Patents

Literature

134results about How to "Reduced breaking strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmaceutical dosage form

ActiveUS20090202634A1Improved controlled releaseEasy to adjustBiocideOrganic active ingredientsControlled releaseBreaking strength

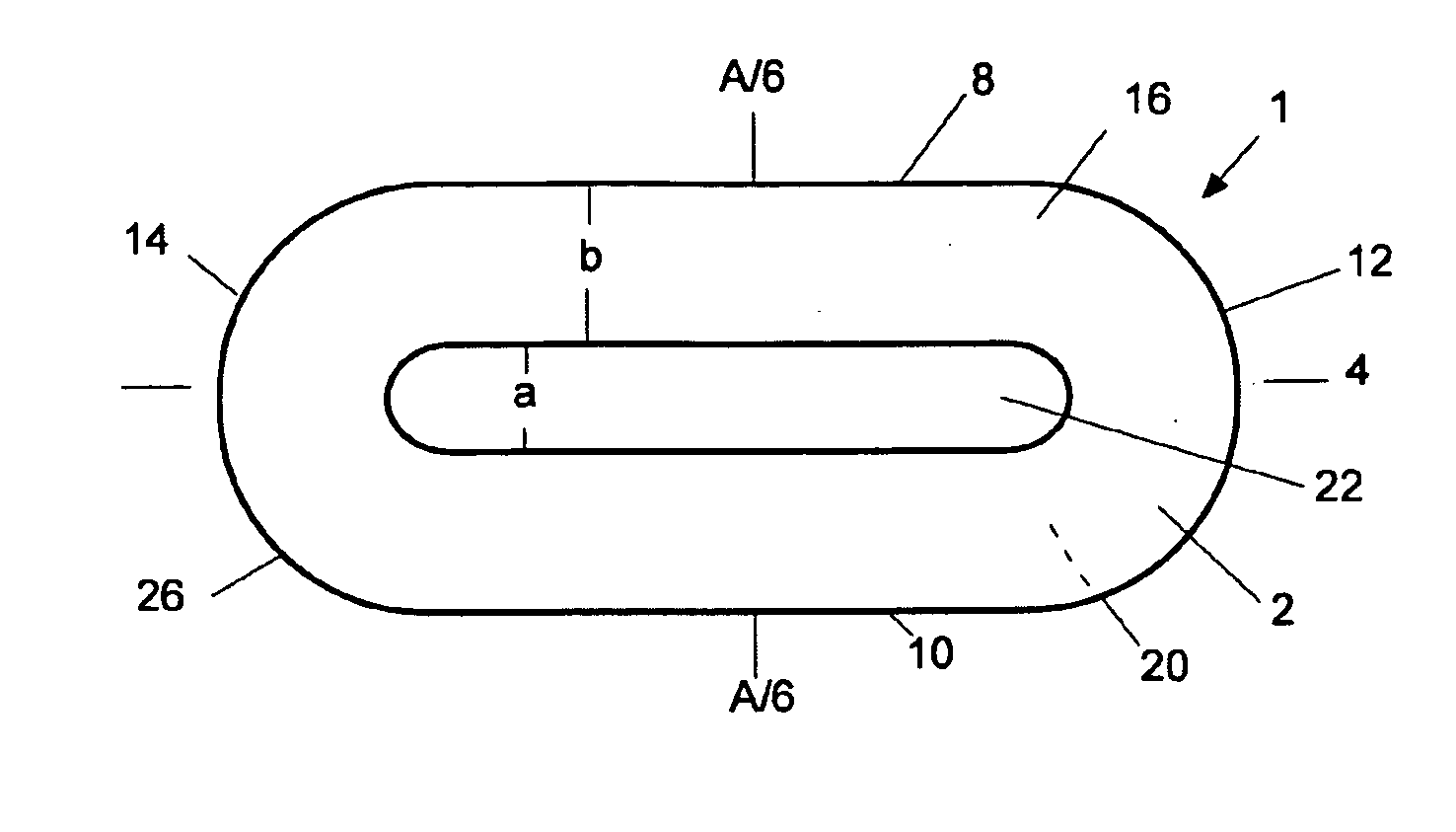

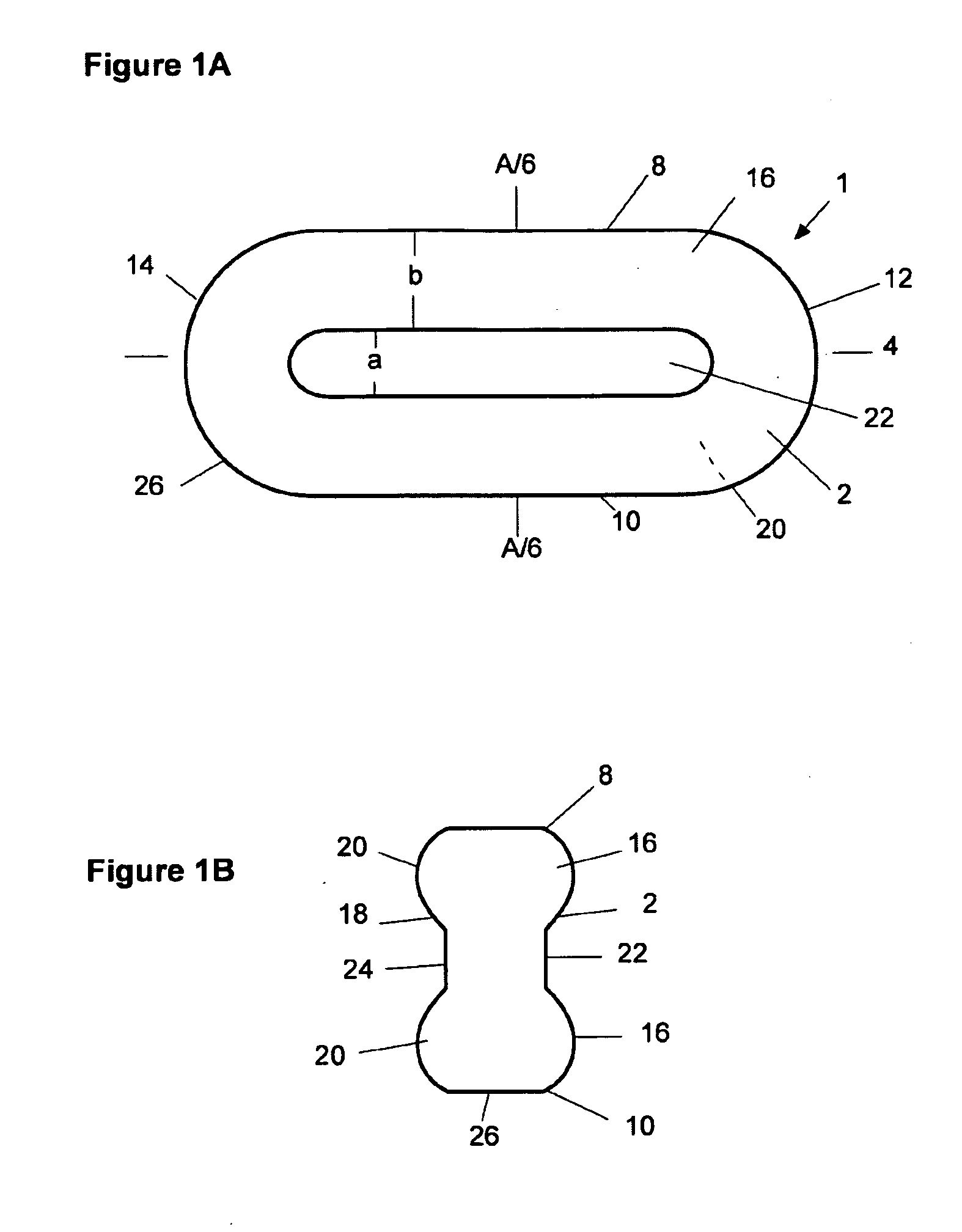

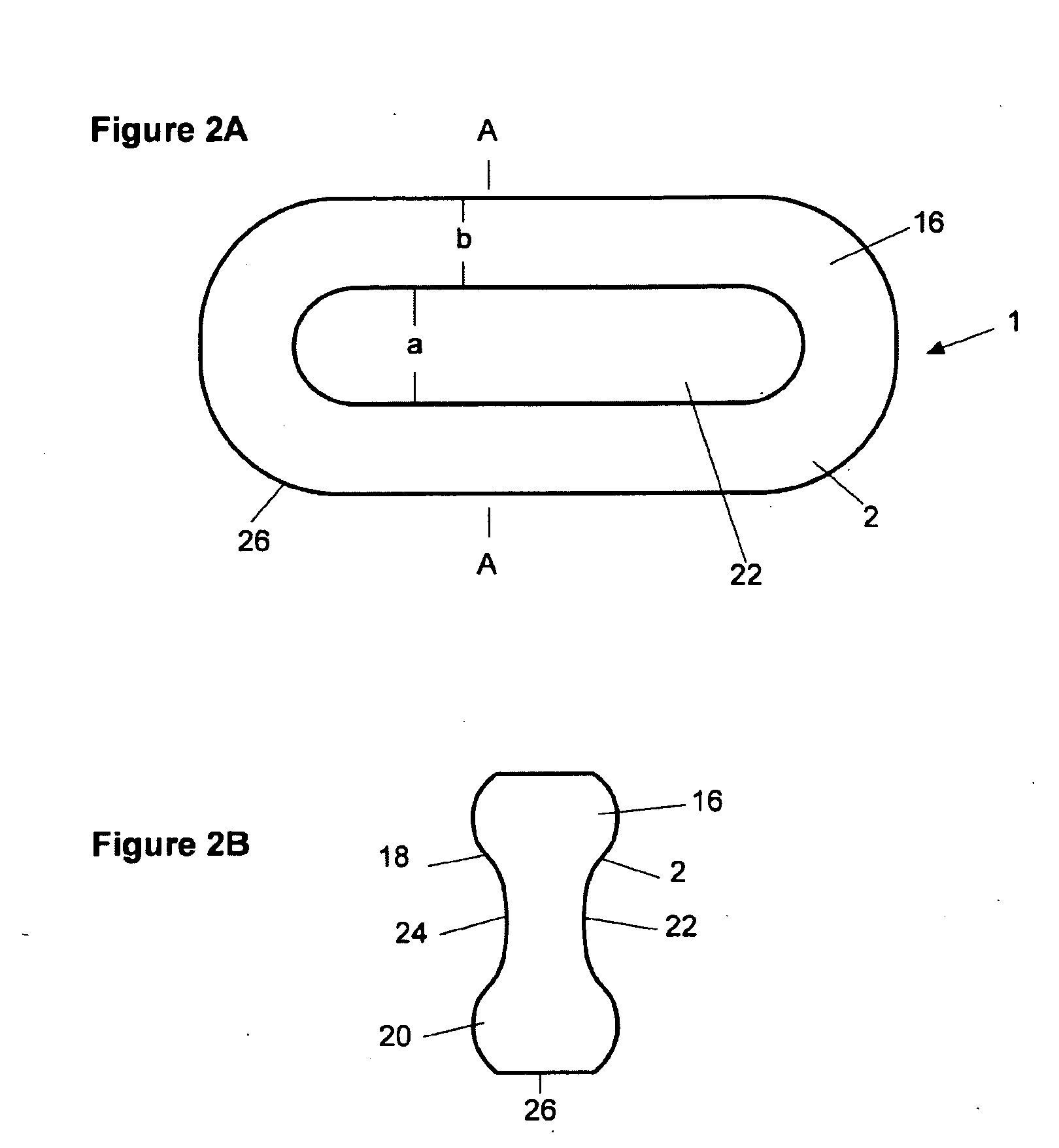

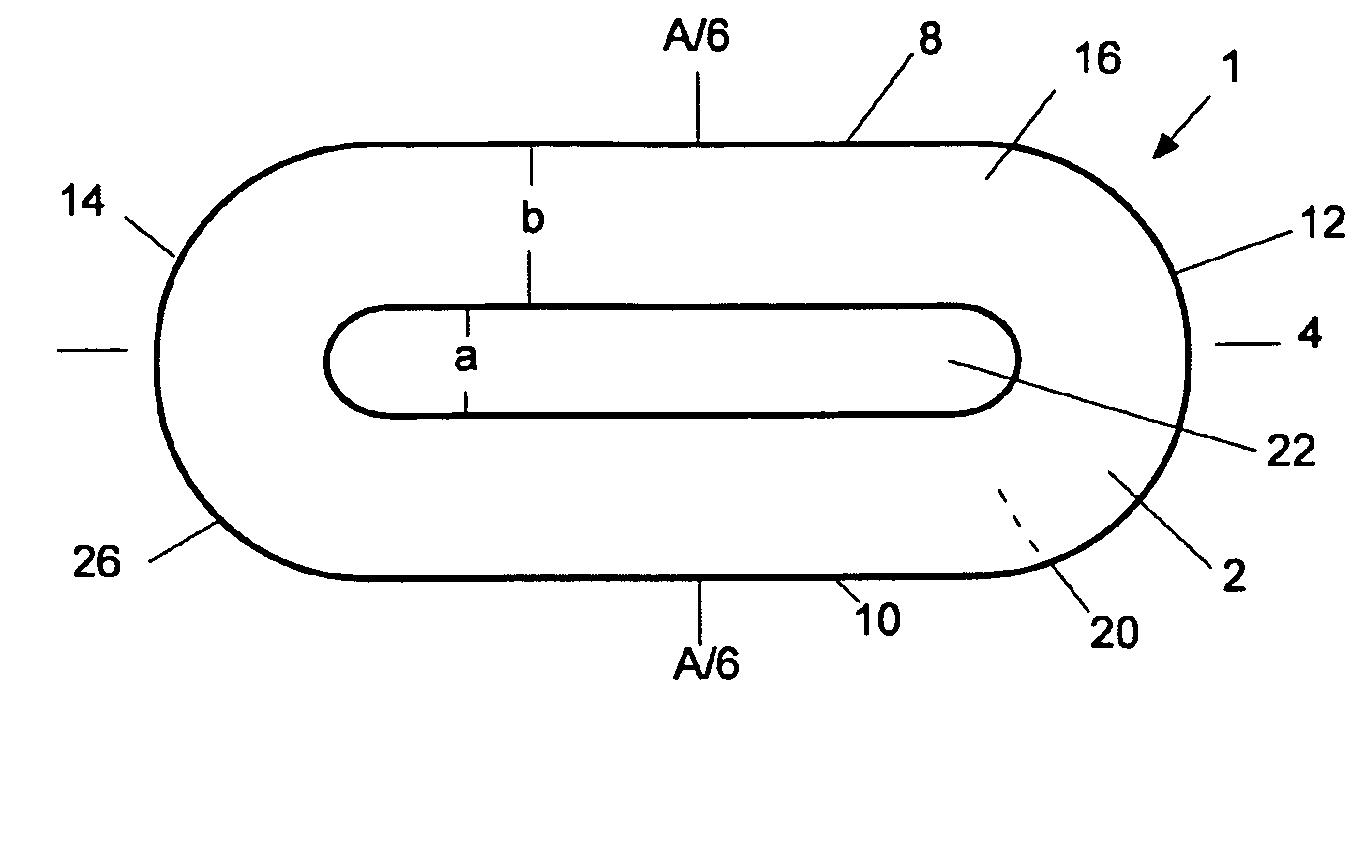

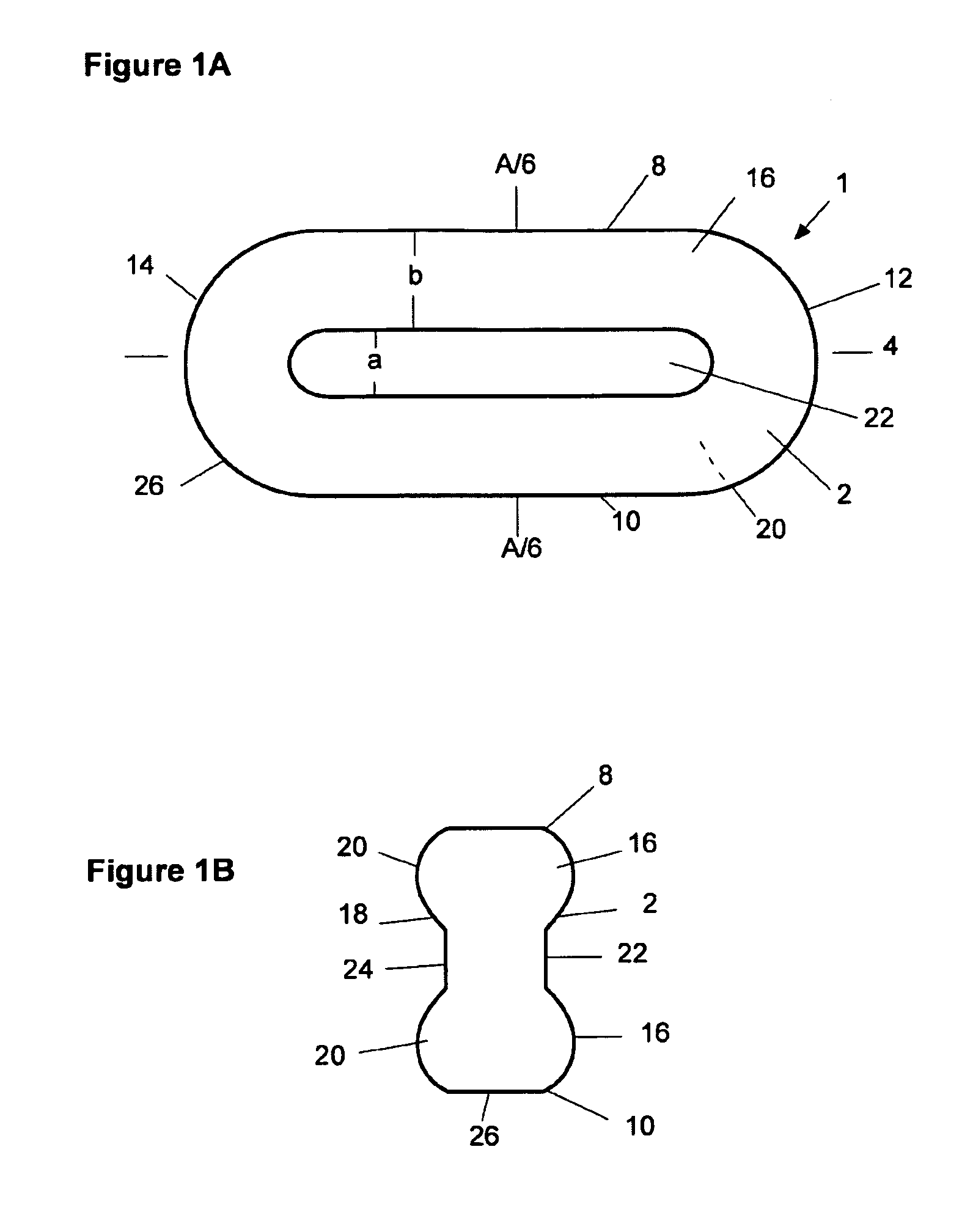

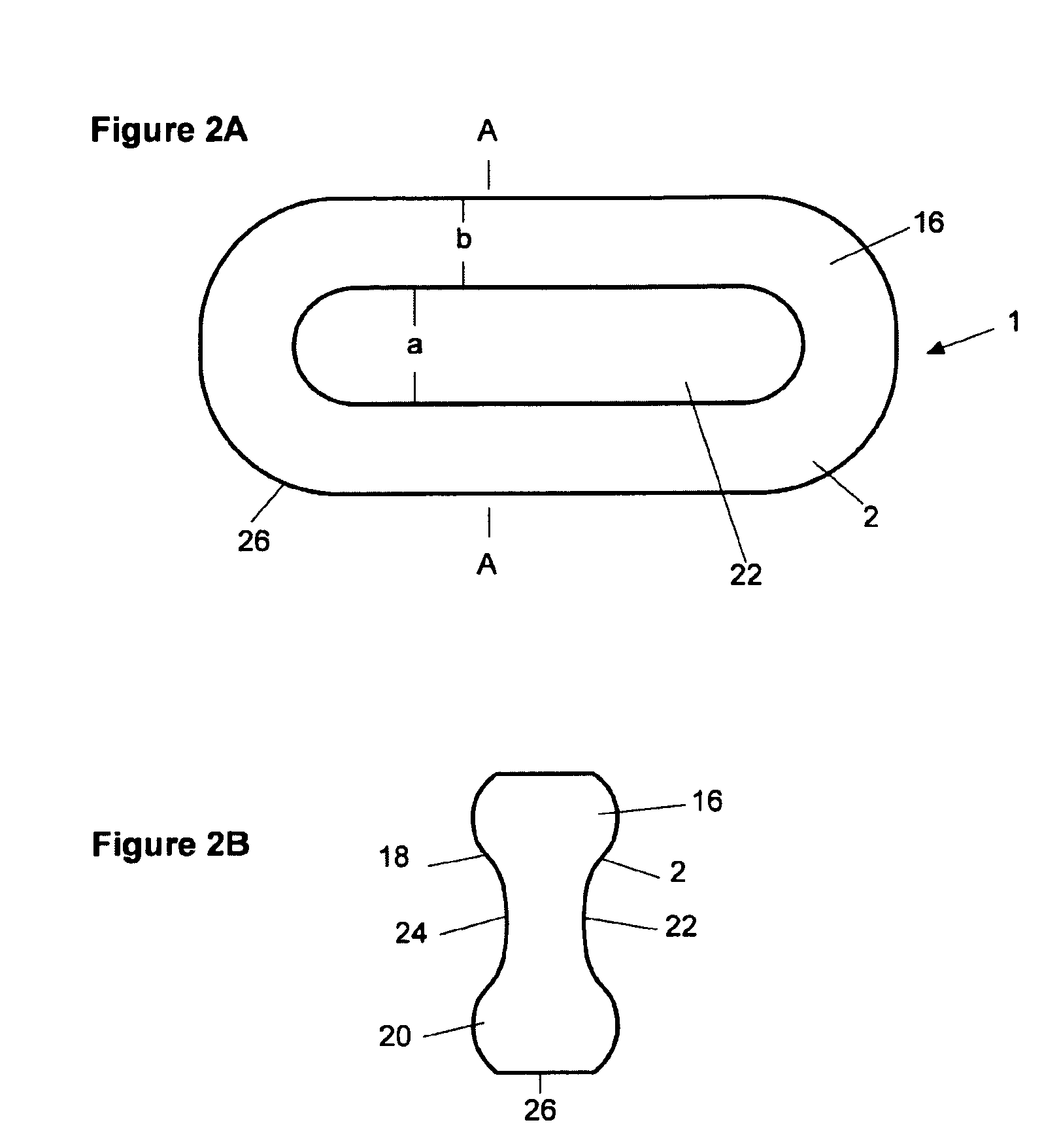

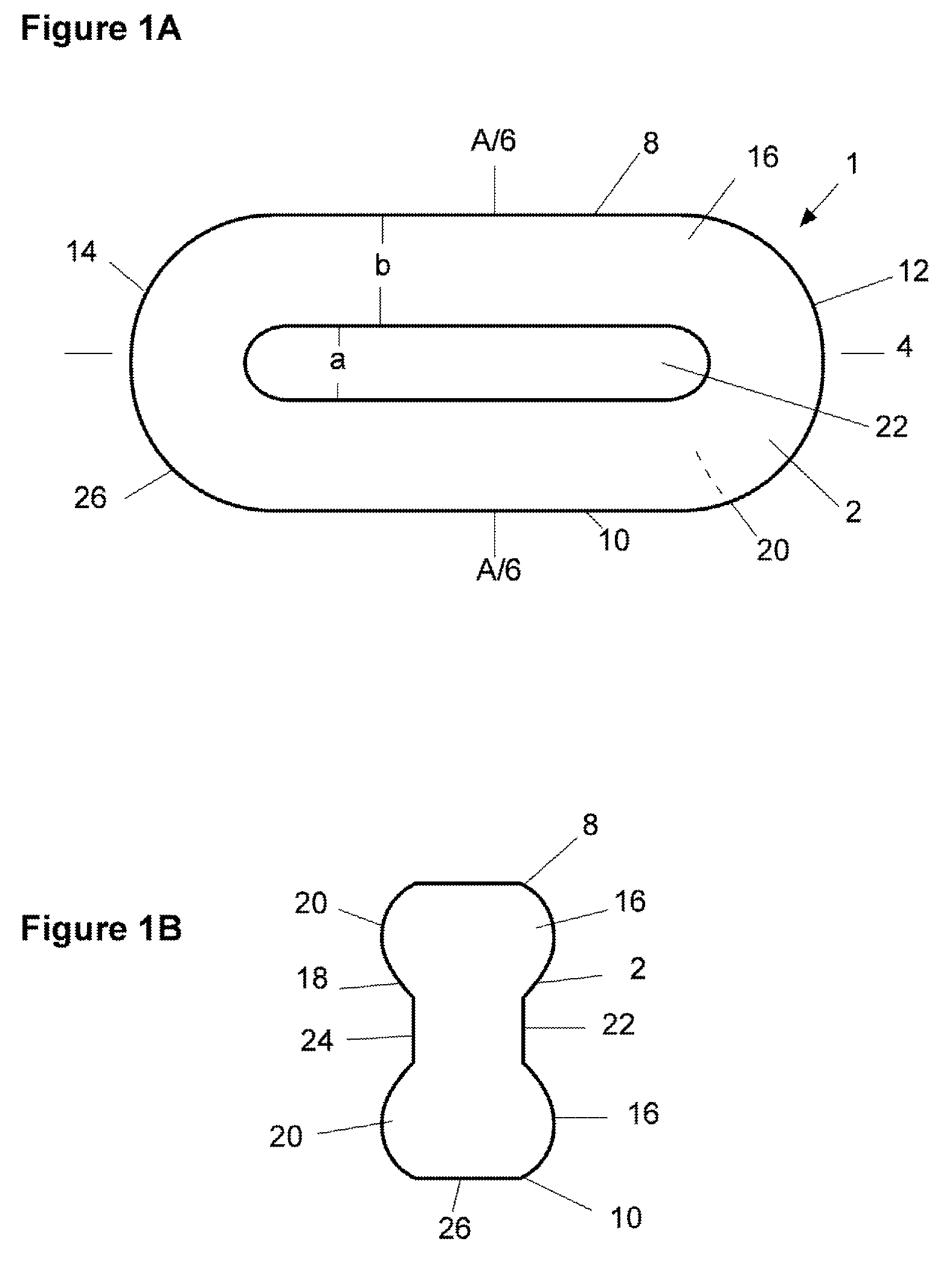

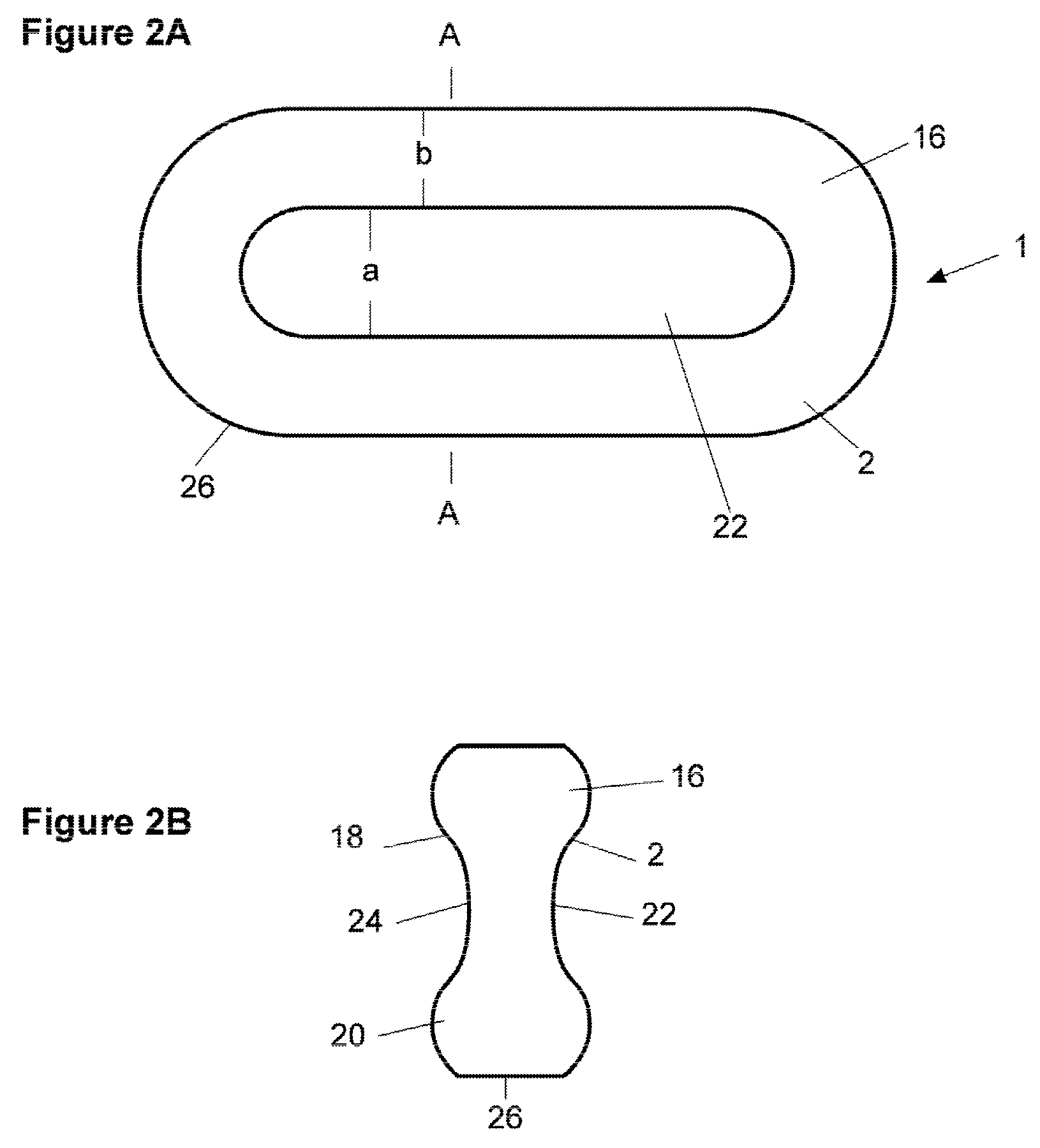

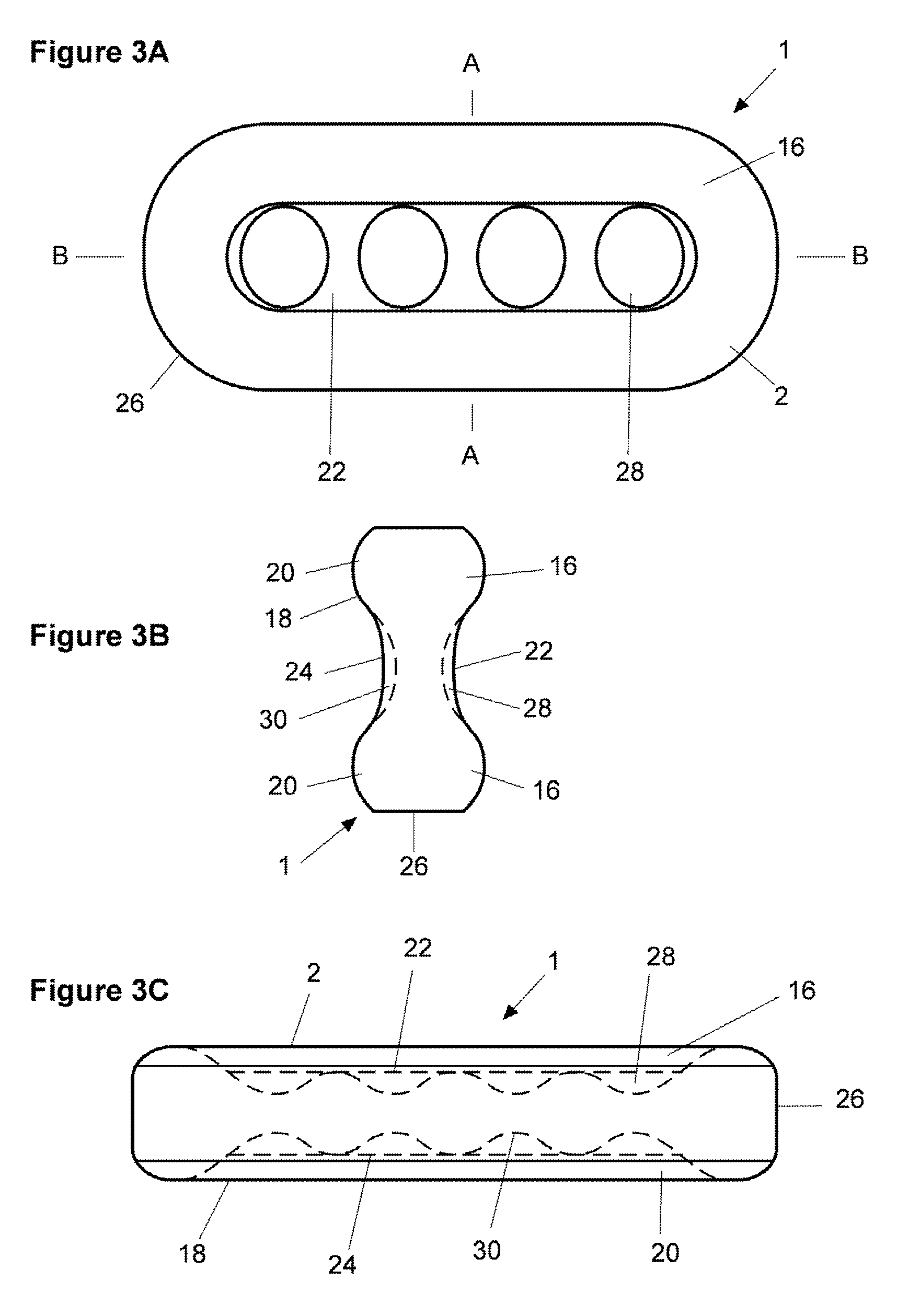

The invention relates to a pharmaceutical dosage form, preferably with controlled release of a pharmacologically active compound (A) contained therein, the pharmaceutical dosage form very preferably being tamper-resistant and most preferably having a breaking strength B1 of at least 500 N in direction of extension E1 and having a breaking strength B2 of less than 500 N in direction of extension E2.

Owner:GRUNENTHAL GMBH

Pharmaceutical dosage form

ActiveUS8383152B2Improved controlled releaseEasy to adjustOrganic active ingredientsBiocideControlled releaseBreaking strength

