High-performance three-proofing anti-bacterial fabric finishing method with simple process

An antibacterial fabric with simple process technology, applied in the direction of repelling fiber, fiber treatment, biochemical fiber treatment, etc. to liquid, which can solve the problem of decreased stability of three-proof and antibacterial composite finishing liquid, impact of three-proof antibacterial performance, complex process, etc. problem, to achieve the effect of good three-proof and antibacterial, good dispersibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

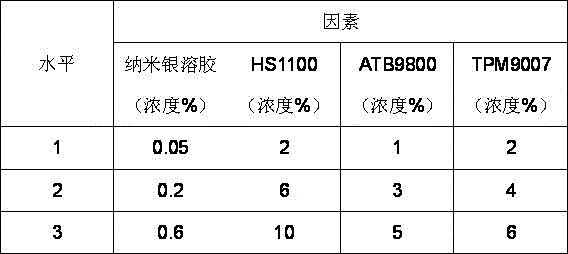

Method used

Image

Examples

Embodiment 1

[0031] The first step is the preparation of nano-silver coated with modified starch, the method is as follows:

[0032] (1) Prepare 0.05mol / L silver nitrate solution and 1% sodium citrate solution for later use;

[0033] (2) Add 50ml of water into the three-necked flask, then add 0.25g of modified starch, turn on the heat-collecting constant temperature heating magnetic stirrer, put the above three-necked flask into it, stir and heat up to 95°C for about 30min to gelatinize the starch;

[0034] (3) Lower the temperature to 70°C, drop 10ml of the prepared silver nitrate solution into the three-necked flask, and continuously stir for 10 minutes;

[0035] (4) Add 2ml of the prepared sodium citrate solution dropwise at a rate of 1 drop / S, and stir to make it fully react;

[0036] (5) After the color of the reaction system no longer changes, that is, after the reaction is complete, the prepared sol is taken out of the reaction flask and cooled naturally.

[0037] The second step ...

Embodiment 2

[0050] The composite three-proof antibacterial finishing agent is prepared, and its preparation steps and process are the same as the first step and the second step of Example 1.

[0051] The third step gray cloth pretreatment

[0052] (1) Prepare a sodium hydroxide solution with a concentration of 2% according to the proportion of 40ml / g fabric;

[0053] (2) Boil the fabric in lye for 10 minutes and take it out;

[0054] (3) Rinse the fabric with clean water until the inspection returns.

[0055] Step 4: Two dipping and two rolling in the same bath

[0056] (1) Padding finishing agent: take 60g / L of self-made composite three-proof antibacterial finishing agent, and adopt the two-dipping and two-rolling process under the conditions of padding temperature 20°C and rolling liquid rate 80%;

[0057] (2) Drying: Dry with hot air at 110°C for 2 minutes;

[0058] (3) Baking: Baking at 175°C for 90s;

[0059] (4) Fabric out: Finish the final processing and out of the fabric, tha...

Embodiment 3

[0061] The composite three-proof antibacterial finishing agent is prepared, and its preparation steps and process are the same as the first step and the second step of Example 1.

[0062] The third step gray cloth pretreatment

[0063] (1) Prepare a sodium hydroxide solution with a concentration of 2% according to the proportion of 30ml / g fabric;

[0064] (2) Boil the fabric in lye for 10 minutes and take it out;

[0065] (3) Rinse the fabric with clean water until the inspection returns.

[0066] Step 4: Two dipping and two rolling in the same bath

[0067] (1) Padding finishing agent: take 30g / L of self-made composite three-proof antibacterial finishing agent, and adopt the two-dipping and two-rolling process at the padding temperature of 30°C and the rolling rate of 75%;

[0068] (2) Drying: Dry with hot air at 120°C for 2 minutes;

[0069] (3) Baking: Baking at 165°C for 90s;

[0070] (4) Fabric out: Finish the final processing and out of the fabric, that is, high-perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com