Reflection enhancement structure of OLED (Organic Light Emitting Diode) anode and reflection enhancement structure of OLED cathode

A technology of anode and cathode, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., and can solve problems such as high cost and Ag pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

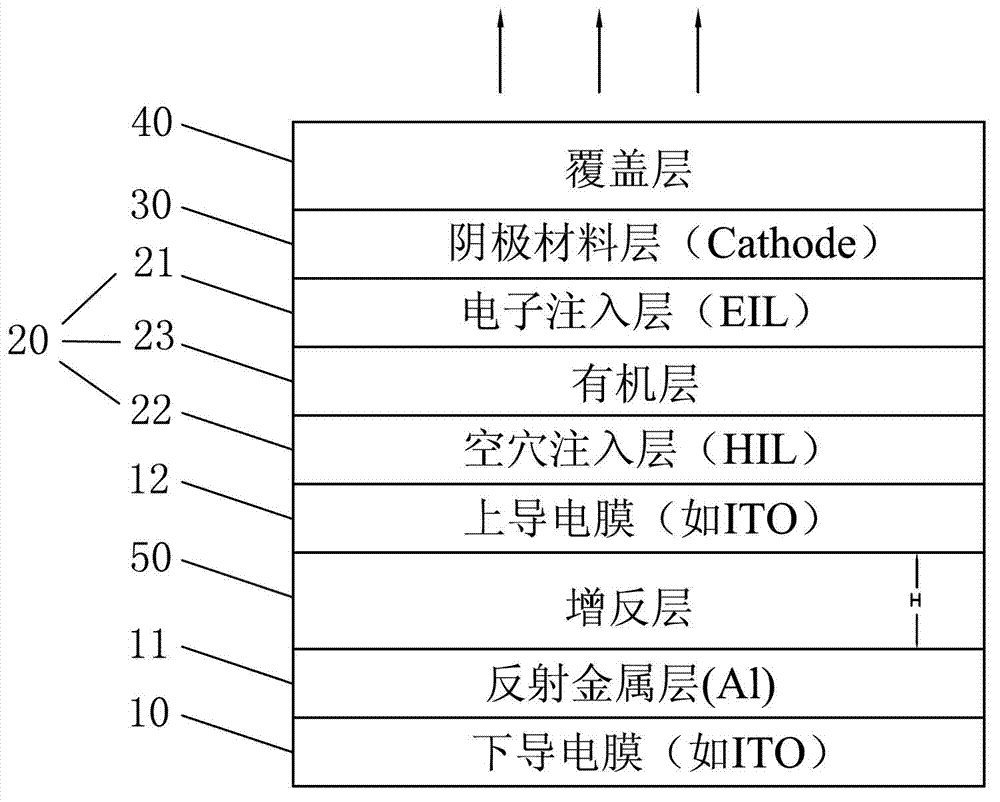

Examples

Embodiment Construction

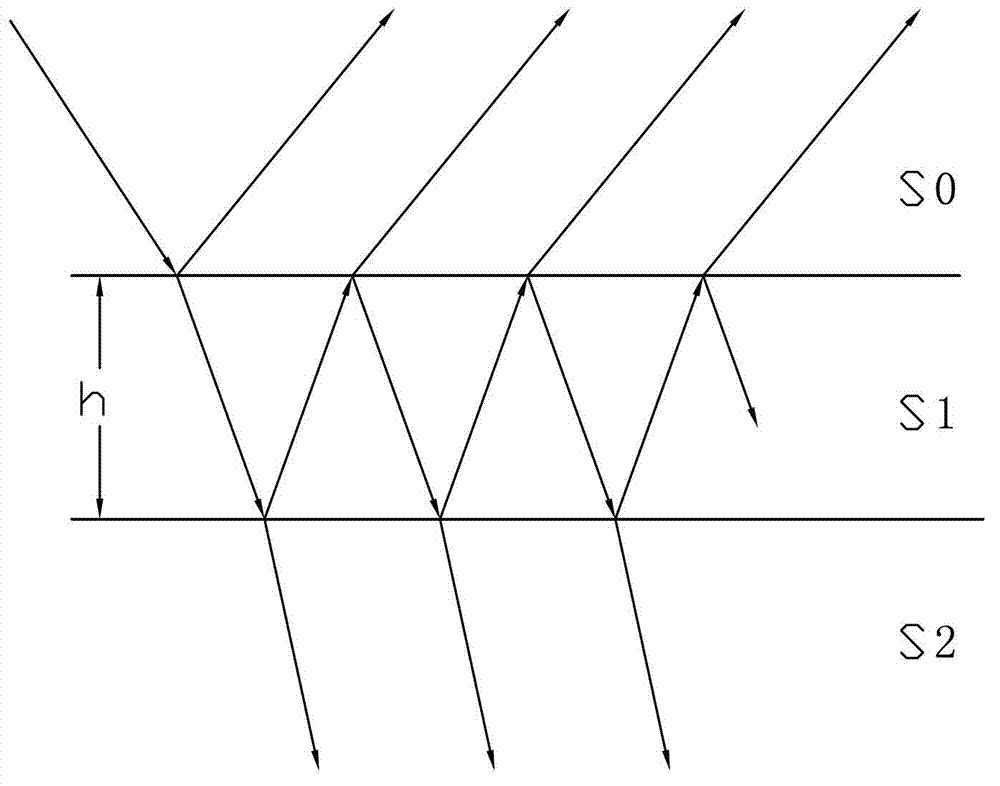

[0035] First, the basic optical principles are introduced as follows:

[0036] like figure 1 As shown, the light from the refractive index n 0 The medium S0 passes through the refractive index n 1 , a dielectric film S1 with a thickness of h incident to the refractive index n 2 The substrate S2, the reflectivity formula on the dielectric film S1 is as follows:

