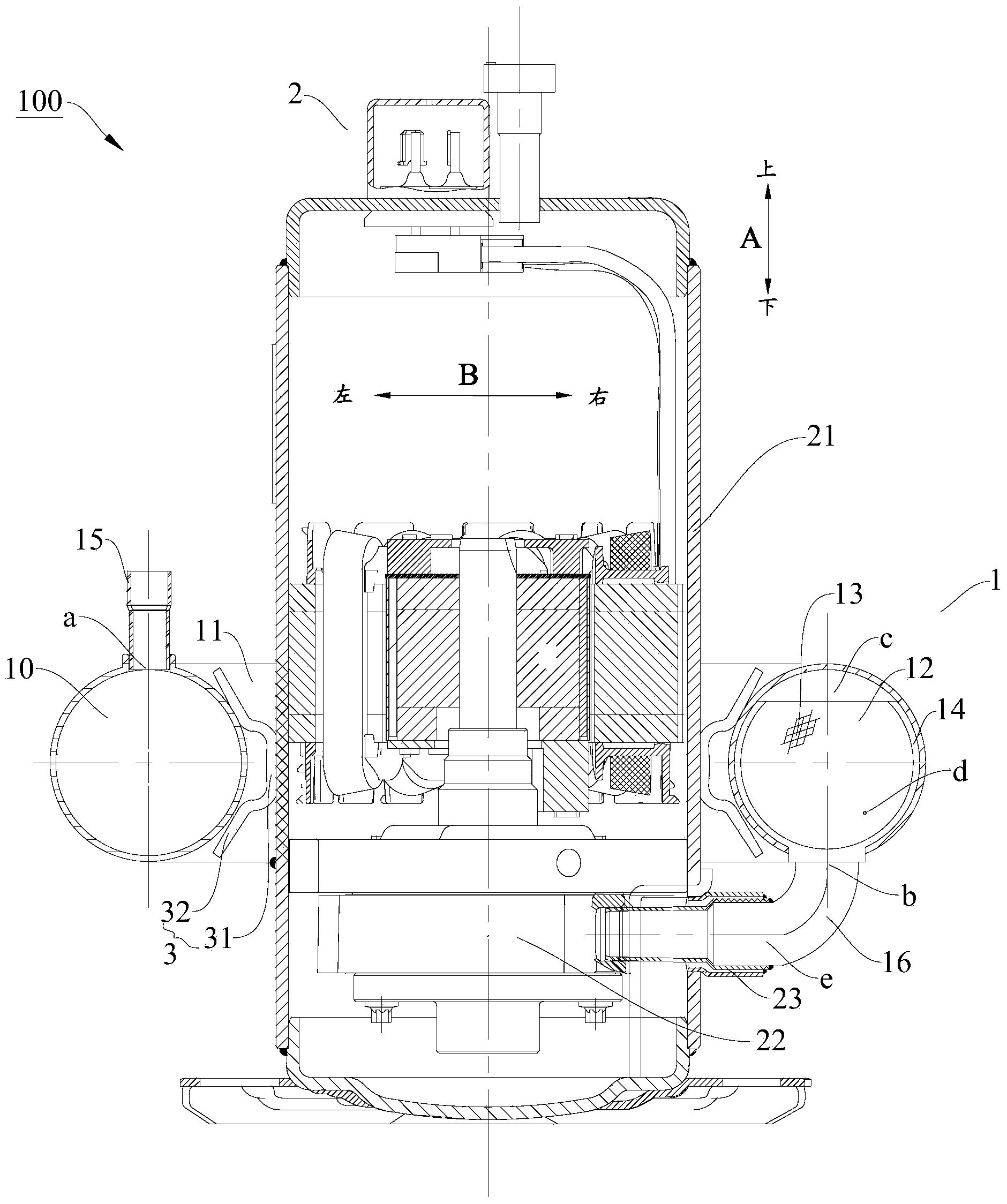

Liquid dispenser used for compressor and compressor thereof

InactiveCN104315761ASmall eccentric massReduce inspiratory resistancePositive displacement pump componentsFluid circulation arrangementRefrigerantLiquid storage

The invention discloses a liquid dispenser used for a compressor and the compressor of the liquid dispenser. The compressor comprises a compressor body. The liquid dispenser comprises a tube, a cushion plate and a filtering net. The tube is arranged on the compressor body in a sleeved mode, a tube cavity is limited in the tube, the tube is provided with an air inlet and an air outlet, the air inlet and the air outlet are communicated with the tube cavity, and the air outlet is suitable for being communicated with the compressor body. The cushion plate is arranged on the inner wall or the outer wall of the tube, and the cushion plate is used for blocking liquid refrigerants in the tube cavity from flowing into the air outlet. The filtering net is arranged on the inner wall or the outer wall of the tube so as to filter the refrigerants in the tube cavity. The liquid dispenser used for the compressor has the functions of liquid dispensing, liquid storage, impurity filtering and oil return. Besides, the tube is arranged on the compressor body in a sleeved mode, when the liquid dispenser is used for the compressor, eccentric mass of the compressor is little, pipeline vibration is little, air absorbing resistance of the compressor is reduced, and performance of the compressor is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

