Highly flame-retardant destatic type butyl rubber composite damping material and preparation method thereof

A composite damping material and butyl rubber technology, which is applied in the field of damping materials, can solve the problems of natural rubber's easy-to-age butyl rubber adhesion, multi-layer bonding is easy to fall off, and complex product technology, so as to improve the vibration damping effect, High safety and reliability, excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

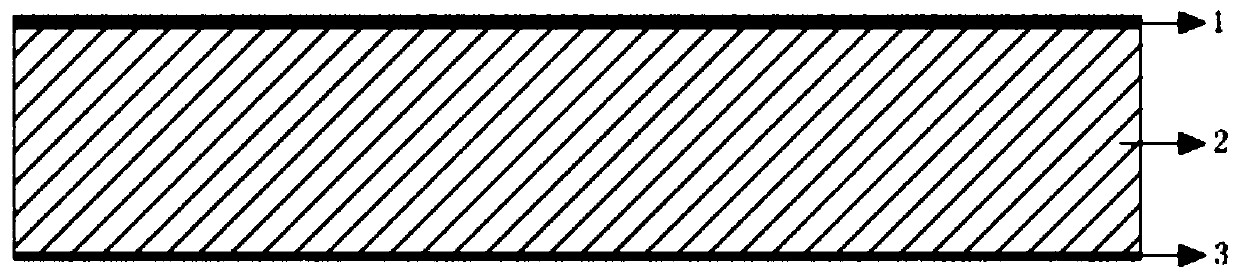

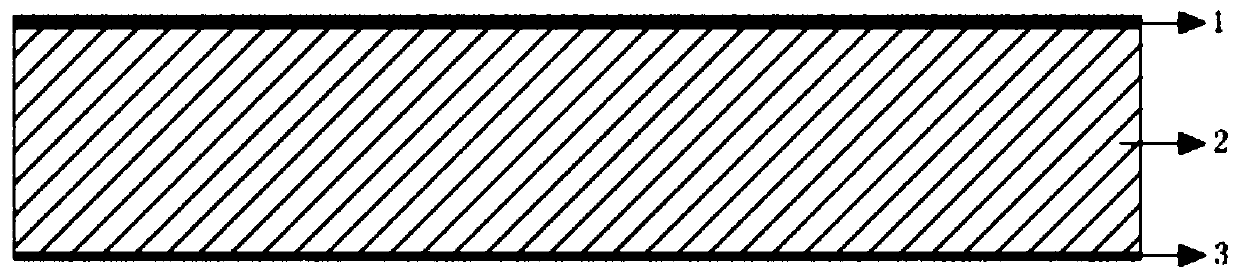

Image

Examples

Embodiment 1

[0027] Preparation of high flame-retardant and static-removing butyl rubber composite damping material

[0028] The raw materials include: 100 parts of bromobutyl rubber, 60 parts of carbon black, 50 parts of carbon nanotube-coated ceramic powder, 5 parts of polytetrafluoroethylene powder, 80 parts of polyisobutylene, 60 parts of petroleum resin, 180 parts of light calcium carbonate , 15 parts of naphthenic oil.

[0029] The preparation method of carbon nanotube-coated ceramic powder includes the following steps: adding ceramic particles (100 parts) and silane coupling agent KH-550 (30 parts) into a high-speed mixer, stirring at a high speed at 80° C. for mixing, stirring for 15 minutes, and then Slowly add a suspension solution containing 5% epoxy resin and 60% carbon nanotubes, continue to stir at 85 °C for 15 minutes, and then place it in a vacuum drying oven to dry after stirring. use.

[0030] The steps of preparing the high flame-retardant conductive butyl rubber compo...

Embodiment 2

[0032] Preparation of high flame-retardant and static-removing butyl rubber composite damping material

[0033] The raw materials include 100 parts of bromobutyl rubber, 40 parts of carbon black, 10 parts of carbon nanotube-coated ceramic powder, 2 parts of polytetrafluoroethylene powder, 50 parts of polyisobutylene, 1 part of petroleum resin, 150 parts of light calcium carbonate, 6 parts of naphthenic oil.

[0034] The preparation method of carbon nanotube-coated ceramic powder includes the following steps: adding ceramic particles (100 parts) and silane coupling agent KH-550 (30 parts) into a high-speed mixer, stirring at a high speed at 100° C. for mixing, stirring for 20 minutes, and then Slowly add a suspension solution containing 5% epoxy resin and 60% carbon nanotubes, continue to stir at 95 °C for 20 minutes, and then place it in a vacuum drying oven to dry after stirring. use.

[0035] The steps of preparing the high flame-retardant conductive butyl rubber composite...

Embodiment 3

[0037] Preparation of high flame-retardant and static-removing butyl rubber composite damping material

[0038] The raw materials include 100 parts of bromobutyl rubber, 50 parts of carbon black, 20 parts of carbon nanotube-coated ceramic powder, 3 parts of polytetrafluoroethylene powder, 60 parts of polyisobutylene, 55 parts of petroleum resin, 165 parts of light calcium carbonate, 8 parts of naphthenic oil.

[0039] Add ceramic particles (100 parts) and silane coupling agent KH-550 (30 parts) into a high-speed mixer, mix at a high speed at 95°C, stir for 17 minutes, and then slowly add 5% epoxy resin and 60% carbon nanometer The suspension solution of the tube was continuously stirred for 18 min under the heating condition of 91 °C, and after stirring, it was placed in a vacuum drying oven for drying, and the dried carbon nanotubes were coated with ceramic powder for use.

[0040]The steps of preparing the high flame-retardant conductive butyl rubber composite damping mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com