Patents

Literature

33results about How to "Adjust curing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-solidification system fast-flowing underfill and preparation method thereof

InactiveCN102010686AGuaranteed reliabilityFast flowOther chemical processesEpoxynovolac adhesivesEpoxyPolyol

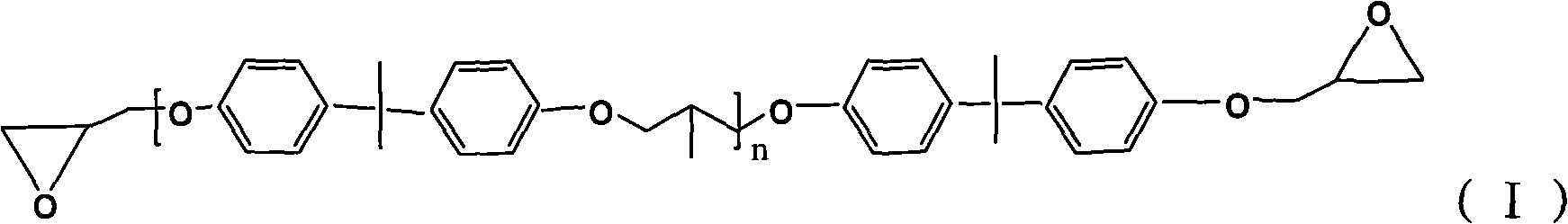

The invention discloses a double-solidification system fast-flowing underfill and a preparation method thereof. The underfill comprises the following raw materials in parts by weight: 30-80% of epoxy resin, 10-50% of epoxy acrylate, 5-30% of acrylate, 2-20% of polyol, 1-20% of silane coupling agent, 0.3-4% of cationic initiator, 0.1-3% of radical initiator and 0.1-0.5% of carbon black; and the preparation method comprises the following steps of: weighing the epoxy resin and the cationic initiator in the proportion, putting in a reaction kettle and stirring into a uniform solution; weighing the epoxy acrylate, the acrylate, the polyol, the silane coupling agent, the radical initiator and the carbon black in the proportion, putting in the reaction kettle in sequence, mixing and stirring to obtain the finished product of the double-solidification system fast-flowing underfill.