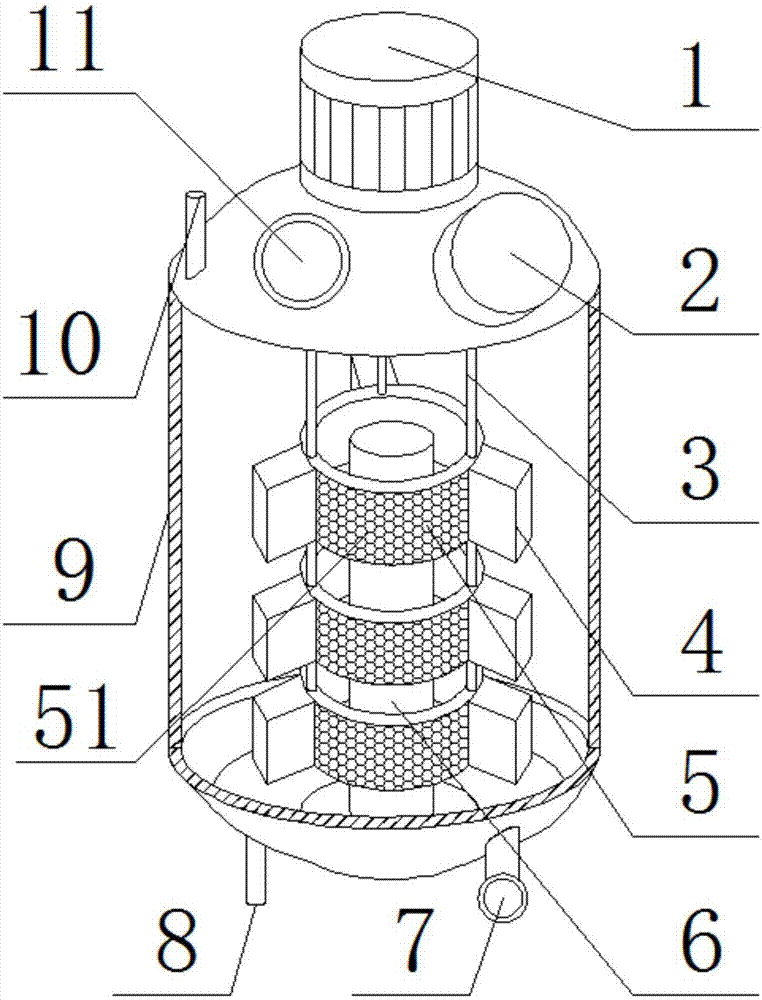

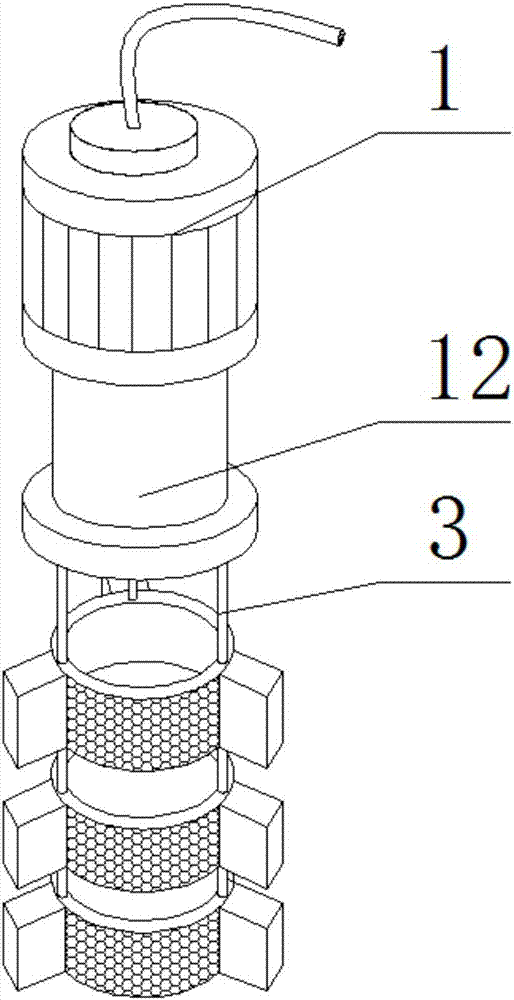

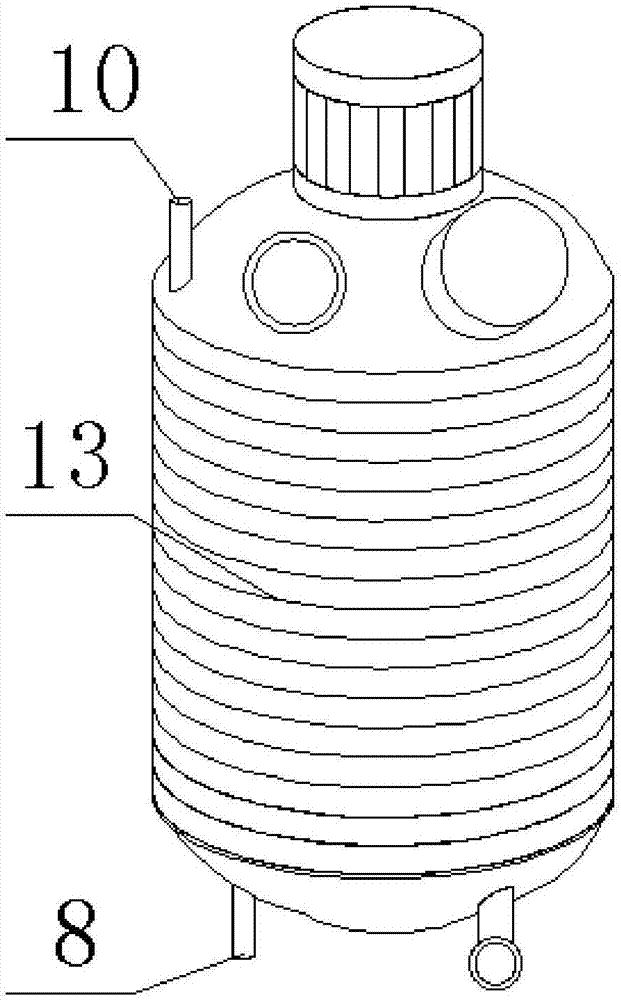

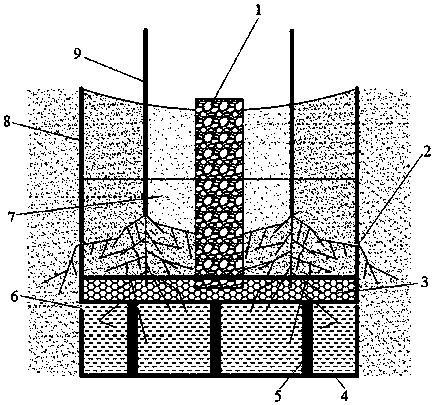

Chemical fiber reaction vessel with cleaning and filtering functions

PendingCN107376819AWith cleaning filterWith cleaning and filtering functionChemical/physical/physico-chemical stationary reactorsFiberCoupling

The invention relates to the technical field of chemical utensil application, especially to a chemical fiber reaction vessel with cleaning and filtering functions. The chemical fiber reaction vessel comprises a shell and a heating pedestal which is arranged at the bottom of the shell. The top of the shell is provided with a motor, one side of which is respectively provided with a feed inlet, a sight glass and an inlet port. The side surface of the shell is provided with a heating pipe. The bottom of the shell is equipped with a discharge port and a level gauge. The top of the heating pedestal is provided with a heating rod, which penetrates through a sealing ring and the shell and also penetrates through sleeves inside the shell. One side of each sleeve is welded with a blade. The sleeves are connected to a rotating shaft, which is connected to a shaft coupling. The shaft coupling penetrates through the shell, and the shaft coupling is connected to the motor. Through the heating rod and the heating pipe for co-heating, heat balance inside and outside the reaction vessel during heating is guaranteed, and safety is enhanced.

Owner:江苏垶恒复合材料有限公司

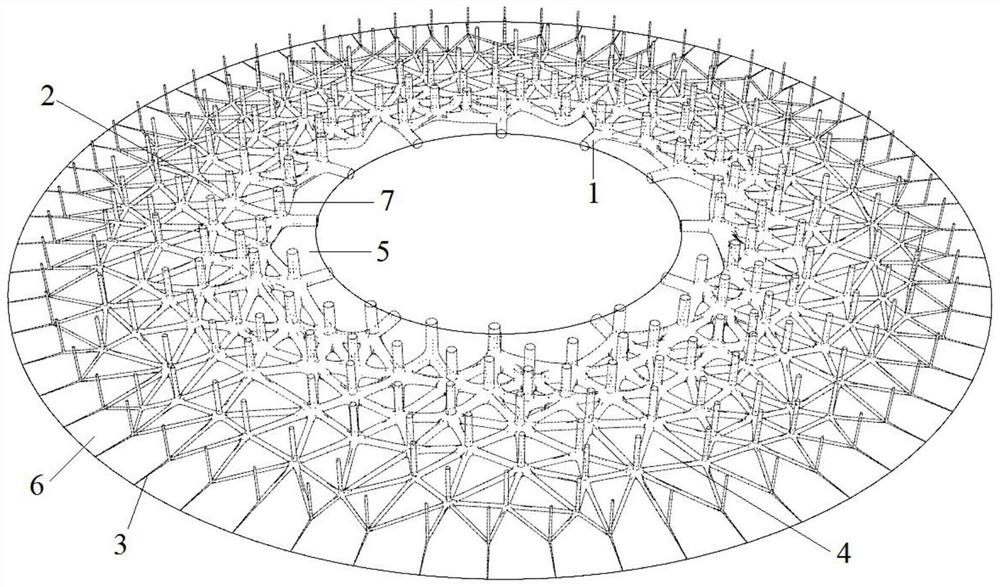

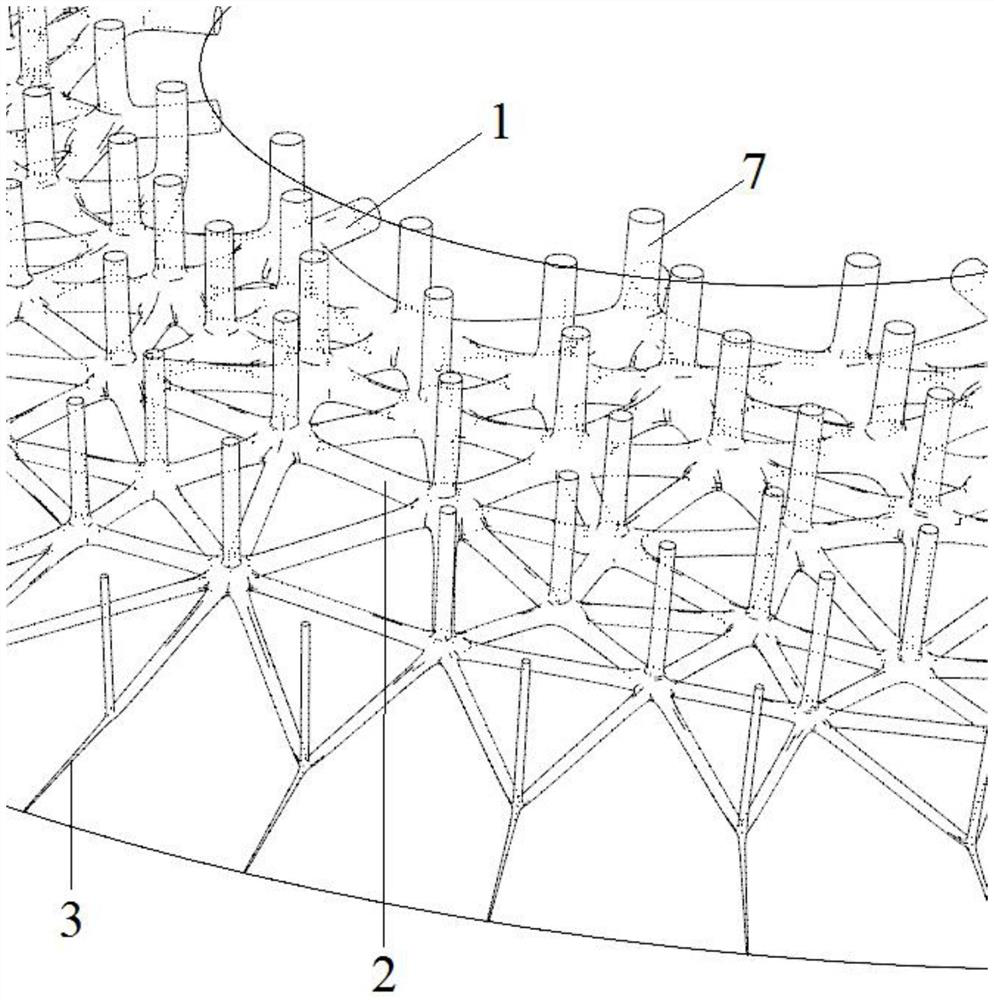

Self-filtering water storage planting auxiliary device

PendingCN110326462AMeet the requirements of ecological environment restorationWith water retentionSelf-acting watering devicesGrowth substratesAridFiltration

The invention discloses a self-filtering water storage planting auxiliary device which comprises a barrel-shaped water storage tank, wherein a plurality of pillars are vertically arranged in the waterstorage tank; the lower ends of the pillars are fixedly connected with the water storage tank; the upper ends of the pillars are fixedly connected with a filter layer; a water delivery channel and acylindrical cultivating device are vertically mounted on the filter layer; the water delivery channel is located in the cultivating device; when the auxiliary device is used, the space enclosed by thecultivating device, the filter layer and the water delivery channel is filled with a nutrient substrate, the nutrition substrate forms a cultivation layer, the top surface of the cultivation layer isa concave surface, and the upper end of the water delivery channel extends outside the top surface of the cultivation layer. The auxiliary device has the functions of water retention, fertilizer conservation, water storage, heat preservation and filtration; after degradation, the auxiliary device can provide required nutrients for subsequent growth of plants, is suitable for vegetation restoration in arid and semi-arid regions of Northwest China, can create stable plant communities, saves a lot of construction costs and maintenance costs, and meets the requirements for bare surface ecologicalenvironment recovery caused by exposed surface and engineering construction in arid and semi-arid regions.