The invention relates to a pharmaceutical dosage form, preferably with controlled release of a pharmacologically active compound (A) contained therein, the pharmaceutical dosage form very preferably being tamper-resistant and most preferably having a breaking strength B1 of at least 500 N in direction of extension E1 and having a breaking strength B2 of less than 500 N in direction of extension E2.

Owner:GRUNENTHAL GMBH

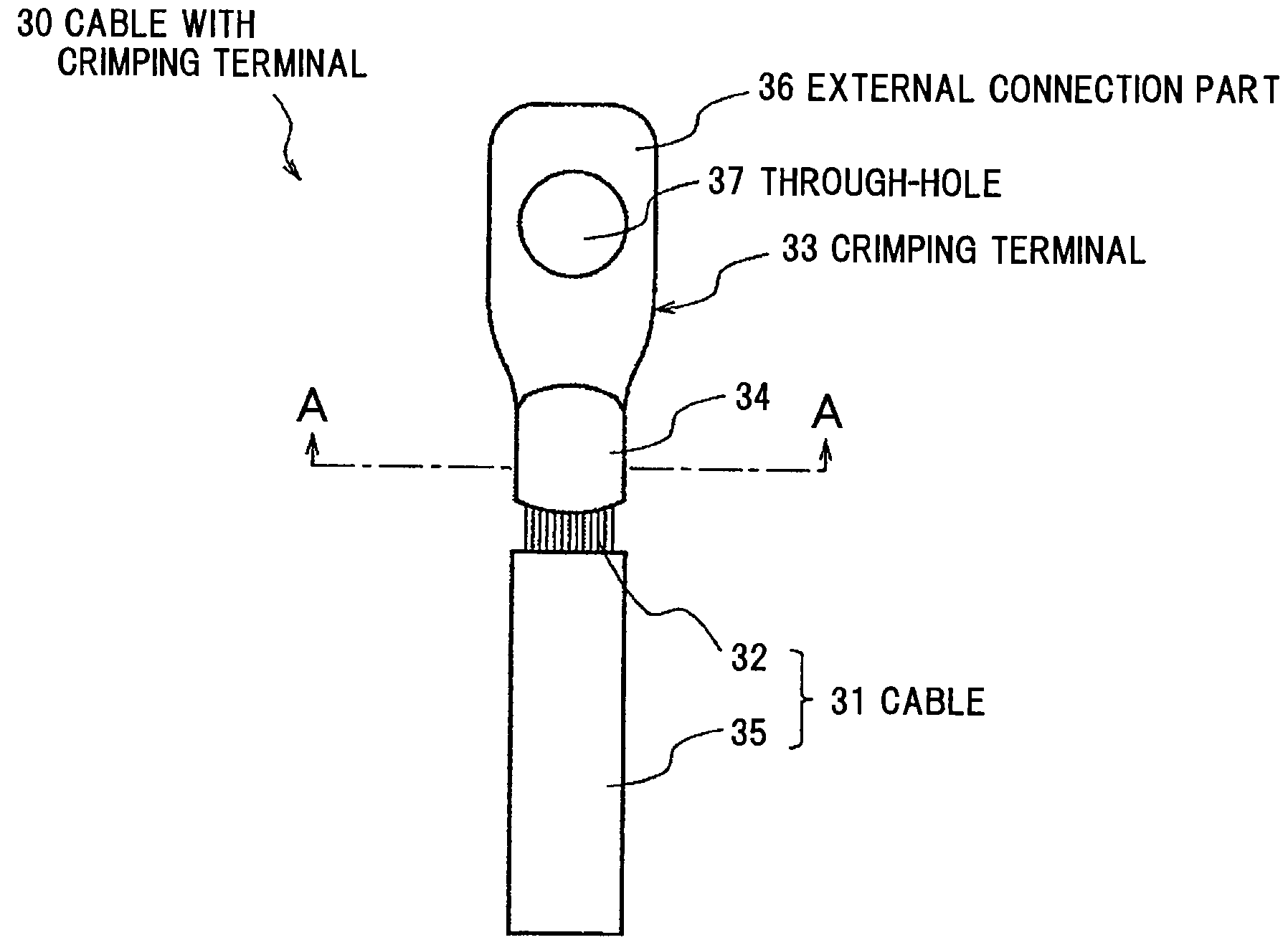

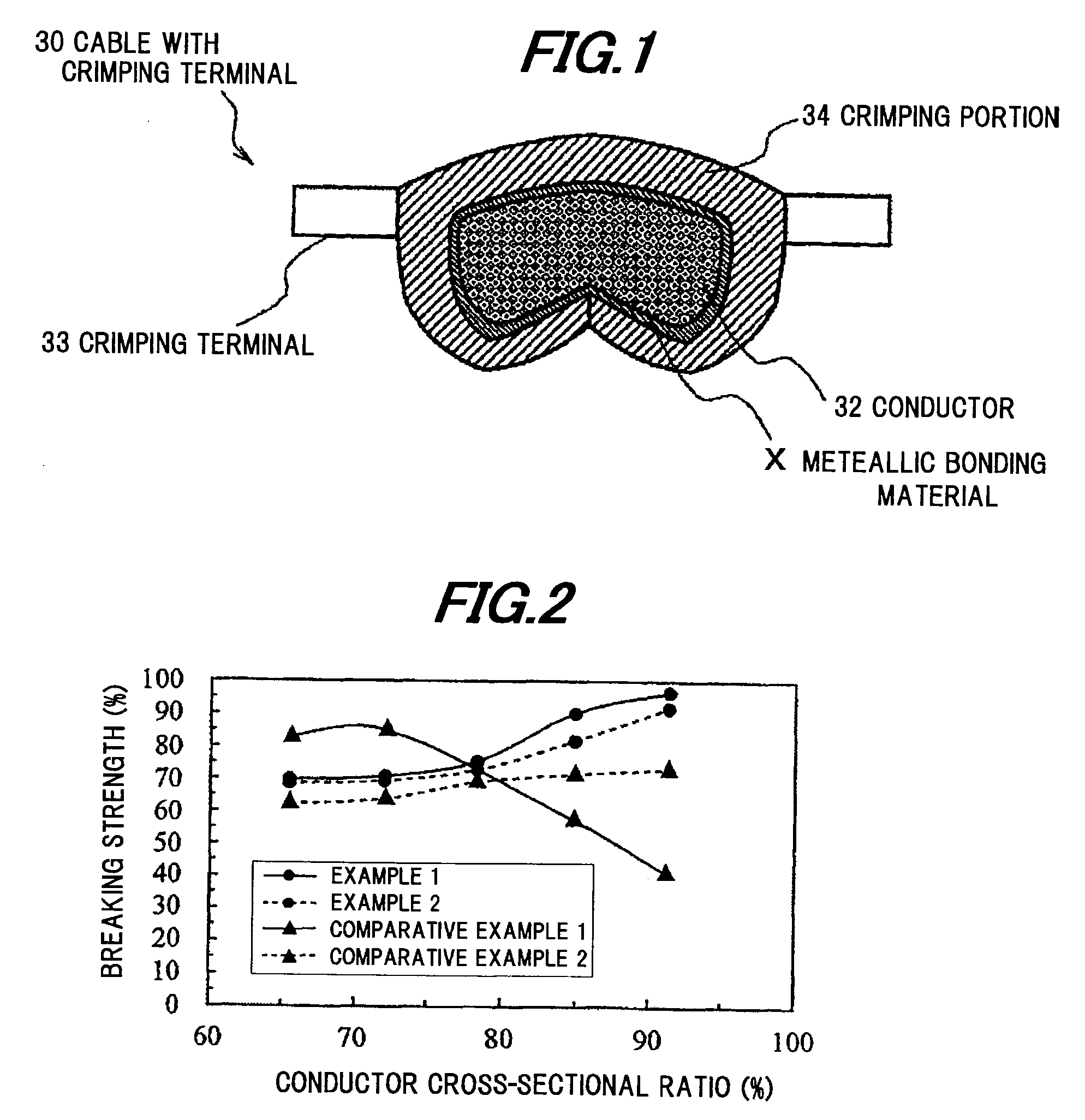

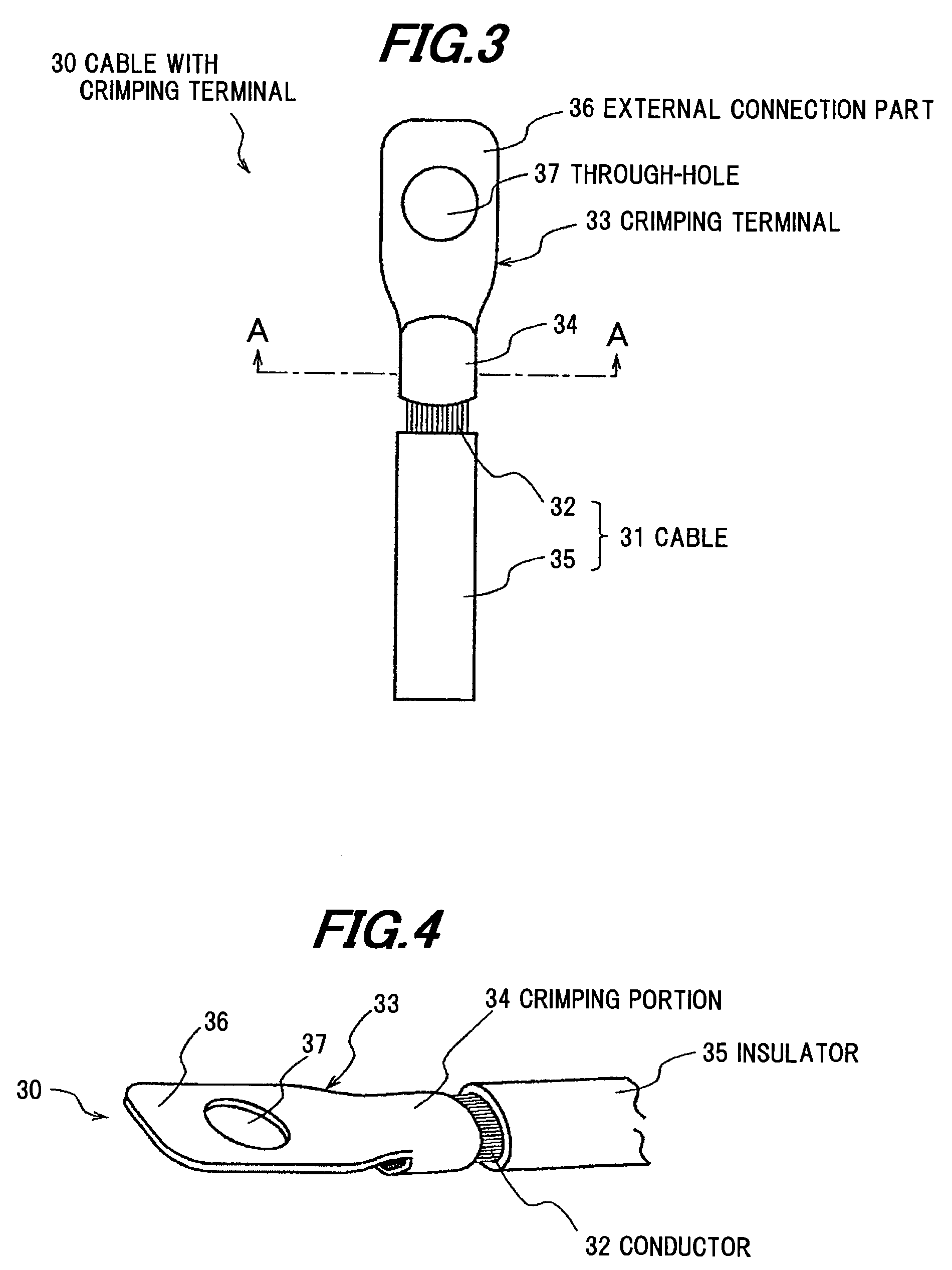

Cable with crimping terminal and method of making the same

InactiveUS20100018768A1High breaking strengthReduced breaking strengthLine/current collector detailsElectrically conductive adhesive connectionsElectrical conductorPlastic materials

A cable with a crimping terminal includes a cable including a conductor and an insulator including a plastic material, and the crimping terminal bonded to the conductor of the cable at a crimping portion by crimping connection. The conductor of the cable is bonded to the crimping terminal by a metallic bonding material at a crimping portion, and the metallic bonding material includes silver as a main component.

