Functional composite face fabric and producing method thereof

A composite fabric and functional technology, applied in the field of textile and clothing, can solve the problems of inability to absorb electromagnetic waves, poor air permeability, poor washability, and enhanced electromagnetic radiation, and achieve the effect of meeting special protection and wearing requirements and flexible and diverse preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

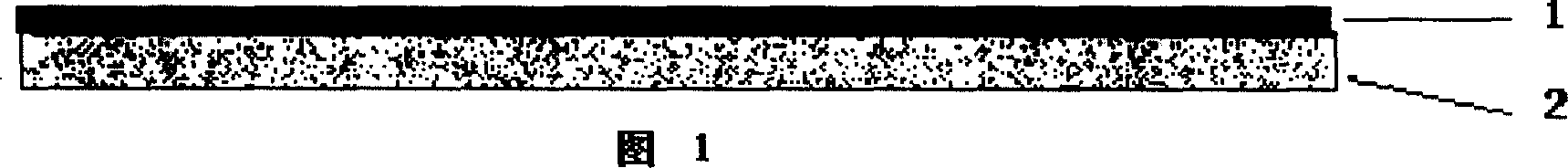

[0028] The preparation method of the novel functional composite fabric is characterized in that it is prepared through the following steps:

[0029] Step 1: Use at least one kind of existing fiber raw material and at least one kind of functional particles to blend and then process through electrospinning process or non-woven process to prepare functional fiber layer 1 or add functional particles in the ordinary spinning process to make The functional fiber layer 1 is obtained by attaching to the fiber;

[0030] The fiber raw material adopts synthetic or recycled raw materials such as: polyolefin, polychlorinated olefin, polyester, polyether, polyamide, polyanhydride, polyvinyl alcohol, polyacrylonitrile, polylactic acid, amino acid, epoxy resin or Natural raw materials such as: natural cellulose fiber, silk, soybean fiber, milk fiber, animal fur, spider silk or inorganic materials such as: aluminum, copper, silver, glass, ceramics;

[0031] The functional particles are carbon...

Embodiment 1

[0042] Preparation method of new functional composite fabric:

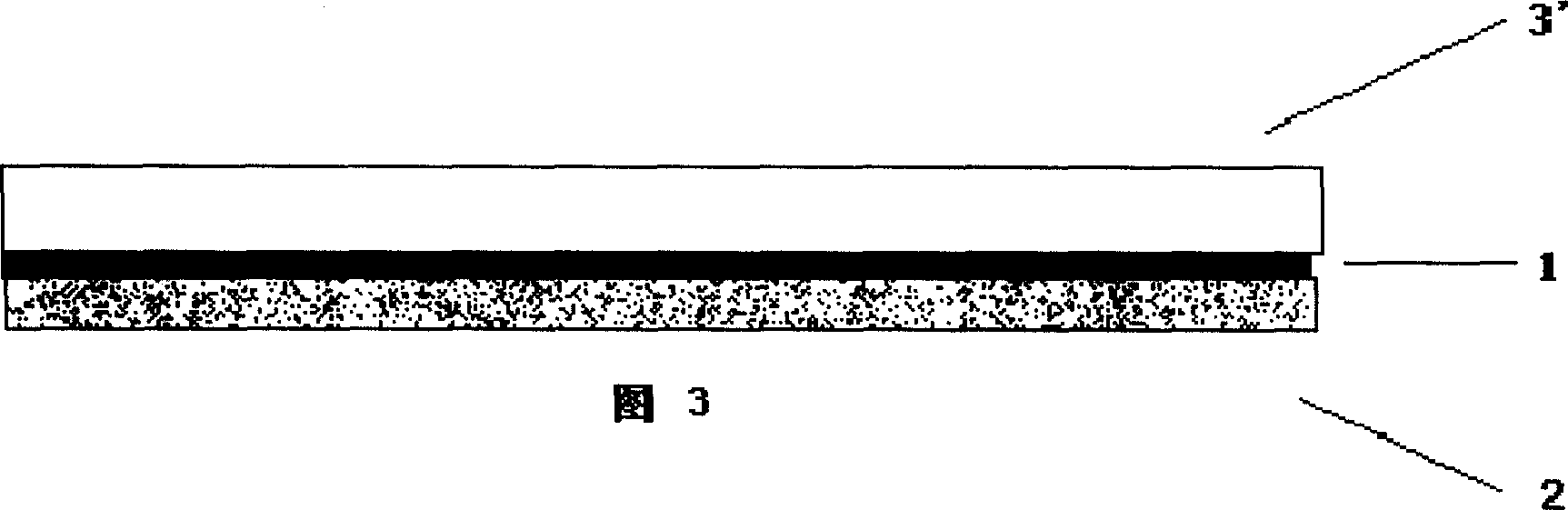

[0043] Step 1: The polyester fiber raw material with a mass percentage of 65, and the single-walled carbon nanotubes with a mass percentage of 35 are blended and then processed through an electrospinning process to obtain a functional fiber layer 1;

[0044] Step 2: using polyacrylonitrile fibers to prepare the attached base layer 2 through a conventional melt-blown non-woven process;

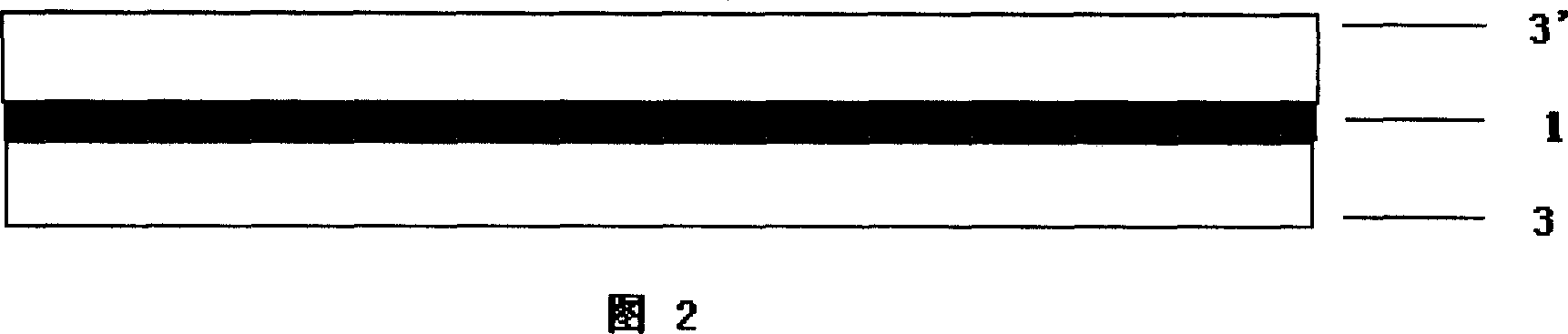

[0045] Step 3: (a) using cotton fibers to produce the lower fabric 3 through conventional spinning and weaving techniques;

[0046] (b) The upper layer fabric 3' is processed through conventional spinning and weaving techniques using polyester fibers;

[0047] Step 4: The functional fiber layer 1, the attached base layer 2, the upper fabric 3', and the lower fabric 3 prepared above are bonded together through the chemical auxiliary glue nitrile latex, and finally a new functional composite fabric is obtained.

[0048] This new fu...

Embodiment 2

[0050] Preparation method of new functional composite fabric:

[0051] Step 1: The polyester fiber raw material with a mass percentage of 80, and the nano-silver particles with a mass percentage of 20 are blended and then processed by an electrospinning process to obtain a functional fiber layer 1;

[0052] Step 2: Adhesive base layer 2 prepared by using viscose fiber raw materials through a conventional spunlace nonwoven process;

[0053] Step 3: the upper fabric 3' produced by conventional spinning and weaving processes using polyamide fiber raw materials;

[0054]Step 4: Combine the functional fiber layer 1 and the attachment base layer 2 prepared above through the acupuncture process, and combine the upper fabric 3' with the functional fiber layer 1 through the chemical auxiliary glue chitin adhesive to obtain New functional composite fabric.

[0055] This new type of functional composite fabric has the functions of antibacterial, sterilizing, and filtering viruses. It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com