Owner:NORTHWEST RES INST CO LTD OF C R E C

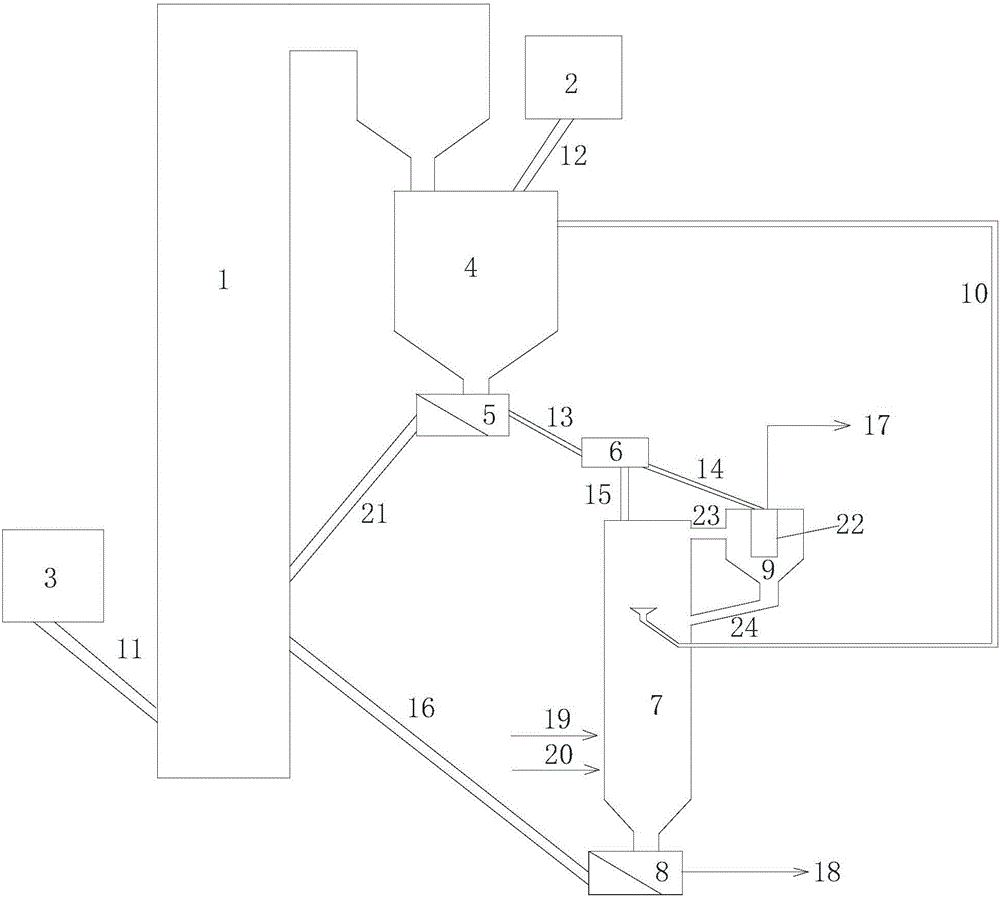

Coal pyrolysis gasification polygeneration device and process based on circulating fluidized bed

InactiveCN103881761BRealize hierarchical optimization utilizationTo solve the purpose of efficient purificationFluidized bed combustionCombustible gas productionElectricityCombustion

The invention discloses a coal pyrolysis gasification poly-generation device and process based on a circulating fluidized bed. A circulating fluidized bed boiler is organically coupled with a moving bed coal pyrolysis reactor and a moving bed gasification furnace, the high temperature circulation ash of the circulating fluidized bed boiler is used as a carrier for pyrolyzing high volatile coal steam coal from a coal funnel in the moving bed coal pyrolysis reactor, the semicoke generated in pyrolysis is separated out from the pyrolysis reactor and is fed into the moving bed gasification furnace for gasification, and at the same time the moving bed gasification furnace is used as a device for purifying a pyrolysis coal gas, thereby achieving the function of on-line dust collection of the pyrolysis coal gas. The gasified activated coke as a byproduct is discharged outside the reaction system. Therefore, through organic combination of three procedures, including pyrolysis, gasification and combustion, graded optimized utilization of the coal resource is achieved, joint production of heat, electricity, tar, coal gas and activated coke is achieved, and meanwhile the purposes of gasifying the coal gas and efficiently purifying the pyrolysis coal gas are achieved.