Owner:YANTAI DARBOND TECH

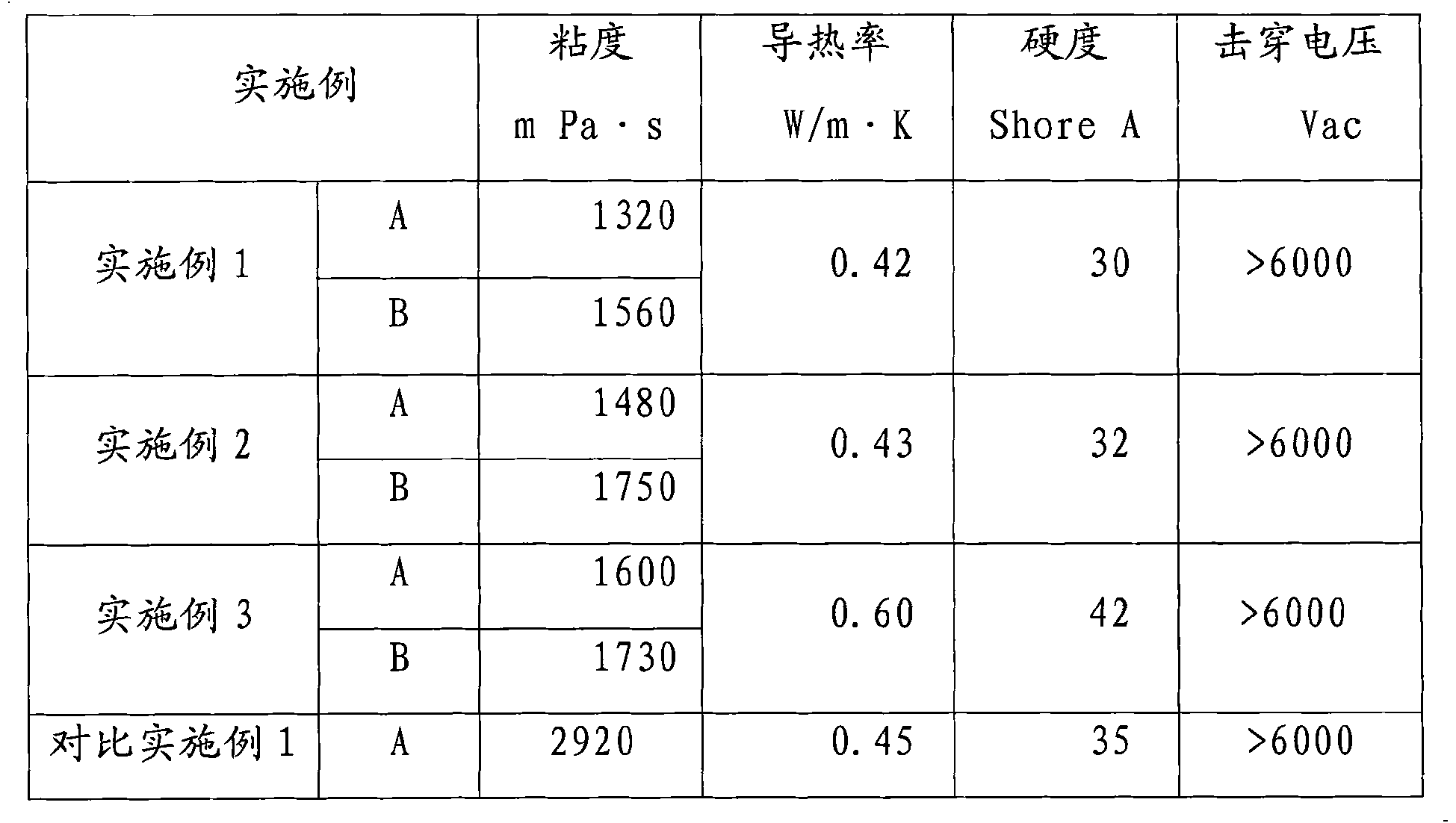

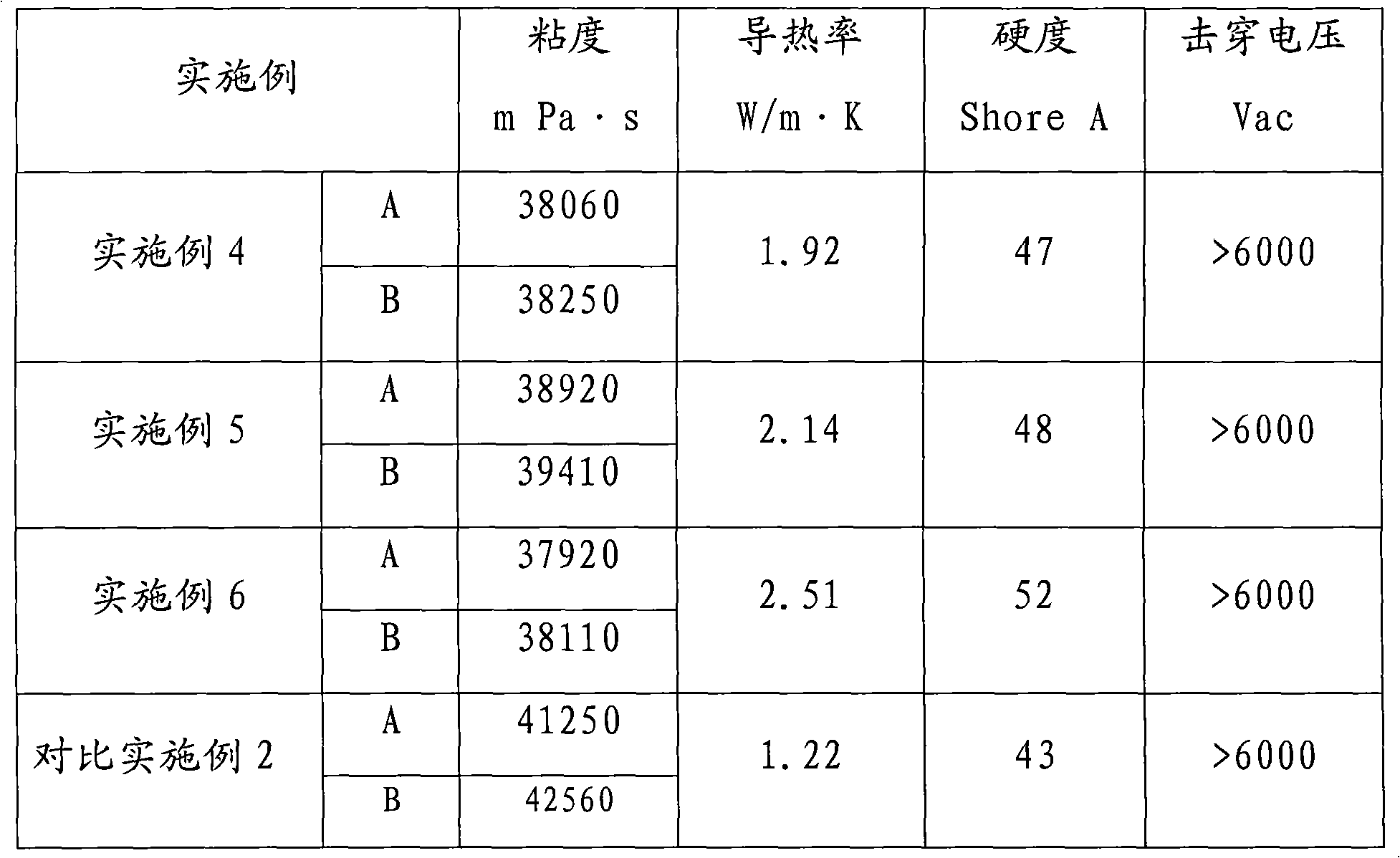

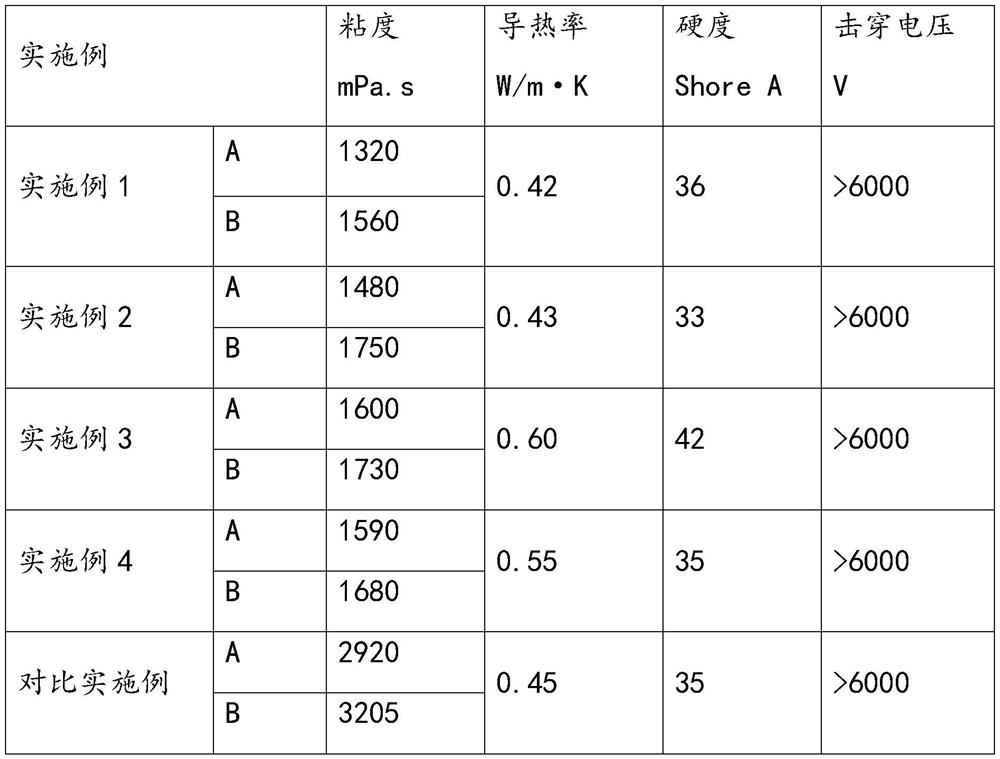

Two-component sealing silica gel with low viscosity and high thermal conductivity and preparation method theref

InactiveCN101962528AEasy to moveGuarantee job stabilityNon-macromolecular adhesive additivesOther chemical processesPolymer scienceAdhesive

The invention relates to a two-component sealing adhesive with low viscosity and high thermal conductivity and a preparation method thereof. The two-component sealing adhesive consists of a component A and a component B in a weight ratio of 100:80-100:125, wherein the component A comprises the following raw materials by weight percent: 40.00%-90.00% of thermal conductive powder, 4.50%-50.00% of low-viscosity liquid silicone oil, 0.50%-10.00% of silicane curing agent and 0.00-5.00% of toner; and the component B comprises the following raw materials by weight percent: 40.00%-90.00% of thermal conductive material, 9.50%-54.00% of low-viscosity liquid silicone oil, 0.04%-1.00% of catalyst and 0.00-5.00% of toner. The preparation method comprises the following steps: weighting all the raw materials according to the weight persentages to prepare the component A and the component B; and when in use, mixing the component A and the component B evenly in a weight ratio of 100:80-100:125, and curing to obtain the sealing adhesive of the invention.

Owner:YANTAI DARBOND TECH

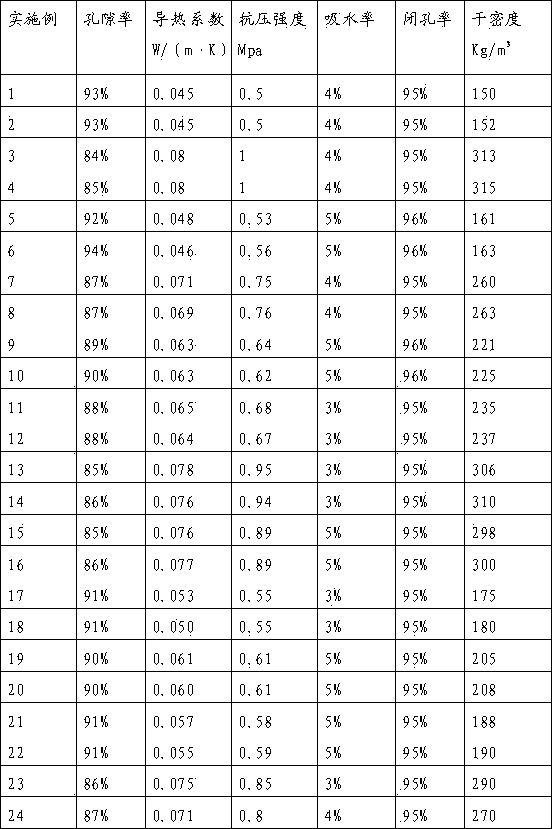

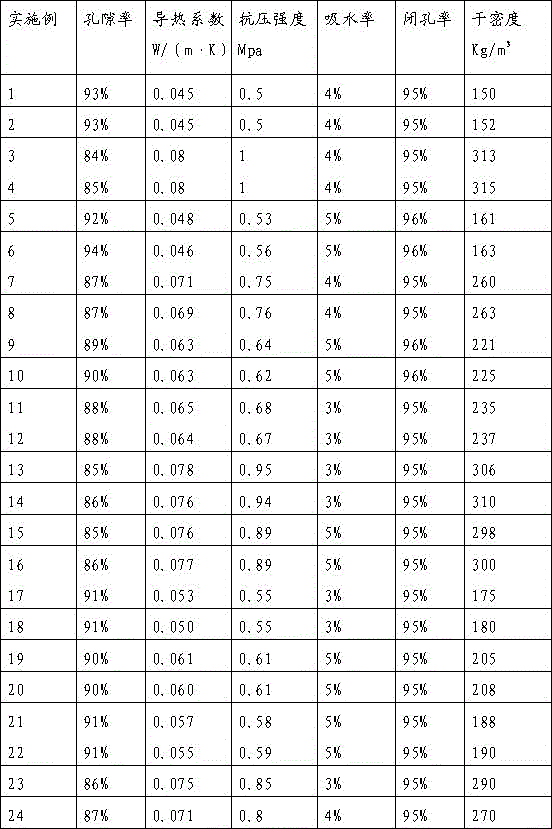

Material used for manufacturing foam cement, method for preparing foam cement from same, and foam cement

ActiveCN103420654ALow thermal conductivityImprove thermal conductivitySolid waste managementCeramicwareFoaming agentThermal insulation

The invention relates to a foamed cement material and a production and a preparation method thereof. The foamed cement material comprises the following components in parts by weight: 32 to 58 parts of cement, 10 to 34 parts of solid waste materials, 2 to 7 parts of foamed hole conditioning agents, 0.2 to 0.5 part of foamed hole wall reinforcing agent, 2.5 to 7 parts of foaming agents, 0.1 to 0.5 part of foaming speed conditioning agent, 0.1 to 1 part of curing speed conditioning agent and the balance of water, wherein the content of all the components reaches 100% after proper amount of the water is added. The foamed cement is an inorganic heat preservation material with the integrated performance of fire prevention and energy conservation. The foaming ratio of the foamed cement material can be regulated by using the foamed hole conditioning agents, so that the heat conductivity coefficient of the foamed cement material is controlled in a definite range. Therefore, the foamed cement material can satisfy the heat preservation and thermal insulation requirements in cold areas and other areas hot in summer and warm in winter. The foamed hole wall conditioning agent, the foamed hole wall reinforcing agent, the foaming agents, the foaming speed conditioning agent and the curing speed conditioning agent are prepared into solutions, so that the transportation and the category of metering equipment are reduced, i.e. the equipment investment is lowered and the dust emission is reduced. As a result, the sanitary production is realized, and the environment-friendly requirement is satisfied.