Owner:HITACHI CABLE

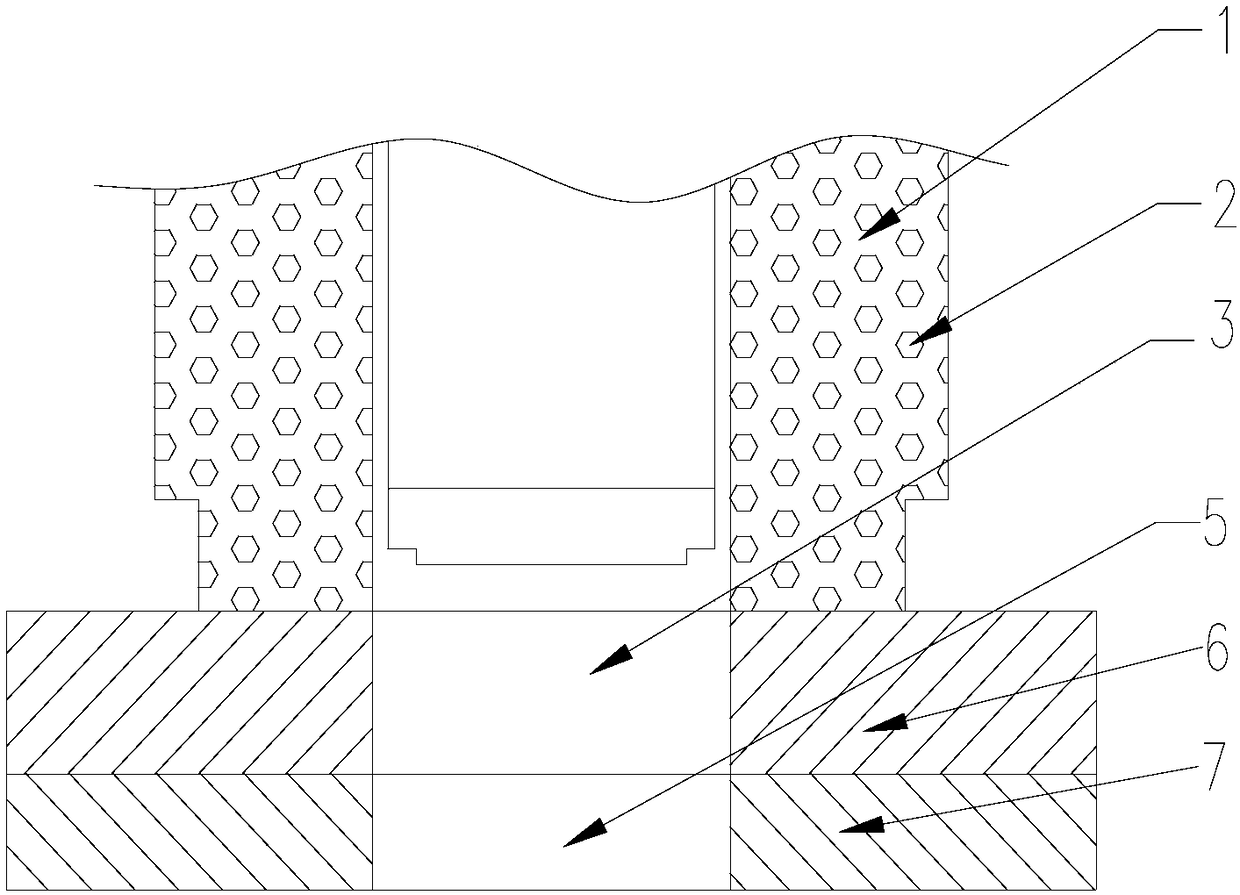

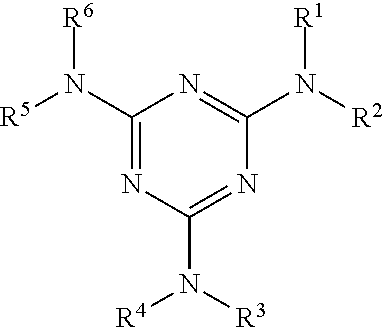

Flame-retardant antibacterial artificial wig hairline

ActiveCN106245156AWith temperature and weather resistanceRich in colorWigsFlame-proof filament manufacturePolyesterMasterbatch

The invention discloses a flame-retardant antibacterial artificial wig hairline, which comprises, by weight, 80-90% of a polyester material, 5-11% of a flame retardant agent, 2.5-6% of an antibacterial agent, 0.3-3% of a dispersing agent, 0.2-0.5% of an antioxidant, and 2-5% of color masterbatch. According to the present invention, the flame-retardant antibacterial artificial wig hairline has characteristics of high simulation degree, flexible hairline, diverse color, flame retardant property, antibacterial property, no fused drop, environmental protection and the like, and can replace the expensive human hairline. The invention further discloses a manufacturing method of the flame-retardant antibacterial artificial wig hairline, wherein the manufacturing method comprises: pre-treating a polyester raw material, carrying out blending granulation on the polyester material, the antibacterial agent, the flame retardant agent, the dispersing agent and the stabilizer by using a double-screw extruder to obtain a flame-retardant antibacterial slice, carrying out melt spinning on the slice, carrying out high-temperature shaping treatment, carrying out washing and drying, and carrying out other steps.

Owner:见喜新材料股份有限公司

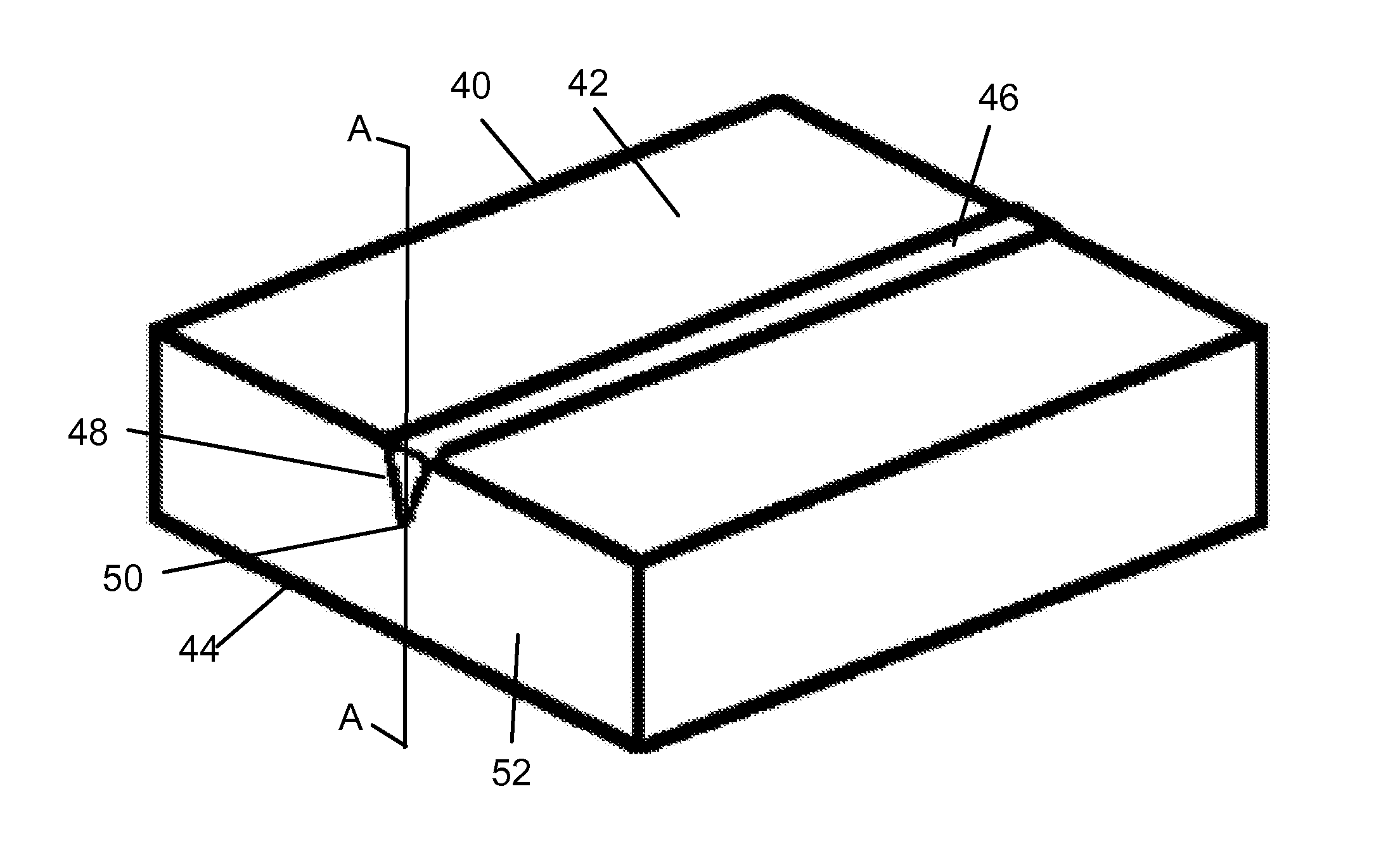

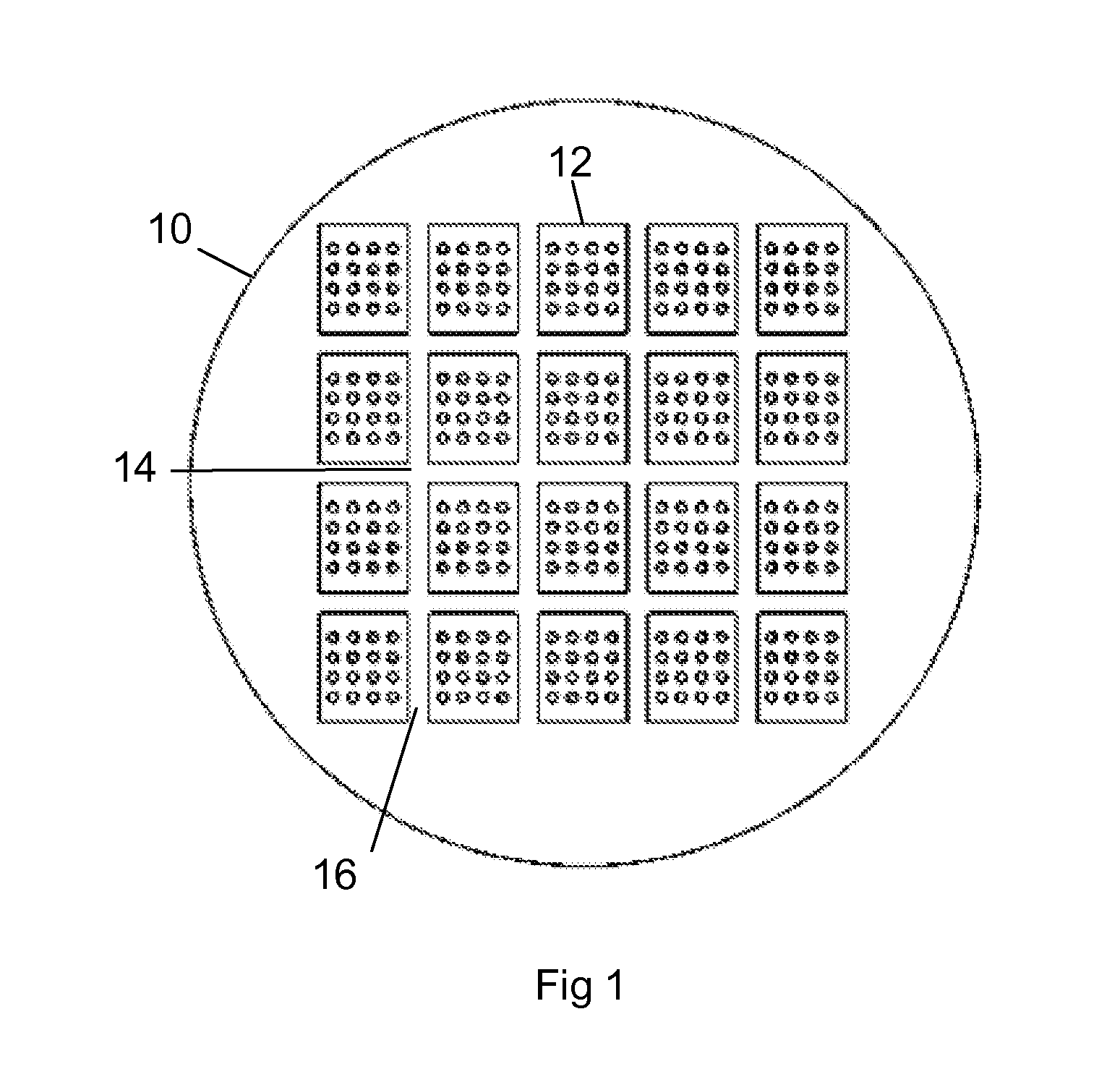

Method and apparatus for improved singulation of light emitting devices

InactiveUS20120175652A1Reduce the amount requiredAvoid thermal damageSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesPicosecond laserLaser processing

The present invention is a system and method for laser-assisted singulation of light emitting electronic devices manufactured on a substrate, having a processing surface and a depth extending from the processing surface. It includes providing a laser processing system having a picosecond laser having controllable parameters; controlling the laser parameters to form light pulses from the picosecond laser, to form a modified region having a depth which spans about 50% of the depth and substantially including the processing surface of the substrate and having a width less than about 5% of the region depth; and, singulating the substrate by applying mechanical stress to the substrate thereby cleaving the substrate into said light emitting electronic devices having sidewalls formed at least partially in cooperation with the linear modified regions.

Owner:ELECTRO SCI IND INC

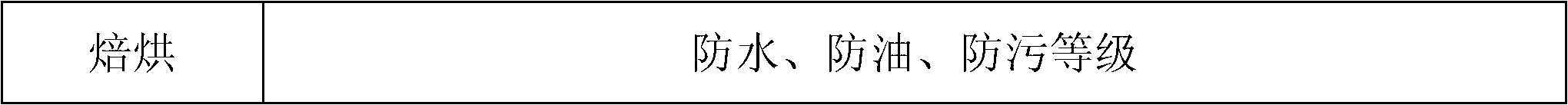

Preparation technology of water, oil and pollution resistant texture fabric

InactiveCN102978901AGood three-defense effectGood breathability and moisture permeabilityFibre typesBreaking strengthColour fastness

The invention provides a preparation technology of a water, oil and pollution resistant texture fabric. The preparation technology is characterized in that pretreatment or dyeing and dip padding fixing finishing of a base cloth is carried out, and the dip padding fixing finishing is carried out in a nanometer finishing liquid comprising a fluorine-containing finishing agent used for water, oil and pollution resistant finishing and a nanometer ceramic powder dispersion liquid. The preparation technology enables the fabric to have very good nanometer water, oil and pollution resistant functions, still have very good water, oil and pollution resistance effects after multi-time water washing, have a high color fastness and a good air and water vapor permeability and have a non-obviously decreased breaking strength after finishing.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

Low-shrinkage high-strength polyester industrial yarn and preparation method thereof

ActiveCN108385189AIncrease the cross-sectional areaReduce the temperatureSpinnerette packsFibre typesYarnThermal insulation

The invention relates to a low-shrinkage high-strength polyester industrial yarn and a preparation method thereof. The preparation method comprises: carrying out solid phase condensation polymerization tackifying on a modified polyester, melting, metering, extruding, cooling, oiling, drawing, carrying out heat setting, and winding, wherein the unchanged longitudinal height is maintained during thecooling, the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method, and the oil agent for oiling contains 67.30-85.58 wt% of crown ether. According to the present invention, the preparation method is simple; the material of the prepared low-shrinkage high-strength polyester industrial yarn is the modified polyester with the molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the fracture strength is more than or equal to 7.3 cN / dtex, and the dry heat shrinkage rates at the conditions comprising 177 DEG C, 10 min and 0.05 cN / dtex and the conditions comprising 190 DEG C, 15 min and 0.01 cN / dtex respectively are 1.8+ / -0.5% and 3.5+ / -0.5%.

Owner:JIANGSU HENGLI CHEM FIBER

Pharmaceutical dosage form

InactiveUS20130251759A1Improved controlled releaseEasy to adjustOrganic active ingredientsNervous disorderControlled releaseBreaking strength

The invention relates to a pharmaceutical dosage form, preferably with controlled release of a pharmacologically active compound (A) contained therein, the pharmaceutical dosage form very preferably being tamper-resistant and most preferably having a breaking strength B1 of at least 500 N in direction of extension E1 and having a breaking strength B2 of less than 500 N in direction of extension E2.