Owner:SHANXI LUAN MINING GRP +1

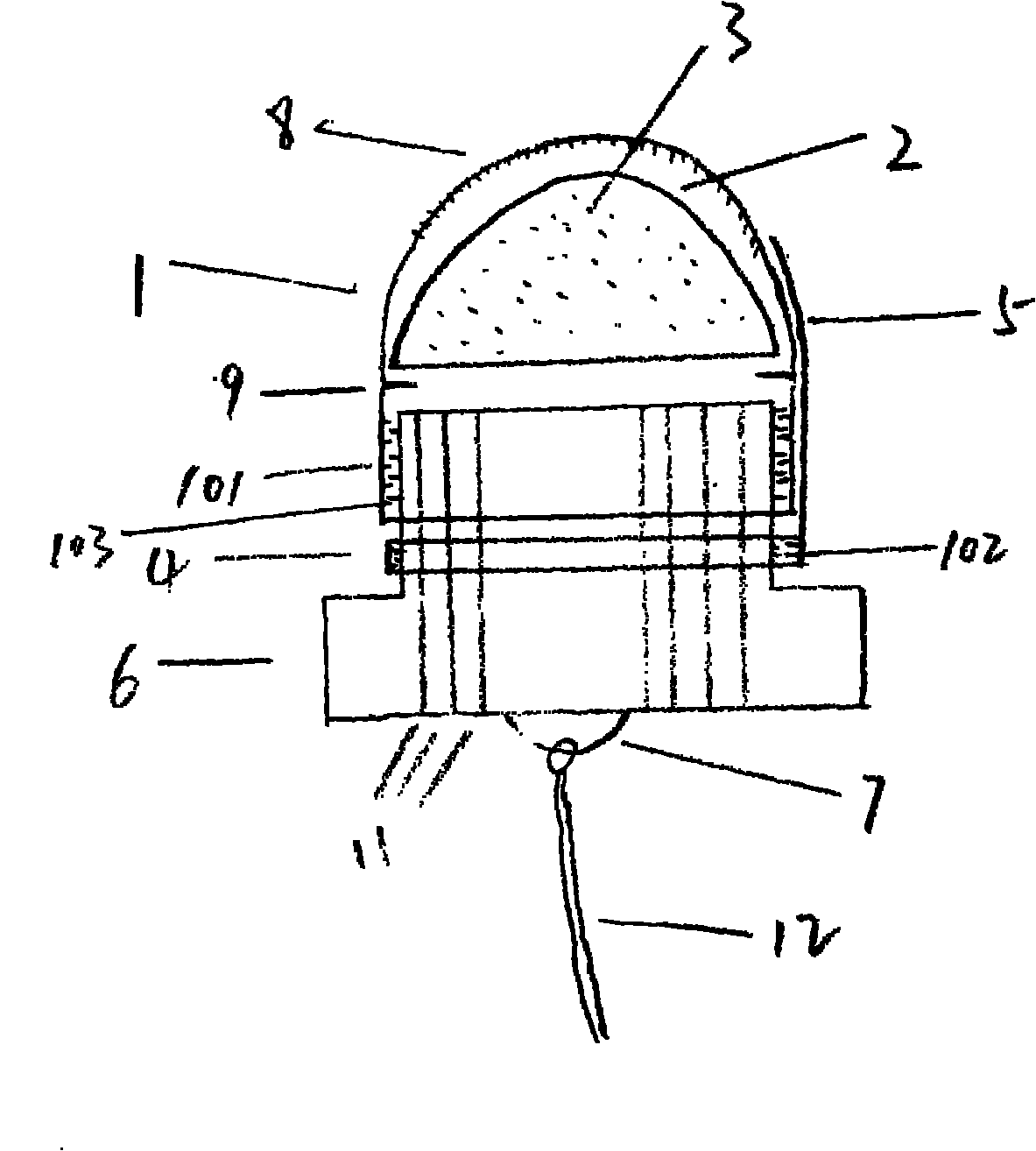

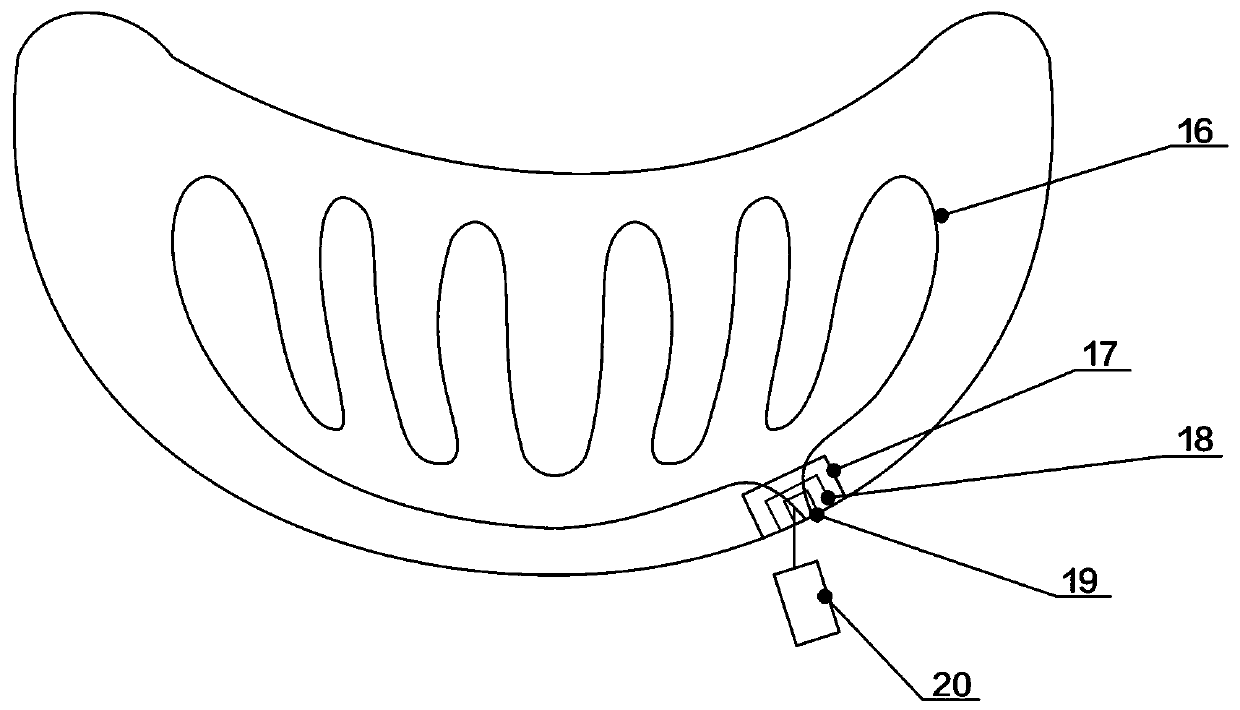

Stuffy nose reliver

The invention aims to provide a stuffy nose reliver which comprises a nasal plug, a filter, a nose clamp, a base and an appendage. The nasal plug is provided with an air hole, provided with a thread at the lower end to be threaded on the base and internally provided with a hollow cavity for storing the filter, the outer surface of the filter is made of an air-permeable material, solid or liquid substances, such as active carbon, nosedrops, and the like can be stored in the filter, the nose clamp is made of a flexible material, connected with the nasal plug by the thread on the base and can fix the nasal plug in the nose, the base is internally provided with a vertical through air hole and provided with a thread at the upper part and a hanging buckle at the bottom end, and the hanging buckle can be connected with a decorative or connective appendage, such as a chain, a rope, and the like. The invention has the advantages of smallness, disguise, convenient use, strong functions of correcting nose shapes, filtering air, treating respiratory diseases, and the like.

Owner:张海峰

Novel protector for preventing and treating coronapneumonia virus in public culture space

InactiveCN111513378AInhibitionReduce the chance of infectionAntiviralsRespiratory disorderHuman healthViral infection

The utility model relates to a protector for preventing and treating novel coronapneumonia virus infection in public culture space, which can effectively block the novel coronapneumonia virus infection and keep breathing smooth so as to protect human health. In order to achieve the purpose, the technical scheme adopted by the embodiment is as follows: the protector for preventing and treating thenovel coronapneumonia virus infection is prepared from traditional Chinese medicinal materials, and comprises a mask consisting of a wrapping layer, an anti-virus layer, an intelligent sterilization system and a belt loop, and a traditional Chinese medicinal material prescription.

Owner:ZAOZHUANG UNIV

Photocatalyst curtain fabric

The invention relates to a photocatalyst curtain fabric, and belongs to the field of textile fabrics. The photocatalyst curtain fabric comprises a curtain fabric body (1), wherein a photocatalyst coating is sprayed on the front surface or the back surface of the curtain fabric body (1); and a plurality of discoid patterns, which are the flower-shaped decorative objects formed by spirally sewing strips of clothes, are formed on the curtain fabric body (1). According to the photocatalyst curtain fabric, the curtain is made of discoid-pattern fabrics, so that the visual aesthetics can be realized; the discoid patterns are three-dimensional, so that a user can feel better by touching, and the curtain is dynamic and gorgeous; the color can be determined according to the requirement on the curtain color; and the curtain fabric is attractive and elegant. The photocatalyst curtain fabric has the effects of shading, insulating heat, filtering ray, proofing ultraviolet ray and purifying harmful gas in the air, so that the fresh and healthy air is provided for a house.

