Production technology of beam-dyed double-layer two-way stretch fabric

A warp beam dyeing and production process technology, applied in the direction of dyeing, fabric surface trimming, weaving, etc., can solve the problems of cloth surface holes, defective cloth drop, broken warp and weaving defects, etc., so as to reduce the process and improve the The effect of productivity, creativity and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

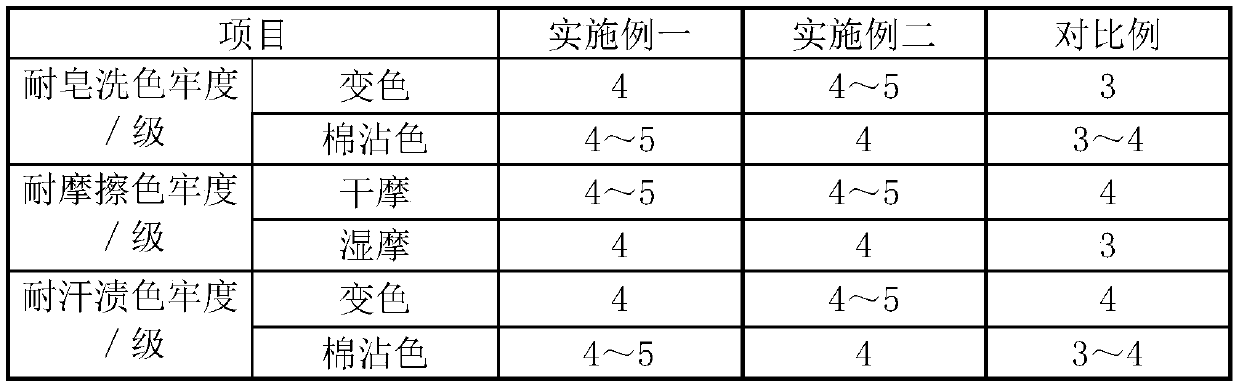

Examples

Embodiment 1

[0040] The production process of a double-layer four-sided stretch fabric with warp beam dyeing involved in this embodiment includes the following steps: step S1: preparation of surface warp beams, step S2 surface warp beam dyeing pretreatment, step S3 surface warp beam dyeing, and step S4 Surface layer warp beam soaping, step S5 surface layer warp beam foam sizing, step S6 preparation of inner layer warp beam, step S7 inner layer warp beam pretreatment, step S8 inner layer warp beam dyeing, step S9 inner layer warp beam soaping, Step S10 inner layer warp beam foam sizing, step S11 weaving, and step S12 finishing.

[0041] In the preparation of the surface warp beam in step S1, the yarn used in the surface warp beam is a core-spun yarn that uses nylon fiber as the covering layer and spandex as the core yarn for the surface warp yarn. The spandex used has a fineness of 20D. The fineness of the coating layer is 21S. Place the surface warp bobbin under the same temperature and humi...

Embodiment 2

[0068] The production process of a double-layer four-sided stretch fabric with warp beam dyeing involved in this embodiment includes the following steps: step S1: preparation of surface warp beams, step S2 surface warp beam dyeing pretreatment, step S3 surface warp beam dyeing, and step S4 Surface warp beam soaping, step S5 surface warp beam foam sizing, step S6 preparation of inner warp beam, step S7 inner warp beam pretreatment, step S8 inner warp beam dyeing, step S9 inner warp beam soaping, Step S10 inner layer warp beam foam sizing, step S11 weaving, and step S12 finishing.

[0069] In the preparation of the surface warp beam in step S1, the yarn used in the surface warp beam is a core-spun yarn that uses nylon fiber as the covering layer and spandex as the core yarn for the surface warp yarn. The spandex used has a fineness of 40D. The fineness of the coating layer is 40S. Place the surface warp bobbin under the same temperature and humidity for 36-48 hours, at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com