Spinning method combining embedding spinning with compact siro spinning

A siro spinning and combined technology, applied in the spinning field of the cotton spinning industry, can solve the problems that the yarn-dyed fabric cannot be realized, the yarn strength, hairiness, and evenness cannot reach high-end customers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

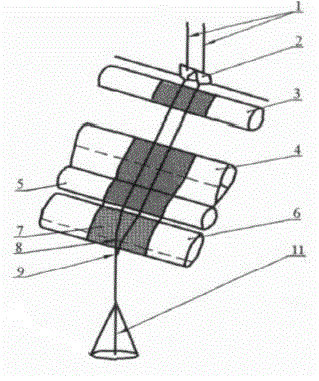

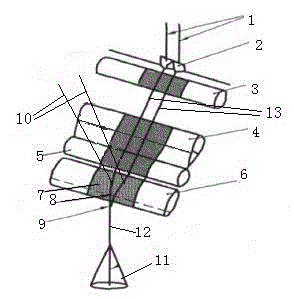

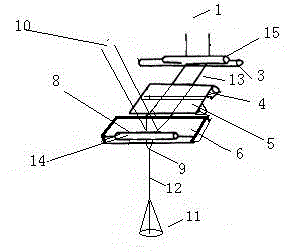

[0010] figure 1 In the process, the two roving slivers 1 of the compact siro spinning are fed into the same drafting mechanism of the ring spinning frame in parallel through the double bell mouth 2 at a certain distance, and are drafted into yarn strands 13 by the drafting mechanism, and are drawn into yarn strands 13 in parallel. At the same time, it enters the drafting zone from the rear roller 3, passes through the drafting middle roller 4, exits from the clamping point of the front roller 5, and then enters the negative pressure accumulation zone. A grid ring 7 is sheathed on the surface of the special-shaped polymer-absorbing pipe 6 which has double grooves and is in a negative pressure state inside, and the grid ring 7 is frictionally driven by output rollers. The two yarn whiskers output by the front roller 5 are absorbed by the negative pressure at the position corresponding to the double grooves on the surface of the grid ring 7, and the yarn whiskers move forward wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com