Owner:CUBIC DIGITAL TECH CO LTD

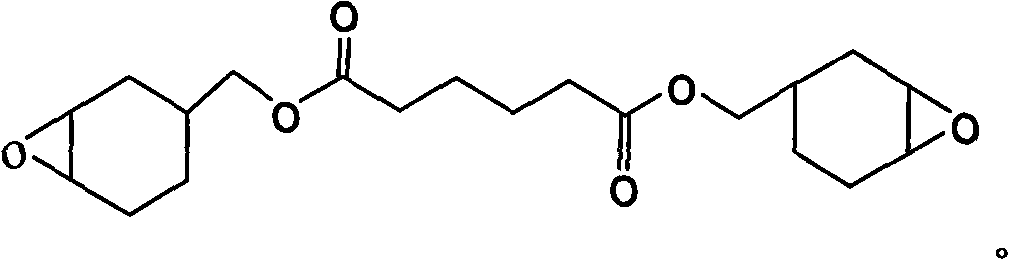

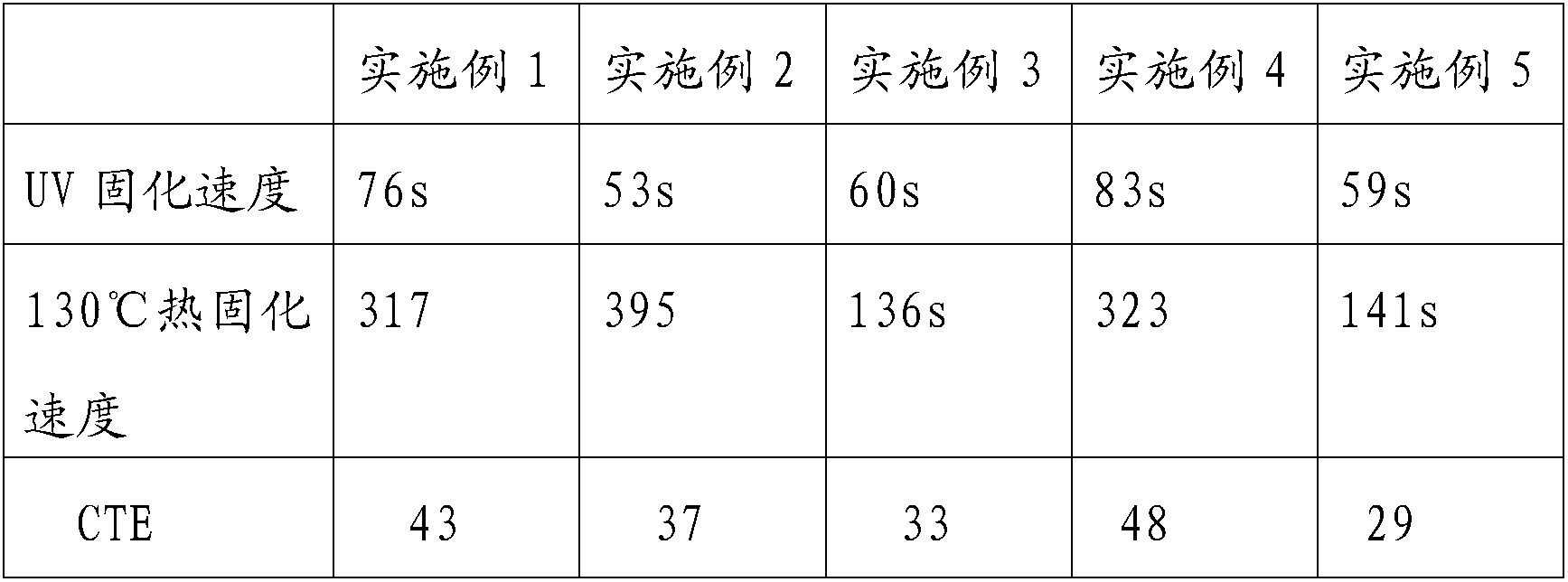

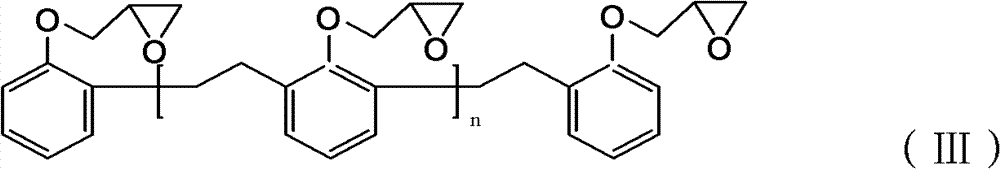

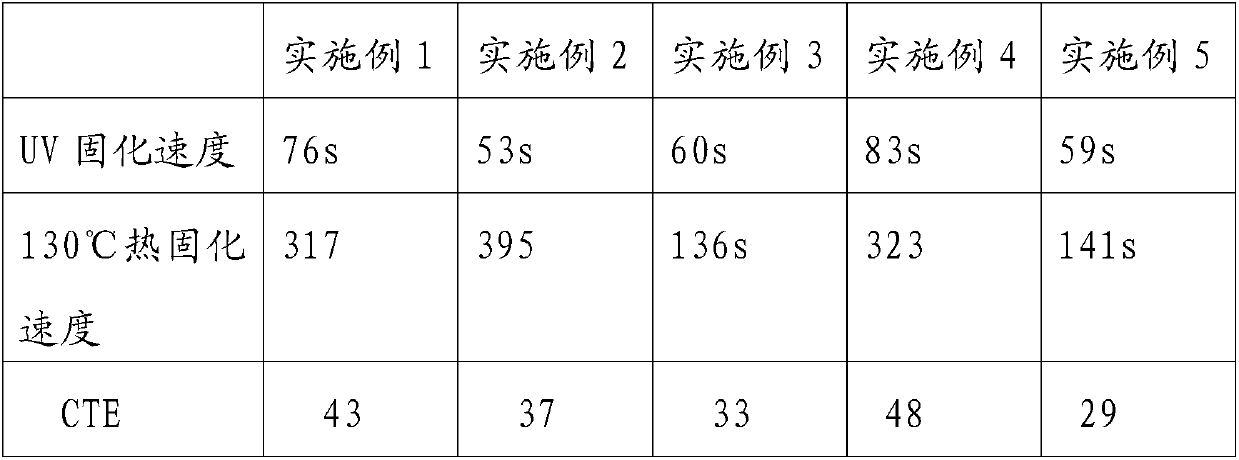

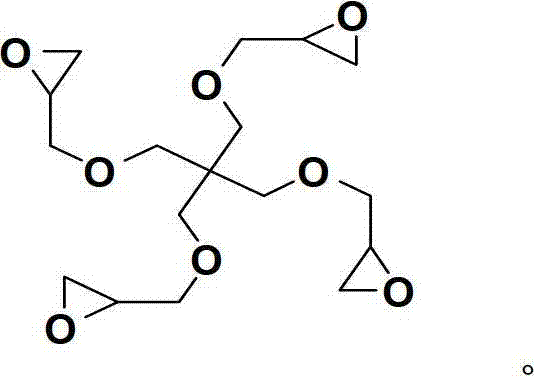

Double curing encapsulating adhesive and preparation method thereof

InactiveCN102504745ALow shrinkageImprove water resistanceNon-macromolecular adhesive additivesOther chemical processesEpoxyPolyol

The invention relates to a double curing encapsulating adhesive and a preparation method thereof. The double curing encapsulating adhesive comprises the following raw materials in percentage by weight: 35 to 60 percent of epoxy resin, 2 to 20 percent of polyol, 1 to 20 percent of silane coupling agent, 0.1 to 2 percent of photoinitiator, 0.1 to 2 percent of thermal initiator and 30 to 60 percent of filler. The double curing encapsulating adhesive provided by the invention with low contraction rate and high water resistance and cold and heat circulation resistance can effectively guarantee that encapsulated elements are reliable; the adhesive can cure quickly and completely under ultraviolet (UV) and heat while delivering quick positioning and excellent mechanical properties; with light smell after curing, the adhesive is environment-friendly; and with high storage stability, the adhesive is suitable to adhere electronic elements.

Owner:YANTAI DARBOND TECH

High-temperature cured two-component pouring sealant and preparation method thereof

InactiveCN102093838AEasy to moveApplicable for a long timeNon-macromolecular adhesive additivesOther chemical processesHeat conductingSealant

The invention relates to a high-temperature cured two-component pouring sealant and a preparation method thereof, and the heat-conducting pouring sealant is prepared by an A component and a B component according to the weight ratio of 100: 80-100: 125, wherein the A component comprises the following raw materials by weight percent: 45.00%-85.00% of heat-conducting powder, 14.00%-50.00% of low-viscosity liquid silicon oil, 0.15%-15.00% of silane curing agent, 0.005-0.02% of inhibitor, and 0.00-5.00% of color toner; and the B component comprises the following raw materials by weight percent: 45.00%-85.00% of heat-conducting material, 14.00%-55.00% of the low-viscosity liquid silicon oil, 0.04%-1.00% of catalyst and 0.00-5.00% of the color toner. The preparation method of the heat-conducting pouring sealant comprises the following steps: respectively preparing the A component and the B component, uniformly mixing the A component with the B component according to the weight ratio of 100: 80-100: 125 during the use, and heating and curing for 2 hours at the temperature of 60-80 DEG C for preparation.

Owner:YANTAI DARBOND TECH

Preparation method of special nano calcium carbonate for polyurethane sealant

InactiveCN105883883AAdjust curing speedControl structureCalcium/strontium/barium carbonatesNon-macromolecular adhesive additivesSealantBinding force

The invention discloses a preparation method of special nano calcium carbonate for a polyurethane sealant. The method comprises steps as follows: A, a crystal form control agent is added to a Ca(OH)2 solution, the mixture is evenly mixed, CO2 is introduced for a bubbling carbonation reaction until the pH of the solution is 7-8, and boiled pulp is obtained; B, the boiled pulp is heated to 60-85 DEG C after being sieved, a mixture of saturated fatty acid sodium and bismuth carboxylate is added to be used as a surfactant in the stirring state, the pH value is adjusted to range from 7 to 9, and the mixture is continuously stirred for 45-60 min; C, the stirred boiled pulp in the step B is subjected to filter pressing, a filter cake is obtained, dried, crushed and further dried, and the special nano calcium carbonate is obtained. The prepared nano calcium carbonate has the higher binding force with a polyurethane system, the mechanical property of the polyurethane sealant can be significantly improved, and the tensile strength, the elongation at break and the tear strength of the polyurethane sealant can be improved after the special nano calcium carbonate is applied to the polyurethane sealant.

