Method for preparing polypropylene fiber earthwork cloth composite drainage net having anti-filtration drainage function

A technology of geotextiles and drainage nets, applied in non-woven fabrics, stretch spinning, rayon manufacturing, etc., can solve the problems of unfavorable stability of roadbed structure, high water content of roadbed soil, and reduced bearing performance of roadbed, etc. High strength, good wicking effect, and the effect of improving load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

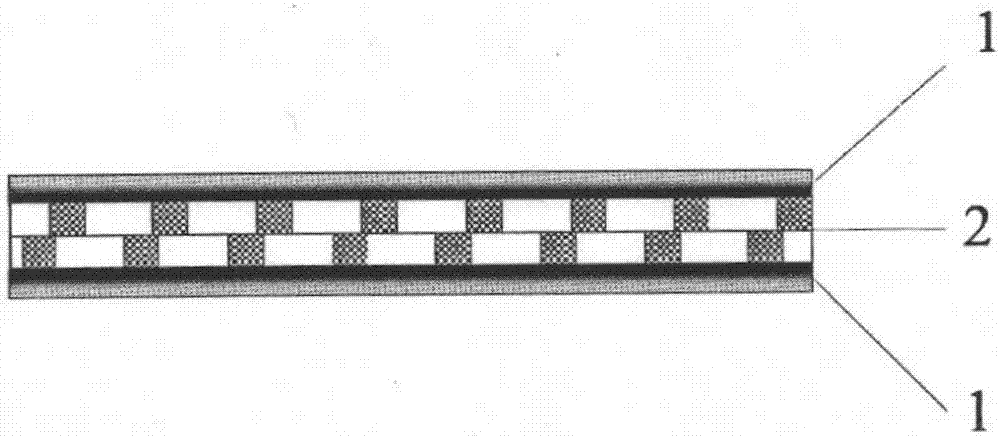

[0030] Such as figure 1 As shown, a polypropylene geotextile composite drainage network with reverse filtration and drainage function is composed of upper and lower layers of geotextile 1 and a layer of two-dimensional geotextile core 2. The preparation method is as follows:

[0031] The first step: The high-strength coarse-denier polypropylene geotextile is prepared by spunbonding and needle-punching. The polymer used is isotactic polypropylene with a high melt index, the melt index is 20g / 10min, and the weight-average molecular weight is 35W; the raw material group Points are recorded in weight fractions, high melt index isotactic polypropylene chips 100 parts, antioxidant 1 part, hindered amine light stabilizer Tinuvin7700.5 parts, benzophenone UV absorber C810.5 parts, PP cooling mother Granules A-4903 parts, wherein the antioxidant is prepared by compounding antioxidant 1010 and antioxidant 168, and the compounding ratio is 7:3; the raw materials are evenly mixed and pour...

Embodiment 2

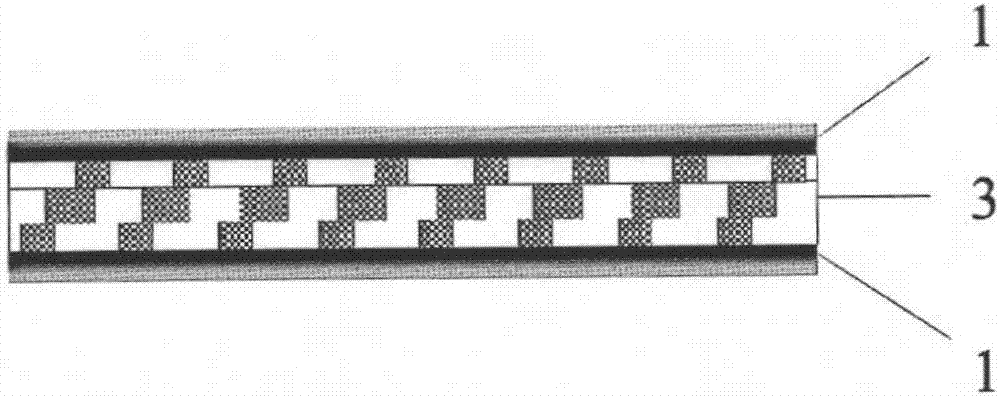

[0035] Such as figure 2 As shown, a polypropylene geotextile composite drainage network with reverse filtration and drainage function is composed of upper and lower layers of geotextile 1 and a layer of three-dimensional geotextile core 3, and its preparation method is as follows:

[0036] The first step: The high-strength coarse-denier polypropylene geotextile is prepared by spunbonding and needle-punching. The polymer used is isotactic polypropylene with a high melt index, its melt index is 30g / 10min, and its weight-average molecular weight is 25W; the raw material group Points are recorded in weight fractions, high melt index isotactic polypropylene slices 100 parts, antioxidant 1.5 parts, hindered amine light stabilizer Tinuvin7700.3 parts, benzophenone UV absorber C810.7 parts, PP cooling mother Granules A-4903 parts, wherein the antioxidant is prepared by compounding antioxidant 1010 and antioxidant 168, and the compounding ratio is 6:4; mix the raw materials evenly and...

Embodiment 3

[0040] Such as figure 2 As shown, a polypropylene geotextile composite drainage network with reverse filtration and drainage function is composed of upper and lower layers of geotextile 1 and a layer of three-dimensional geotextile core 3, and its preparation method is as follows:

[0041] The first step: The high-strength coarse-denier polypropylene geotextile is prepared by spunbonding and needle-punching. The polymer used is isotactic polypropylene with a high melt index, its melt index is 40g / 10min, and its weight-average molecular weight is 15W; the raw material group Points are recorded in weight fractions, high melt index isotactic polypropylene chips 100 parts, antioxidant 0.5 parts, hindered amine light stabilizer Tinuvin7700.7 parts, benzophenone ultraviolet absorber C810.3 parts, PP cooling mother Granules A-4903 parts, wherein the antioxidant is prepared by compounding antioxidant 1010 and antioxidant 168, and the compounding ratio is 5:5; the raw materials are ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com