[0037]

[0038] Where: R is the reflectivity on the dielectric film S1;

[0039] is the optical thickness of the dielectric film S1.

[0040] The above formula shows that for a certain substrate S2 and dielectric film S1, n 1 and n 2 is a constant, R varies with (i.e. with n 1 h) change.

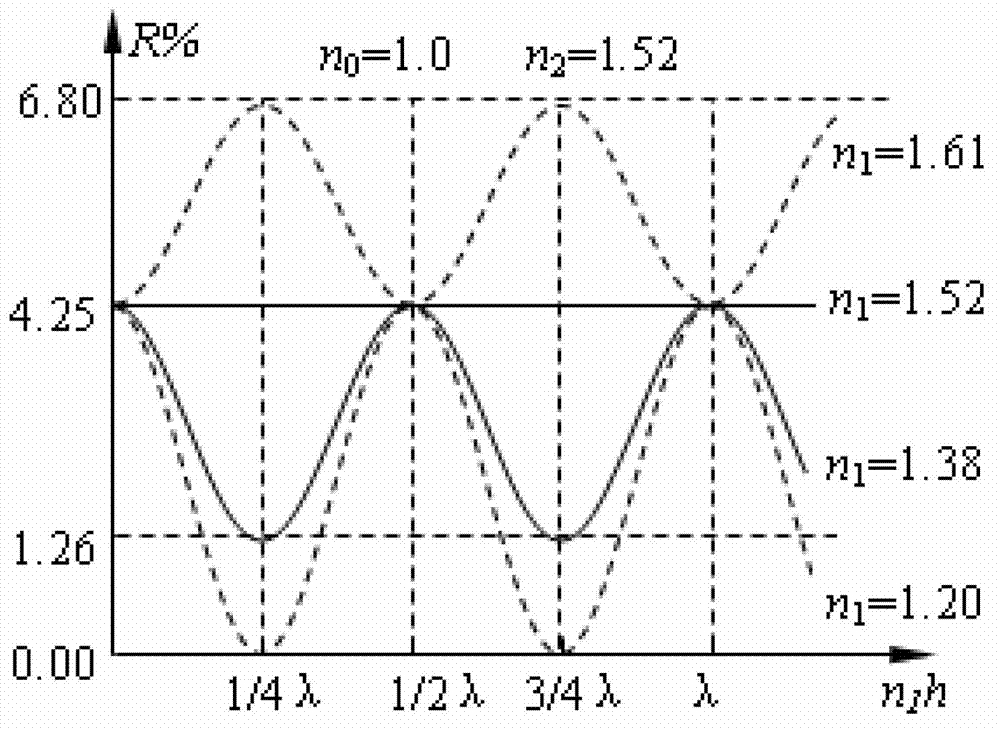

[0041] Below: crown brand K9 glass (refractive index n 2 =1.52) the surface is coated with a thin film (refractive index n 1 ), light of wavelength λ travels from air (refractive index n 0 ) in normal incidence as an example, for a given wavelength λ and different refractive index n 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com