Owner:GUANGXI PINGNAN COUNTY HENGXIANG CALCIUM CARBONATE CO LTD

Preparation method of special nano calcium carbonate for polyurethane sealant

InactiveCN106277015AAdjust curing speedHigh strengthCalcium/strontium/barium carbonatesMaterial nanotechnologyCarboxylic acidSurface-active agents

The invention discloses a preparation method of special nano calcium carbonate for polyurethane sealant. The preparation method includes the following steps that A, a crystal form control agent is added into a Ca(OH)2 solution, the mixture is stirred and mixed evenly, CO2 gas is injected for a bubbling carbonation reaction until the pH value of the solution is 7-8, and then boiled liquid is obtained; B, the boiled liquid is sieved and heated to 60 DEG C-85 DEG C, a mixture of saturated fatty acid and carboxylic acid bismuth salt is added under a stirring state to serve as a surface active agent, the pH value is regulated to be 7-9, and stirring is continued for 45-60 minutes; C, the stirred boiled liquid in step B is subjected to filter pressing, so that a filter cake is obtained, the filter cake is dried, smashed and further dried, and then the special nano calcium carbonate is obtained. Bonding force between nano calcium carbonate and a polyurethane system is good, the mechanical property of the polyurethane sealant can be obviously improved, and when the nano calcium carbonate is applied to the polyurethane sealant, the tensile strength, elongation at break and tearing strength of the polyurethane sealant can be improved.