Owner:GRUNENTHAL GMBH

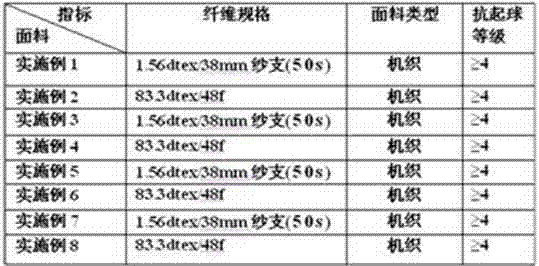

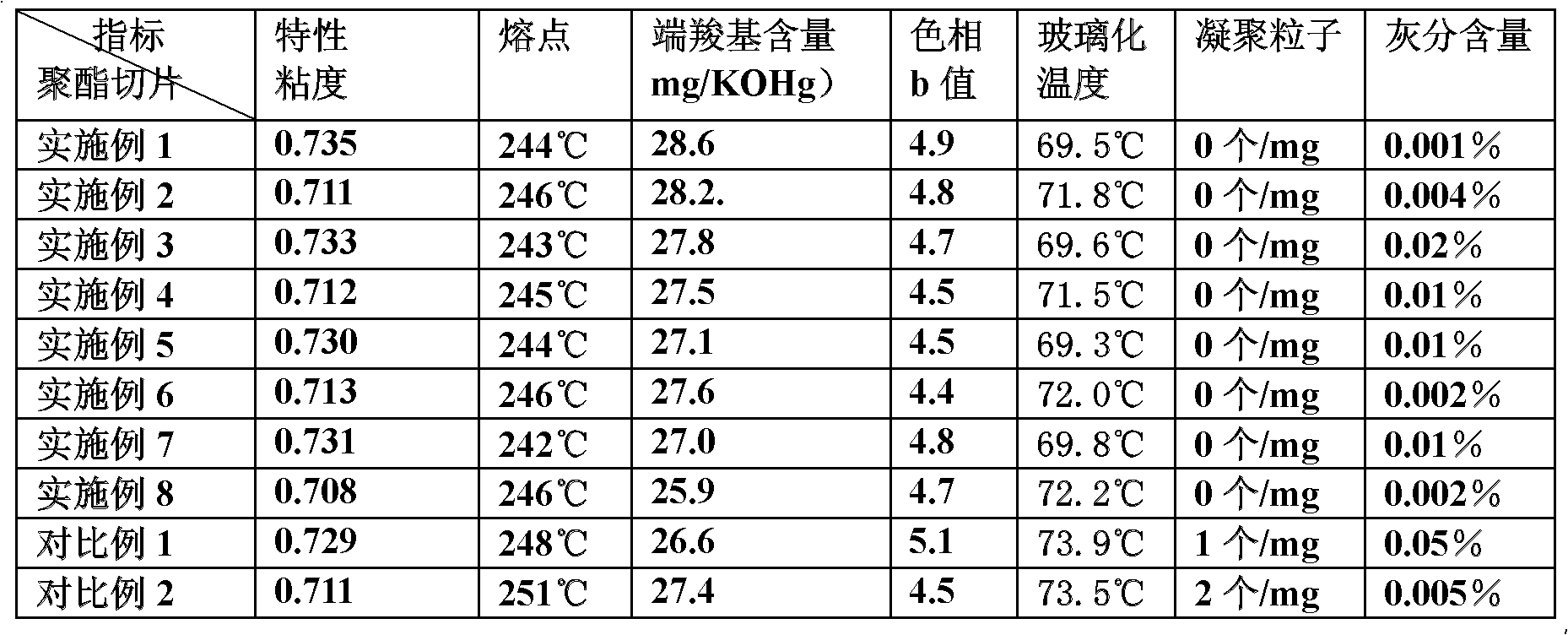

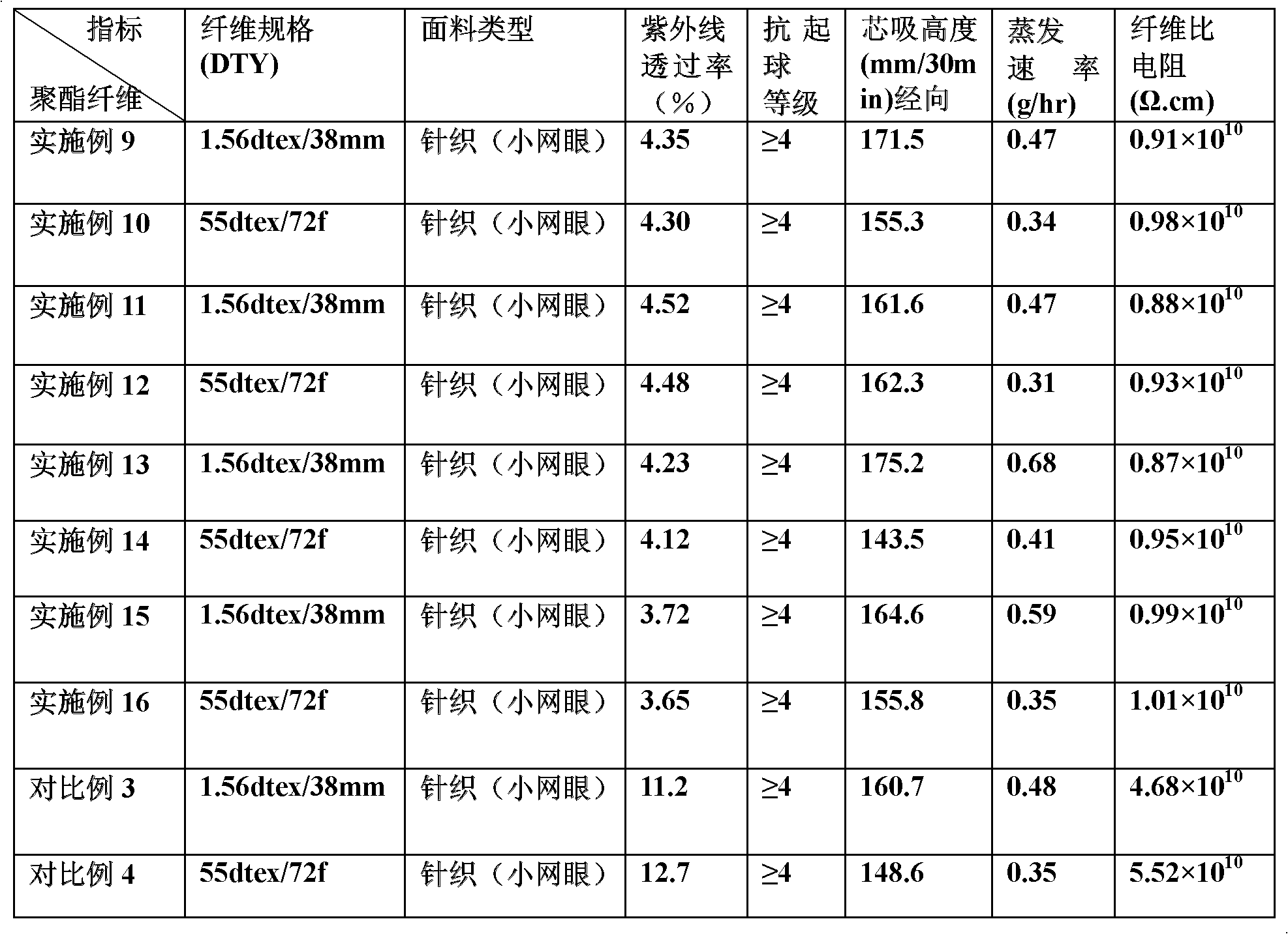

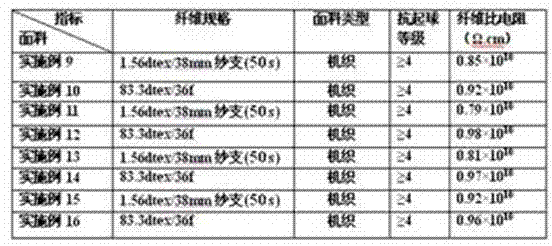

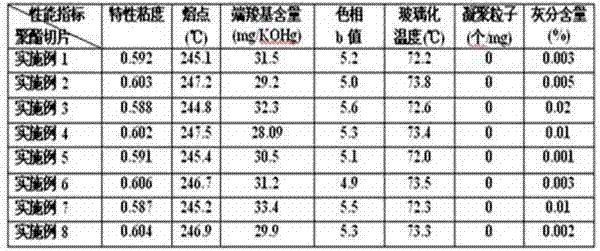

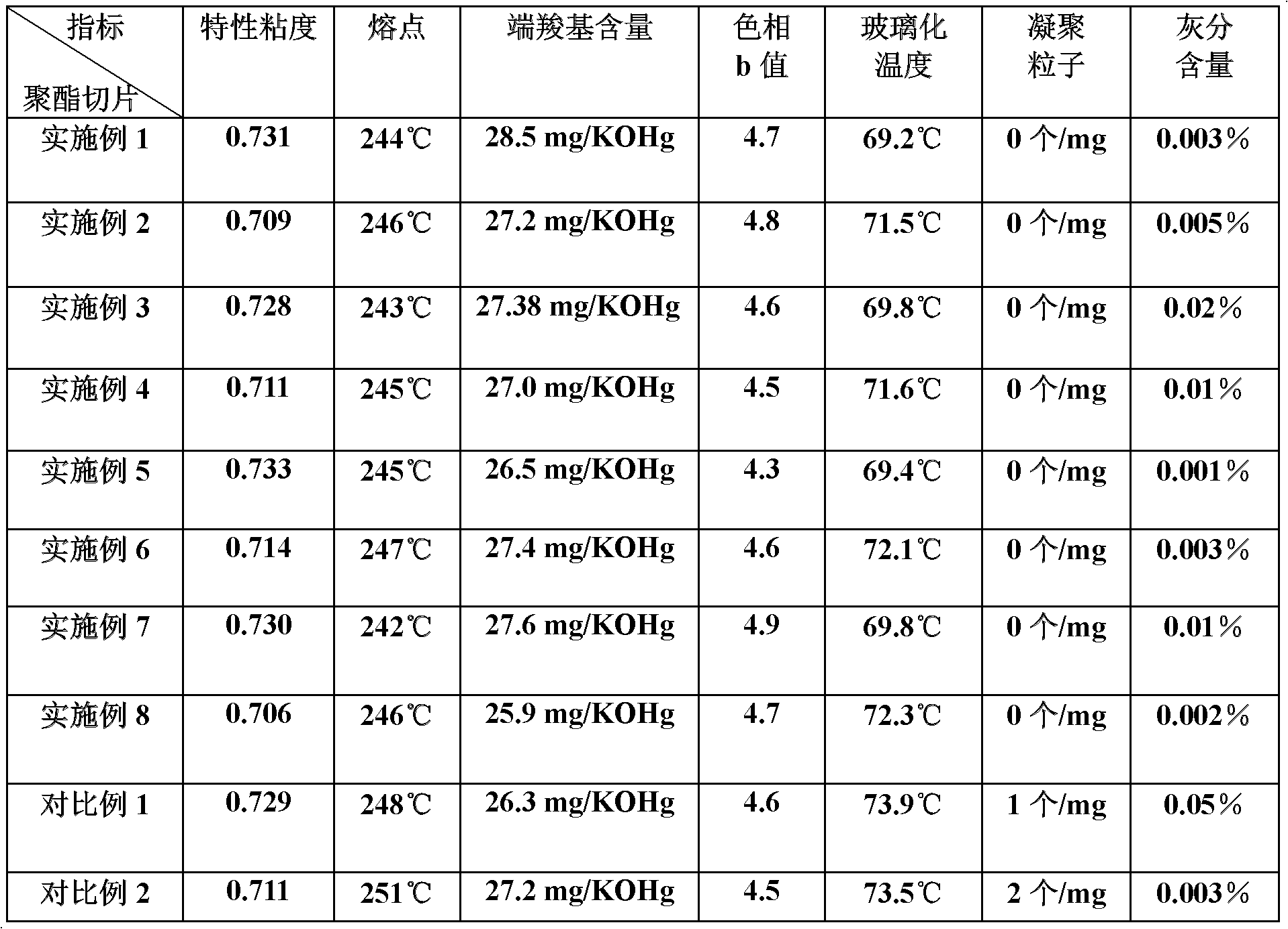

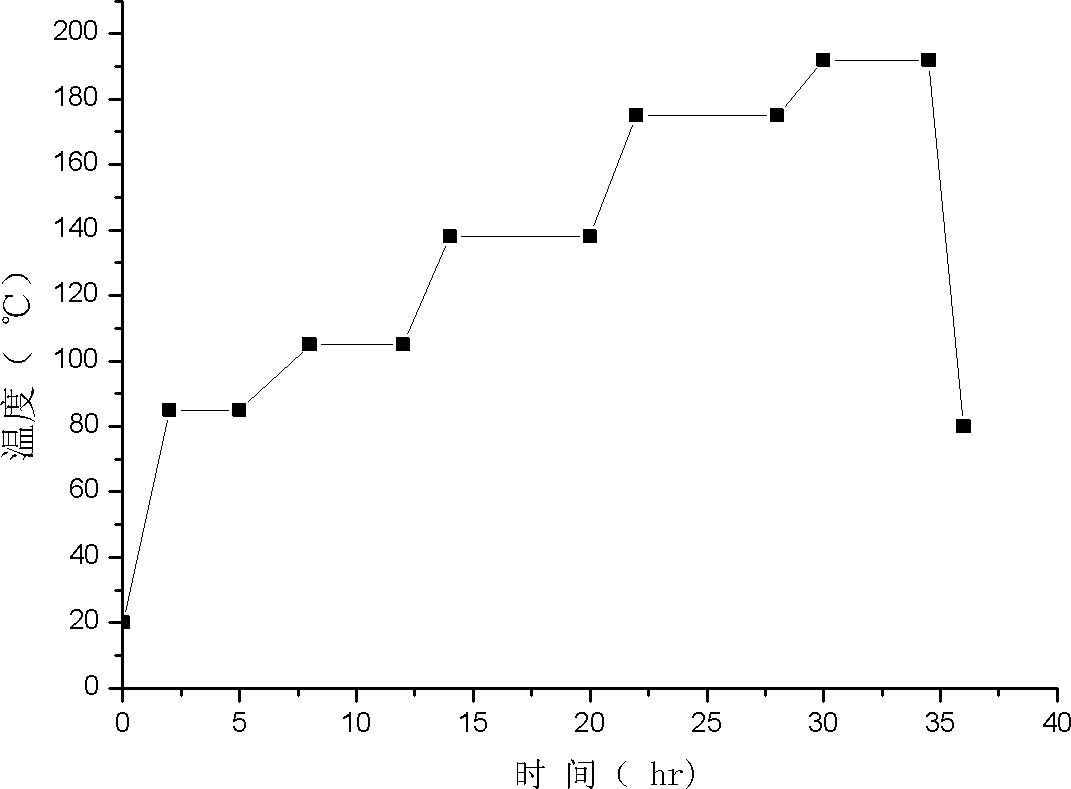

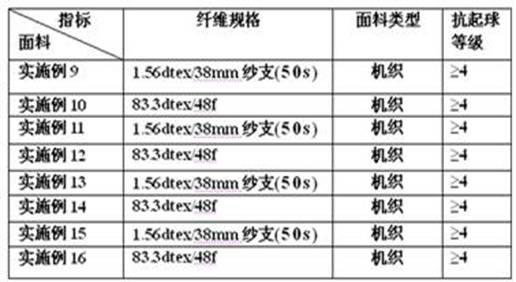

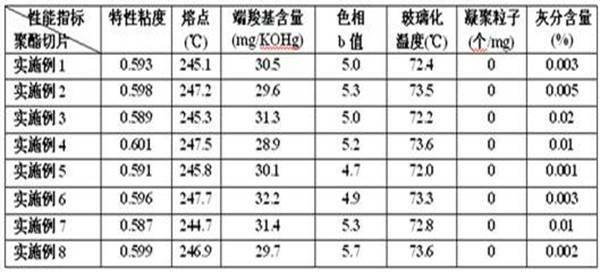

Preparation method for anti-pilling, anti-ageing and normal-pressure cation dyeable polyester chips

InactiveCN102391487AAvoid stickingAvoid self-polymerizationMonocomponent polyesters artificial filamentPolyesterTrans esterification

The invention relates to a preparation method for anti-pilling, anti-ageing and normal-pressure cation dyeable polyester chips. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and the polyester slices are precrystallized and dried before the spinning procedure. A fabric prepared from fibers spun by the polyester chips has a high anti-pilling property and high light fastness; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the polyester fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers spun by the polyester chips are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

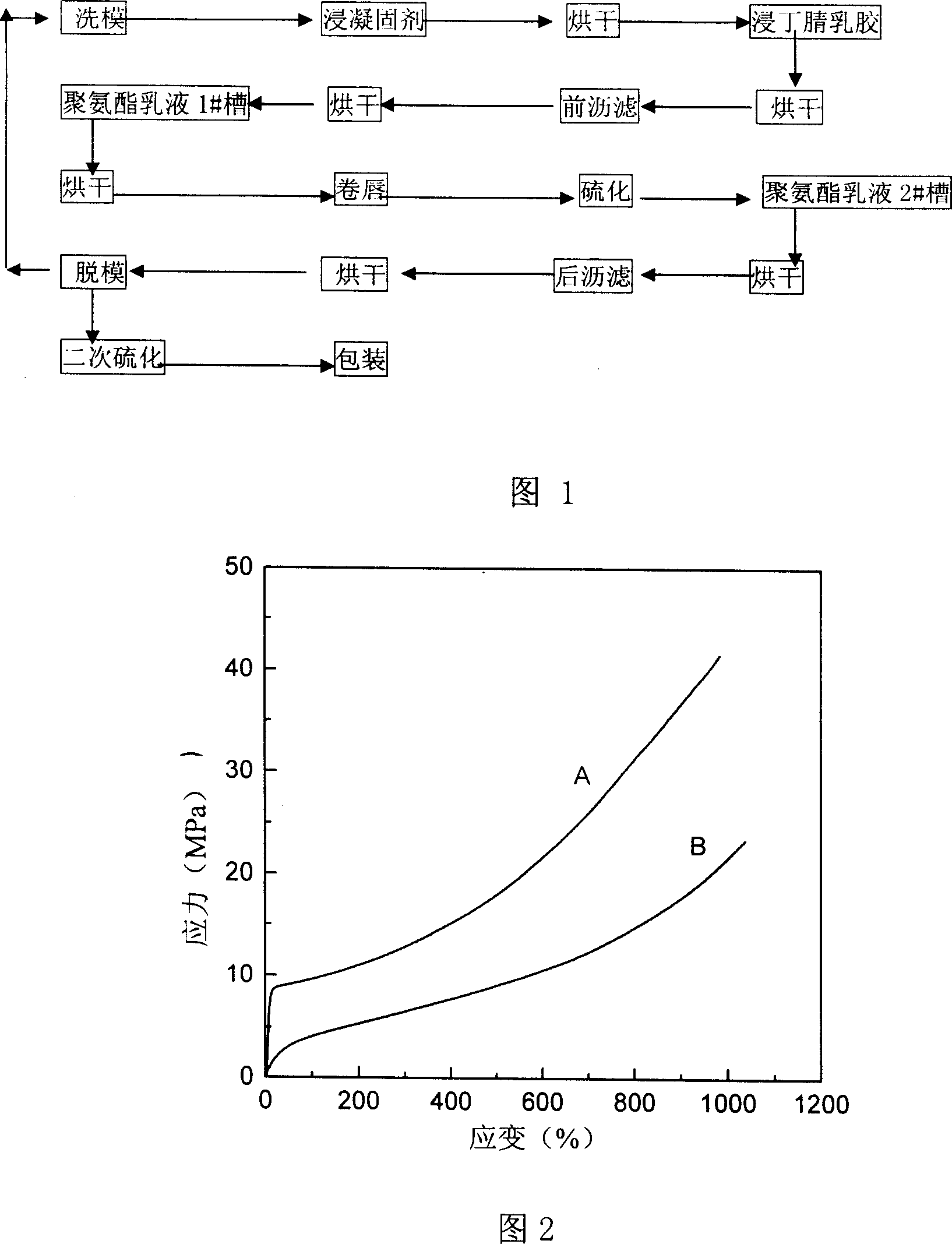

Method for fabricating one-off composite glove of nitrile butadiene rubber polyurethane

InactiveCN101003165AGood breathability and moisture permeabilityImprove wearing comfortDiagnosticsGlovesHigh resistanceEmulsion

A process for preparing the expendable composite nitrile rubber-polyurethane glove includes generating a layer of nitrile rubber film on a mould, and dipping it in aquatic polyurethane emulsion. The resultant glove has high resistance to oil and bacterial osmosis, high weatherability, and high air and moisture permeability.

Owner:TIANJIN GREENCOAT POLYMER MATERIAL TECH CO

Technique for producing medium strong polyester filament yarn by melt direct spinning

InactiveCN101205632AReduced breaking strengthBreaking strength ≥ 6.0g/d, low elongation at breakFilament manufactureMelt spinning methodsMaterials scienceFilament yarn

The invention aims to provide a processing technology for utilizing a melt direct spinning production mode to produce medium strength polyester fiber filaments (FDY). Technical routes adopted by the invention are the same with conventional varieties, but first hot-roller temperature and second hot-roller temperature which are higher than universal-energy domestic filaments and higher drafting multiple are adopted, and simultaneously winding devices are improved in a certain degree, thereby the medium strength polyester fiber FDY filaments meeting requirements can be produced on the premise that large equipment investment is not increased. The FDY filaments have the characteristics of high strength and low elongation at break. The invention is mainly applied in the polyester fiber sewing thread and paper package rib reinforcement weaving field.

Owner:SHENGHONG GRP CO LTD

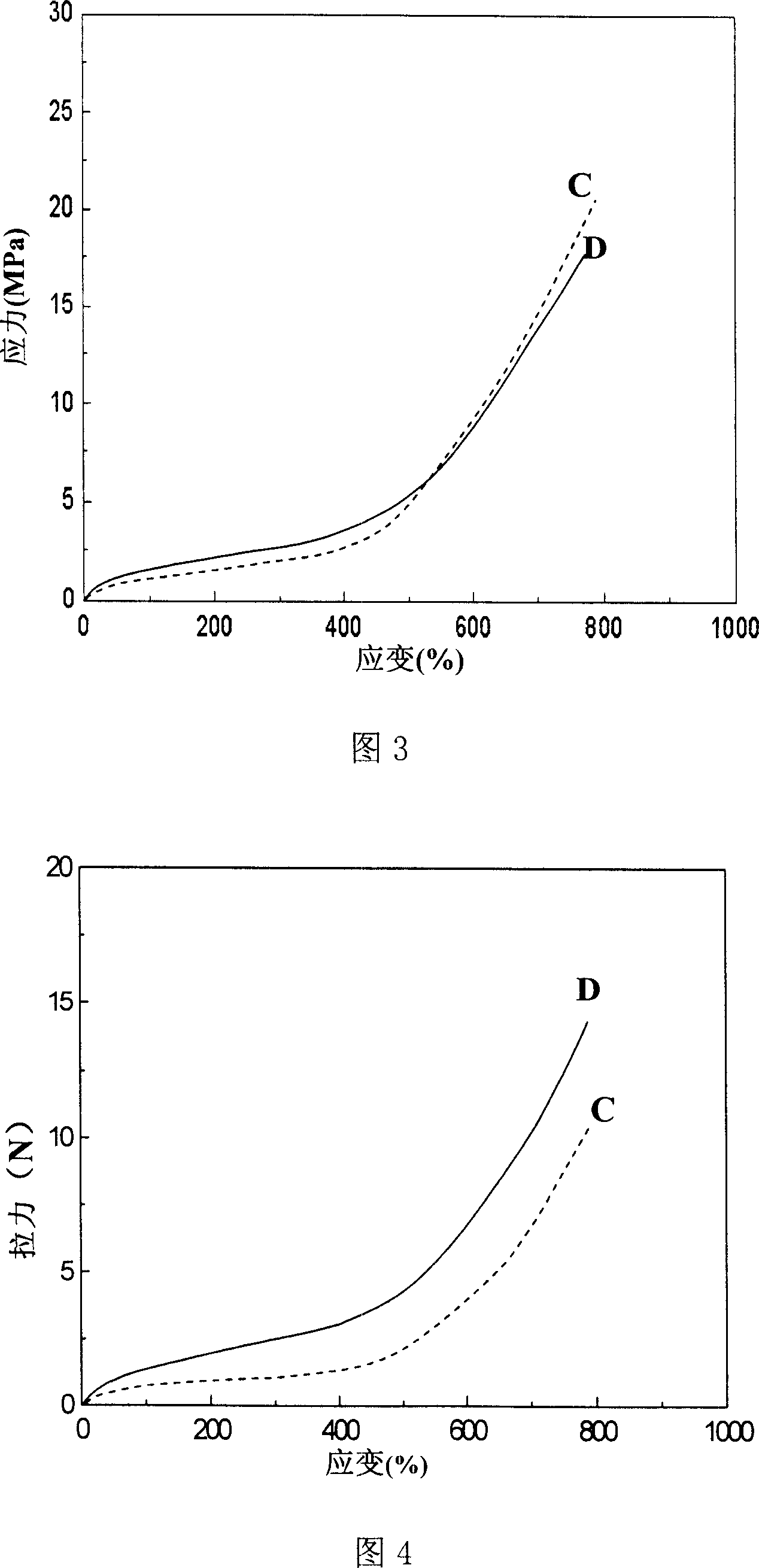

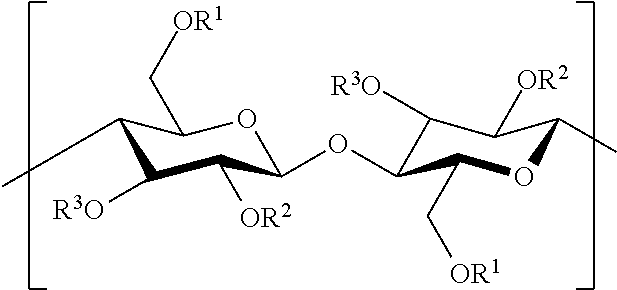

Elastomeric compositions comprising cellulose ester additives

An elastomeric composition is provided comprising at least one elastomer, at least one cellulose ester additive, at least one methylene acceptor, at least one methylene donor, and optionally, at least one filler; wherein the cellulose ester additive comprises at least one cellulose ester. The cellulose ester additive can also comprise at least one compatibilizer and / or plasticizer.

Owner:EASTMAN CHEM CO

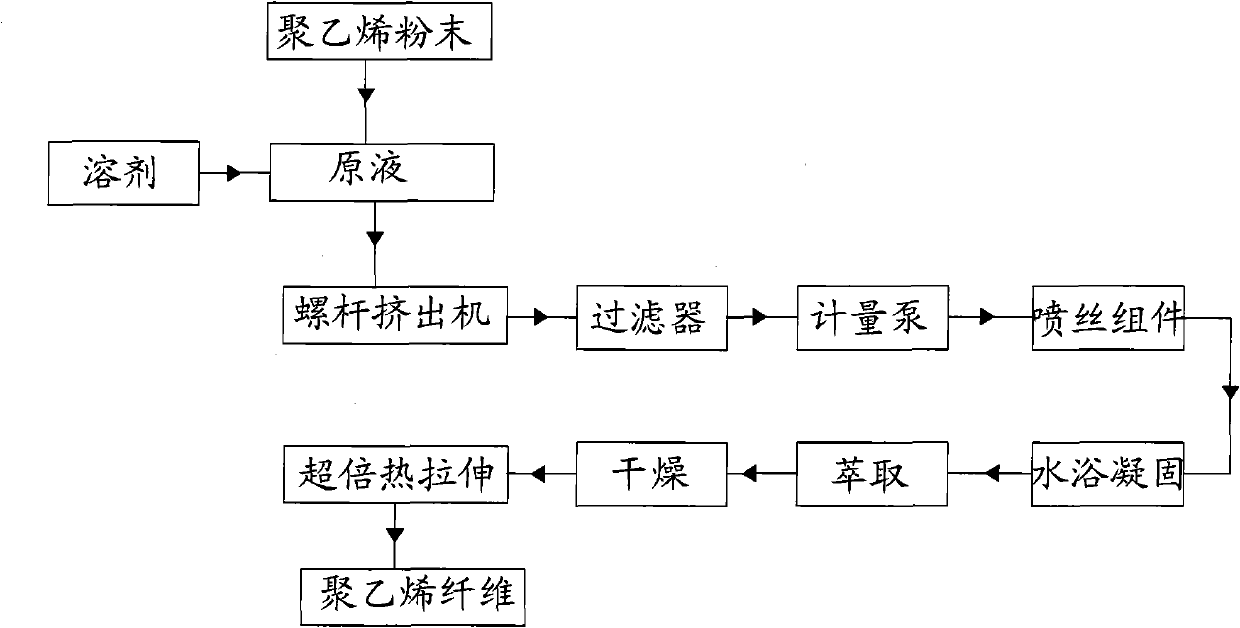

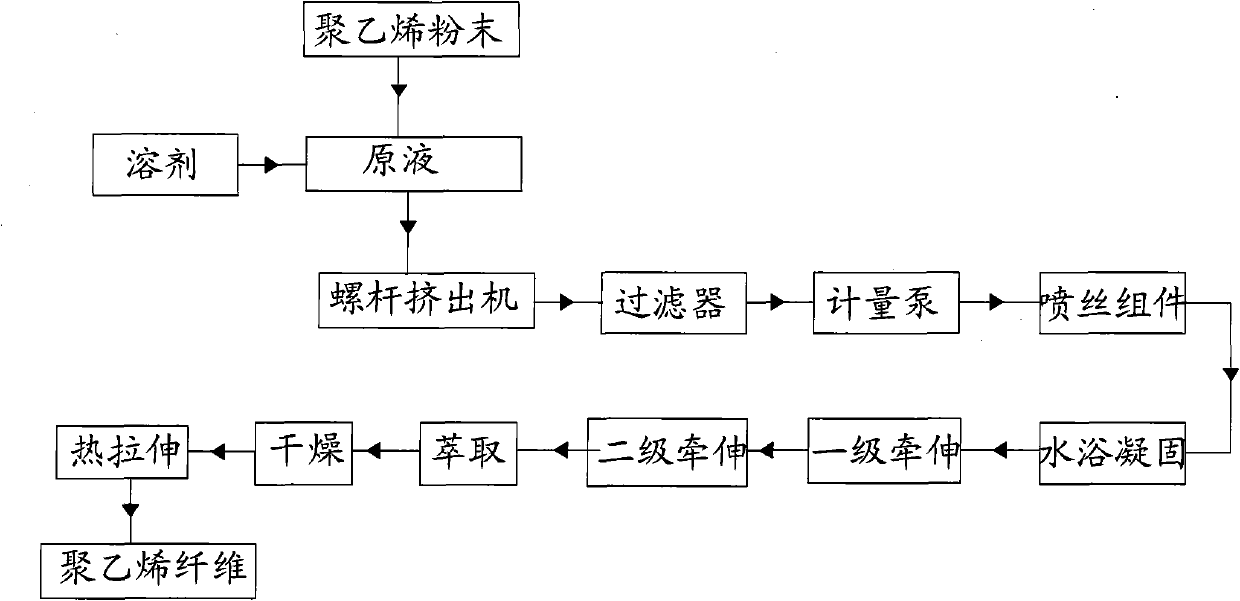

Preparation method of ultrahigh molecular weight polyethylene fiber

ActiveCN101768786AReduced breaking strengthReduce dosageWet spinning methodsMonocomponent polyolefin artificial filamentUltra-high-molecular-weight polyethyleneFiber

The invention relates to a method of preparing ultrahigh molecular weight polyethylene fiber through gel spinning method. The method comprises the following steps: (1) preparing gel protofilament of ultrahigh molecular weight polyethylene; and (2) processing the gel protofilament through extracting, drying and hot drawing to obtain the ultrahigh molecular weight polyethylene fiber. The method is characterized in that the method also comprises the step of pre-drawing the gel protofilament obtained in the step (1) before the step (2), wherein the pre-drawing time is 2.2-24 times and the total hot drawing time in the step (2) is 30-45 times. The method of the invention can be used to obtain ultrahigh molecular weight polyethylene fiber product with low size and high breaking strength and the production cost is low.