Owner:奚晓莉

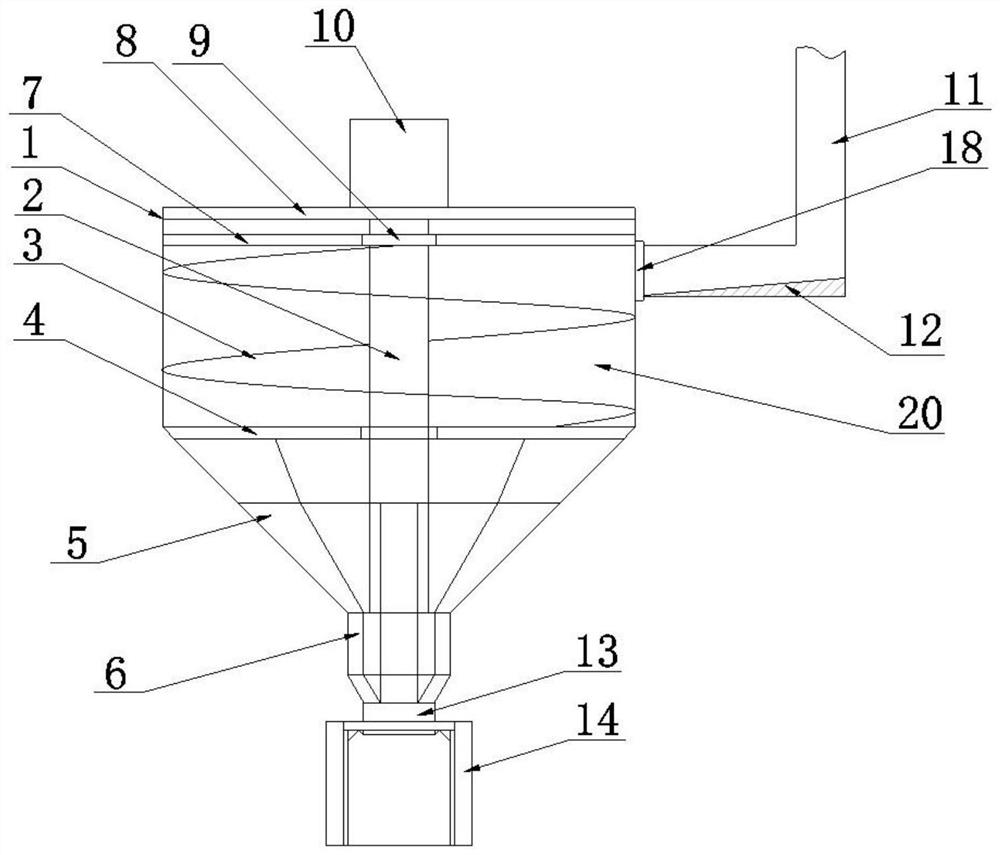

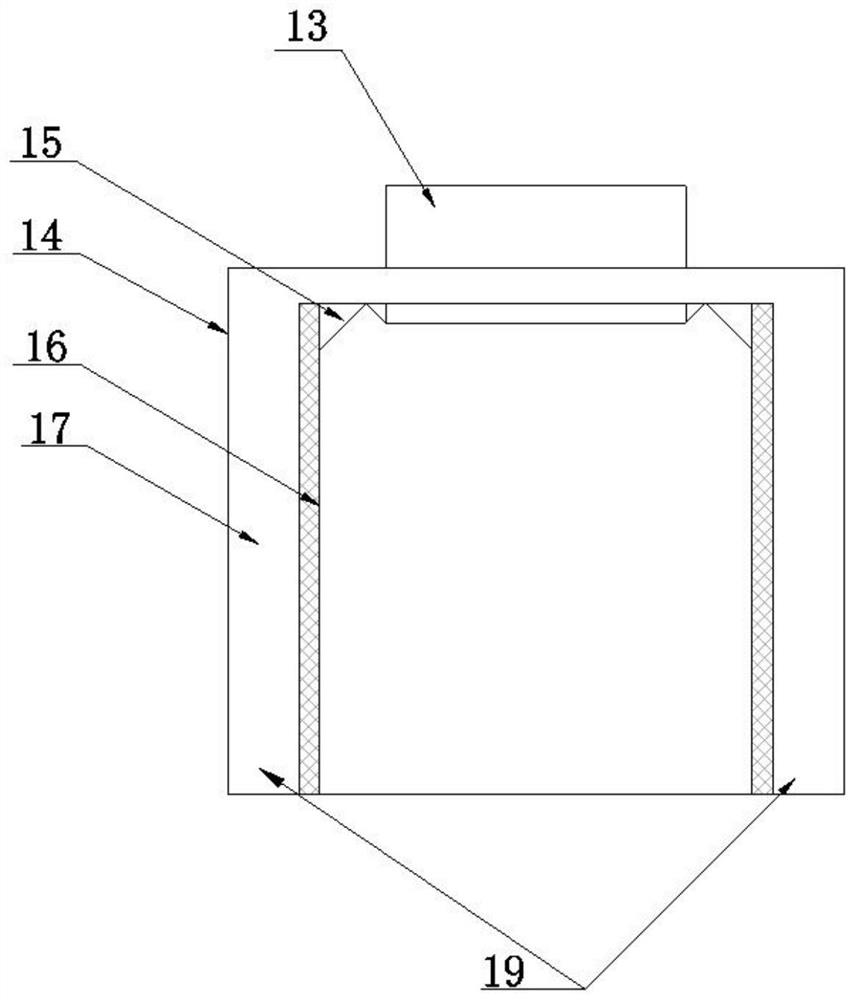

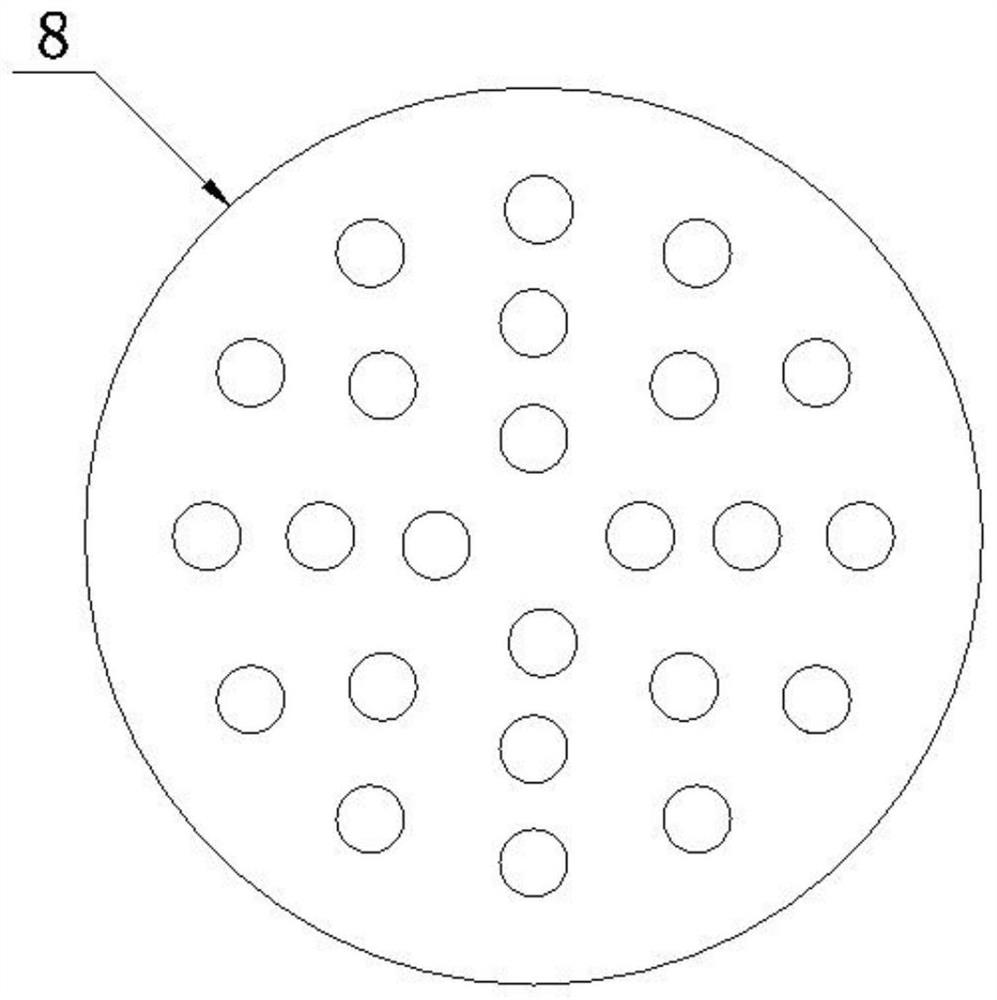

Barium carbonate dustproof feeding device

The invention discloses a barium carbonate dustproof feeding device. The barium carbonate dustproof feeding device comprises a dustproof feeding device body, a storage tank is arranged on the dustproof feeding device body, a discharging rotary vane is arranged on the outer side of a rotary shaft in the center of the interior of the storage tank, a top dust filtering net is arranged at the top of the storage tank, and a pressure reduction exhaust plate is arranged above the top dust filtering net. Exhaust vents in the pressure reduction exhaust plate communicate with one another, a material distributing and discharging hopper is arrange at the bottom end of the storage tank, a connecting mechanism is arrange at the bottom end of the material distributing and discharging hopper, the connecting mechanism can be well connected with a tank body, and when barium carbonate materials are injected, the connecting mechanism can rapidly discharge gas carried in the discharging process; and bariumcarbonate can be prevented from flying out, and the effects of rapid feeding and dust prevention are achieved.

Owner:湖南乐晟新型材料有限公司

Drain device

The invention relates to a drain device, which comprises a body, a top cover assembly and a bottom cover. The body is provided with an inner space, and a plurality of permeable parts running through the inner space. The top cover assembly is separably arranged on the top of the body and comprises a top cover and a plurality of connecting pieces. The connecting pieces extend a certain length from the bottom of the top cover. The bottoms of the connecting pieces are connected with each other. Each connecting piece is provided with an upper elastic sheet and a lower elastic sheet. The upper and lower elastic sheets are provided with corresponding convex parts towards the outside of the top cover. The bottom cover is separably arranged on the bottom of the body. A certain space is formed between the bottom cover and the body. The bottom cover is provided with a permeable part. Due to the combination of the components, an outer edge of each convex part protrudes out of the body and an outer side wall of the bottom cover, and can be applied with a force so that the convex part inwards contracts toward the inside of the top cover, and the convex part can be automatically popped up when the external force is eliminated so that the outer edge of the convex part protrudes out of the body and the outer side wall of the bottom cover again.

