Manufacturing method of array substrate and array substrate

A technology of an array substrate and a manufacturing method, which is applied in the display field, can solve problems such as poor contact, abnormal opening, thick insulating layer, etc., and achieve the effects of cost saving and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

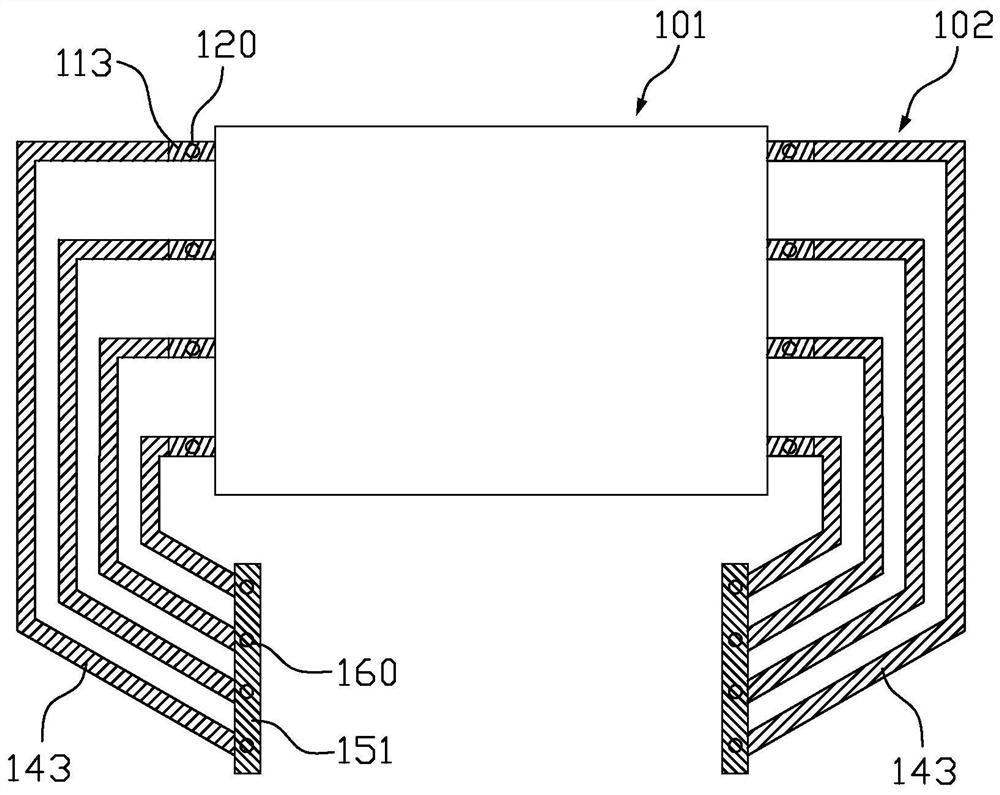

[0031] The manufacturing method of the array substrate according to Embodiment 1 of the present invention includes: Figure 1 to Figure 3l as shown,

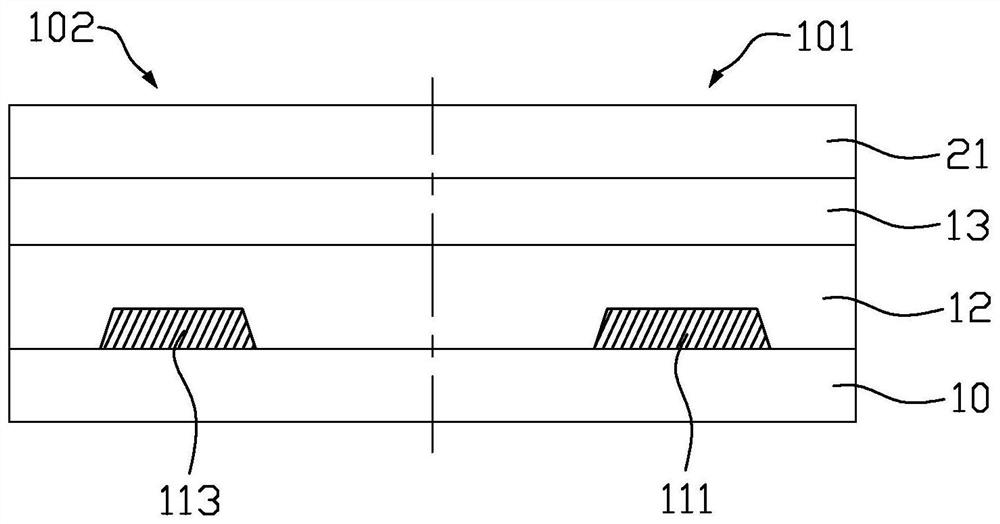

[0032] A substrate 10 is provided. The substrate 10 includes a display area 101 and a non-display area 102 located on the periphery of the display area 101 . The array substrate is fabricated on the substrate 10 at the same time. Specifically, the substrate 10 is a transparent substrate 10, for example made of glass.

[0033] A first metal layer (not shown) is formed on the substrate 10, and the first metal layer is patterned to form gates 111 and scan lines (not shown) in the display area 101, and form The first lead 113 of the area 102 is electrically connected to the scan line. Specifically, the material of the first metal layer is made of stacked Mo (molybdenum), Al (aluminum), and Mo (molybdenum), and the first metal layer is exposed, developed and etched, thereby forming the gate 111, scanning wire and the first lead 11...

Embodiment 2

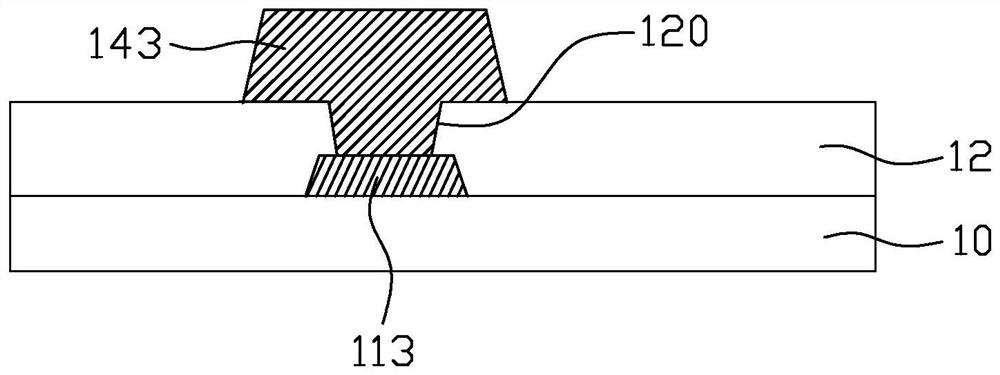

[0058] The part of this embodiment is the same as that of Implementation 1, and the same part will not be repeated here. The difference is that: Figure 5a to Figure 5l As shown, before the step of forming the first contact hole 120 penetrating through the active layer film 13 and the first insulating layer 12, the active layer film 13 is patterned to form silicon islands 131 in the display area 101, and in the non- An etching guide 132 is formed in the display area 102 , and the etching guide 132 corresponds to the position of the first contact hole 120 .

[0059] Specifically, such as Figure 5a to Figure 5c As shown, the fourth photoresist layer 24 is coated on the active layer film 13, and after exposure, development and etching, a part of the active layer film 13 remains at the position where the first contact hole 120 is formed, as a guide for subsequent etching. Or transition, that is, etch the guide portion 132 . Such as Figure 5d As shown, the fourth photoresist l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com