Method for designing tobacco formula

A design method and tobacco leaf technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of long-term stability and sustainable development of unfavorable product quality, lack of comprehensive utilization means, lack of formula combination recommendation and proportion design, etc. Improves creativity and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

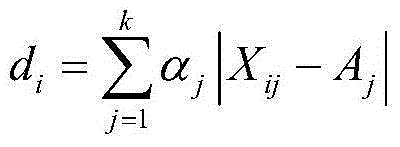

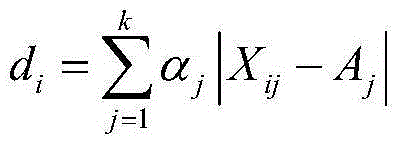

[0047] Follow the steps below to design the tobacco formulation:

[0048] (1) Collect 10 kinds of tobacco leaf raw materials with different origins and grades, and detect the nicotine index, total sugar index, part index, aroma index, middle aroma index, fragrance index, and quality index of each tobacco leaf raw material according to conventional methods. 7 kinds of characteristic parameters (in practical application, characteristic parameters are not limited to above several); The characteristic parameters of each tobacco leaf raw material are as shown in table 1;

[0049] Table 1: Characteristic parameters of tobacco leaf raw materials

[0050]

[0051] (2) According to the design requirements, set the target value of the characteristic parameter in the target formula, and set the weight value and allowable error value of the characteristic parameter in the target formula according to the production experience, as shown in Table 2;

[0052] Table 2: Target value,...

Embodiment 2

[0064] On the basis of Example 1, all the samples contained in the obtained module design formula are used as the first type of collection; the first tobacco leaf raw material with significant differences from the priority sample in the distance sequence is used as the second type of standard sample , the rest of the tobacco leaf raw materials are subjected to t-tests with the second-type standard samples in the order of the distance sequence, and the set is composed of the second-type standard samples and samples with no significant difference with them, that is, the second-type set; and so on, to obtain the gradient category gather;

[0065] Set the required number of categories to 4, randomly select a sample from the first 4 category sets to form a gradient set of tobacco leaf raw materials, that is, the skeleton design formula, as shown in Table 5;

[0066] Table 5: Skeleton Design Recipe

[0067] category

[0068] In this embodiment, the skeleton design formula...

Embodiment 3

[0070] This embodiment uses the linear programming method with the additional mean value vector as the minimum value target to solve the gradient set of tobacco leaf raw materials obtained in embodiment 2, and obtain the consumption of each tobacco leaf raw material, that is, the new tobacco leaf formula, as shown in Table 6;

[0071] Table 6: New Tobacco Leaf Formulation

[0072] category

[0073] In this embodiment, a tobacco leaf product was further prepared according to the new tobacco leaf formula obtained in Table 6, and was inspected by manual smoking; after inspection, the formula met the design requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com