Owner:CHANGSHU SUPERFIBER

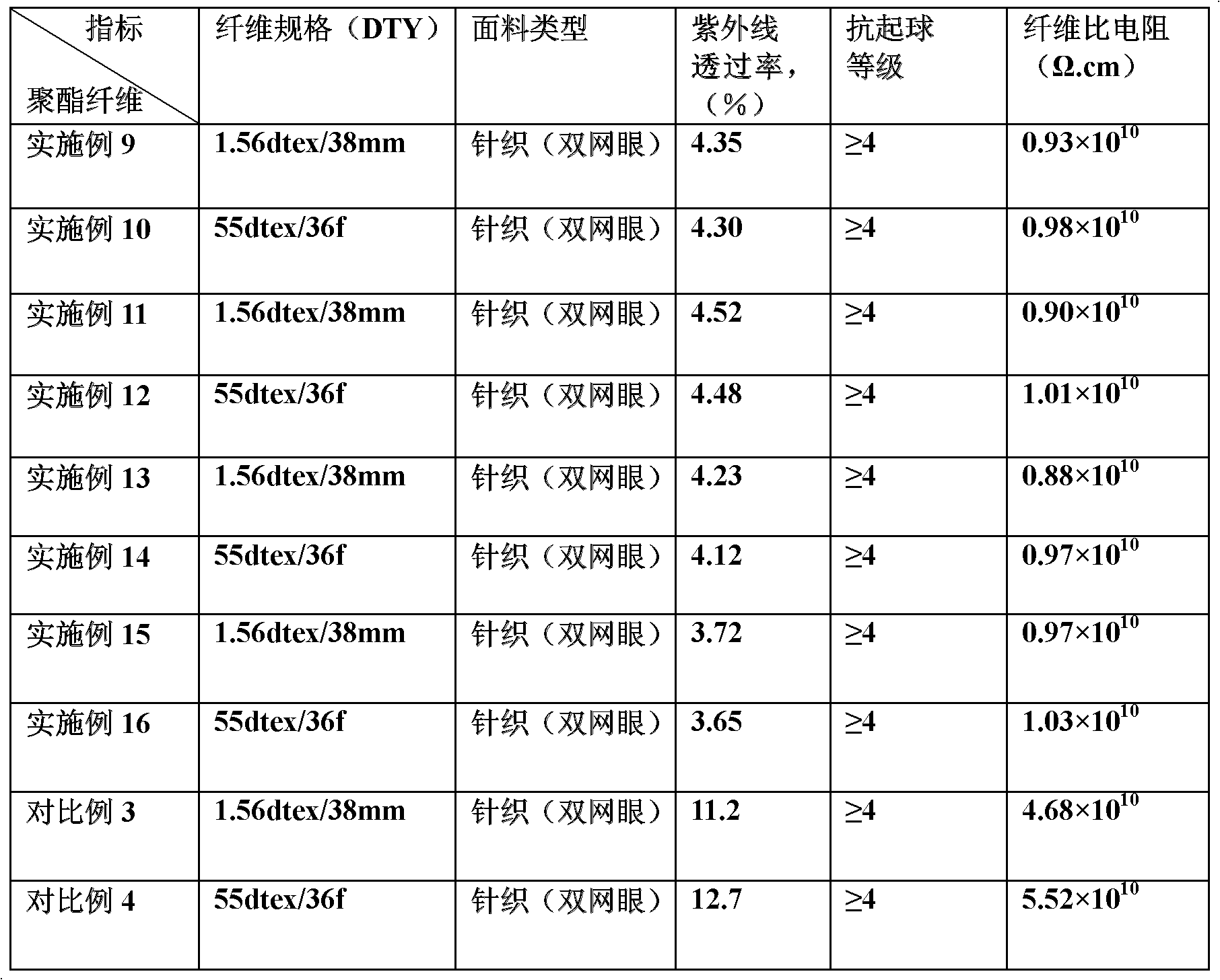

Method for preparing high-comfortable composite functional polyester fiber

ActiveCN102409429AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentSolventAntistatic agent

The invention relates to a method for preparing a high-comfortable composite functional polyester fiber, comprising the steps of: first esterification reaction section, secondary esterification reaction section, polymerization reaction process and spinning process, wherein aliphatic dicarboxylic acid and / or non-centrosymmetrically aromatic dicarboxylic acid is led into the first esterification reaction section to serve as a third monomer; flexible polyethylene glycol is led into the secondary esterification reaction section to serve as a fourth monomer; after finishing the esterification reactions, hindered amine light stabilizer and hindered phenolic antioxidant which are respectively prepared by taking acetic acid and ethylene glycol as solvents and hydroxyl silicone oil are added; after finishing pre-polymerization and before final polymerization of the polymerization reaction process, ultraviolet light absorber and antistatic agent are added; and before finishing the spinning process, polyester slices are performed pre-crystallization and drying; fibers with odd-shaped cross sections of three-leaf, cross, five-leaf and the like are prepared by melt spinning. The obtained polyester fiber is anti-ultraviolet light, antistatic, anti-pilling and has wet-absorbing quick-drying performance; and the fabric has high comfort.

Owner:JIANGSU ZHONGLU TECH DEV +1

Preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cation dyeable compound functions

InactiveCN102391486AAvoid self-polymerizationEasy-to-stain function guaranteeMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cationic dyeable compound functions. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and an antistatic agent is added after the prepolymerization and before final polymerization. Fabric spun by the polyester fibers has high anti-static and anti-pilling properties; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

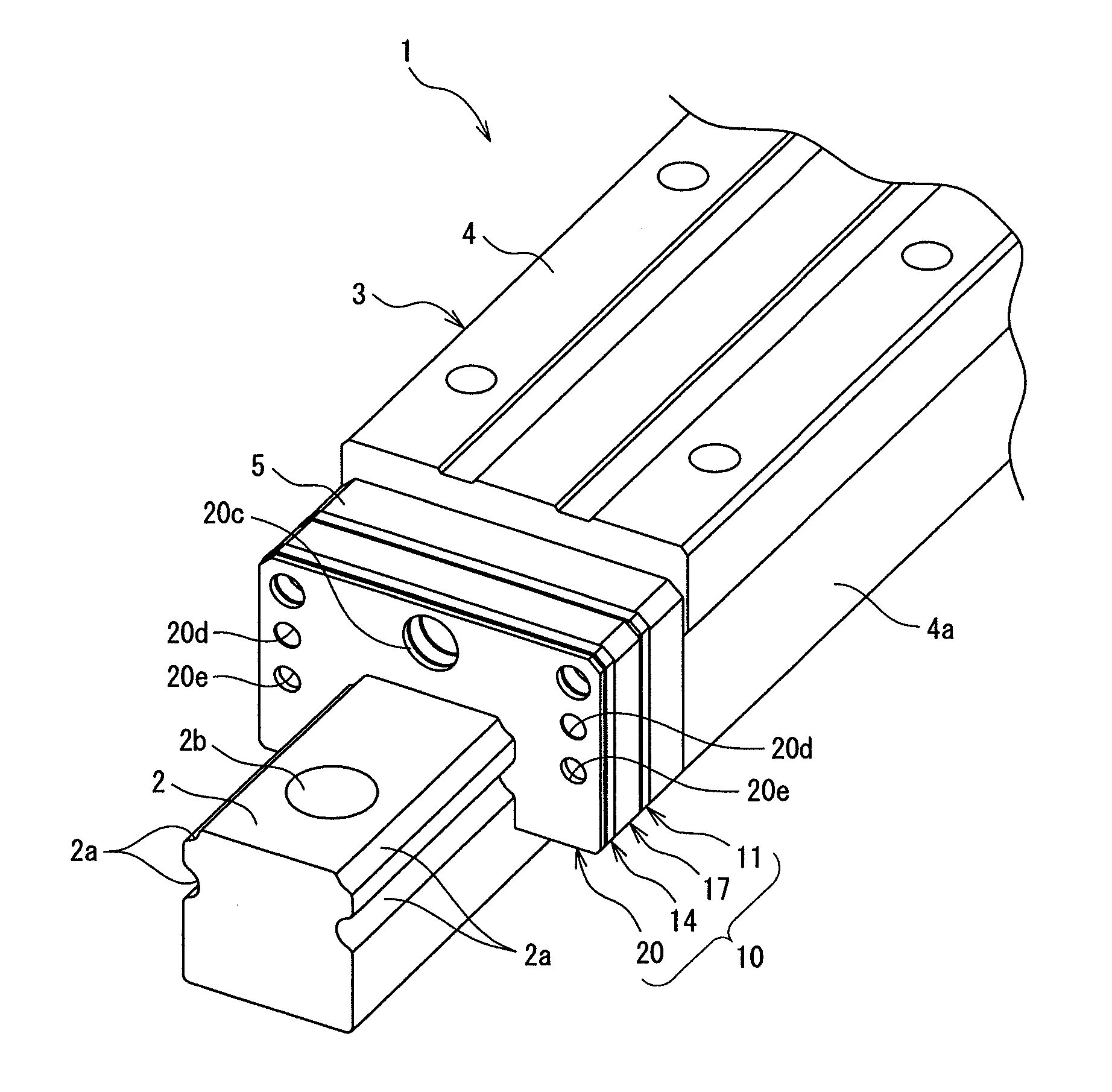

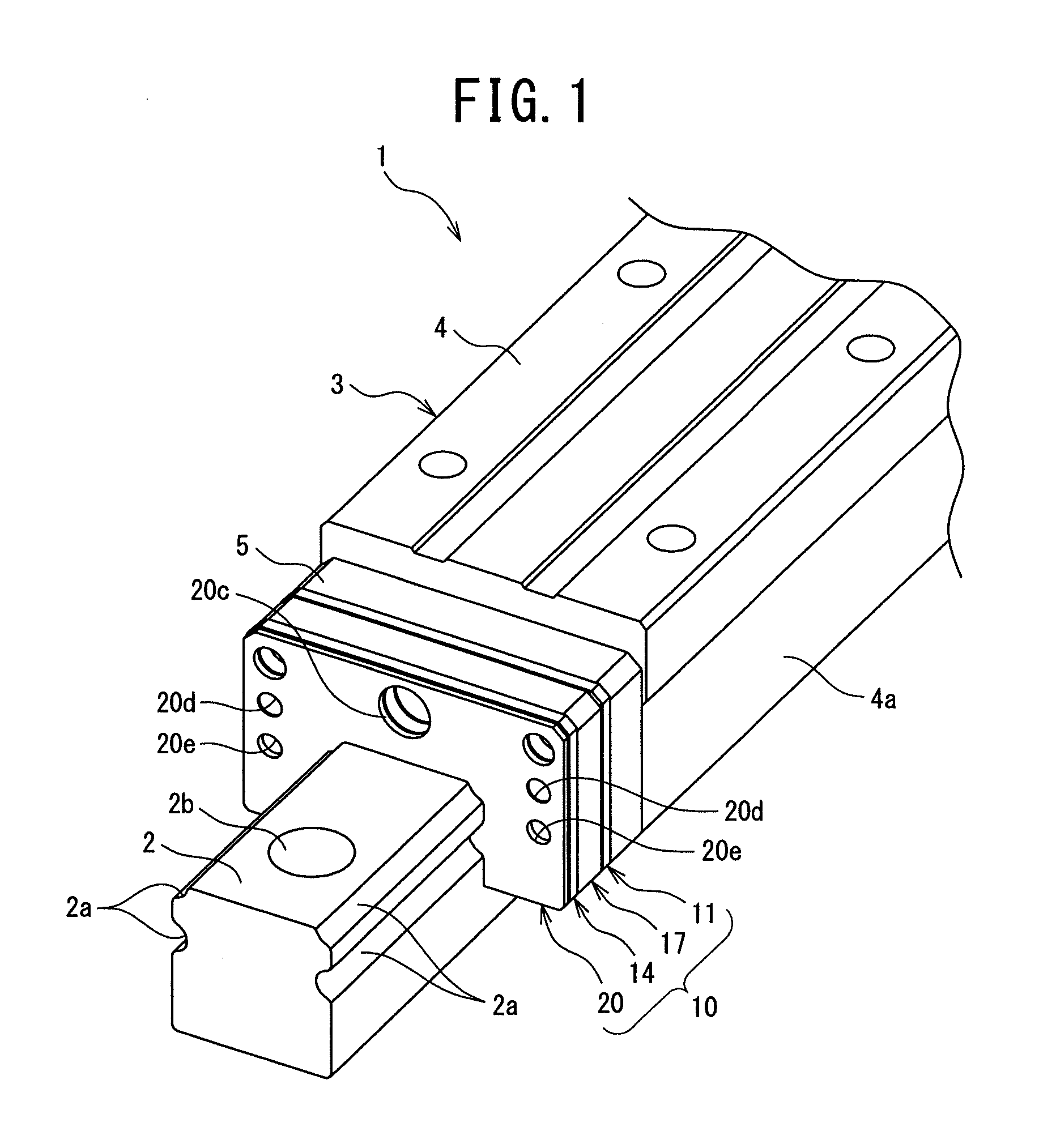

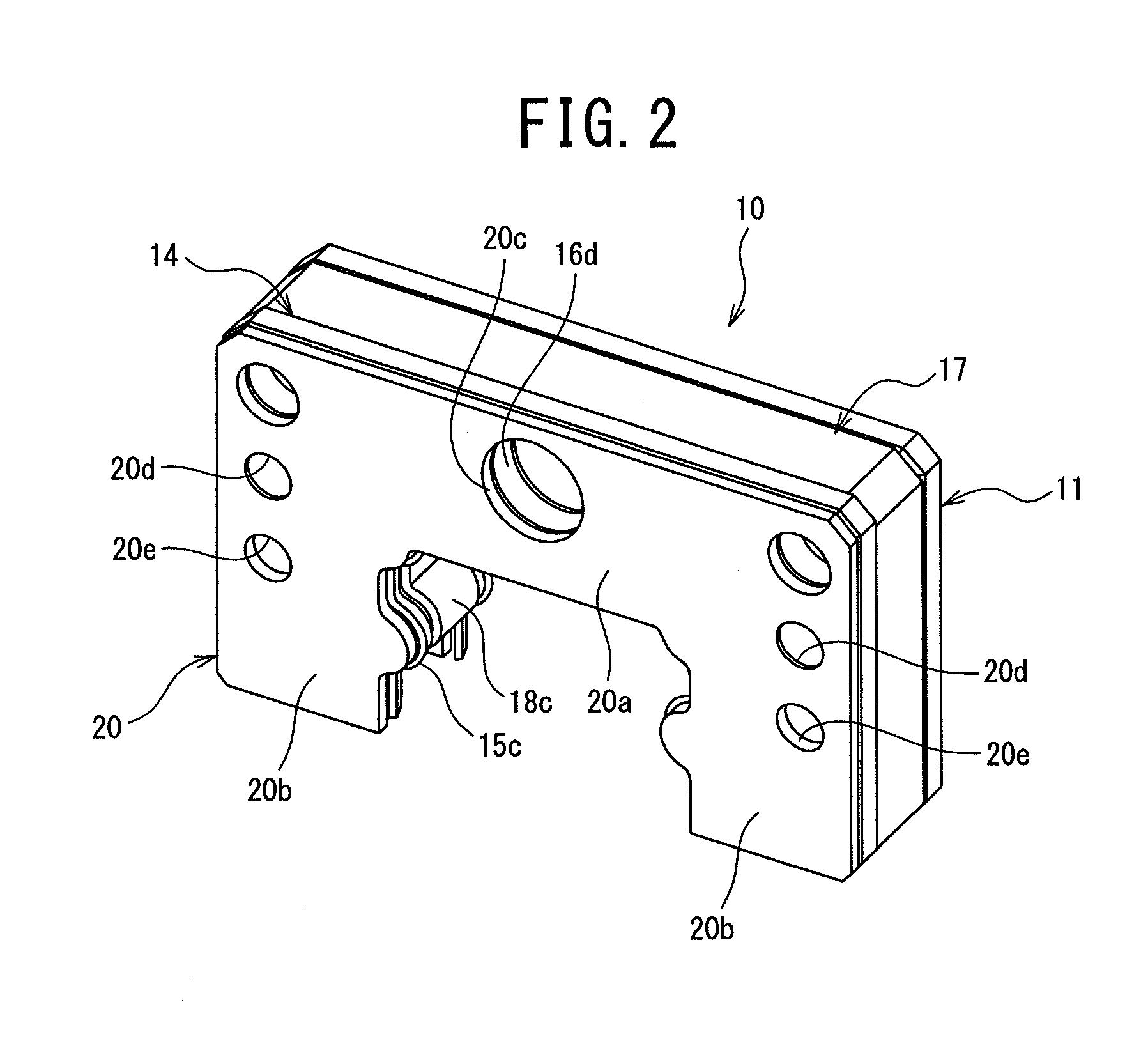

Linear Guide Apparatus

A linear guide apparatus maintaining a high dust-proof performance over an extended period of time and includes side seal units attached to end parts of a slider in the axial direction. Each side seal unit is provided with: a first seal member, at the slider, arranged in the axial direction of the slider; a second seal member at the outside of the slider in the axial direction; and a lubricating member held between the first and second seal members. The first seal member has first lip parts sliding against the rolling element rolling grooves of the guide rail, while the second seal member has second lip parts sliding against the rolling element rolling grooves. The lubricating member has a first oil-containing member for supplying lubricant to the rolling element rolling grooves. The first and second lip parts are arranged not to come into contact with the first oil-containing member.

Owner:NSK LTD

Preparation method for polyester fiber with composite ultraviolet, static electricity and pilling resisting functions

ActiveCN102409427AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureArtificial filament heat treatmentSolventTransmittance

The invention relates to a preparation method for a polyester fiber with a composite ultraviolet, static electricity and pilling resisting function. The preparation method comprises an esterification reaction procedure, a polymerization reaction procedure and a spinning procedure. The esterification reaction procedure comprises a primary esterification reaction stage and a secondary esterification reaction stage, flexible polyethylene glycol is introduced as a third monomer in the secondary esterification reaction stage, and after esterification is finished, a hindered amine light stabilizer,a hindered phenol anti-oxidant and hydroxyl silicone oil are added, wherein the hindered amine light stabilizer and the hindered phenol anti-oxidant are prepared by taking an acetic acid and ethyleneglycol as solvents. In the polymerization reaction procedure, after prepolymerization and before final polymerization, an ultraviolet absorbent and an antistatic agent are added. Before the spinning procedure, polyester is sliced for pre-crystallization and drying. The polyester fiber obtained by the method has the outstanding ultraviolet, static electricity and pilling resisting functions, and after being woven into knitted machine-made fabrics, is tested to have related technical indexes comprising the ultraviolet light transmittance of less than or equal to 5.0%, the pilling resistance of more than or equal to level 4 and the fiber volume specific resistance of less than or equal to 10*10<10> ohm.cm.

Owner:JIANGSU ZHONGLU TECH DEV +1

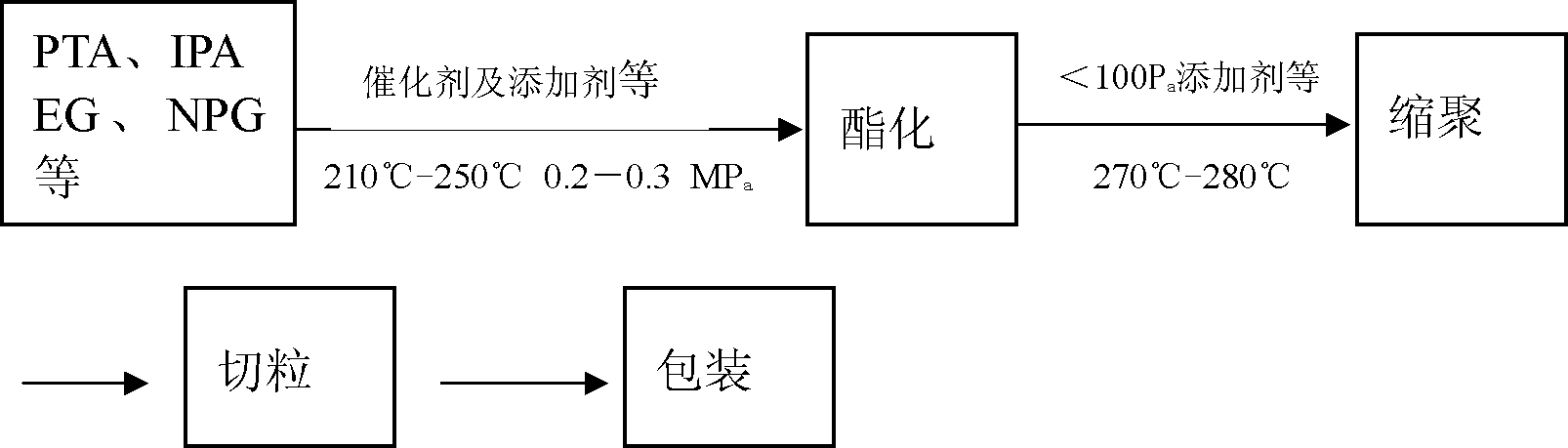

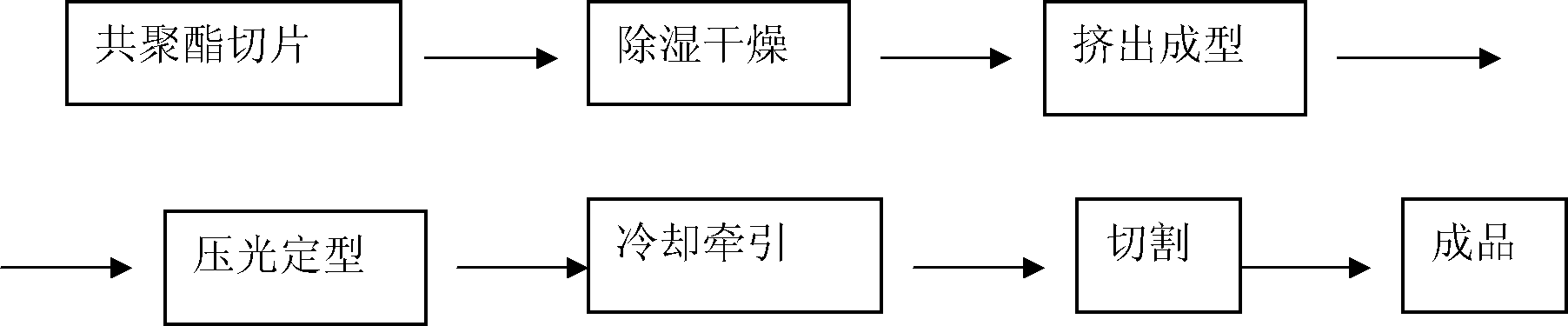

Transparent modified copolyester and its sheet material preparation method

The invention relates to a modified copolyester and its preparation method, especially to a transparent modified copolyester and its sheet material preparation method. Raw materials contain purified terephthalic acid, glycol, neopentylene glycol and / or m phthalic acid. The mol ratio of each structural unit in the transparent modified copolyester is: PTA:IPA=1:0-0.1, (PTA+IPA):MEG:NPG=1:0.60-0.99:0.01-0.40. According to the transparent modified copolyester, its intrinsic viscosity is 0.5-0.7dl / g and its melting point is 200-239 DEG C. With the increase of NPG and IPA, crystallizability of the copolyester is reduced and its transparency is increased. By controlling the copolymerization components, the copolyester with different crystallization degrees and different intrinsic viscosities is prepared, thus satisfying different needs of the market.