Owner:THANK GOD ENTERPRISE

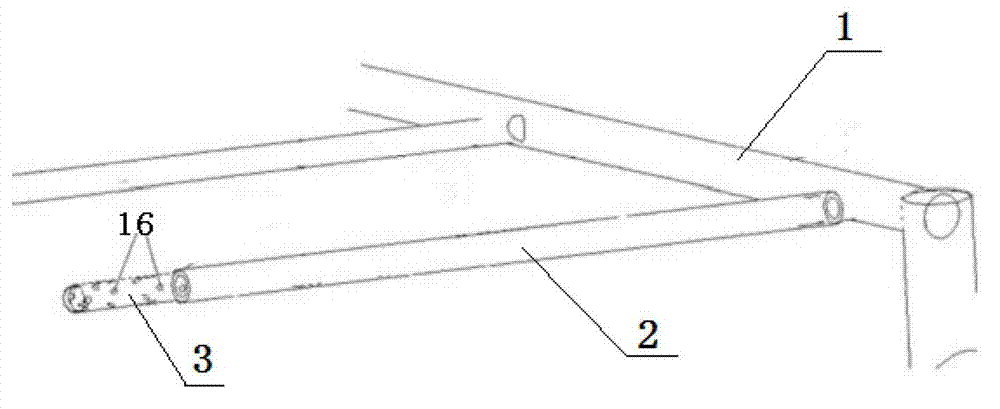

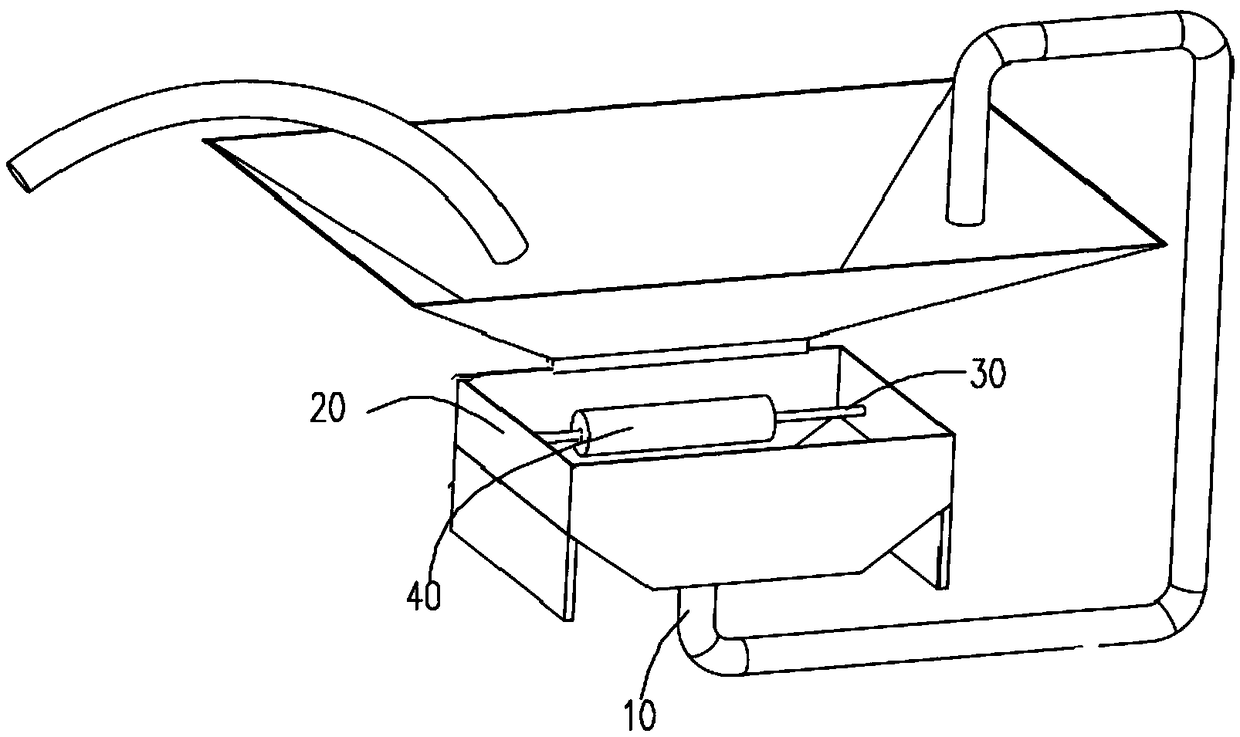

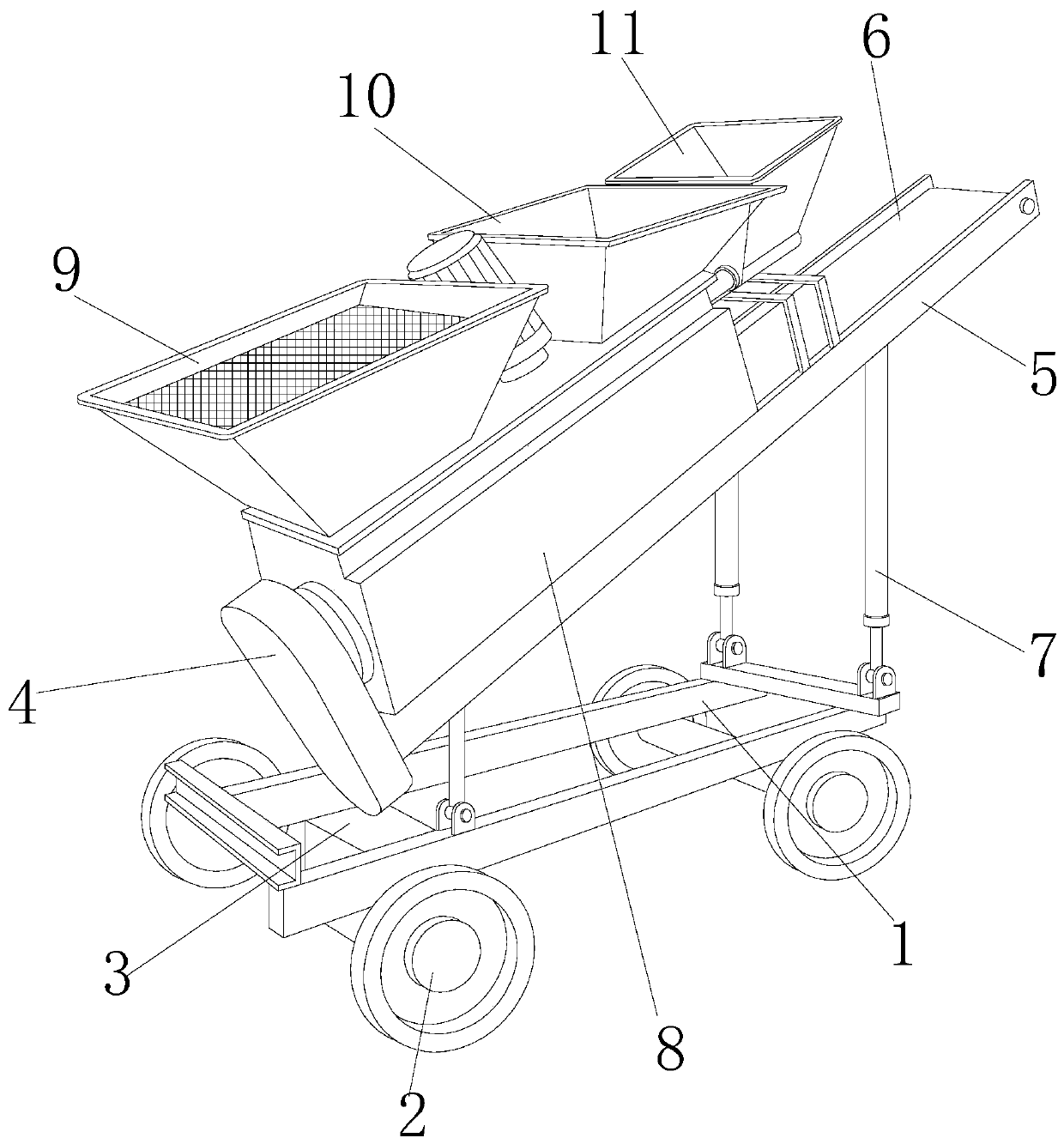

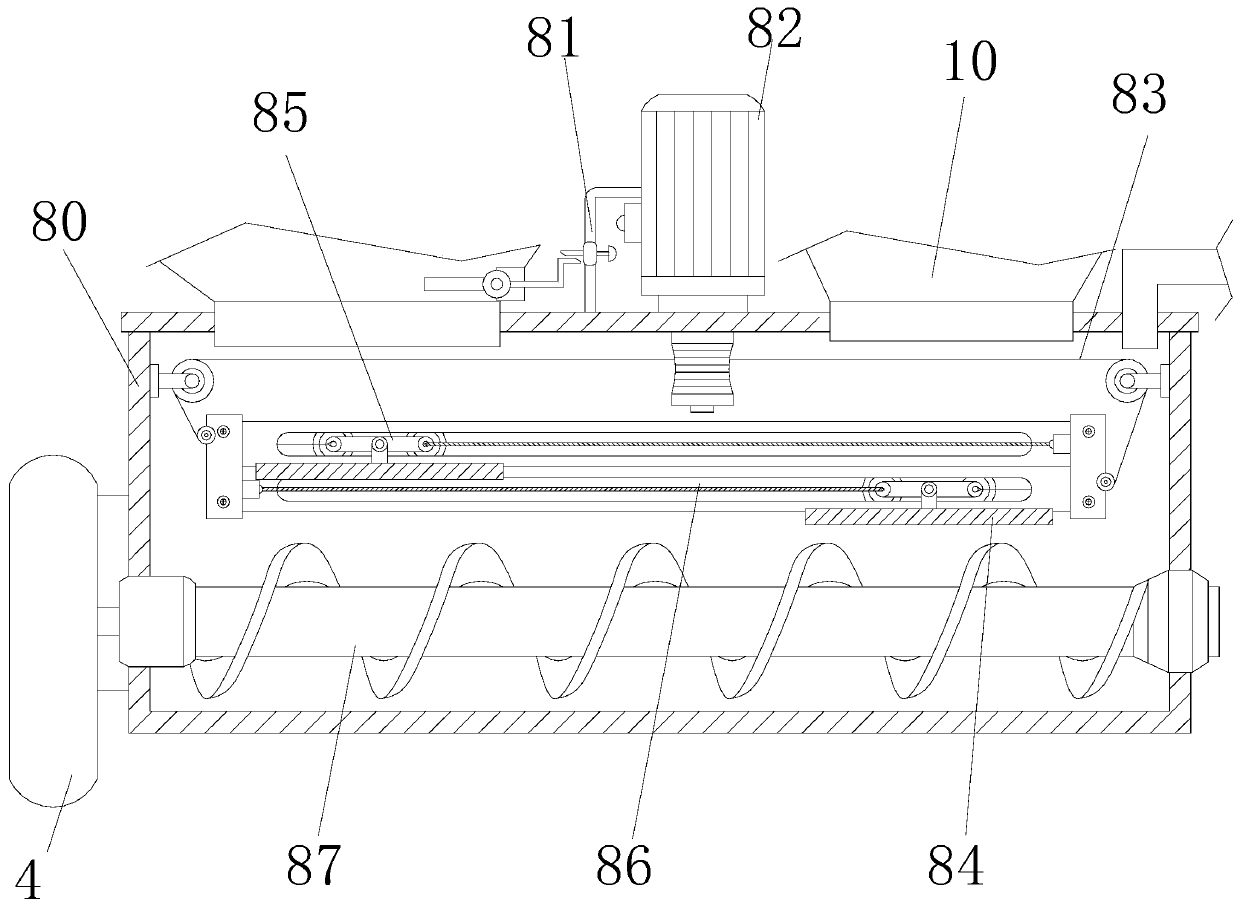

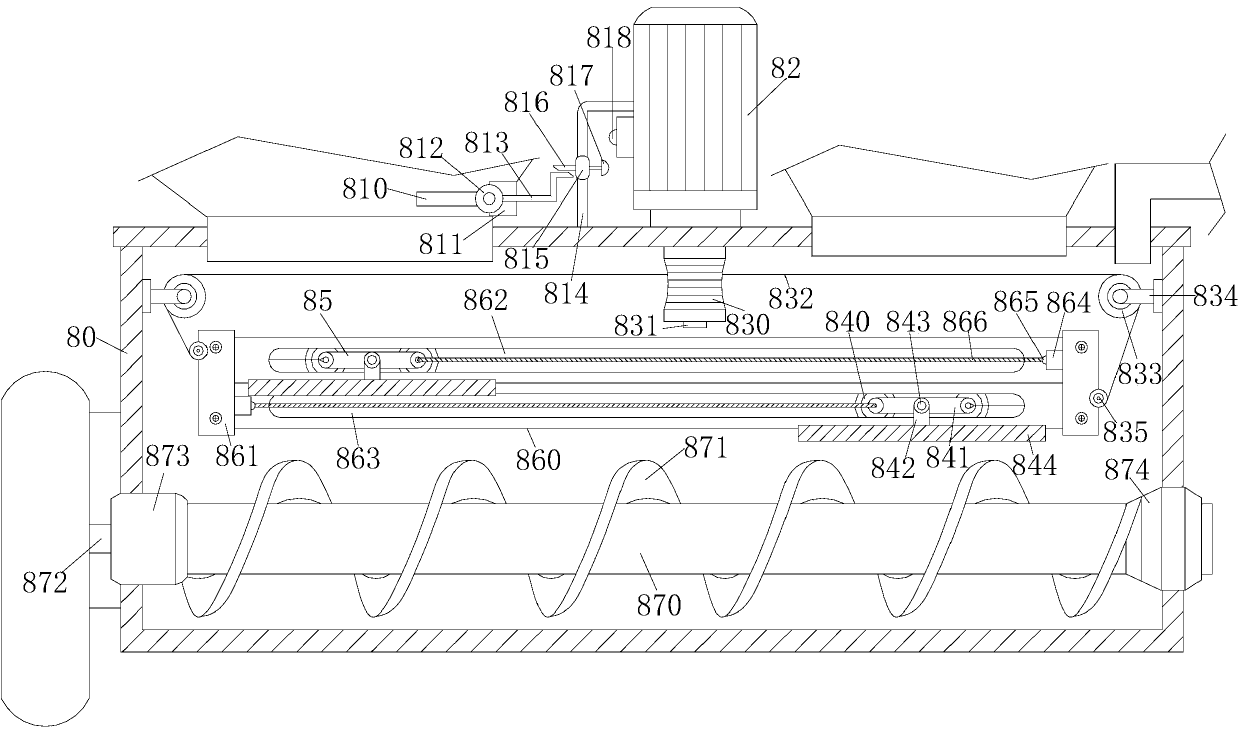

A Multifunctional Concrete Conveying Device

ActiveCN108657763BWith filterEfficient mixingSupporting framesMechanical conveyorsClassical mechanicsHydraulic pressure

The invention discloses a multifunctional concrete conveying device, the structure of which comprises a supporting base frame, moving rollers, a motor box, a power transmission device, a concrete conveying table, a conveying belt, an angle-adjusting hydraulic rod, a high-efficiency mixing conveying device, and sand and gravel filter Feeding hopper, cement feeding hopper, additive feeding hopper, moving rollers are set at the four ends below the supporting chassis and their axles are fixedly connected with the supporting chassis through electric welding, and the motor box is set inside the supporting chassis and meshed with the power transmission device , The concrete conveying platform is arranged on the top of the support chassis in an inclined shape and is flexibly connected through the angle adjustment hydraulic rod. The invention realizes that the concrete conveying device has the functions of filtering, high-efficiency mixing and stirring, and conveying at the same time by providing a high-efficiency mixing and conveying device, realizes multi-functionality, and combines multiple processes required for concrete preparation into one, effectively improving the working efficiency of the device.

Owner:常熟市宇隆混凝土有限公司

A kind of production method of conductive geotextile

The invention relates to a production method, in particular to a method for producing conductive geotextile. The method for producing the conductive geotextile comprises the steps of raw material selection, raw material screening, drying, fusion, spinning, cross air blow cooling, airflow drafting, swinging, net laying, mixed even feeding of metal fibers, carbon fibers and other short fibers, ironing conducted by a hot roller, shaping conducted by a pre-needle machine, reinforcing shaping conducted by a first