Owner:连州市万仕达新材料有限公司

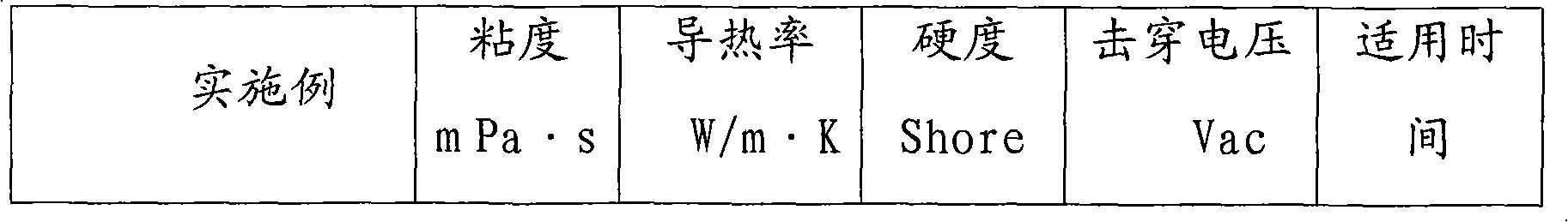

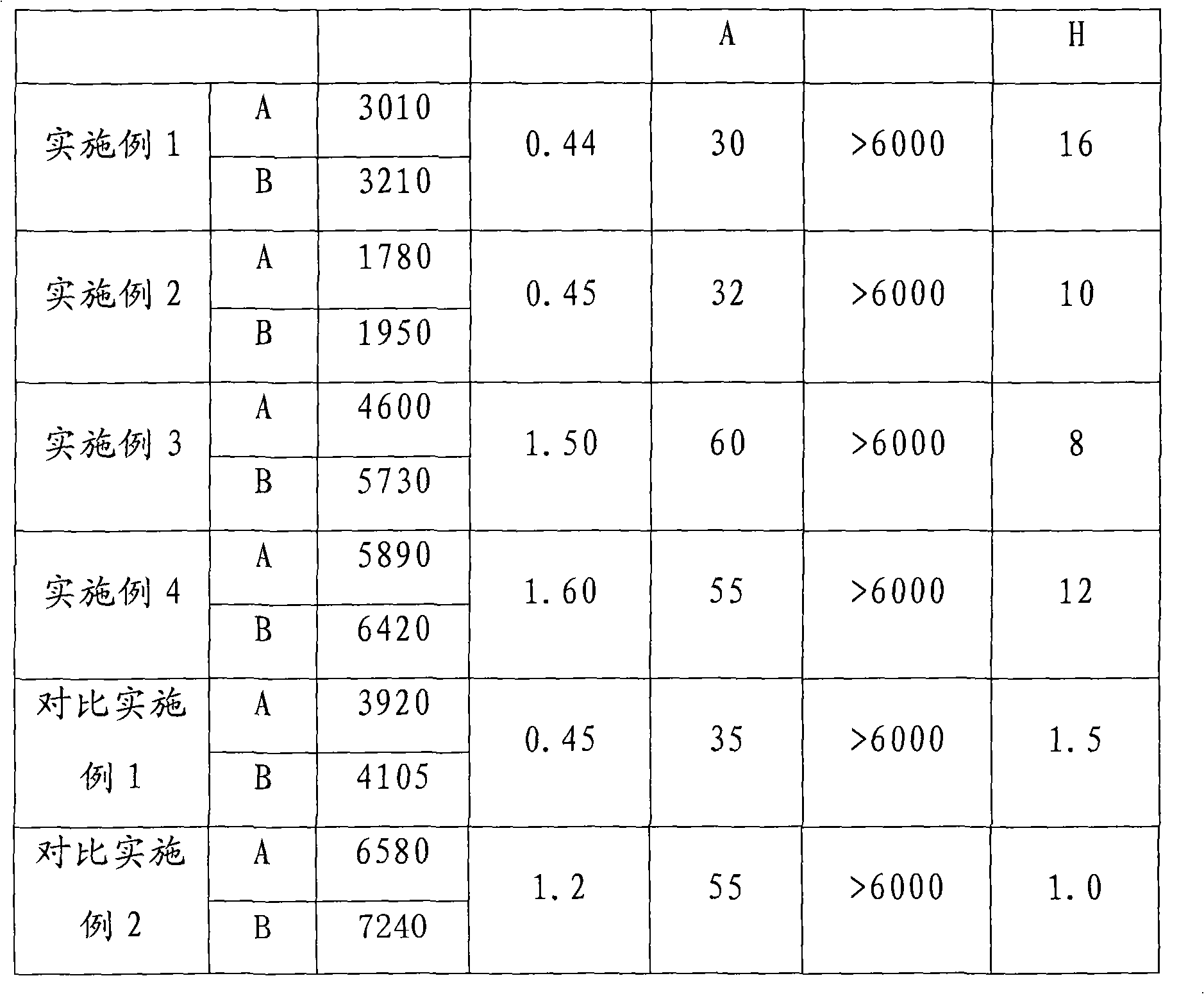

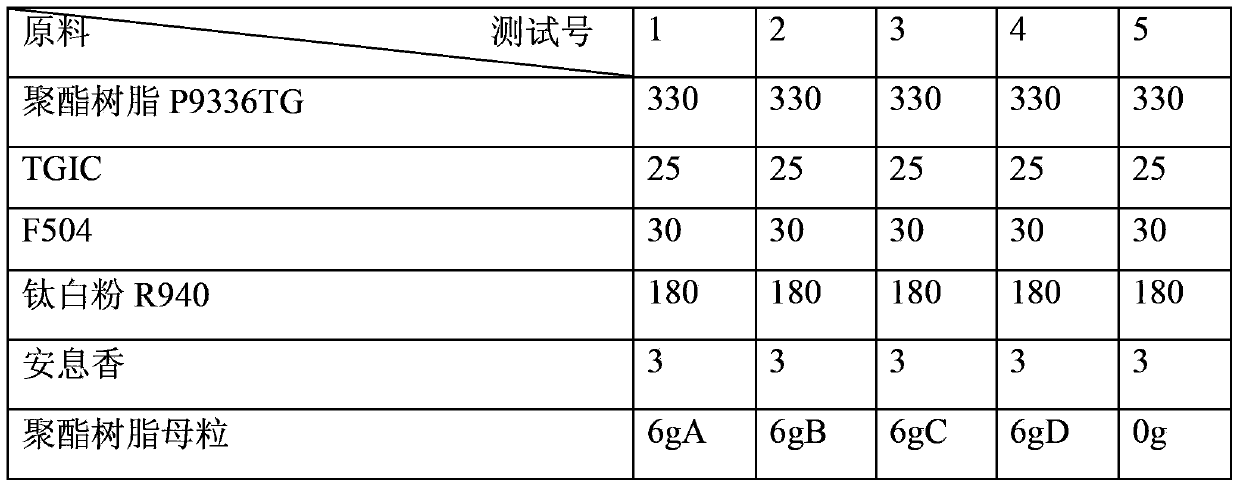

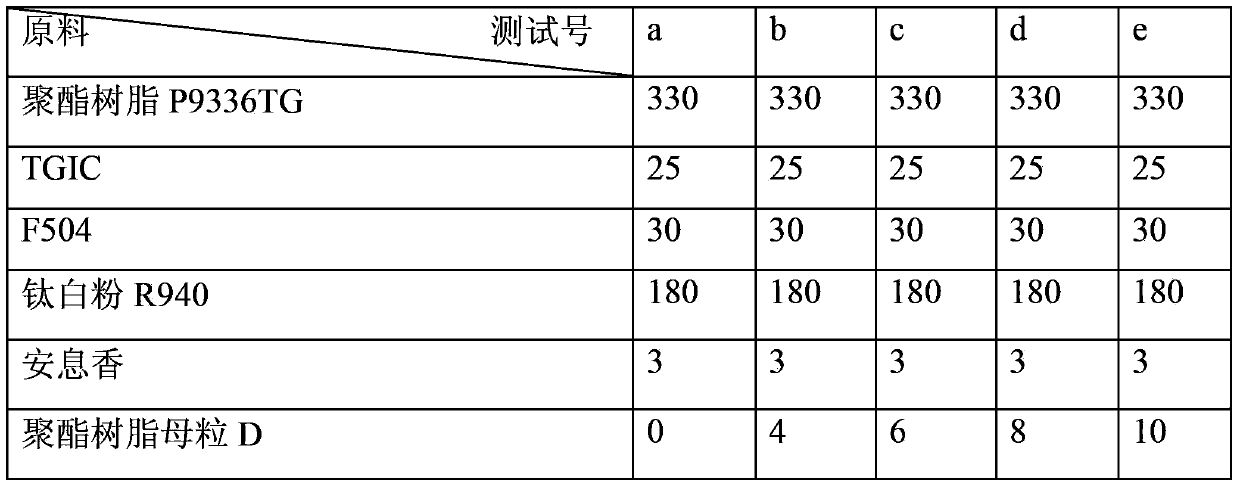

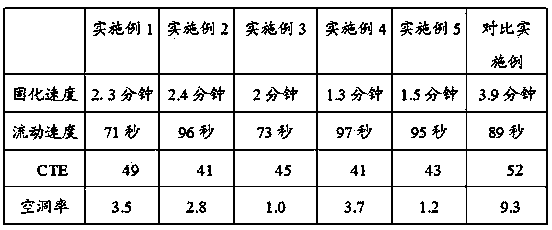

Preparation method of polyester resin master batch for regulating and controlling solidification speed of powdery coating, and application of polyester resin master batch

InactiveCN103396724AAdjustable curing speedHigh glass transition temperaturePowdery paintsPolyester coatingsAlcoholPhosphonium salt

The invention relates to the powdery coating field and discloses a preparation method of a polyester resin master batch for regulating and controlling solidification speed of a powdery coating, and application of the polyester resin master batch to powdery coating. The method provided by the invention employs alcohol and acid in a molar ratio of 1.02-1.2 / 1 to prepare the linear polyester resin master batch; and an added curing accelerator accounts for 0.2-8 wt%. The polyester resin master batch prepared according to the method has an acid value of 30-50 mg KOH / g and high glass-transition temperature; and the curing accelerator quaternary phosphonium salt and (or) quaternary ammonium salt in the weight proportion of 0.2-8% is added, so as to prepare the polyester resin master batch for regulating and controlling solidification speed of the powdery coating. The method provided by the invention can effectively shorten solidification time or reduce solidification temperature of the powdery coating, thereby reducing energy consumption and expanding scope of application of the powdery coating.

Owner:浙江中法新材料有限公司

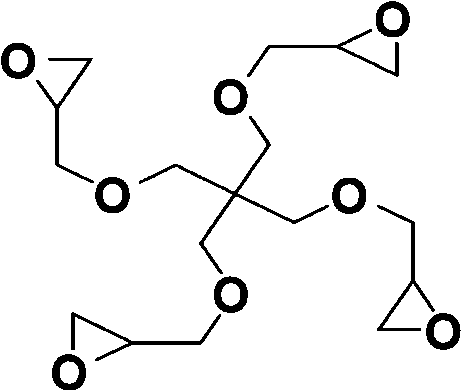

Underfill adhesive with good compatibility and preparation method thereof

InactiveCN103436211AFast flowImprove compatibilityNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyEnvironmental resistance

The invention relates to an adhesive, and particularly relates to an underfill adhesive with good compatibility and a preparation method thereof, which are applicable to the underfilling for packaging such as chip size packaging (CSP), ball grid array (BGA) packaging and the like, and belong to the field of adhesives. The underfill adhesive is composed of the following raw materials in parts by weight: 20-50 parts of epoxy resin, 5-20 parts of rosin epoxy resin, 2-15 parts of polyols, 5-10 parts of a silane coupling agent, 0.5-1 part of a cationic initiator, 35-55 parts of silicon powder, and 0.5 part of carbon black. The underfill adhesive disclosed by the invention is high in flow speed, and meets the requirements for high density packaging; the underfill adhesive has good compatibility with a soldering flux, and the formation of defects in the processes of flowing and curing is reduced; the shrinkage rate is low, and the reliability of packaging components is effectively guaranteed; the underfill adhesive is small in smell after being cured, thereby complying with the trend of environmental protection; and the underfill adhesive is good in storage stability, and convenient to use and store.

Owner:YANTAI DARBOND TECH

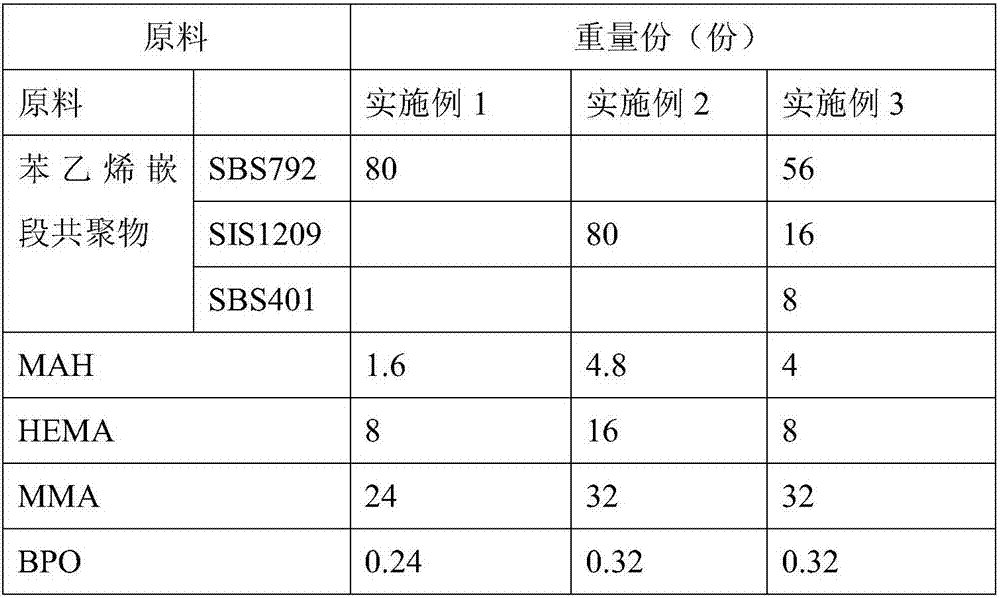

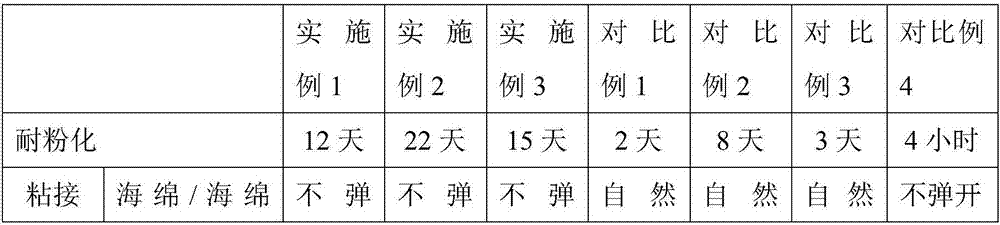

Chalking-resistant spray gel and preparation method thereof

ActiveCN107502231AImproved chalking resistanceImprove performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomer(Hydroxyethyl)methacrylate

The invention discloses a chalking-resistant spray gel and a preparation method thereof. The chalking-resistant spray gel is prepared from the following raw materials in parts by weight: 10 to 16 parts of butadiene-stryrene copolymer elastomer, 10 to 18 parts of hydrogenated rosin, 3 to 16 parts of hydrogenerated pentaerythritol rosin resin, 1 to 5 parts of alkyl phenolic resin magnesium oxide chelating matter, 5 to 8 parts of styrene block graft polymer, a proper amount of dispersing solvent, and 1 to 2 parts of solvent, wherein the viscosity of the alkyl phenolic resin magnesium oxide chelating matter is greater than 3000cps when determining by a No.3 rotor at the temperature of 25 DEG C; the styrene block graft polymer is prepared from the following raw materials in parts by weight: 100 parts of styrene block copolymer, 2 to 6 parts of MAH (maleicanhydride) monomer, 10 to 20 parts of HEMA (hydroxyethyl methacrylate) monomer, 30 to 40 parts of MMA (methyl methacrylate) monomer, 0.3 to 0.4 part of initiator, and 350 to 400 parts of solvent; the styrene block graft polymer is prepared by firstly grafting the styrene block copolymer, the MAH monomer and the HEMA monomer and then grafting with the MMA monomer; the styrene block copolymer is selected from one or several of SBS (styreneic block copolymers) or SIS (styrene isoprene styrene). The chalking-resistant spray gel has good chalking-resistant property.