Owner:CHINA PETROLEUM & CHEM CORP +2

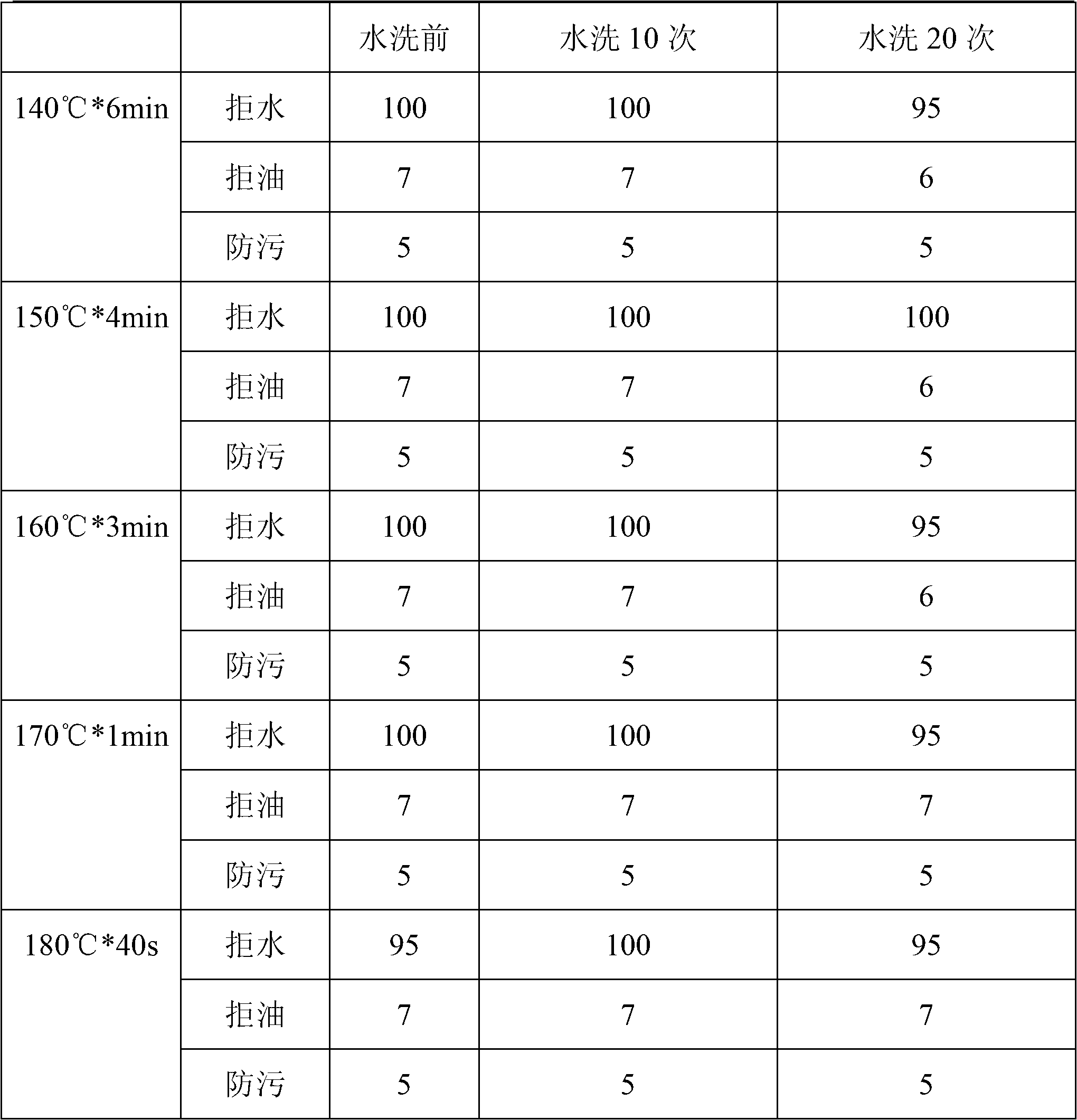

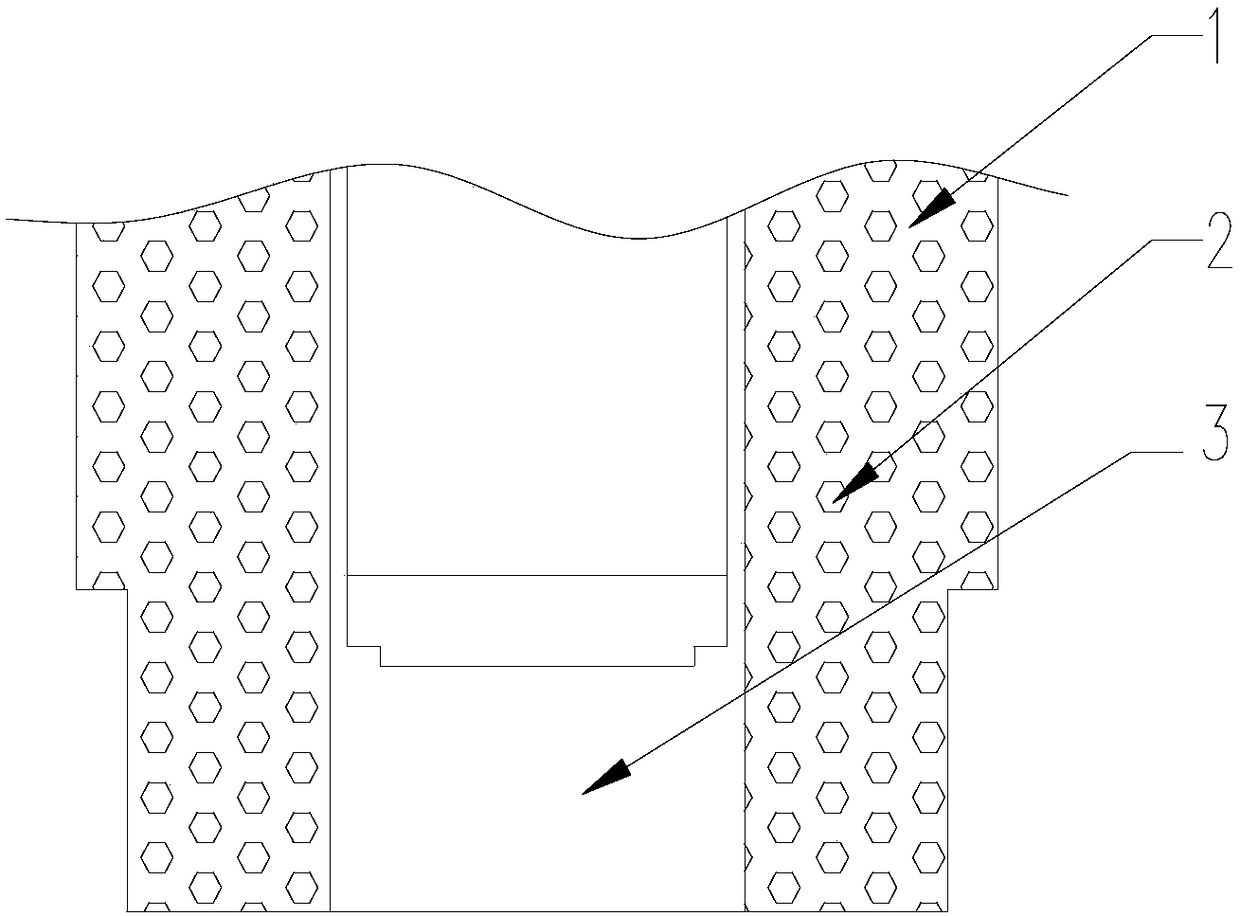

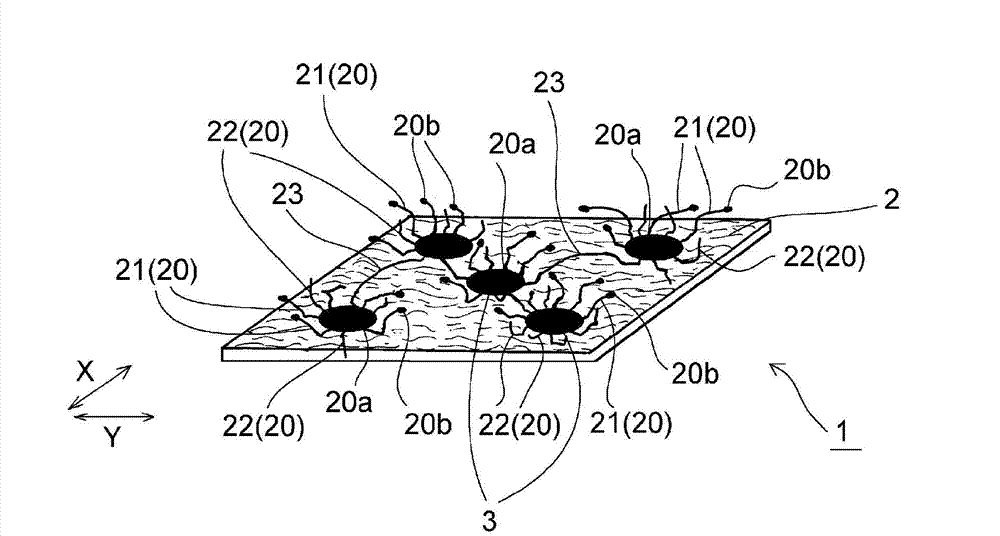

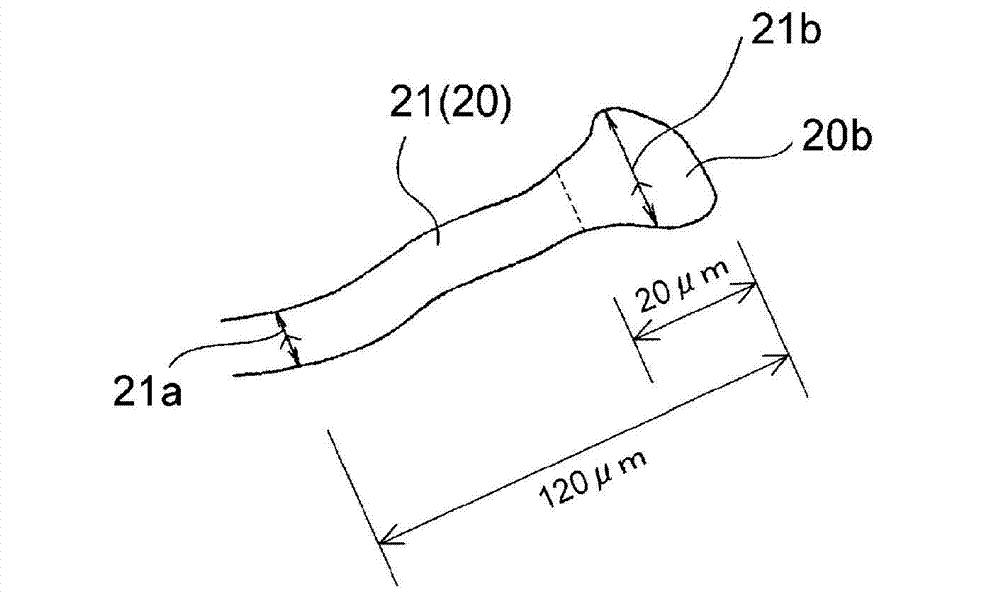

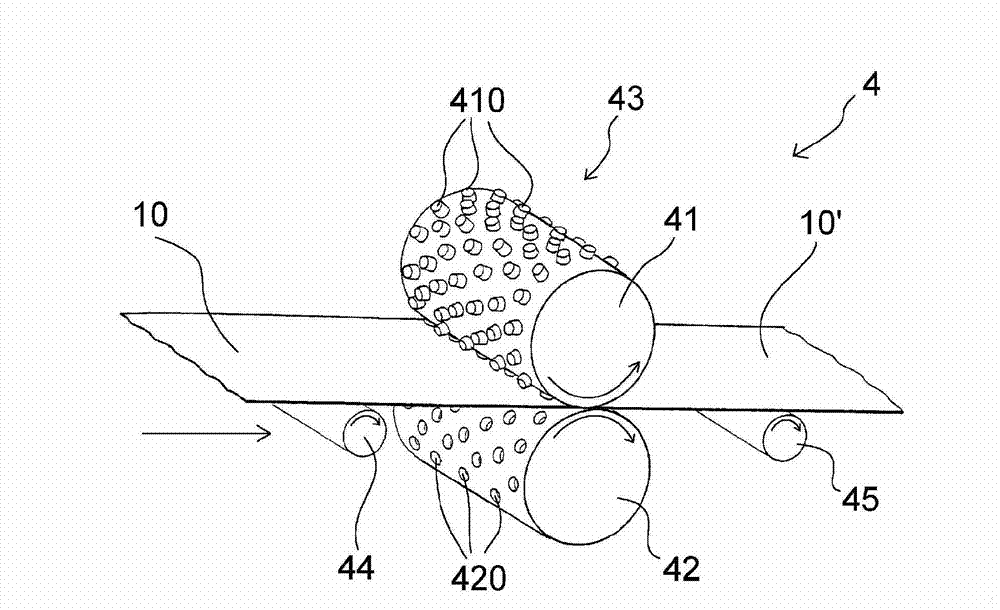

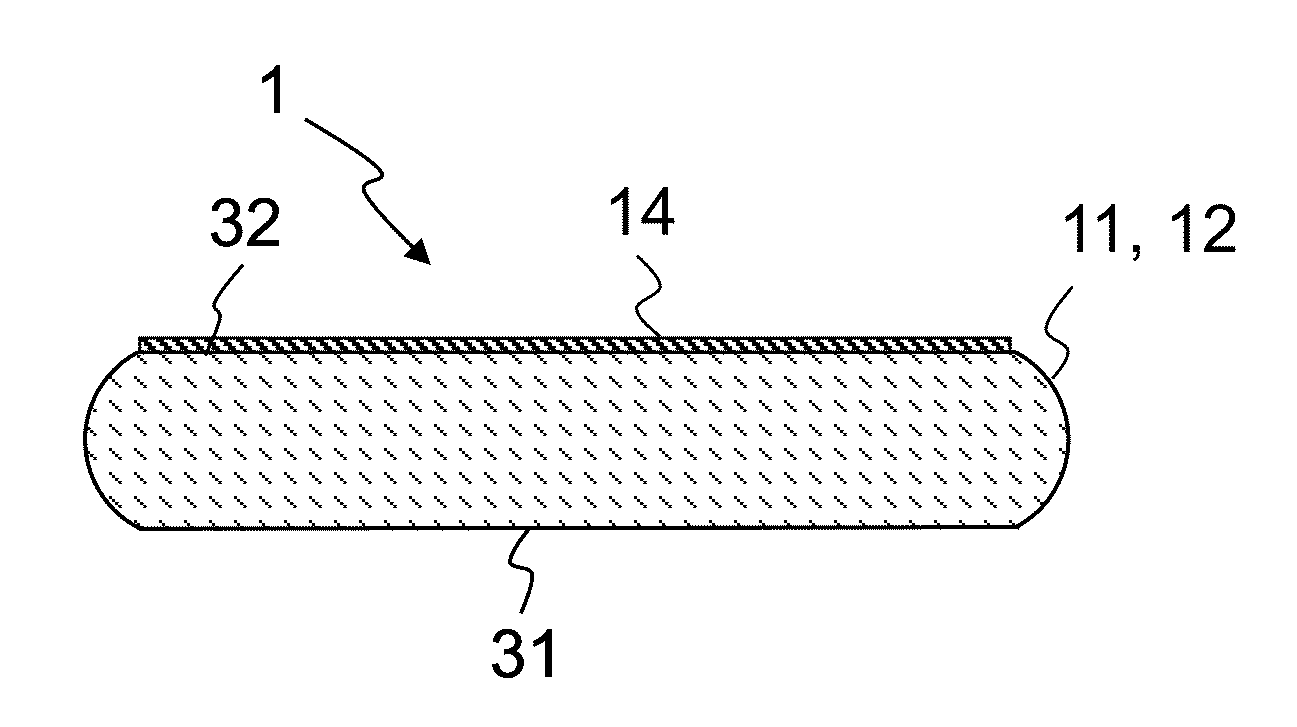

Non-woven fabric and method for producing non-woven fabric

ActiveCN103080399AGood skin feelReduced breaking strengthNon-woven fabricsStretchingWoven fabricEngineering

The present invention provides a non-woven fabric (1) wherein a web comprising a long fiber (2) is fixed by a heat sealing part (3). The non-woven fabric (1) according to the invention is provided with a fiber (21) wherein the long fiber (2) is partially broken and one end (20a) thereof is exclusively fixed by the heat sealing part (3) while the free end (20b) in the other end side is thickened. In the non-woven fabric (1) according to the invention, the fiber (21) having the thickened free end (20b) shows an increase in the terminal diameter of the fiber of 15% or greater.

Owner:KAO CORP

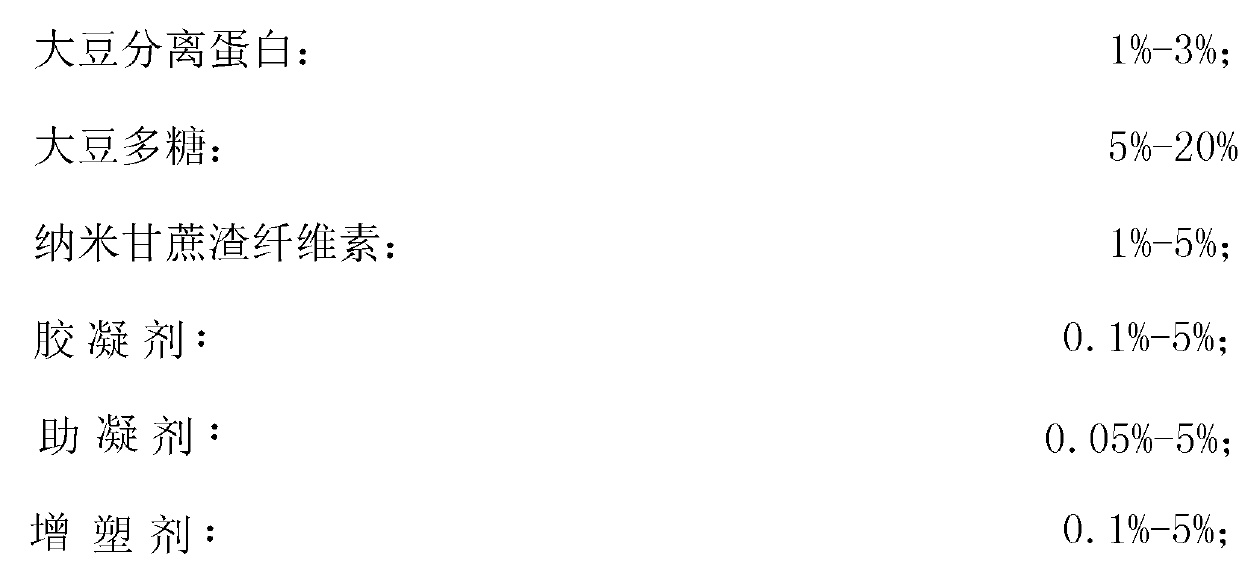

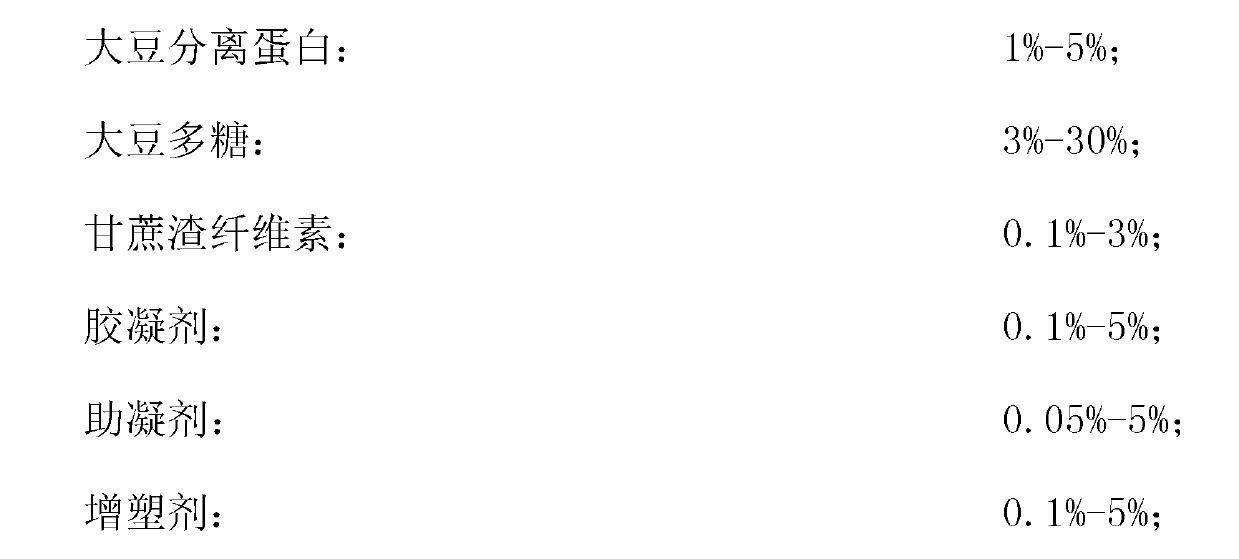

Plant empty capsule and preparation method thereof

InactiveCN103127029AHigh barrierImprove mechanical propertiesCapsule deliveryFood shapingCellulosePlasticizer

The invention discloses a plant empty capsule and a preparation method thereof. The plant empty capsule takes soy isolate protein, soybean polysaccharide and bagasse cellulose which are of different proportions as main raw materials. The preparation method comprises the following steps of a. after mixing the soy isolate protein, the soybean polysaccharide and nanometer bagasse cellulose, and adding a plasticizer so as to prepare and obtain a glue solution I; b. adding a gelling agent and a coagulant aid into deionized water so as to prepare and obtain a glue solution II; c. mixing the glue solution I and the glue solution II so as to prepare and obtain a glue solution III; d. putting the glue solution III at 40-50 DEG C and decompressing and defoaming; and e. preparing the empty capsule through a membrane dipping manner.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

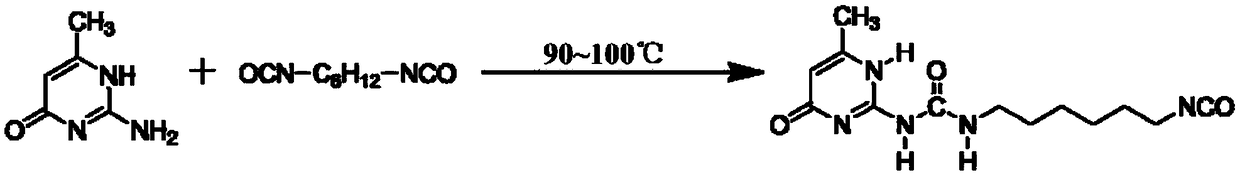

Preparation method of epoxy resin composite material based on quadruple hydrogen bond supermolecular self repairing

The invention provides a preparation method of an epoxy resin composite material based on quadruple hydrogen bond supermolecular self repairing. The preparation method comprises the following steps: preparing a quadruple hydrogen bond-based supermolecular self-repairing component by taking 2-amino-4-hydroxyl-6-methyl pyridine, hexamethylene diisocyanate and a terminal amino or terminal hydroxyl polymer as raw materials, dissolving and blending epoxy resin containing the quadruple hydrogen bond and a supermolecule in a solution to form a homogeneous mixing system, removing a solvent by a heating and vacuumizing mode, adding a curing agent, and curing to obtain the self-repairing epoxy resin composite material. The composite material prepared according to the preparation method has excellentheat stability and high mechanical property, has a certain self-repairing capability, improves the reliability in the use period and prolongs the service life of the material; furthermore, the sources of the raw materials are wide, and the preparation method has the characteristics of simple process, high practicability, high applicability and the like.