main needle machine, repair shaping conducted by a second main needle machine, cloth containing conducted by a cloth containing machine, trimming and rolling. The geotextile produced according to the method for producing the conductive geotextile has the protective performance, the isolating performance, the waterproof performance, the filtering performance and the like of traditional geotextile, further has the conductive characteristic and is a good electrode material. According to the method for producing the conductive geotextile, the production technology is stable, control over the thickness of a material is good, the control range of the puncture density is large and is 50 to 500 stitches / cm<2>, the controllable range of the permeability performance of the material is large and is (1.0-9.9)*(10<-1>-10<-3>)cm / s, the strength of the product is high, and the thickness reaches 20mm.

Owner:大连格尔迈斯合成材料有限公司

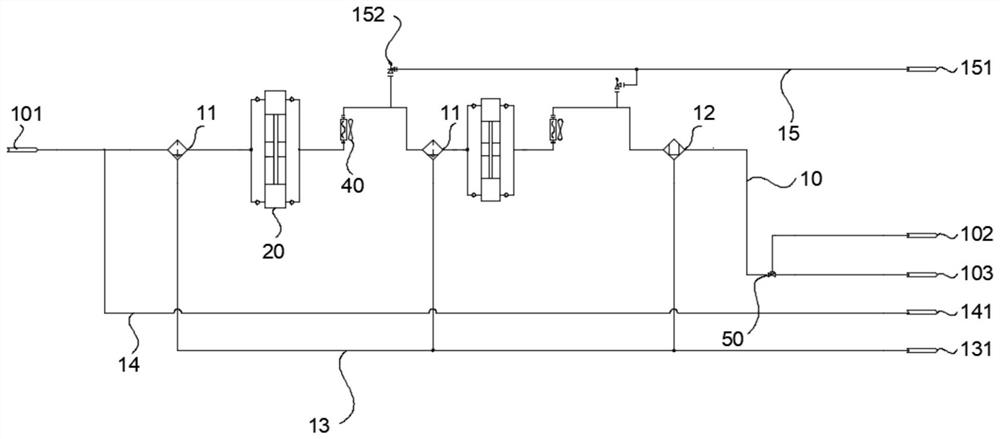

Natural gas hydraulic compressor

ActiveCN112855511AImprove adaptabilityImprove energy savingInternal combustion piston enginesPositive displacement pump componentsHydraulic cylinderPetroleum engineering

The invention discloses a natural gas hydraulic compressor. The natural gas hydraulic compressor comprises a natural gas pipeline; the natural gas pipeline comprises a main pipeline; one end of the main pipeline is connected with a gas inlet, the other end of the main pipeline is connected with a plurality of gas outlets, at least one gas outlet is a high-pressure gas outlet, and at least one gas outlet is a medium-pressure gas outlet; a plurality of hydraulic cylinders are connected to the main pipeline; ball valves are arranged at the gas outlets of the main pipeline; and an air cooler is further arranged on the main pipeline. According to the technical scheme, the natural gas hydraulic compressor has the advantages that the performance of the natural gas compressor for a substation can be improved through the overall design, the adaptability can be enhanced, the energy-saving effect is better, the overall arrangement is reasonable, the structure is more compact, and the energy-saving performance is more excellent.

