Integral-molded large mold with complicated structure

A complex structure and mold technology, applied in the field of large-scale molds, can solve the problems of heavy metal molds, large thermal expansion coefficients, smashing, etc., and achieve the effects of saving operating time, low thermal expansion coefficients, and preventing product undercuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

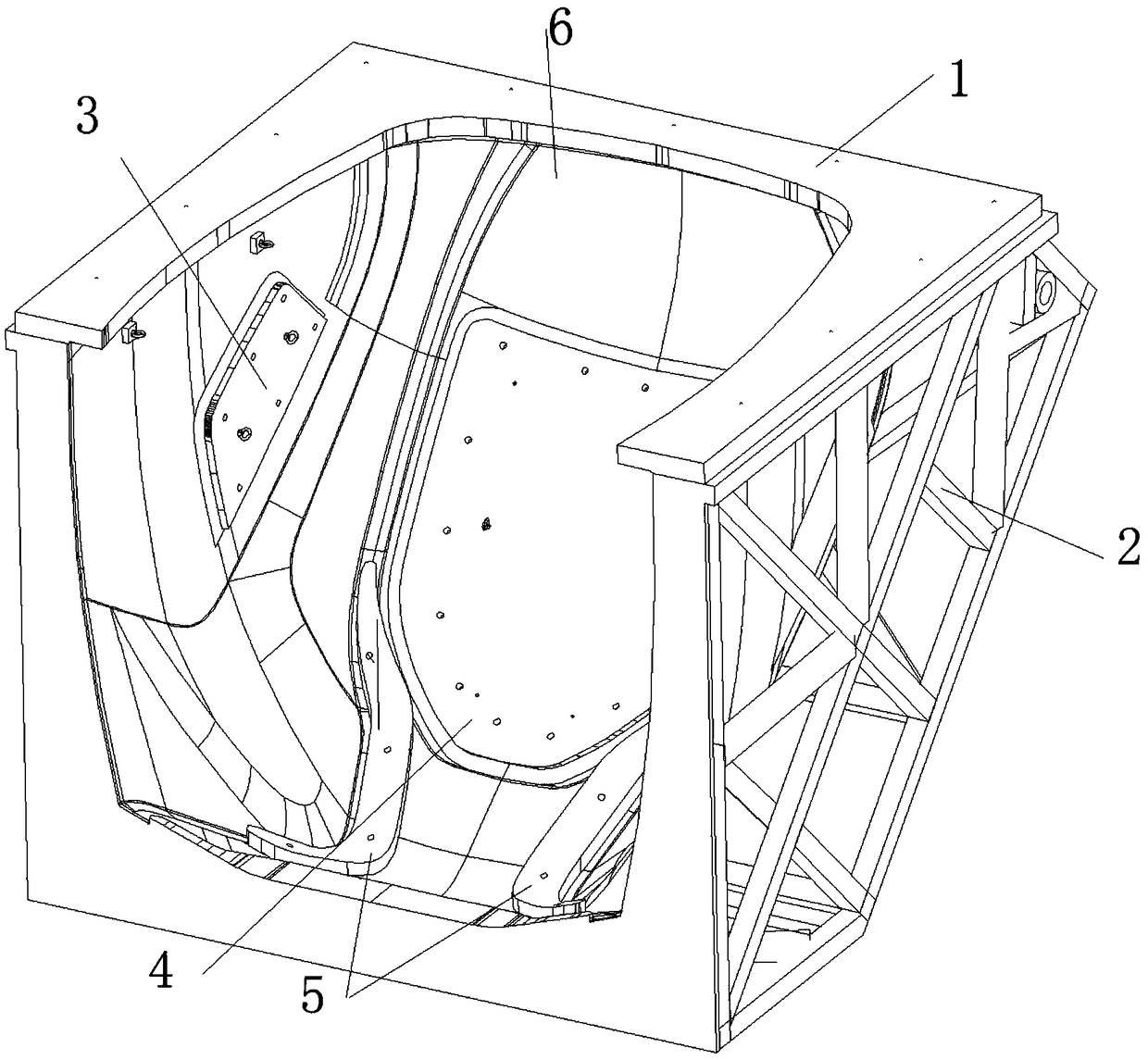

[0015] figure 1 It is a schematic diagram of the overall structure of the present invention. The large-scale mold with integrally formed complex structure provided by the present invention includes: a mold body 6, a mold frame 2, an upper cover plate 1 on the upper part of the mold body 6, inserts 3 on both sides inlaid on both sides of the mold body 6, and inlaid on the bottom of the mold body 6 The bottom insert 5, the front end of the mold main body 6 is inlaid with the front end insert 4; the upper cover plate 1, the inserts on both sides 3, the bottom insert 5 and the front end insert 4 can be detachably embedded on the mold main body 6; the mold frame 2 is located on The outer side of the mold body 6, the mold frame 2 and the mold body 6 are bonded together by resin and reinforced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com