Fluorine-containing organic silicon coating adhesive and preparation method thereof

A coating adhesive and silicone technology, which is applied in the field of fluorine-containing silicone coating and its preparation, can solve the problem that the anti-salt spray, chemical corrosion resistance and other properties of the silicone coating are not good enough, and the anti-salt spray and chemical resistance are not good enough. Corrosion performance can not meet the requirements and other problems, to achieve the effect of adjustable curing speed, excellent adhesion, and enhanced chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

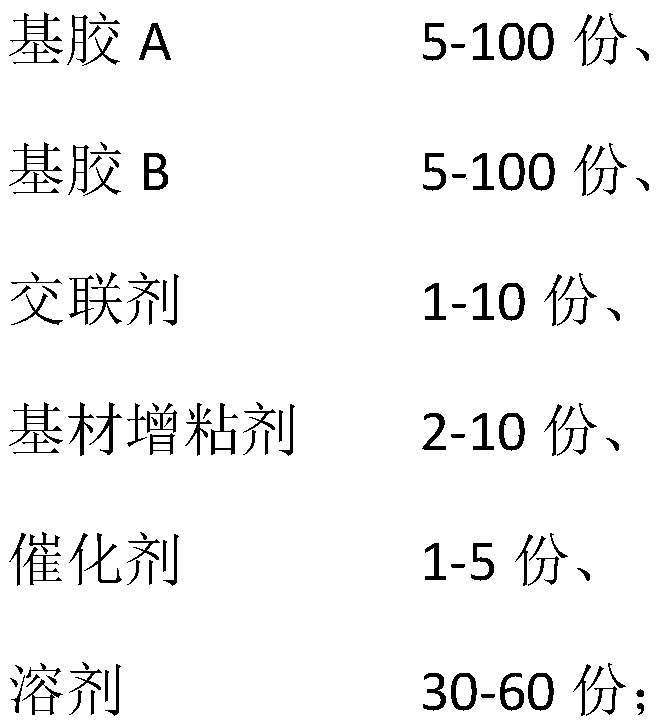

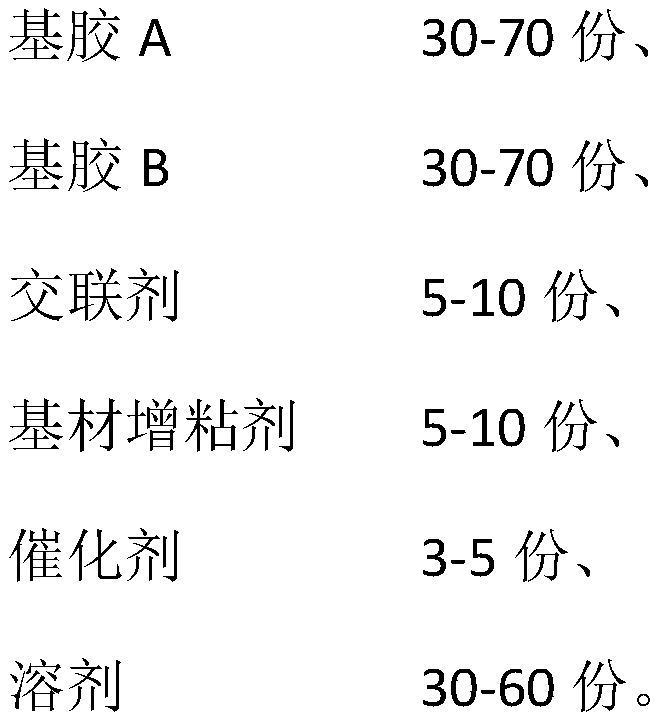

Method used

Image

Examples

Embodiment 1

[0049] This example provides a fluorine-containing silicone coating glue and its preparation method, the steps are as follows:

[0050] (1) Prepare substrate tackifier

[0051] (3,3,3-trifluoropropyl)methyldimethoxysilane, (3,3,3-trifluoropropyl)methyltrimethoxysilane and γ-aminopropyltrimethoxysilane according to The molar ratio is 4:3:3 and mixed and stirred to obtain a mixture.

[0052] Add dropwise an aqueous solution of hydrochloric acid accounting for 30wt% of the total weight of the mixture in the mixture, the concentration of the aqueous solution of hydrochloric acid is 2wt%, the dropping time is controlled at 2h, and the reaction temperature is controlled at 55°C. After the dropwise addition, continue to keep warm React for 2 hours, then wash with water for 3 times, separate the oil layer and dry it, and finally remove the low boilers by distillation under reduced pressure at 80°C and -0.095Mpa to obtain the substrate tackifier.

[0053] (2) Preparation of fluorine-...

Embodiment 2

[0056] This example provides a fluorine-containing silicone coating glue and its preparation method, the steps are as follows:

[0057] (1) Prepare substrate tackifier

[0058] Mix and stir (3,3,3-trifluoropropyl)methyldimethoxysilane and γ-aminopropyltrimethoxysilane at a molar ratio of 1:1 to obtain a mixture.

[0059] In the mixture, add dropwise an aqueous solution of potassium hydroxide accounting for 25wt% of the total weight of the mixture, the concentration of the aqueous solution of potassium hydroxide is 2.5wt%, the dropping time is controlled at 1.5h, and the reaction temperature is controlled at 60° C., dropwise After the addition is complete, continue to keep warm for 3 hours, then wash with water for 3 times, separate the oil layer and dry it, and finally remove the low boilers by distillation under reduced pressure at 80°C and -0.095Mpa to obtain the substrate tackifier.

[0060] (2) Preparation of fluorine-containing silicone coating glue

[0061] Mix 60 part...

Embodiment 3

[0063] This example provides a fluorine-containing silicone coating glue and its preparation method, the steps are as follows:

[0064] (1) Prepare substrate tackifier

[0065] (3,3,3-trifluoropropyl)methyldiethoxysilane, (3,3,3-trifluoropropyl)methyltriethoxysilane and γ-aminopropyltriethoxy The silane is mixed and stirred according to the molar ratio of 1:1:1 to obtain a mixture.

[0066] In the mixture, add dropwise an aqueous solution of hydrochloric acid accounting for 35wt% of the total weight of the mixture, the concentration of the aqueous solution of hydrochloric acid is 1.5wt%, the time for dropping is controlled at 2h, and the reaction temperature is controlled at 60°C. After the dropwise addition, continue Insulate and react for 3 hours, then wash with water for 3 times, separate the oil layer and dry, and finally remove the low boilers by distillation under reduced pressure at 80°C and -0.095Mpa to obtain the substrate tackifier.

[0067] (2) Preparation of fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com