Owner:GUANGDONG ORIENT RESIN

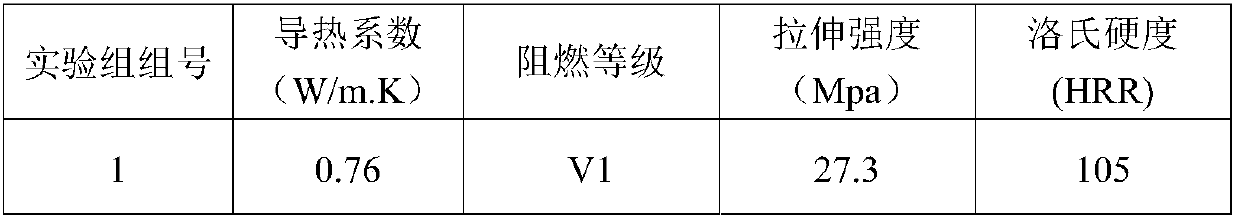

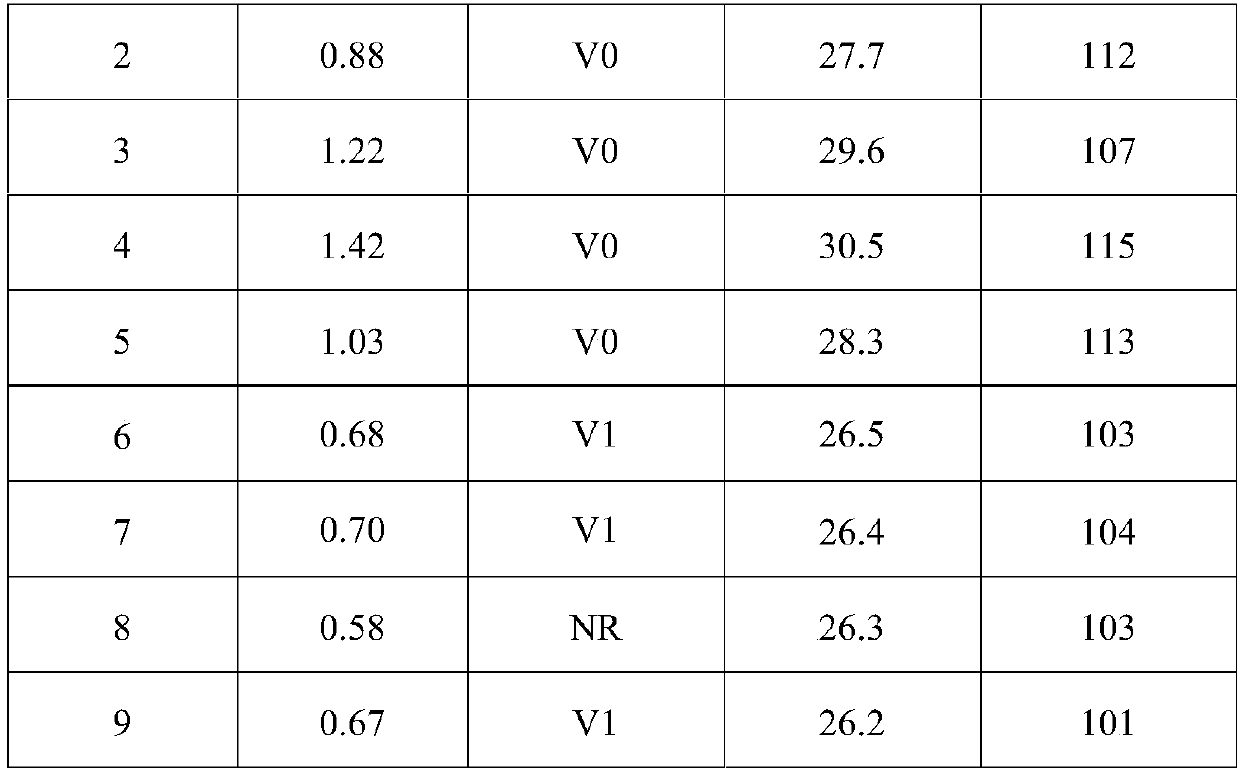

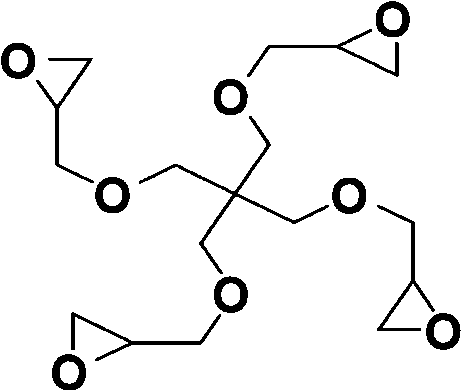

High-heat-conduction halogen-free expansion flame-retardant epoxy resin pouring sealant and preparation method thereof

InactiveCN108018010AHigh flame retardant efficiencyImprove toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceBoron nitride

The invention relates to the technical field of flame retardant modification, and provides a high-heat-conduction halogen-free expansion flame-retardant epoxy resin pouring sealant and a preparation method thereof. The preparation method comprises the following steps: preparing a first epoxy component, namely mixing epoxy resin, a toughening agent, an epoxy active diluent, a dispersing anti-settling agent and a defoaming agent for forming a first mixture, mixing zinc oxide and boron nitride to obtain a high-heat-conduction filler component, adding the high-heat-conduction filler component intothe first mixture for forming a second mixture, preparing a halogen-free expansion flame-retardant filler component by using crystalline II type diammonium polyphosphate and dipentaerythritol, addingthe halogen-free expansion flame-retardant filler component into the second mixture, and carrying out mixing and defoaming to obtain a first epoxy component; preparing a second epoxy component, namely mixing methyl tetrahydrophthalic anhydride, methyl hexahydrophthalic anhydride, a curing accelerator and a defoaming agent, and then carrying out defoaming to obtain a second epoxy component; and mixing the first epoxy component and the second epoxy component, carrying out defoaming, and then carrying out curing twice. The preparation method has simple operation and low production cost, and theprepared epoxy resin pouring sealant has excellent thermal conductivity and flame retardance.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT +1

Acrylic acid structural adhesive with good weatherability and stability

InactiveCN104327752AGood high and low temperature resistanceLong operating timeOrganic non-macromolecular adhesiveChemistryPlasticizer

The invention relates to an acrylic acid structural adhesive with good weatherability and stability and a preparation method thereof, the acrylic acid structural adhesive comprises a component A and a component B, the component A is composed of an acrylic acid ester monomer, an elastomer, a promoter, a coupling agent, a stabilizing agent and an auxiliary agent, and the component B is composed of an oxidizing agent, a plasticizer, epoxy resin and an auxiliary agent. The prepared acrylic acid structural adhesive has the characteristics of good weatherability, high stability, good manufacturability and high strength.

Owner:YANTAI DARBOND TECH

High-reliability intelligent-card encapsulating glue and preparation method thereof

InactiveCN102061060ALow shrinkageExcellent water resistance and heat and cold cycle resistanceOther chemical processesSilane couplingChemistry

The invention relates to high-reliability intelligent-card encapsulating glue and a preparation method thereof. The high-reliability intelligent-card encapsulating glue comprises the following raw materials in percentage by weight: 30-50 percent of epoxy resin, 5-30 percent of functional resin, 2-20 percent of polylol, 1-20 percent of silane coupling agent, 0.3-4 percent of light trigger and 30-60 percent of filler. The high-reliability intelligent-card encapsulating compound disclosed by the invention has low shrinkage ratio and excellent water resisting property and cold-hot circulation resisting property, effectively ensures the reliability of encapsulated components, conforms to the high-efficiency tempo in modern production due to rapid ultraviolet curing, complies with the trend of environmental protection due to little odor after curing, has good storage stability and is applicable to the encapsulation of an intelligent-card module integrated circuit chip.

Owner:YANTAI DARBOND TECH

Printing ink as well as preparation method and application thereof

The invention belongs to the technical field of preparation of photocuring silk-screen printing ink, and particularly relates to printing ink as well as a preparation method and application thereof. The ink comprises aliphatic polyurethane acrylate, modified epoxy acrylate, coated silver paste and / or coated aluminum paste, a reactive diluent, a photoinitiator, a co-initiator and a polymerization inhibitor, wherein the aliphatic polyurethane acrylate is difunctional polyether polyol polyurethane acrylate, and the molecular weight of the aliphatic polyurethane acrylate is 3000 to 8000. The ink provided by the invention does not contain volatile solvents, is odorless, does not discharge VOC (volatile organic compounds), and is environment-friendly. According to the ink, an ink layer obtained through the synergistic effect of all the components has certain ductility, can automatically fall back during scraping and cannot form fragment powder to fall off, and the scraping difficulty cannot be increased along with the increase of storage time; and the ink is high in curing speed and can be deeply cured, and the problem that part of ink is not cured does not exist.

