Conducing composite material and preparation method thereof

A technology of conductive composite materials and carbon nanotubes, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of limited application range, performance limitations, low efficiency, etc., to achieve increased antistatic performance, performance improvement, The effect of expanding the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

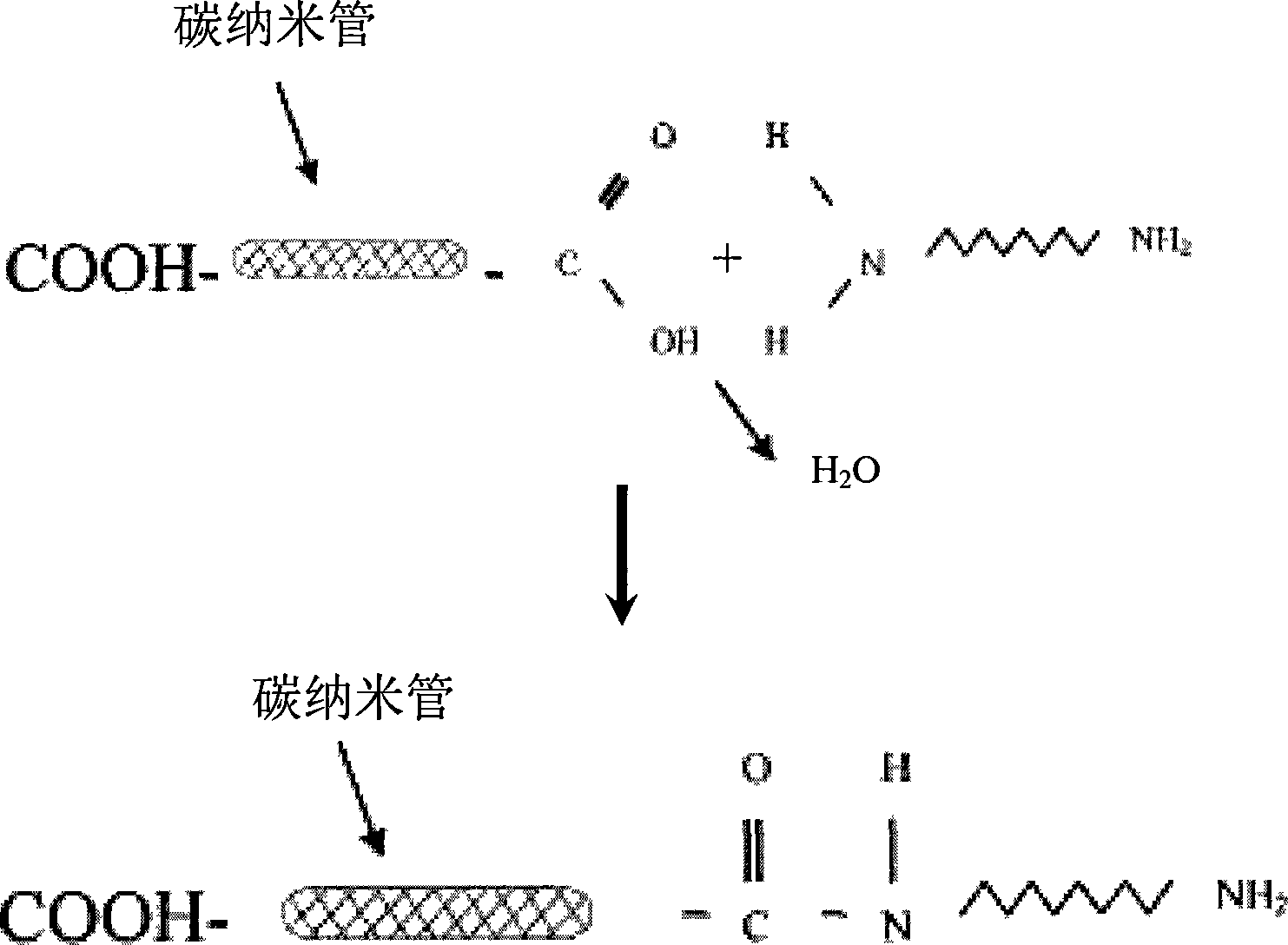

Method used

Image

Examples

Embodiment 1

[0031] Preparation of 1% carbon nanotube / nylon 6 (PA6) composite material:

[0032] 1. Preparation of mixture of caprolactam and carbon nanotubes:

[0033] Weigh 3.0 grams of caprolactam, 150 mg of 6-aminocaproic acid and 150 mg of benzoyl peroxide on an analytical day, mix them evenly and place them in an agate mortar, grind them into a white powder, and then add 30 mg of carboxyl single-walled carbon Nanotubes (65% concentrated nitric acid at 90° C., ultrasonic vibration, reflux for 3.5 hours) and mixed uniformly.

[0034] 2. Polycondensation of a mixture of caprolactam and carbon nanotubes:

[0035] Take a 25×150mm test tube with a side tube as a polycondensation tube, add the above-mentioned mixture of caprolactam and carbon nanotubes, and press it to the bottom of the test tube as far as possible with a glass rod. The side port of the polycondensation tube is used as the nitrogen outlet, and a rubber tube is connected to the water. Nitrogen was blown for 5 minutes, the...

Embodiment 2

[0038] Preparation of 2% carbon nanotube / nylon 6 (PA6) composite material:

[0039] 1. Preparation of a mixture of caprolactam and carbon nanotubes:

[0040] Weigh 3.0 grams of caprolactam, 150 mg of 6-aminocaproic acid and 150 mg of azobisisobutyronitrile with an analytical balance, mix them evenly and place them in an agate mortar, grind them into a white powder, and then add 60 mg of carboxylated single-walled carbon Nanotubes (65% concentrated nitric acid refluxed at 90°C for 3.5 hours) and mixed well.

[0041] 2. Polycondensation of a mixture of caprolactam and carbon nanotubes:

[0042] Same as Example 1, carbon nanotubes account for 2% of the polyamide weight in the composite material obtained, measure its electrical conductivity with four-probe method, and the measurement result is 10 -6 S / cm.

Embodiment 3

[0044] Preparation of 3% carbon nanotube / polyamide (PA6) composite material:

[0045] 1. Preparation of a mixture of caprolactam and carbon nanotubes:

[0046] Weigh 3.0 grams of caprolactam, 150 mg of 6-aminocaproic acid and 150 mg of sodium hydroxide with an analytical balance, mix them evenly and place them in an agate mortar, grind them into a white powder, then add 90 mg of carboxylated single-walled carbon nanotubes ( 65% concentrated nitric acid was refluxed at 90°C for 3.5 hours) and mixed evenly.

[0047] 2. Polycondensation of a mixture of caprolactam and carbon nanotubes:

[0048] Same as Example 1, carbon nanotubes account for 3% of the polyamide weight in the composite material obtained, measure its electrical conductivity with four-probe method, and the measurement result is 4 * 10 -6 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com