Preparation technology of water, oil and pollution resistant texture fabric

A technology of textile fabric and preparation process, which is applied in the field of textile fabric preparation technology, can solve the problems of poor air and moisture permeability, improper selection, and poor three-proof effect of fabrics, and achieve good air and moisture permeability, good three-proof effect, and color The effect of high fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

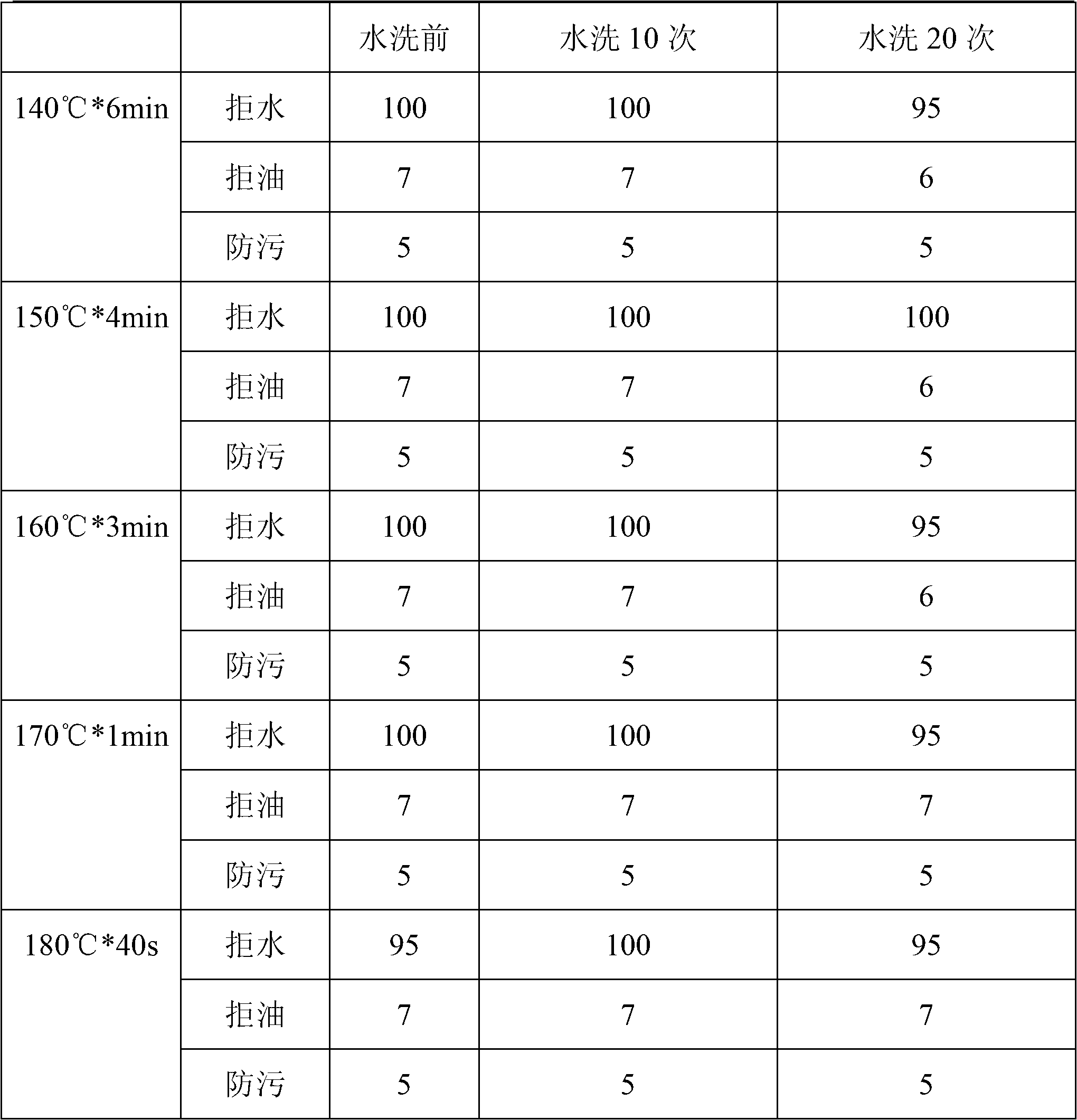

Embodiment 1

[0015] A preparation process for waterproof, oil-proof and stain-proof textile fabrics, including pre-treating the base fabric or dyeing it for setting, padding and finishing, and during the padding and finishing, the fabric is used for waterproofing, oil-proof, The fluorine-containing finishing agent for antifouling finishing and the nano-finishing nano-ceramic powder dispersion liquid are pad-rolled and shaped-finishing. The nano-finishing liquid also includes a cross-linking agent, a penetrating agent, and citric acid. The amount of the fluorine-containing finishing agent per liter of the nano-finishing liquid is 30-60 g, the amount of the nano-ceramic powder dispersion liquid is 30-60 g, and the cross-linking agent The amount of penetrant is 5~15g, the amount of penetrant is 0.5~2.5g, and the amount of citric acid is 0.5~2.5g. The amount of fluorine-containing finishing agent per liter of nano-finishing liquid is 45g, the amount of nano-ceramic powder dispersion liquid is ...

Embodiment 2

[0017] The difference from Example 1 is that the amount of fluorine-containing finishing agent per liter of nano-finishing liquid is 30 g, the amount of nano-ceramic powder dispersion liquid is 30 g, the amount of cross-linking agent is 5 g, and the amount of penetrating agent is 0.5 g , The amount of citric acid is 0.5g.

Embodiment 3

[0019] The difference from Example 1 is that the amount of fluorine-containing finishing agent per liter of nano-finishing liquid is 60 g, the amount of nano-ceramic powder dispersion liquid is 60 g, the amount of cross-linking agent is 15 g, and the amount of penetrating agent is 2.5 g , The amount of citric acid is 2.5g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com