Owner:上海抚佳精细化工有限公司

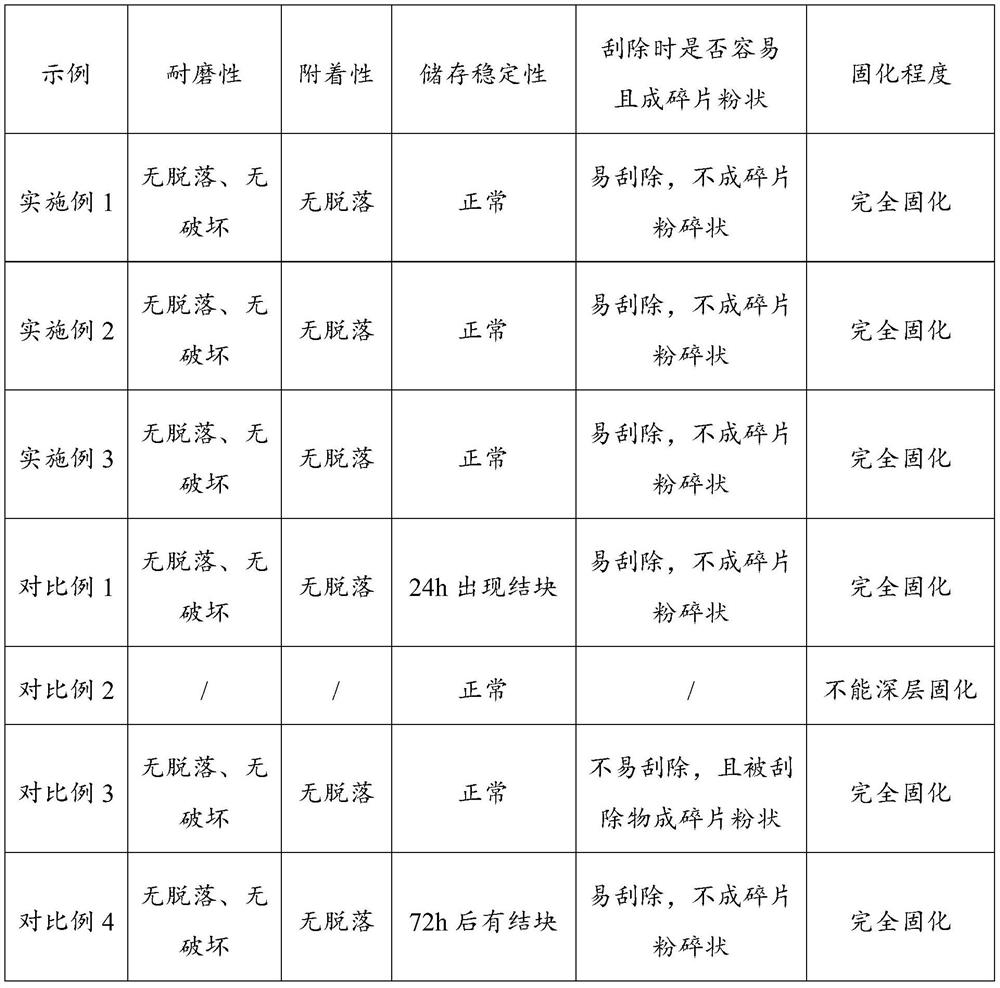

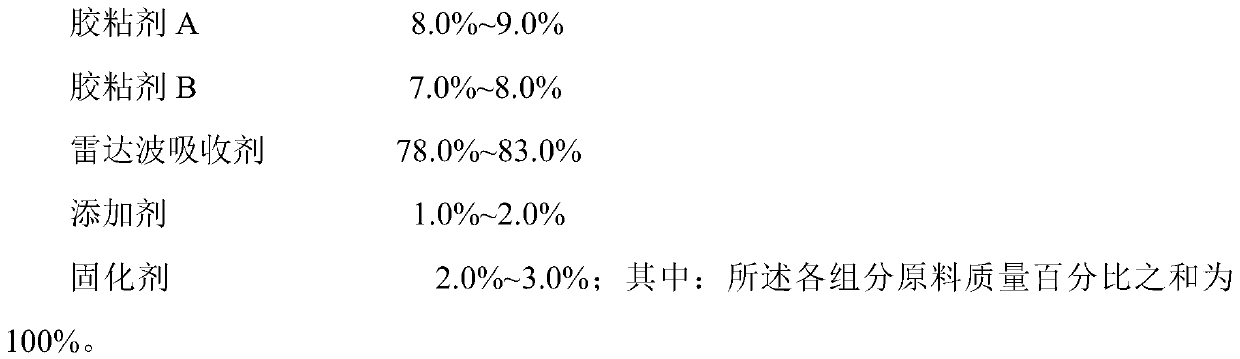

Fast-curing radar wave absorbing putty, preparation method and applications thereof

InactiveCN110845892AAdjust curing speedAdjust adhesionOther chemical processesFilling pastesAdhesive cementPolymer science

The invention discloses fast-curing radar wave absorbing putty, a preparation method and applications thereof, wherein the putty is prepared from two components, and specifically comprises, by weight,8.0-9.0% of an adhesive A, 7.0-8.0% of an adhesive B, 78.0-83.0% of a radar wave absorbent, 1.0-2.0% of an additive, and 2.0-3.0% of a curing agent. The preparation method comprises: adding the adhesive A, the adhesive B and the additive into a beaker according to the formula ratio, uniformly stirring, adding the radar wave absorbent and the curing agent, and continuously stirring to obtain the quick-curing radar wave absorbing putty. According to the invention, the quick-curing radar wave absorbing putty coating is obtained through a blade coating process, and has characteristics of good radar wave absorbing performance, high curing speed and good flexibility.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

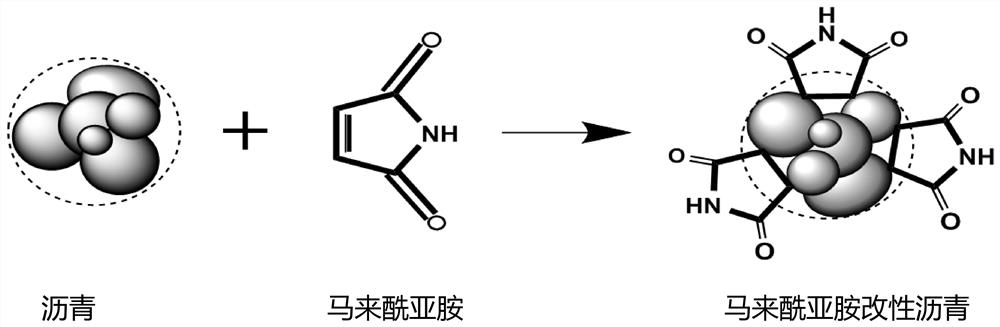

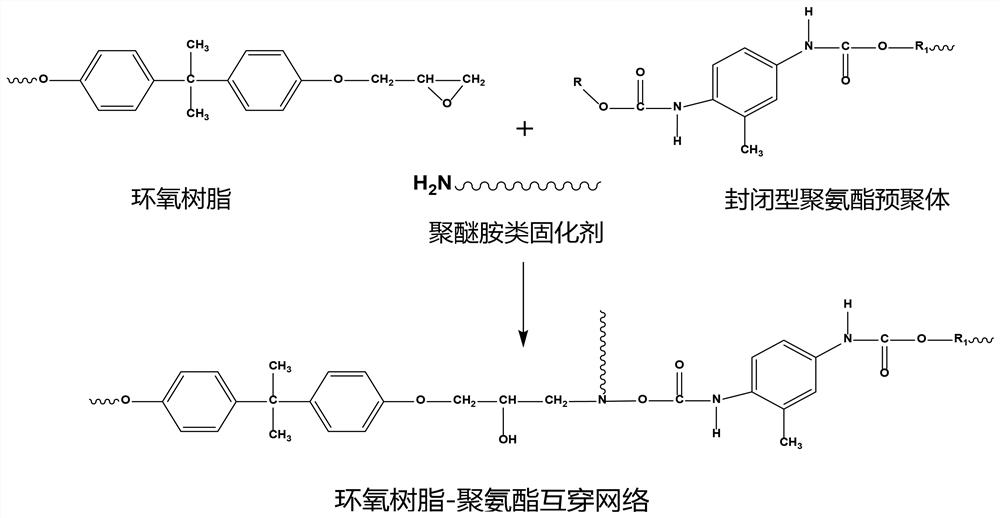

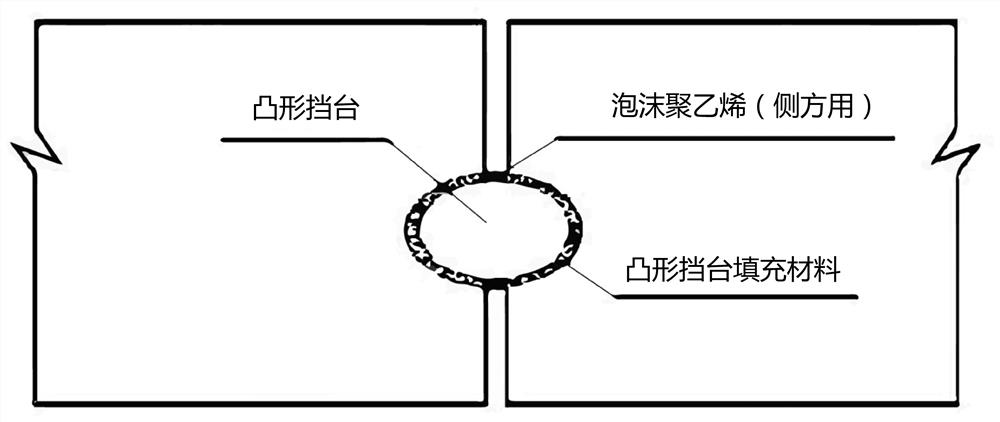

High-speed railway ballastless track convex blocking table filling material and preparation method thereof

ActiveCN112280326ASatisfy cohesivenessMeet aging resistanceBuilding insulationsPolymer sciencePolymer network

The invention provides a high-speed railway ballastless track convex blocking table filling material and a preparation method thereof. The material comprises the following raw materials: a component Amaleimide modified asphalt, a component B epoxy resin and a component C epoxy resin curing agent, the component C is prepared from the following raw materials in parts by weight: 100 parts of a polyether amine curing agent, 20-45 parts of a blocked polyurethane prepolymer, 10-20 parts of amino polydimethylsiloxane, 0-2.5 parts of a curing accelerator and 5-17.5 parts of an auxiliary agent; the mass ratio of the component B to the component C is 1: (0.65-1.35), and the mass ratio of the component A to the sum of the component B and the component C is (0.5-1.5): 1. After the filling material iscured, an epoxy resin-polyurethane interpenetrating polymer network or island structure is formed, the flexibility of the material is greatly improved, and the shearing strength, the adhesive force,the tensile strength, the bending strength and the like of an adhesive layer are improved.

