Production method for 20D/24F complete-extinction nylon 6 fully-drawn yarn

A technology of fully drawn yarn and production method, applied in the field of synthetic fiber processing, can solve the problems of inconvenient weaving process, poor dyeing uniformity, rough drafting process, etc., and achieve stable product quality, excellent mechanical properties, and simple and easy process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

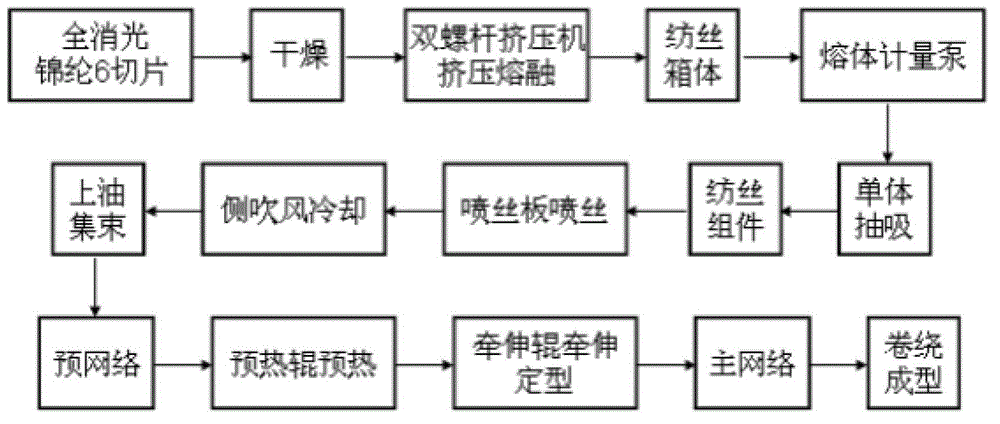

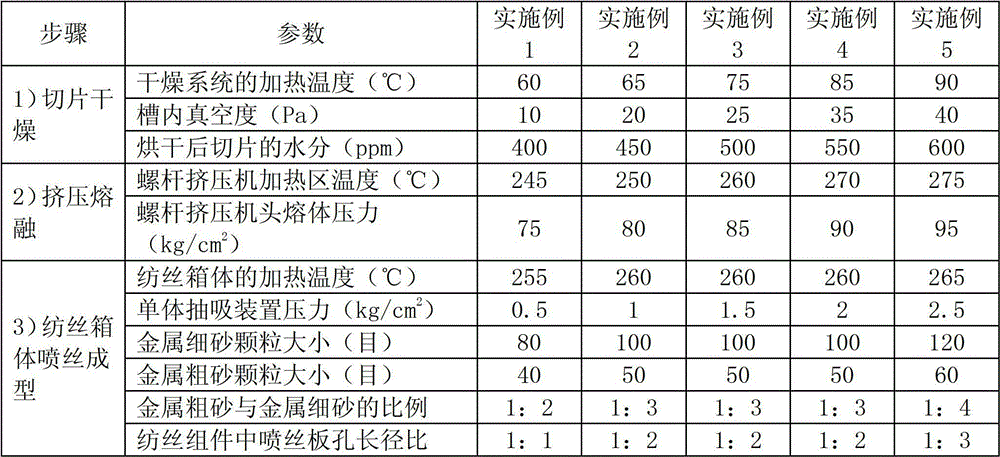

[0033] A kind of production method of 20D / 24F full-dull nylon 6 full-drawing yarn, comprises the steps:

[0034] 1) Drying of slices: Slice the raw material of full-dull nylon 6 and dry it in vacuum;

[0035] 2) Extrusion melting: the dried slices are melted through a twin-screw extruder, and the melt is extruded, and then evenly distributed to each spinning box through the melt distribution pipe;

[0036] 3) Spinning forming of the spinning box: the melt in the spinning box is metered by a metering pump, and the excess monomer impurities are first extracted by a monomer suction device, and then the melt is evenly distributed to each spinning assembly by an equal-length pipeline In the process, after the melt is sheared by the metal sand in the component sand cup, it is finally sprayed out from the spinneret to form primary filaments;

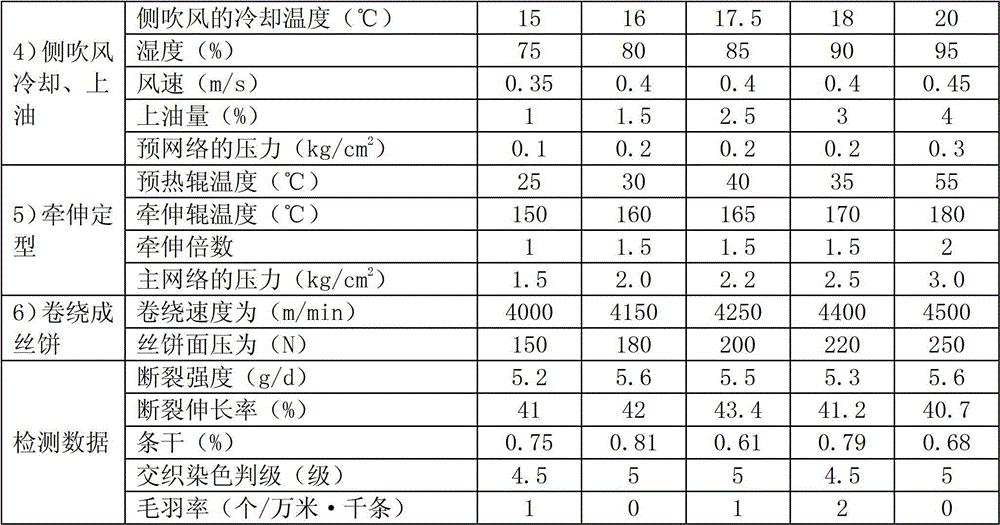

[0037] 4) Cooling and oiling by side blowing: the primary tow is cooled and shaped by side blowing conditions of constant temperature and hum...

Embodiment 2

[0044] The method of Example 1 was repeated according to the parameters specified in Table 1 below, and the test data were listed in the table.

Embodiment 3

[0046] The method of Example 1 was repeated according to the parameters specified in Table 1 below, and the test data were listed in the table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com