Material stirring device for compound fertilizer production

A compound fertilizer and material inlet technology, applied to mixers, mixer accessories, transportation and packaging, etc., can solve the problems of poor cushioning performance, single function, simple structure, etc., and achieve convenient maintenance, diversified functions, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

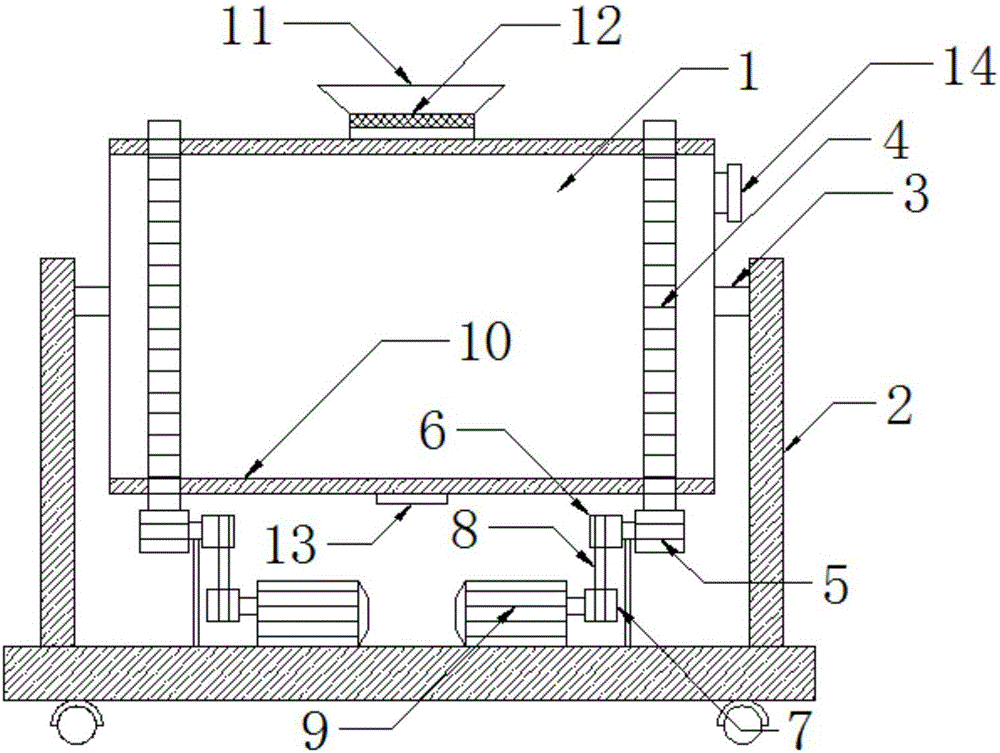

[0017] Such as figure 1 As shown, a kind of mixing device for compound fertilizer production of the present invention comprises a mixing drum 1, a workbench 2, a rotating shaft 3, a ring gear 4, a gear 5, a driven wheel 6, a driving wheel 7, a transmission belt 8, and a servo motor 9 , Infrared heating lining plate 10, material inlet 11, vibrating screen 12, material outlet 13, exhaust valve 14;

[0018] The two ends of the mixing drum 1 are set on the support of the workbench 2 through the rotating shaft 3, and a sealing pair is arranged between the rotating shaft 3 and the stirring drum 1;

[0019] The outer side of the mixing drum 1 is provided with a ring gear 4, the ring gear 4 is meshed with the gear 5, the gear 5 is connected with the driven wheel 6 through the connecting shaft, and the driven wheel 6 is connected with the driving wheel 7 driven by the servo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com