A biocompatible heterogeneous ion exchange membrane material and its preparation method

A technology of biocompatibility and ion exchange membrane, which is applied in the field of heterogeneous ion exchange membrane materials and its preparation, can solve the problems of poor biocompatibility and low mechanical properties, and achieve stable performance, low cost and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

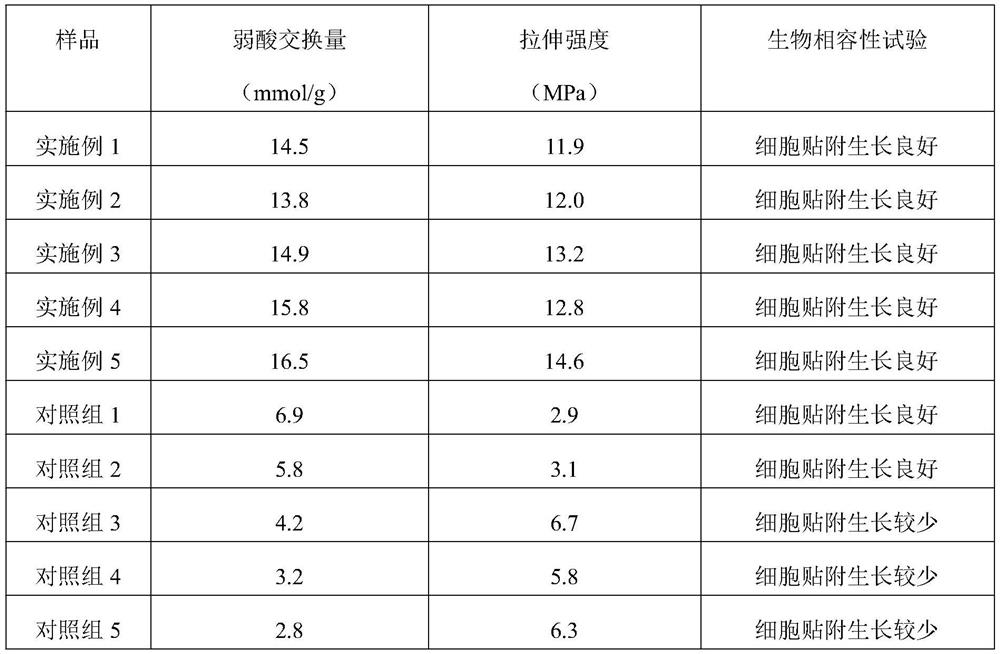

Examples

Embodiment 1

[0026] The preparation of a biocompatible heterogeneous ion exchange membrane material comprises the following steps:

[0027] (1) Weigh 20 parts of biopolymer polylactic acid, 80 parts of methacrylic acid, 80 parts of cross-linking agent divinylbenzene, 0.5 parts of dispersant polyvinyl alcohol, 20 parts of silica gel, benzene peroxide, etc. according to the required parts by weight. 0.5 part of formyl, 20 parts of micro-nano 45S5 bioactive glass, 20 parts of zeolite powder; the particle size of silica gel is 100 μm, the particle size of micro-nano bioactive glass is 100 nm; the particle size of zeolite powder is 80 nm.

[0028] (2) Add the biopolymer material, bioactive glass and zeolite powder weighed in step (1) into the organic solvent tetrahydrofuran which is 3 times the weight of the biopolymer material and heat and stir at 65°C until completely dissolved to obtain the biopolymer material mixture solution.

[0029] (3) Add the dispersant weighed in step (1) into water ...

Embodiment 2

[0032] The preparation of a biocompatible heterogeneous ion exchange membrane material comprises the following steps:

[0033] (1) Weigh 50 parts of biopolymer material polycaprolactone, 100 parts of methacrylic acid, 100 parts of crosslinking agent ethylene glycol methacrylate, 2 parts of dispersing agent sodium chloride, silica gel according to the required parts by weight. 50 parts, benzoyl peroxide 2 parts, micronano 45S5 bioactive glass 40 parts, zeolite powder 50 parts. The particle size of the silica gel is 500 μm, the particle size of the micro-nano bioactive glass is 500 nm; the particle size of the zeolite powder is 250 nm.

[0034] (2) Add the biopolymer material, bioactive glass and zeolite powder weighed in step (1) into the organic solvent chloroform which is 3 to 5 times as much as the biopolymer material, and heat and stir at 65 to 85°C until completely dissolved, A biopolymer material mixture solution was obtained.

[0035] (3) After dissolving the dispersan...

Embodiment 3

[0038] The preparation of a biocompatible heterogeneous ion exchange membrane material comprises the following steps:

[0039] (1) Take by weighing 30 parts of biopolymer material poly(lactic-co-glycolic acid copolymer), 82 parts of methacrylic acid, 85 parts of crosslinking agent divinylbenzene, 1 part of dispersing agent gelatin, 30 parts of silica gel, 1 part of benzoyl oxide, 25 parts of micro-nano 45S5 bioactive glass, 25 parts of zeolite powder. The particle size of the silica gel is 400 μm, the particle size of the micro-nano bioactive glass is 300 nm; the particle size of the zeolite powder is 150 nm.

[0040](2) Add the biopolymer material, bioactive glass and zeolite powder weighed in step (1) into acetone, an organic solvent that is 4 times as much as the biopolymer material, and heat and stir at 70°C until completely dissolved to obtain a biopolymer material mixture solution.

[0041] (3) Add the dispersant weighed in step (1) into water 10 times its weight and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com