A kind of fabric three-proof finishing agent and its preparation method and application

A three-proof finishing agent and fabric technology, which is applied in textiles and papermaking, fiber treatment, and liquid-repellent fibers, etc., can solve the problems of imperviousness to washing, poor adsorption, etc., and achieve good binding force and long-lasting water repellency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

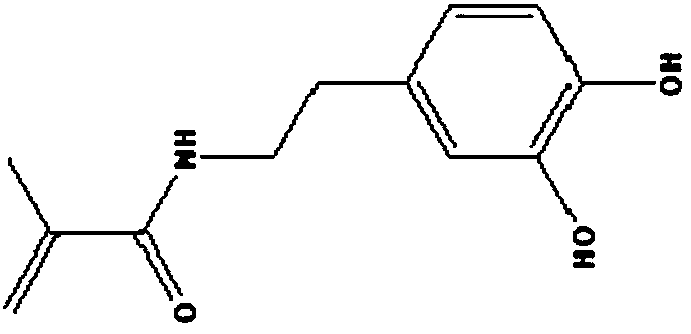

[0059] Will C 6 f 13 CH 2 CH 2 OC(O)-C(Cl)=CH 2 10g, 8g of stearyl methacrylate, 1g of glycidyl acrylate, 2g of dopamine methacrylamide, 10g of cationic silica hydrosol with an average particle diameter of 30nm and a mass content of 30%, dodecyl-3 -Mix 0.5g of methylammonium bromide, 1g of AEO-7, 33g of deionized water, and 15g of acetone, stir and emulsify at 40°C for 10 minutes, and then ultrasonically emulsify at this temperature for 5 minutes to obtain a monomer pre-emulsion.

[0060] Then put the monomer pre-emulsion in a 100ml four-necked flask equipped with a stirring paddle, a thermometer, a reflux tube, and a nitrogen device, add 0.3g of azobisisobutylamidine hydrochloride, replace the gas in the bottle with nitrogen, and stir The temperature was raised to 70° C. to initiate polymerization for 5 hours, and the temperature was maintained at 75° C. for 2 hours to obtain a translucent emulsion with bluish light. After cooling down to room temperature, the target pro...

Embodiment 2

[0062] Will C 4 f 9 SO 2 N(CH 3 )CH 2 CH 2 OC(O)-CH=CH 2 10g, 12g of cetyl methacrylate, 0.5g of hydroxyethyl acrylate, 1g of dopamine methacrylamide, 10g of cationic silica hydrosol with an average particle diameter of 30nm and a mass content of 30%, hexadecane Mix 0.6g of 3-methylammonium bromide, 0.6g of NP-40 with 36g of deionized water and 20g of ethylene glycol methyl ether, stir and emulsify at 40°C for 10 minutes, and then carry out ultrasonic emulsification at this temperature for 3 minutes. A monomer pre-emulsion is obtained.

[0063] Then the monomer pre-emulsion is placed in a 100ml four-necked flask with a stirring paddle, a thermometer, a reflux tube, and a nitrogen device, and 0.3g of azobisethylbutyronitrile is added to replace the gas in the bottle with nitrogen, and the temperature is raised to Initiate polymerization at 70°C for 4 hours, keep warm at 75°C for 3 hours to obtain a bluish translucent emulsion, and cool down to room temperature to obtain...

Embodiment 3

[0065] Will C 6 f 13 SO 2 N(C 2 h 5 )CH 2 CH 2 OC(O)-C(CH3)=CH 2 14g, stearyl methacrylate 10g, methylol acrylamide 0.5g, dopamine methacrylamide 0.5g, the average particle diameter is 30nm, and the mass content is 10g of cationic silica hydrosol of 25%, ten Mix 0.9g of octaalkyl-3-methylammonium chloride, 0.6g of NP-40 with 42.5g of deionized water and 18g of propylene glycol methyl ether, stir and emulsify at 40°C for 10 minutes, and then carry out ultrasonic emulsification at this temperature for 3 minutes , to obtain a monomer pre-emulsion.

[0066] Then the monomer pre-emulsion is placed in a 100ml four-necked flask with a stirring paddle, a thermometer, a reflux tube, and a nitrogen device, and 0.2 g of azobisethylheptanonitrile is added to replace the gas in the bottle with nitrogen, and the temperature is raised to Initiate polymerization at 70°C for 6 hours, keep warm at 75°C for 1 hour to obtain a bluish translucent emulsion, and cool down to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com