Owner:HARBIN ENG UNIV

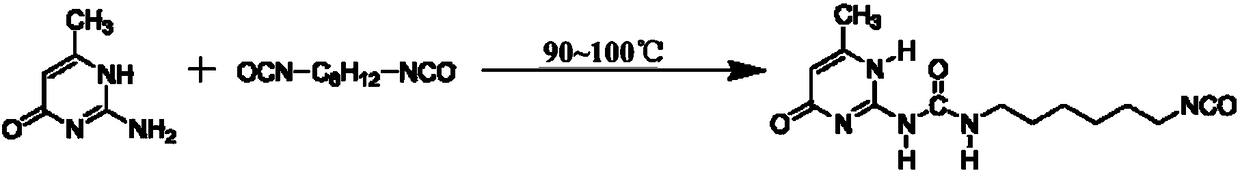

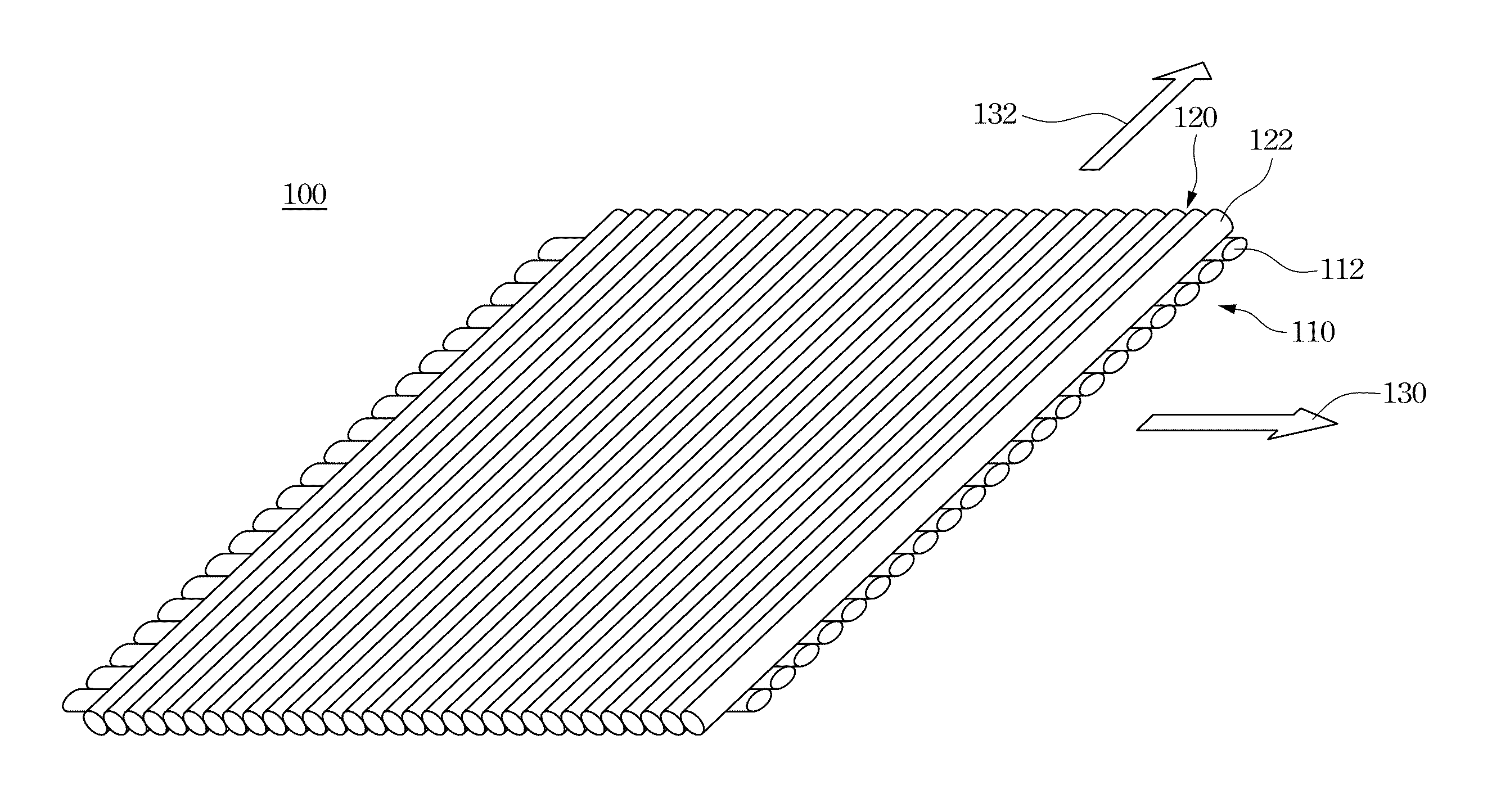

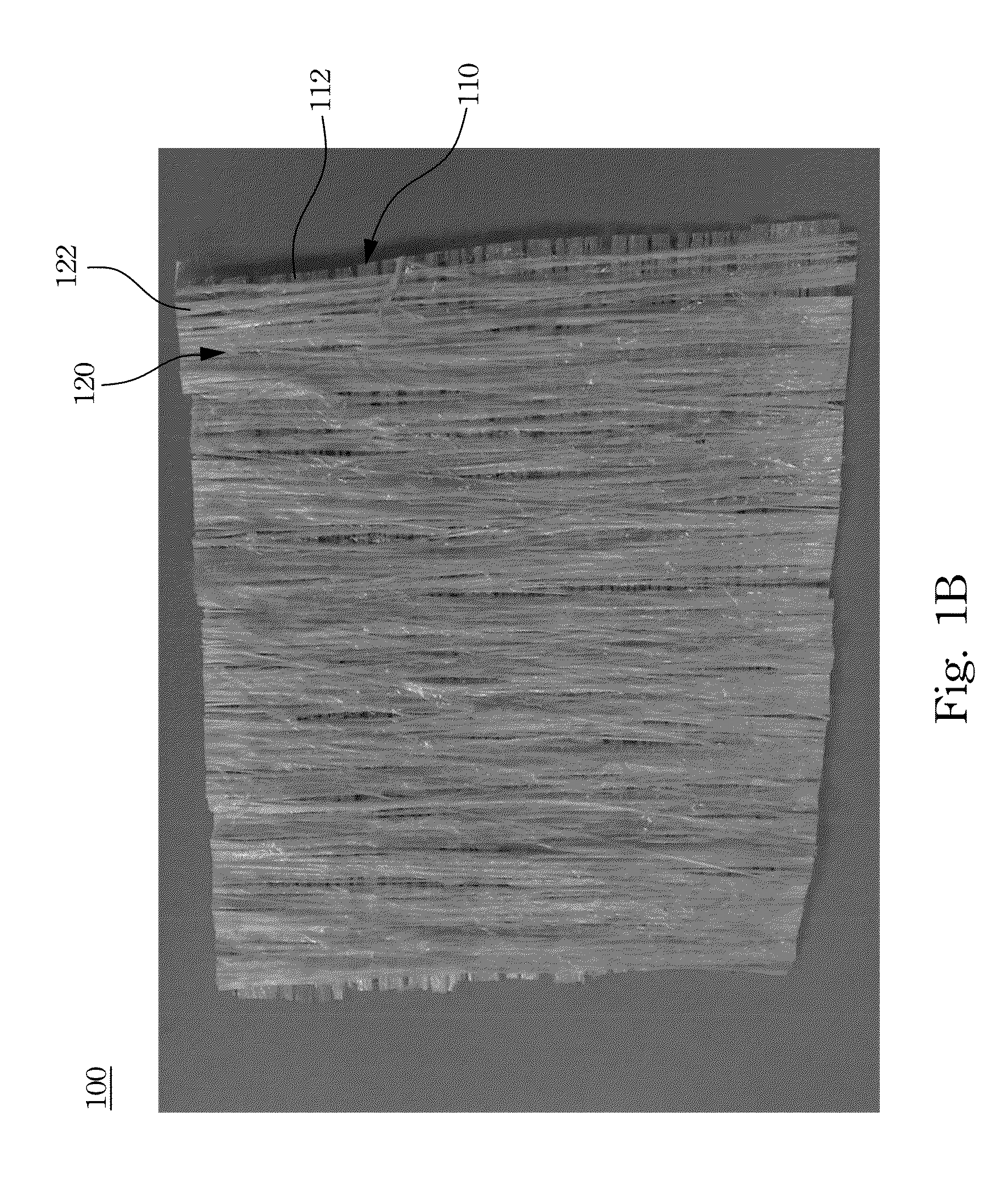

Alginate-Containing Wound Dressing, Method and Apparatus for Making the Same

ActiveUS20110027344A1Reduced breaking strengthHigh breaking strengthMechanical working/deformationNon-adhesive dressingsSecondary layerFiber layer

Disclosed herein is a wound dressing. The wound dressing includes a first fiber layer and a second fiber layer stacked on and bound to the first fiber layer. The first fiber layer consists of a plurality of a first fiber that are made of an alginate wherein the first fibers are respectively bound with one another, and are substantially extended in parallel along a first direction. The second fiber layer consists of a plurality of a second fiber that are made of an alginate, wherein the second fibers are respectively bound with one another, and extend in parallel along a second direction that is not parallel to the first direction. The second layer is stacked on the first layer with the second fibers being bound with the first fibers. The first fibers and the second fibers respectively have a length such that the wound dressing has a breaking strength for at least 1.5 kg.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

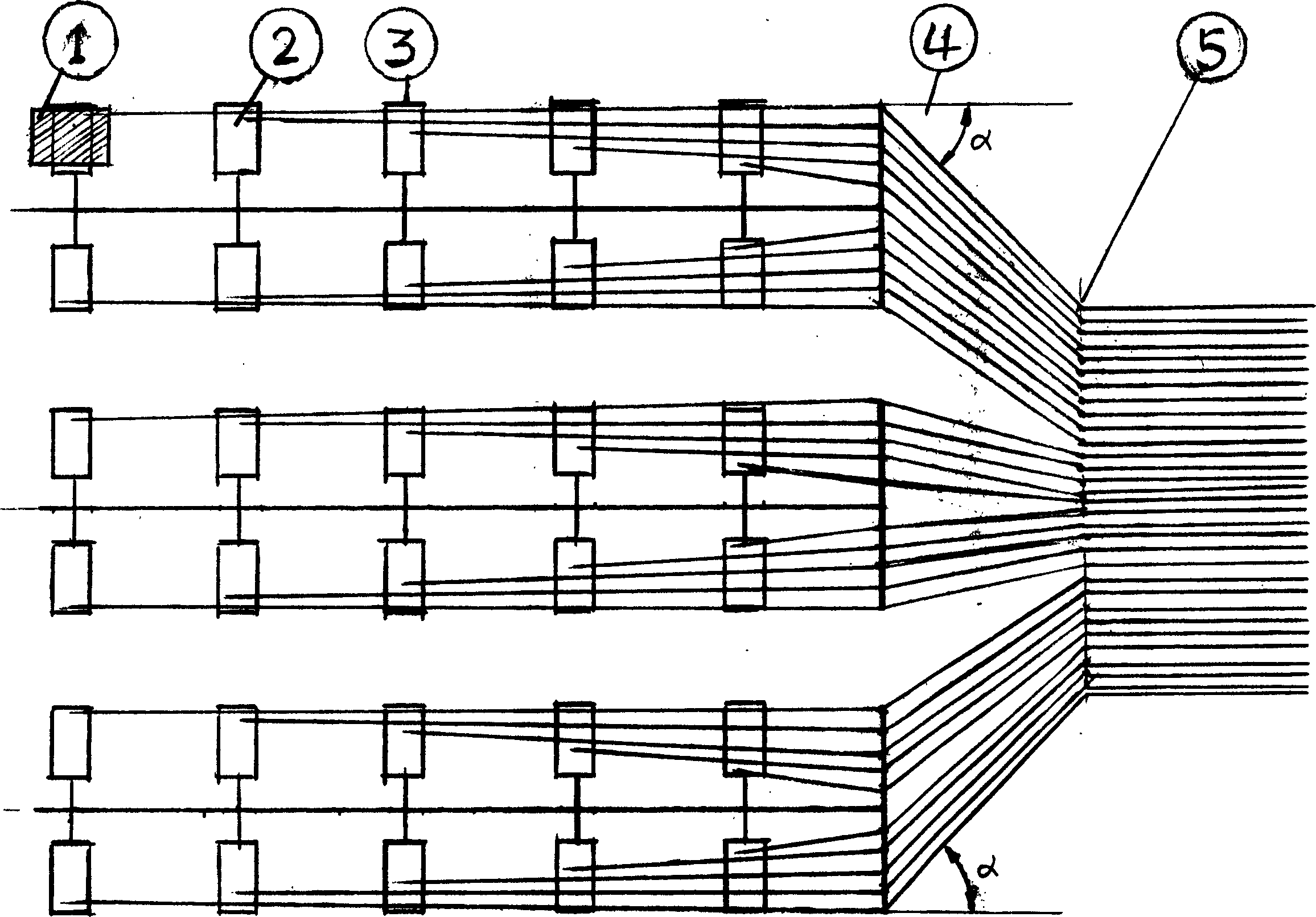

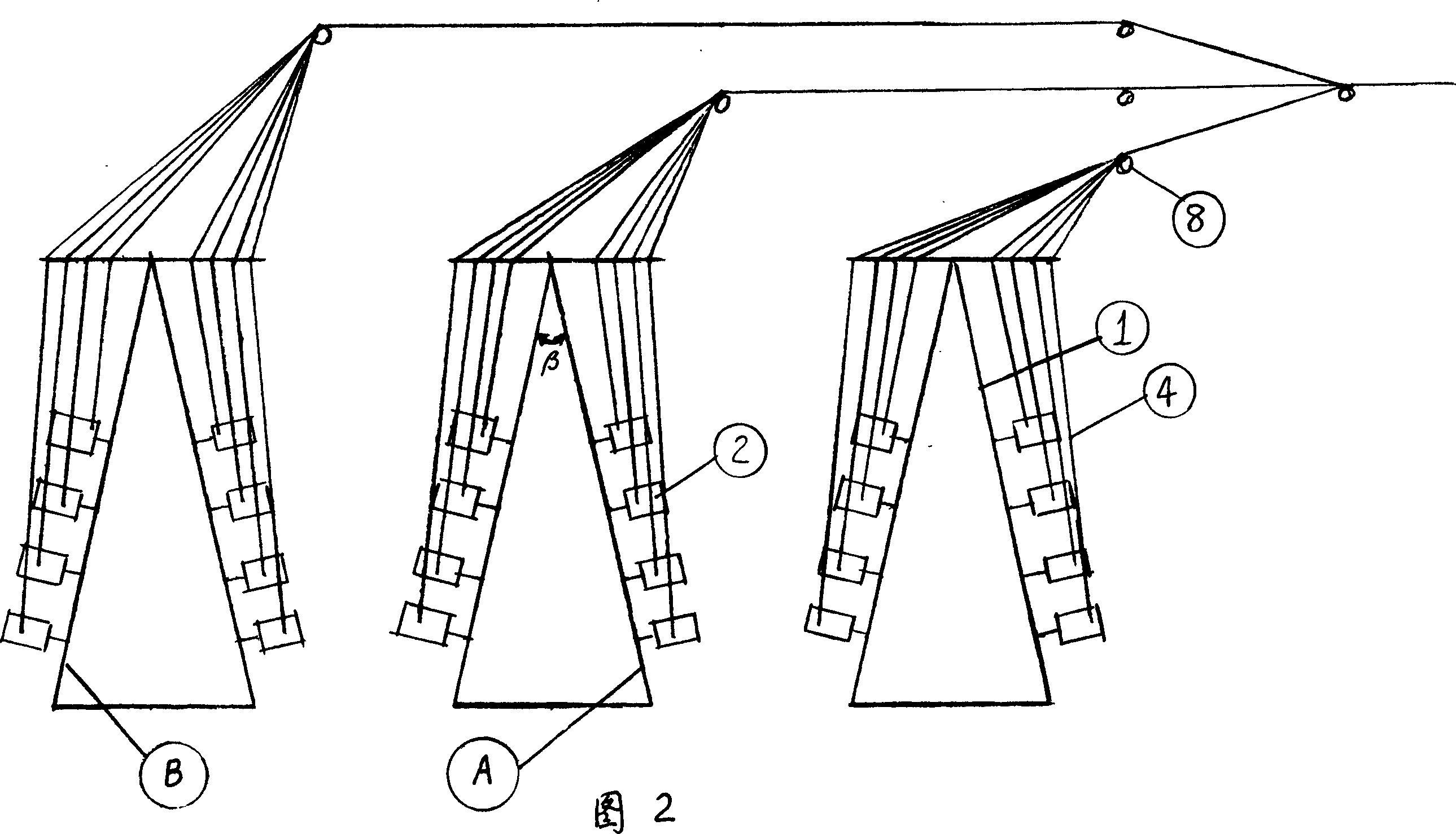

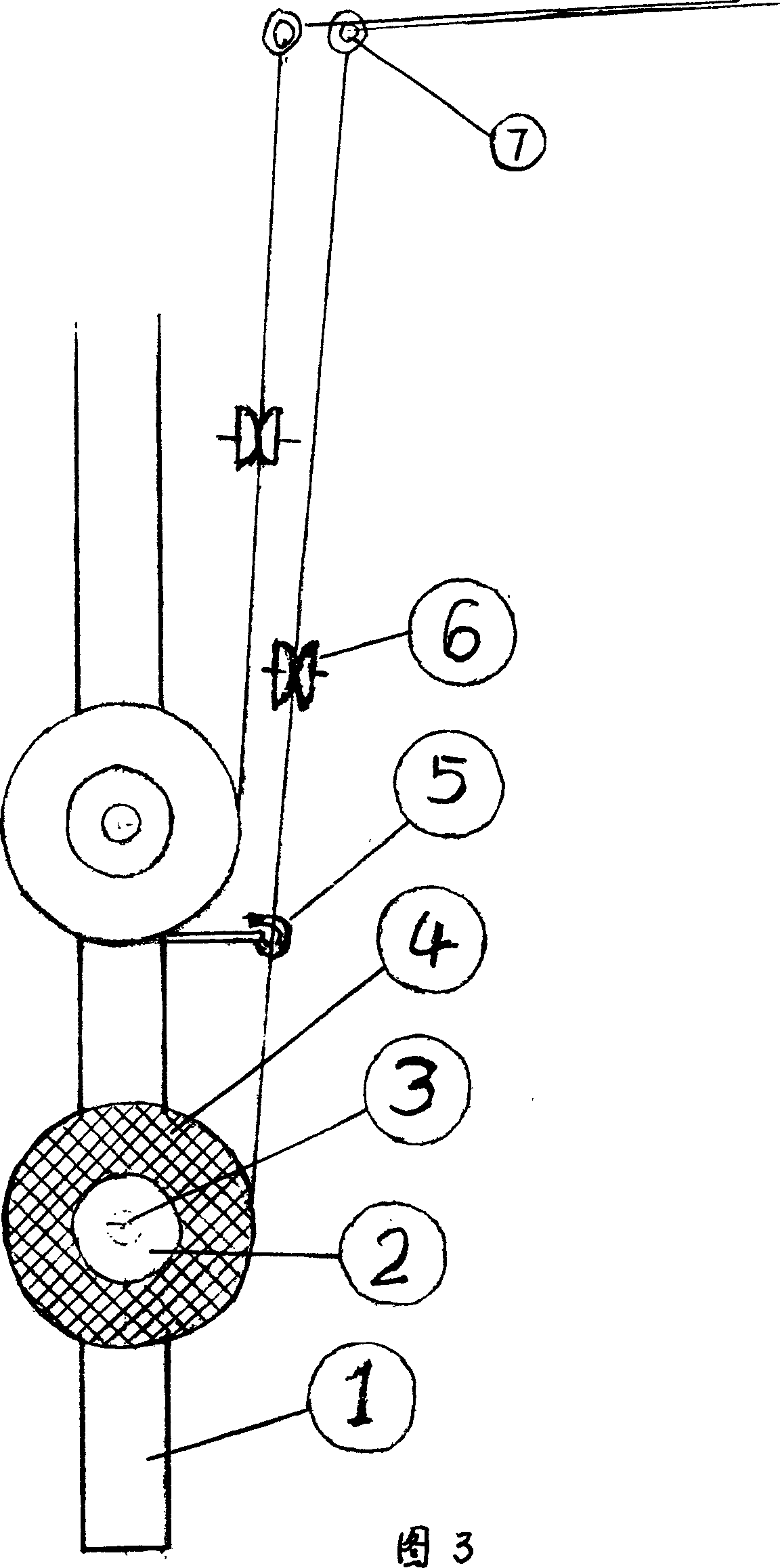

Loom let-off bobbin rack for wearing flat coarse warp woven fabric

The let-off creel for weaving flat coarse warp fabric, such as large tow carbon fiber fabric includes several basic frames arranged in the loom breadth direction and in the back of the loom, and each basic frame has two work planes in 10-20 deg angle including one front work plane and one back work plane with yarn guiding ceramic holes 10-30 mm higher than those in the front one. Each of the work plane has 7 or 8 layers of 8 or 9 lines of bobbins mounted, with the bobbins in the lower layer are 5 mm over shifted relatively to those in the upper layer. The interval between the yarn guiding hook and corresponding bobbin shaft is greater than 250 mm and there is operating passage between the basic frames. The present invention has the advantages of homogeneous wrap tension, raised fabric breaking strength, reduced crossed wear, simplified creel structure and small covered area.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD +1

Method for preparing polyester fiber having compound functions of pilling resistance, ageing resistance and normal-pressure cationic dyeability

InactiveCN102433604AAvoid self-polymerizationEasy-to-stain function guaranteeMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to a method for preparing a polyester fiber having compound functions of pilling resistance, ageing resistance and normal-pressure cationic dyeability, comprising a primary esterification reaction step, an ester exchange reaction step, a secondary esterification reaction step and a polymerization reaction step, wherein three monomers are added in the ester exchange reaction step; a hindered amine light stabilizer and a hindered phenol antioxidant as well as hydroxyl silicone oil are added after the secondary esterification reaction and a pre-polymerization reaction; and pre-crystallization and drying are performed on polyester slices before a spinning step. Fabrics made of the polyester fibers of the invention are good in pilling resistance and good in light fastness, and can be dyed into various beautiful colors by means of the normal-pressure cationic dyeability of the fibers, thereby meeting the uniform requirements of the present high-grade spring-summer dresses for functionality and colors; the obtained polyester fibers also can be subjected to apposition dyeing with wool; and as being blended with wool, good dressing effect can be obtained. The polyester fiber of the invention is an important supplement for the cationic dyeable polyester market at present in China.

Owner:WUJIANG GANGYANG CHEM FIBER +1

Method for producing fluorine-containing elastomer

InactiveUS20140039130A1Reduce decreaseHigh compression set characteristicBreaking strengthPolymer science

A peroxide-crosslinkable fluorine-containing elastomer IS produced by subjecting a fluorine-containing olefin and a perfluoroalkyl divinyl ether monomer represented by the general formula:CF2═CF—[OCF2CF(CF3)]aO(CF2)bO[CF(CF3)CF2O]c—CF═CF2 wherein a+c is an integer of 0 to 4 and b is an integer of 2 or more, to a copolymerization reaction; wherein the perfluoroalkyl divinyl ether monomer is added for copolymerization separately before and after the copolymerization reaction starts, or the total amount thereof is added for copolymerization after the copolymerization reaction starts. A peroxide-crosslinked molded product of the obtained fluorine-containing elastomer exhibits high compression set characteristic, while reducing a decrease in breaking strength, a decrease in elongation at break or an increase in hardness.

