Residual heat removal facility for spent fuel shipping flask

A transport container and waste heat discharge technology, which is applied to portable protective containers, nuclear engineering, etc., can solve the problems of nuclear power plants shutting down, inoperability, and complex equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

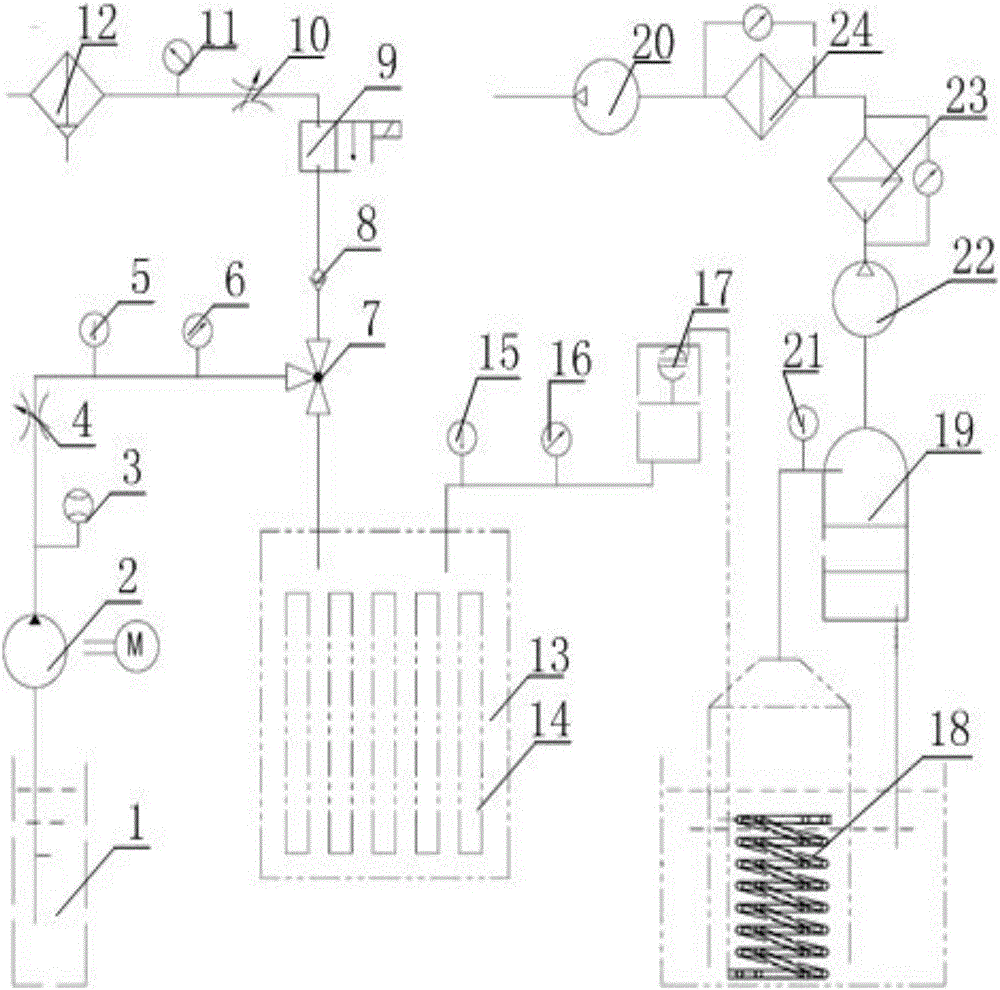

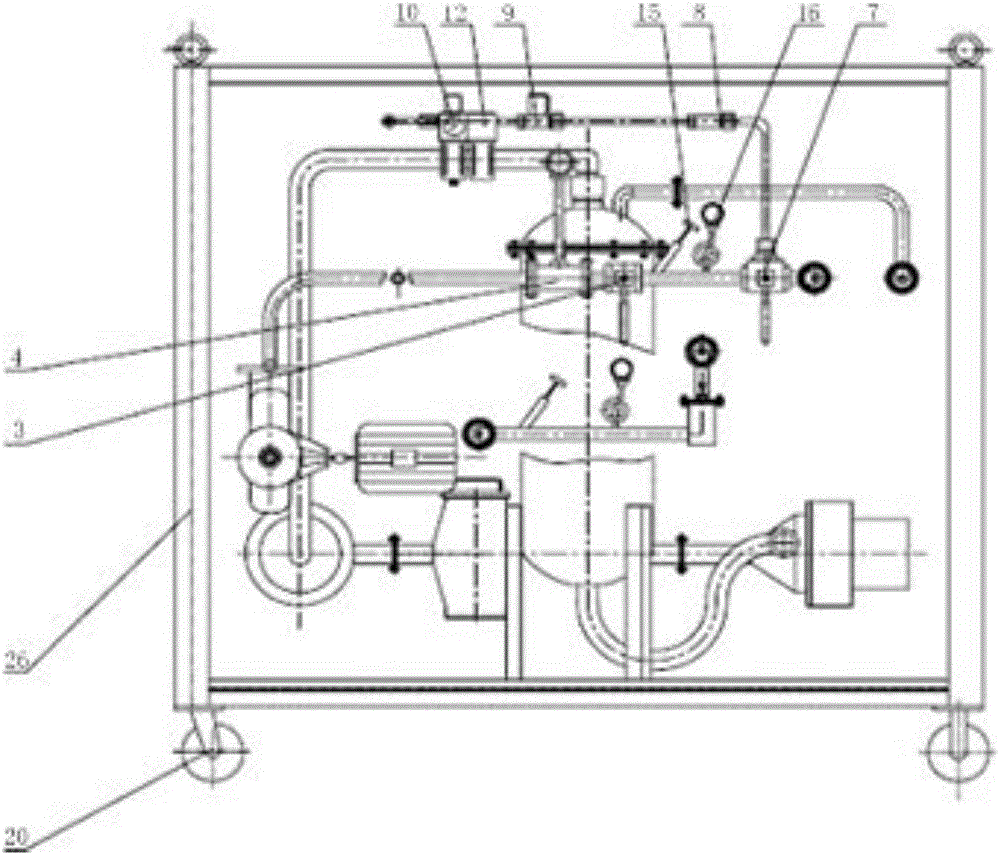

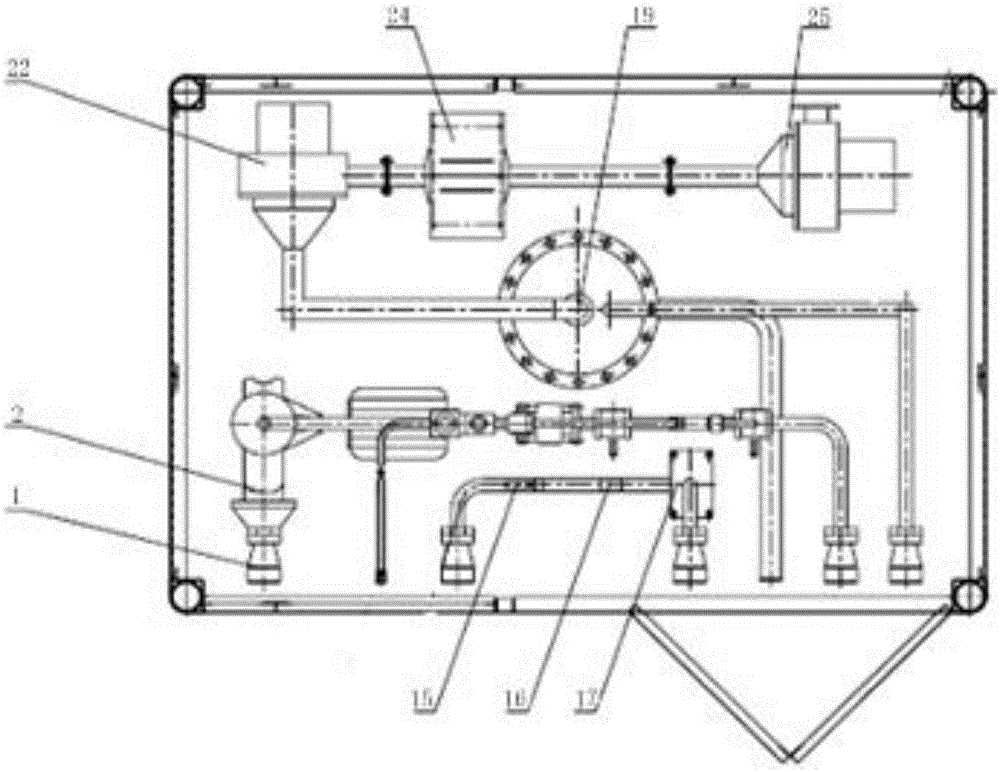

[0053] Such as Figure 1 to Figure 6 As shown, a waste heat removal device for a spent fuel transportation container is characterized by: comprising a water filling circuit, a charging circuit, a gas-water discharge circuit, a gas-water separator 19, an exhaust circuit, and the water charging circuit and the charging circuit share a tee After the valve 7 is connected with the gas-water discharge circuit, the gas-water discharge circuit is connected with the cooling system, and the cooling system is connected with the gas-water separator and then connected with the exhaust circuit;

[0054] The cooling system includes an immersed heat exchanger 18, which is located in the water storage device. The lower end of the heat exchange tube in the immersed heat exchanger 18 is connected to the air-water discharge circuit through a pipeline, and the upper end of the heat exchange tube is connected to The water holding device is connected, and the water holding device is connected to the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com