Owner:ZIGONG TONGDA MACHINERY MFG

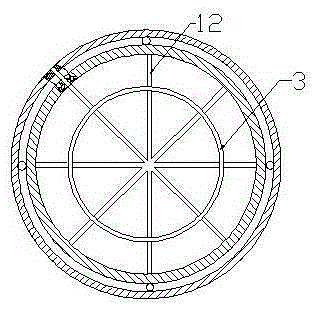

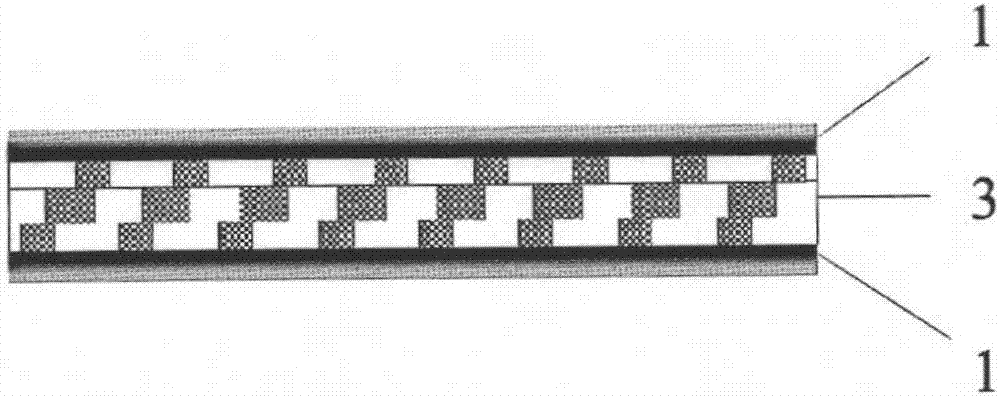

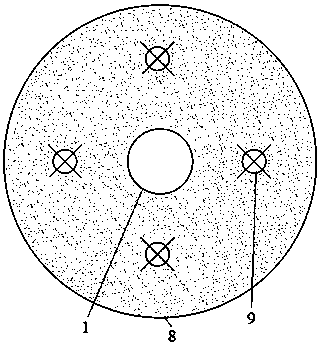

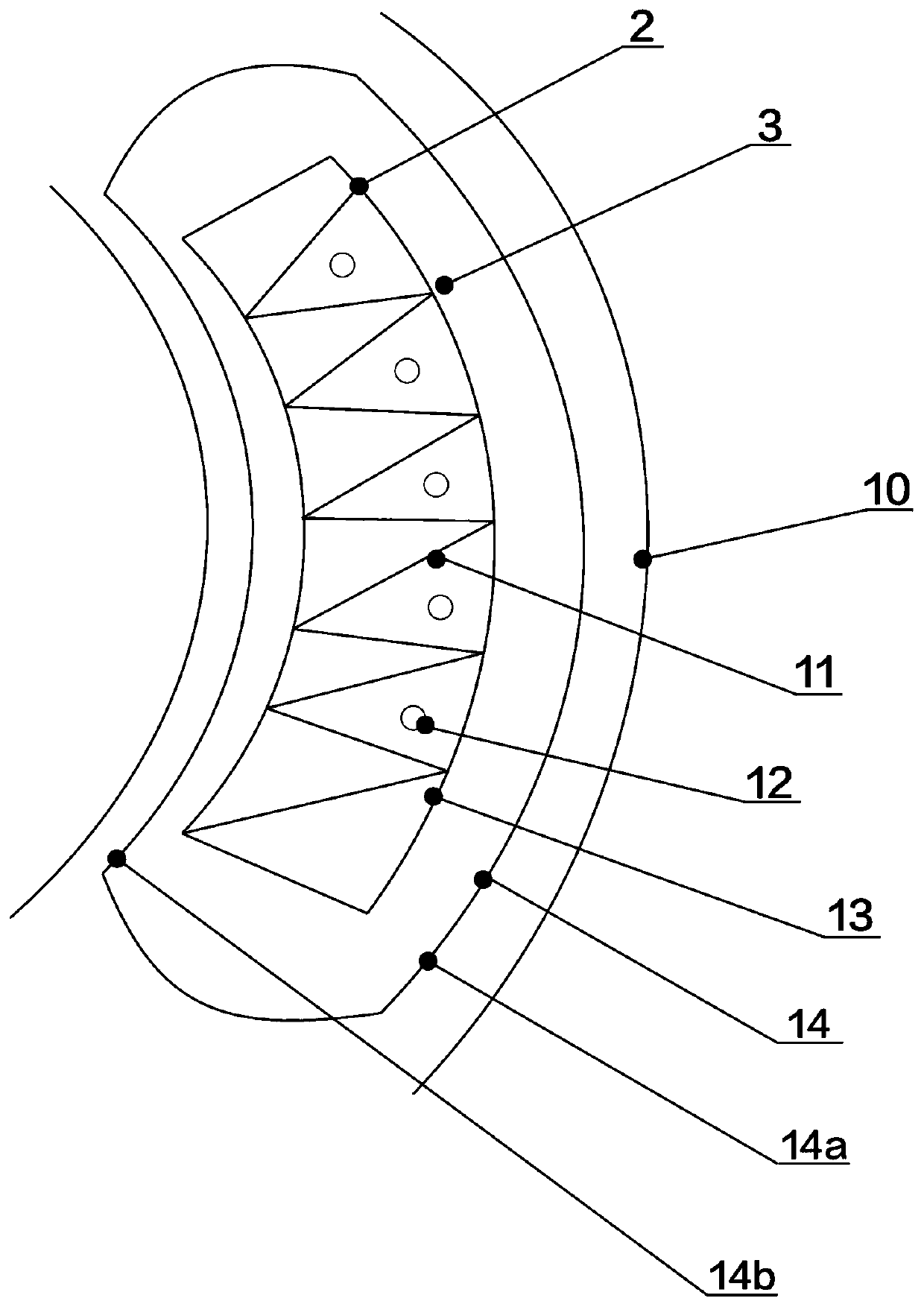

Pipeline capable of being pre-buried in rare earth dump leaching field

ActiveCN113444881AMeet leaching needsWith filterProcess efficiency improvementSoil scienceFiltration

The invention discloses a pipeline capable of being pre-buried in rare earth dump leaching field. The pipeline is characterized in that the pipeline comprises a pipeline body, a three-dimensional hole net is arranged in the pipe wall of the pipeline body, and the three-dimensional hole net comprises a plurality of layers of transverse hole channel nets arranged at intervals in the axial direction of the pipeline body; the transverse hole channel nets comprise inner water seepage hole channel nets, middle hole channel nets and outer water seepage hole channel nets which are sequentially distributed from inside to outside; the inner water seepage hole channel nets comprise a plurality of inner water seepage holes which are evenly distributed in the circumferential direction of the pipeline body, one end of each inner water seepage hole communicates with the corresponding middle hole channel net, and the other ends of the inner water seepage holes are arranged on the inner wall of the pipeline body; the outer water seepage hole channel nets comprise a plurality of outer water seepage holes which are evenly distributed in the circumferential direction of the pipeline body, one end of each outer water seepage hole communicates with the corresponding middle hole channel net, and the other ends of the outer water seepage holes are arranged on the outer wall of the pipeline body; and the hole diameter of the inner water seepage holes, the hole diameter of hole channels in the middle hole channel nets and the hole diameter of the outer water seepage holes are gradually increased from the outer wall of the pipeline body to the direction close to the inner wall of the pipeline body. The pipeline has the functions of being capable of achieving reverse filtration and drip infiltration and not prone to blockage.

Owner:NANCHANG UNIV

A pipeline that can be pre-buried in a rare earth heap leaching field

ActiveCN113444881BMeet leaching needsWith filterProcess efficiency improvementFiltrationHeap leaching

The invention discloses a pipeline that can be pre-buried in a rare earth heap leaching field, which is characterized in that it comprises a pipeline, and a three-dimensional hole network is arranged in the pipe wall of the pipeline, and the three-dimensional hole network includes several layers spaced along the axial direction of the pipeline Arranged transverse pore network, the transverse pore network includes the inner seepage pore network, the middle pore network and the outer seepage pore network distributed sequentially from the inside to the outside. The inner seepage holes connected by the channel network, the other end of the inner seepage hole is arranged on the inner wall of the pipeline, and the outer seepage water channel network includes a plurality of outer seepage water holes uniformly distributed along the circumference of the pipeline, one end of which is connected to the middle channel network, and the outer seepage water hole The other end of the hole is arranged on the outer wall of the pipeline; the apertures of the inner seepage holes, the apertures of the middle channel network and the outer seepage holes all gradually increase from the outer wall of the pipeline to the inner wall of the pipeline. The invention has the functions of reverse filtration, drip seepage and not easy to block.

Owner:NANCHANG UNIV

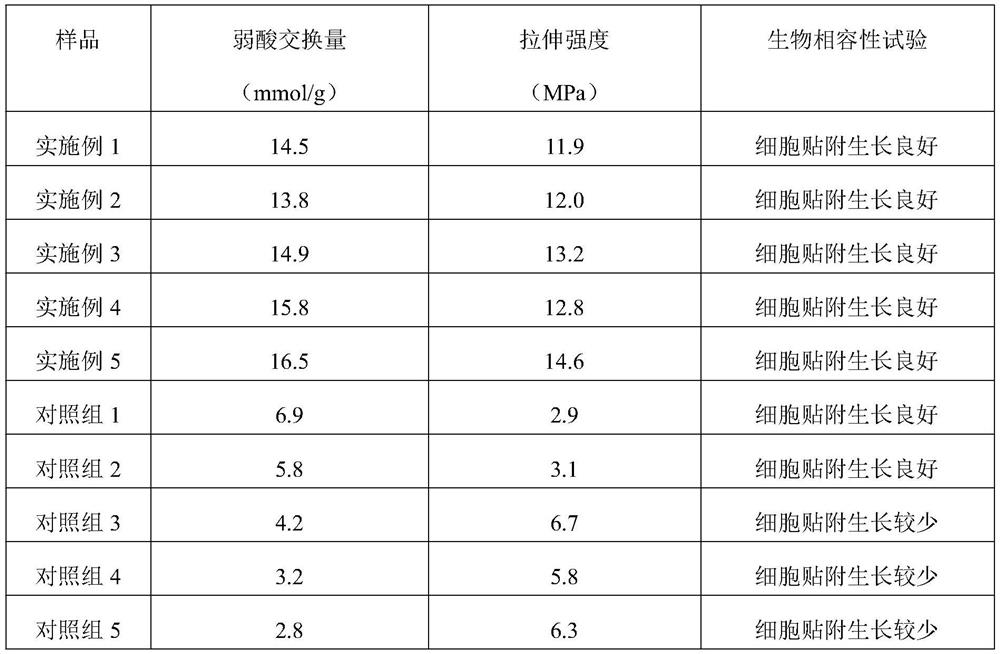

A biocompatible heterogeneous ion exchange membrane material and its preparation method

ActiveCN108912276BGood biocompatibilityEasy to makeSemi-permeable membranesMembranesMicro nanoBenzoyl peroxide

The invention relates to a biocompatible heterogeneous ion exchange membrane material and a preparation method thereof, which solves the technical problems of low mechanical performance and poor biocompatibility of the heterogeneous ion exchange membrane in the prior art. The invention provides a biocompatible heterogeneous ion exchange membrane material, which is made of the following raw material components in parts by weight: 20-50 parts of biopolymer material, 80-100 parts of methacrylic acid, cross-linked 80-100 parts of dispersant, 0.5-2 parts of dispersant, 20-50 parts of silica gel, 0.5-2 parts of benzoyl peroxide, 20-40 parts of micro-nano bioactive glass, 20-50 parts of zeolite powder; biopolymer materials It is any one of polylactic acid, polycaprolactone and polylactic-co-glycolic acid copolymer; meanwhile, its preparation method is also provided. The invention is widely used in the field of ion exchange membrane materials.

Owner:HARBIN INST OF TECH -WEIHAI INNOVATION PARK WEIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com