Owner:UNIMATEC CO LTD

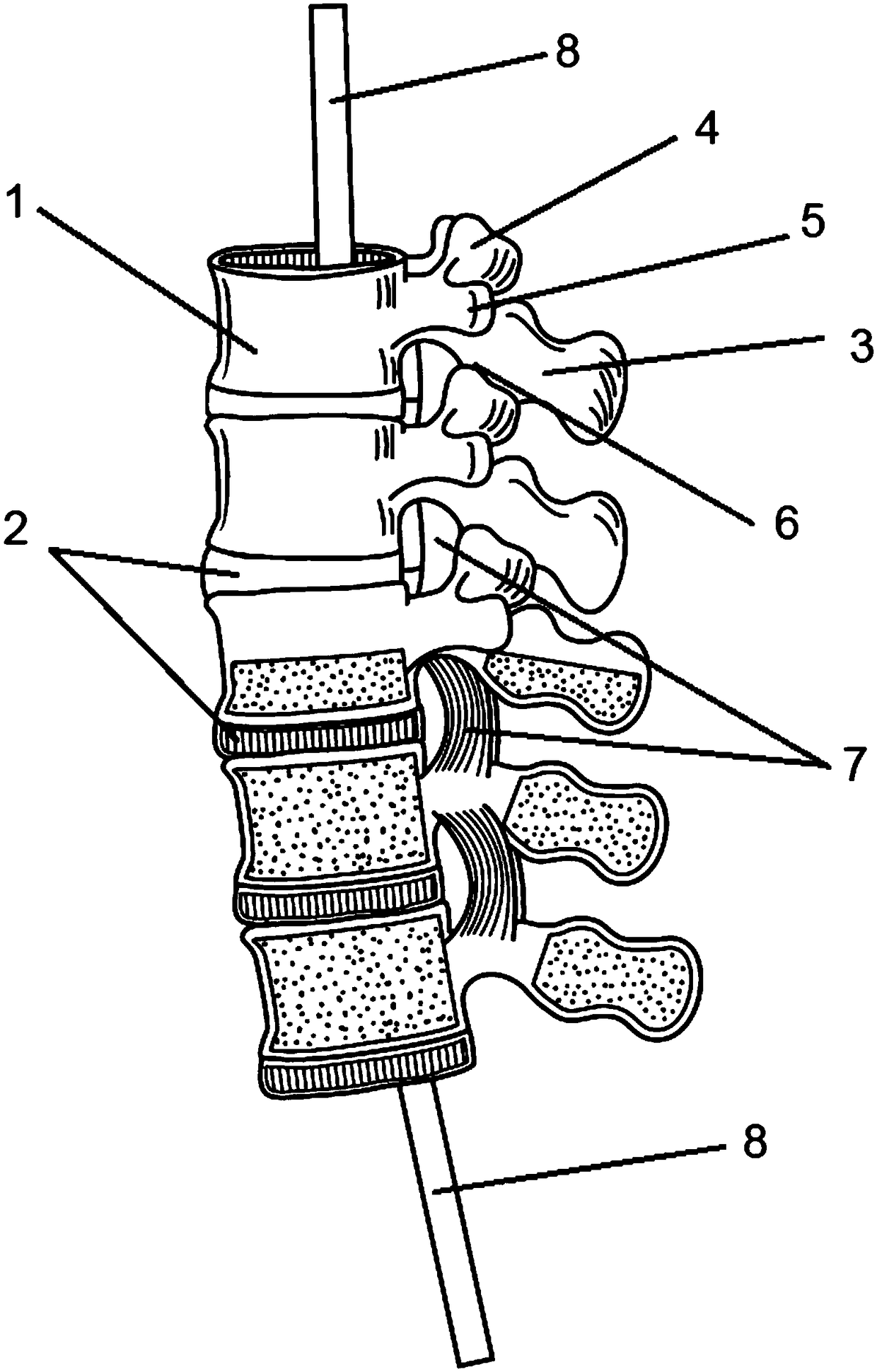

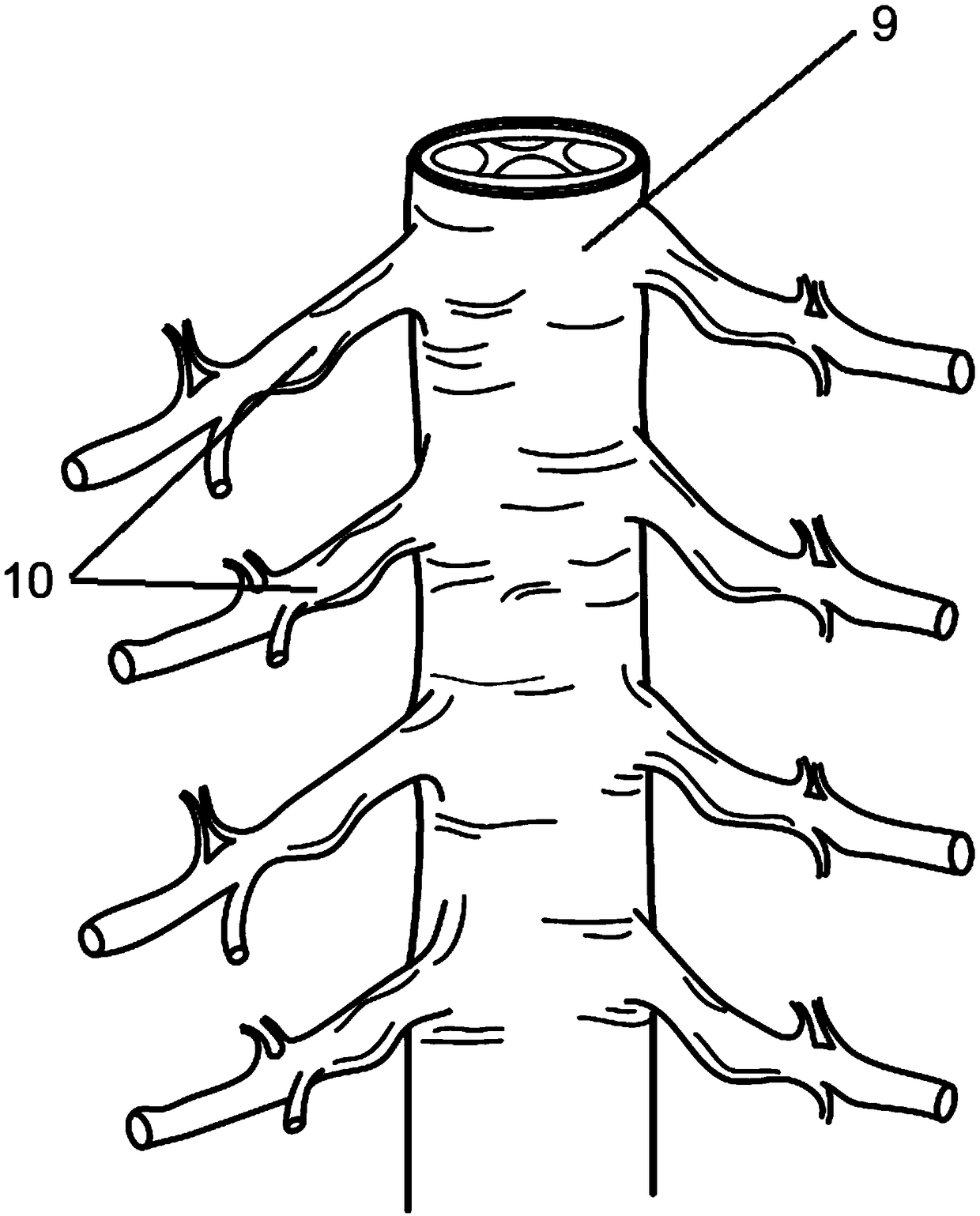

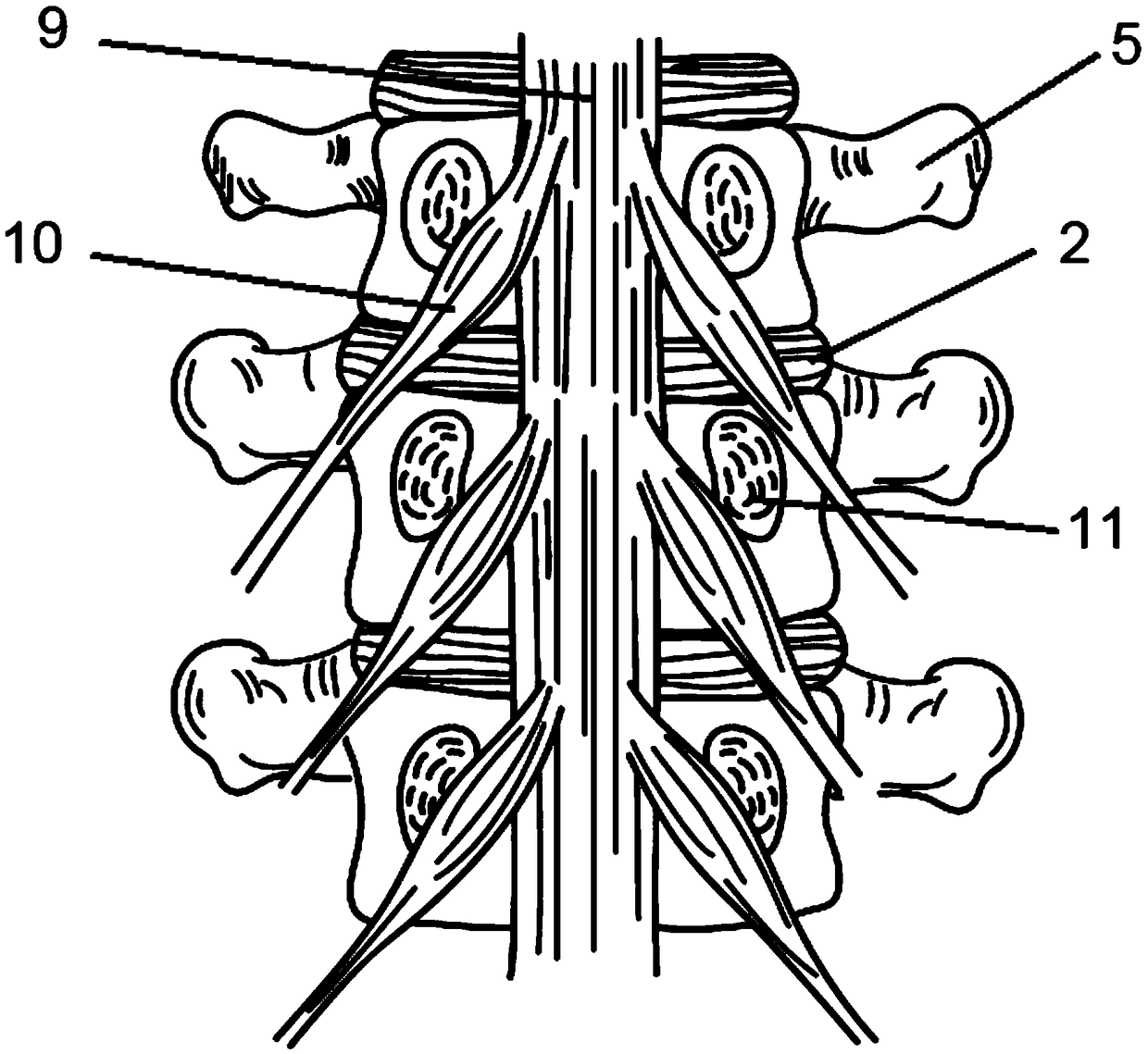

Spinal intervertebral foramen surgery model and manufacturing method thereof

InactiveCN108648593AConform to the real stateHave memoryEducational modelsSpinal columnTraining period

The invention discloses a spinal intervertebral foramen surgery model. The model comprises an artificial spine composed of multiple segments of artificial vertebral bones,an artificial intervertebraldisc located between every two adjacent artificial vertebral bones,an intervertebral disc protrusion simulated object bonded to each artificial intervertebral disc and artificial tissue wrapped on theexterior of the artificial spine; the intervertebral disc protrusion simulated objects are made of viscose fibers and bonded to arbitrary positions of the corresponding artificial intervertebral discs. The intervertebral disc protrusion simulated objects made of the viscose fibers can be glued to appropriate positions outside the corresponding intervertebral discs to simulate different types of intervertebral disc protrusions,and the shape and size of the intervertebral disc protrusion simulated objects can be adjusted according to needs to be better in line with the real state of the human body. Compared with a traditional mode of using corpses or non-dedicated models for training,the model has the advantages that the cost of training doctors can be greatly reduced,the repeatability is excellent,surgical modes are diversified,and the training period can be shortened.

Owner:JIANGSU PROVINCE HOSPITAL THE FIRST AFFILIATED HOSPITAL WITH NANJING MEDICAL UNIV

Multifunctional finishing agent

ActiveCN109457475AImprove antibacterial propertiesImproves UV resistanceHeat resistant fibresVegetal fibresEgg proteinPolyvinyl alcohol

The invention discloses a multifunctional finishing agent which comprises chitosan, sericin, titanium dioxide, hydrosol, aloin, tea polyphenol, quaternary ammonium salt, ethylenediamine tetraacetic dianhydride, polyatomic acid, glucose, hexa (4-amino phenoxy) cyclotriphosphazene, ammonium polyphosphate, guanidine carbonate, graphene oxide, montmorillonoid, magnesium chloride, egg protein, polyvinyl alcohol, coupling agents, acetic acid and solvents. The multifunctional finishing agent is reasonable in formula, and a finished fabric is good in antibacterial property, excellent in flame resistance, soft in hand feeling, resistant to creasing and washable.

Owner:JILIN NORMAL UNIV

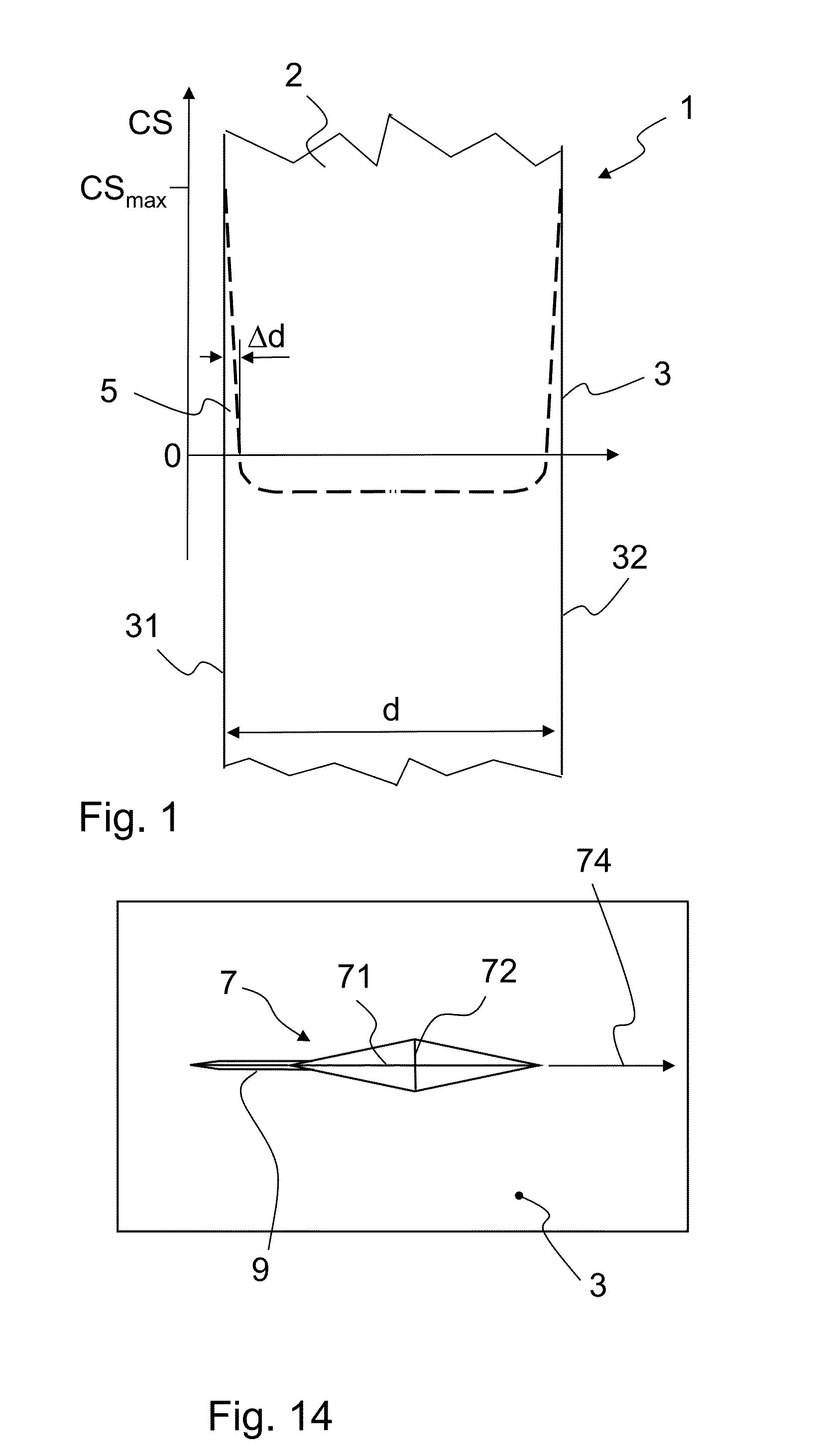

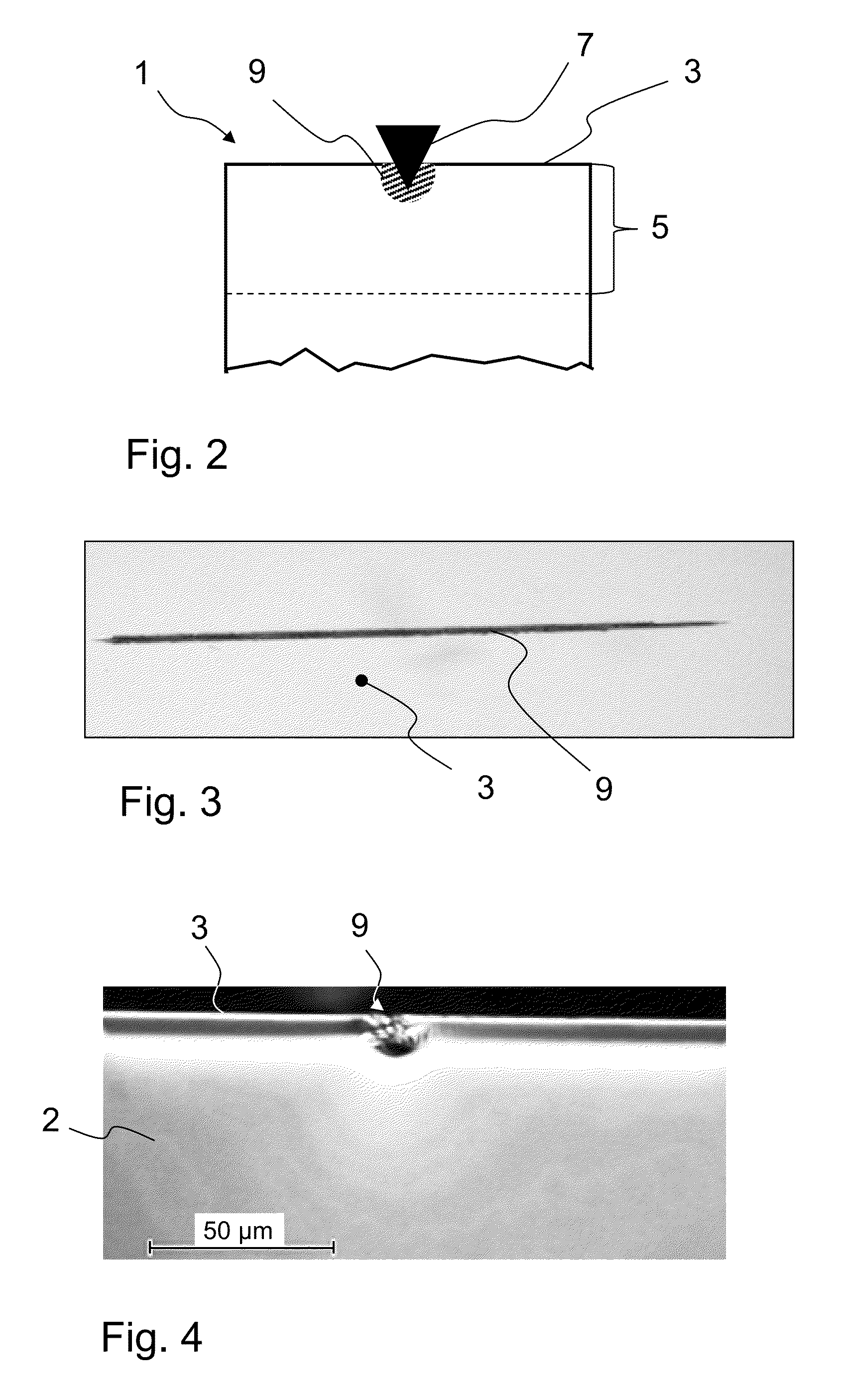

Glass element with high scratch tolerance

Owner:SCHOTT AG

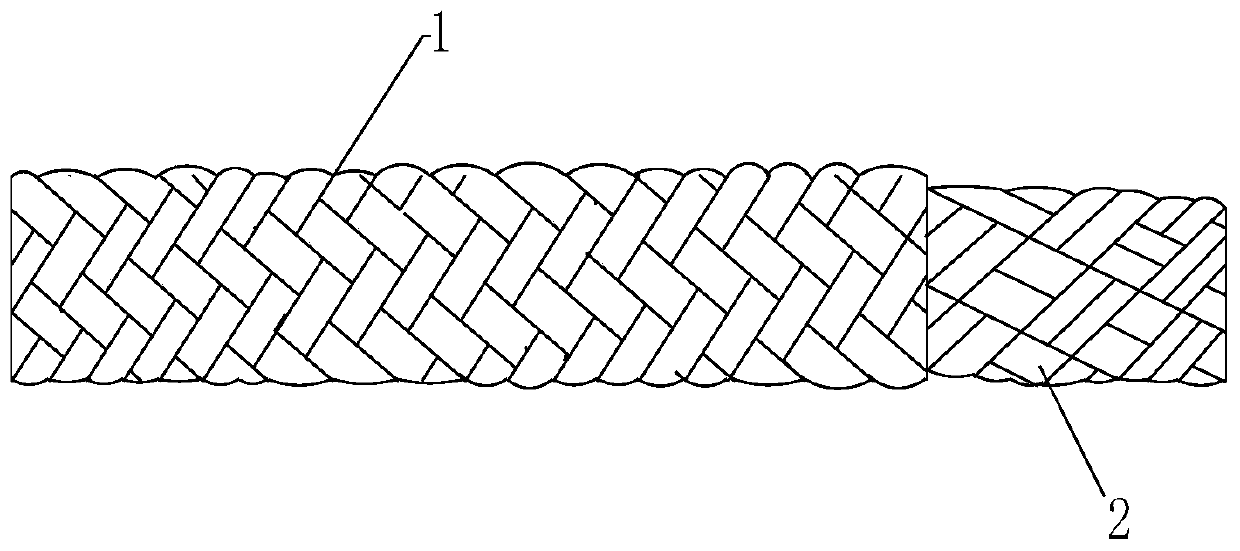

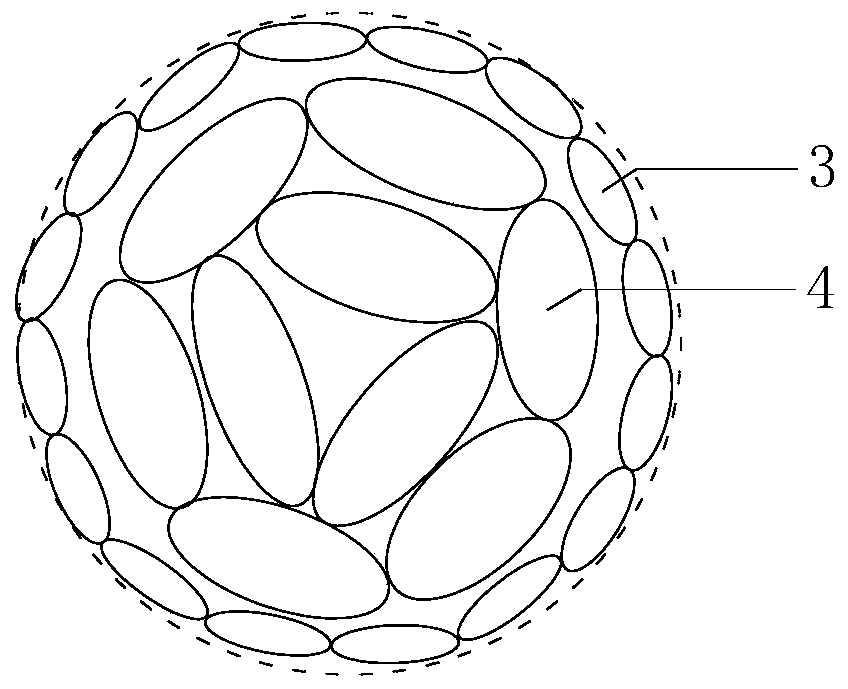

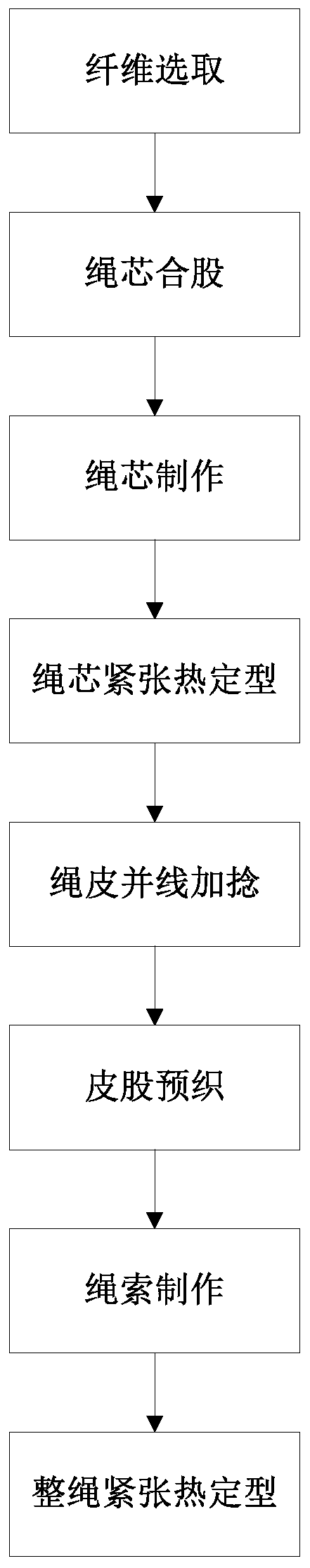

High-strength low-extension anti-bending-fatigue sailboat rope and manufacturing method thereof

PendingCN110016758AReduced load elongationReduced breaking strengthBraidLiquid/gas/vapor yarns/filaments treatmentFiberBreaking strength

The invention discloses a high-strength low-extension anti-bending-fatigue sailboat rope and a manufacturing method thereof. The sailboat rope comprises a woven rope core and a rope skin wrapping therope core, and the rope core is made from high-strength fibers; the rope skin is woven from multiple rope strands composed of multiple high-strength fibers through twisting; the rope core component orthe whole rope is subjected to tension thermal-setting treatment. On the premise of ensuring sufficient fullness and flexibility of a sailboat rope body, higher breaking strength and lower loading extension rate are achieved, and the anti-bending-fatigue performance of the sailboat rope is significantly improved.

Owner:TAIAN ROPE NET PLASTIC +1

Preparation method of antistatic, anti-balling, and ordinary pressure cation dyeable polyester chip

InactiveCN102433605AAvoid self-polymerizationEasy-to-stain function guaranteeElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method of an antistatic, anti-balling, and ordinary pressure cation dyeable polyester chip, comprising the following steps: a primary esterification reaction step, an ester exchange reaction step, a secondary esterification reaction step, and a polymerization reaction step, wherein, a ternary-monomer is added in the ester exchange reaction step, hindered anime light stabilizers, hindered phenol antioxygens and hydroxyl silicone oil are added after the ester exchange reaction and before a prepolymerization reaction, and an antistatic agent is added after the prepolymerization of the polymerization reaction step and before a final polymerization. Fabrics prepared from polyester fibers produced by using the polyester chips disclosed herein have good antistatic behavior and good anti-balling behavior, and have unlimited dyeing possibilities by using the ordinary pressure cation dyeability, thus the uniform requirements of present high-grade spring and summer clothes for functionality and colors can be satisfied. The obtained fibers can be dyed with wool together, and the blending of the fibers with wool has good dress effect. The polyester chips and fibers disclosed herein are an important supplement of present cation dyeable polyester fiber market, and have a wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com