Owner:南京阿斯孚特新材料科技有限公司

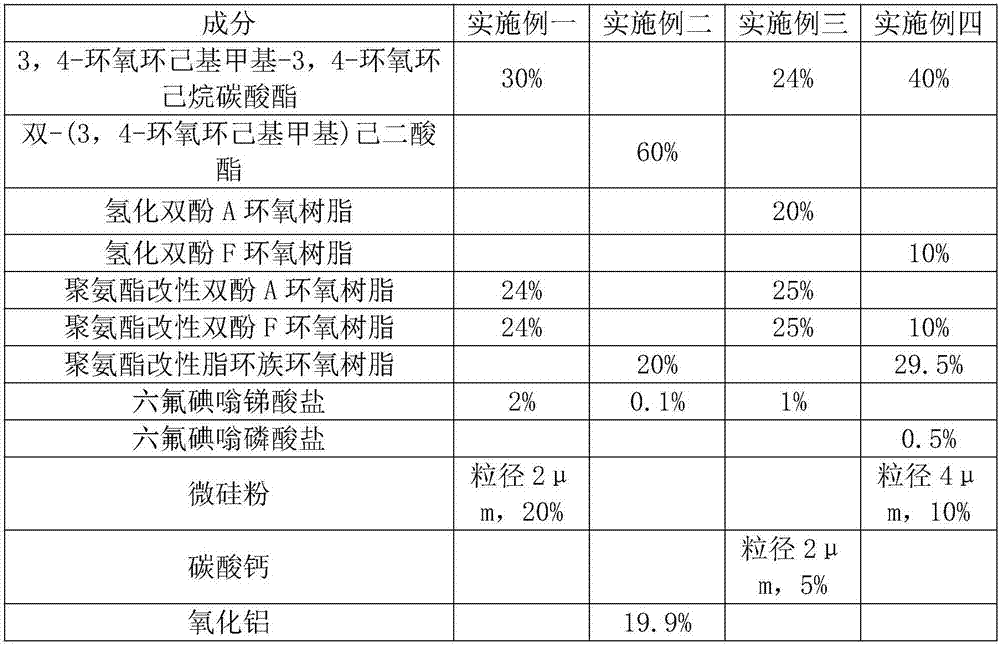

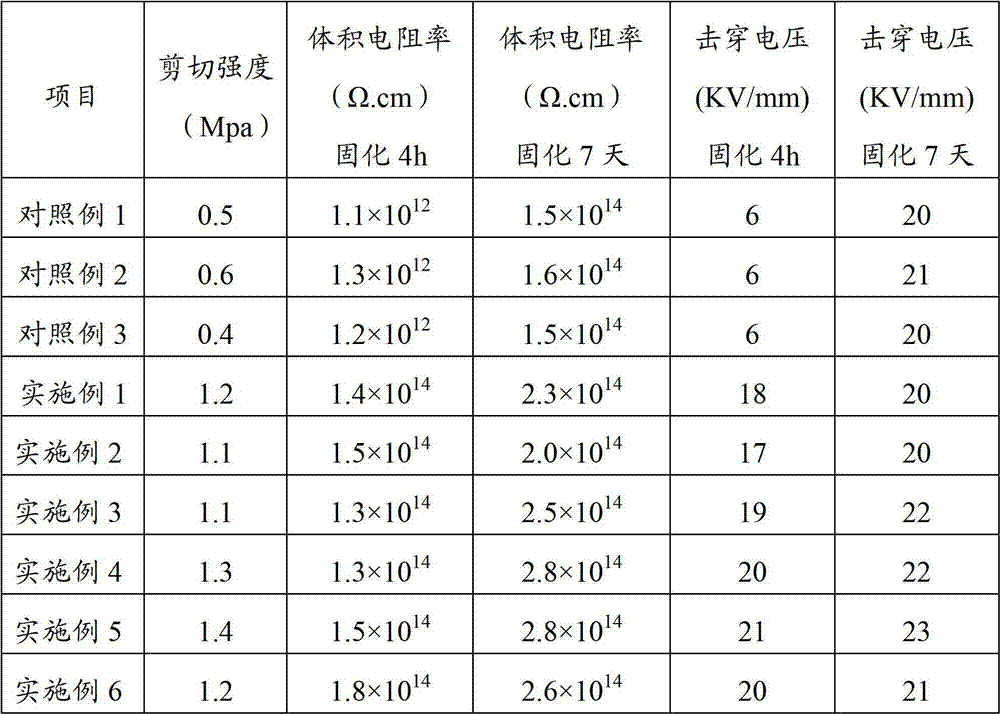

UV photocuring glue applicable to electronic chip encapsulation

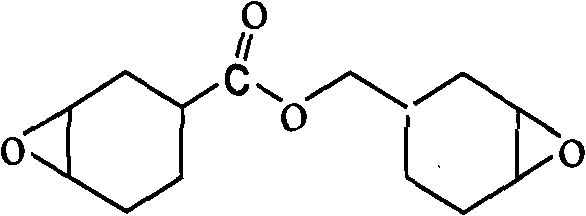

InactiveCN107573879AEfficient curingHigh hardnessNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyElectronic chip

The invention discloses UV photocuring glue applicable to electronic chip encapsulation. The UV photocuring glue is prepared from the following components: epoxy resin, flexibilizer, inorganic fillerand a photoinitiator. According to the UV photocuring glue provided by the invention, polyurethane modified epoxy resin can be used as the flexibilizer, so that the UV photocuring glue has the advantages that a cured product is relatively high in aging resistance and high in adhesiveness. The UV photocuring glue can be used for encapsulation of semiconductor integrated circuit devices; during use,the UV photocuring glue can perform good physical protection.

Owner:CHINA NAT ELECTRIC APP RES INST

Bicomponent condensed type room temperature vulcanization silicon rubber

The invention discloses a bicomponent condensed type room temperature vulcanization silicon rubber comprising the following components in parts by weight: 190-240 parts of component A and 8.5-16 parts of component B, wherein the component A is prepared by grinding the following raw materials in parts by weight through a three-roller grinder: 100 parts of hydroxyl-terminated polydimethylsiloxane, 30-40 parts of plasticizers and 60-100 parts fillers; and the component B is prepared by mixing the following raw materials in parts by weight under the protection of nitrogen: 5-10 parts of cross-linking agents, 3-5 parts of tackifiers and 0.5-1 parts of catalysts. The tackifier is an isocyanate hydrocarbyl silane coupling agent. The bicomponent condensed type room temperature vulcanization silicon rubber overcomes the defect of poor initial electric property the traditional bicomponent condensed type room temperature vulcanization silicon rubber system by adopting an isocyanate alkylsilane coupling agent and achieves the effect of fine initial electric property, high ageing resistance and good bonding property, thereby meeting the requirements for fast encapsulation and use of electrons.

Owner:YANTAI DARBOND TECH

Plugging agent for drilling fluid and preparation method thereof

The invention discloses a plugging agent for drilling fluid and a preparation method thereof. The plugging agent is prepared from the following components in parts by weight: 100 parts of matrix asphalt, 10-40 parts of a microcapsule modifier, 1-20 parts of a dispersing agent, 5-20 parts of a curing agent, 0.5-5 parts of an accelerant and 100-200 parts of water. The plugging agent can effectively reside at entrances of malignant leakage strata such as large cracks and karst caves to form solid sealing, and particularly, the retention plugging capacity and the water washing resistance are improved at high temperature and high pressure, so that the plugging success rate is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

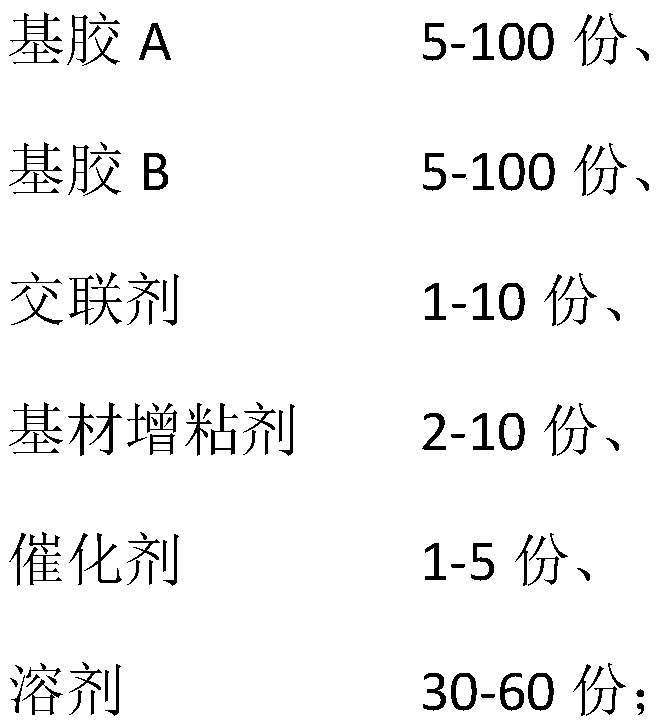

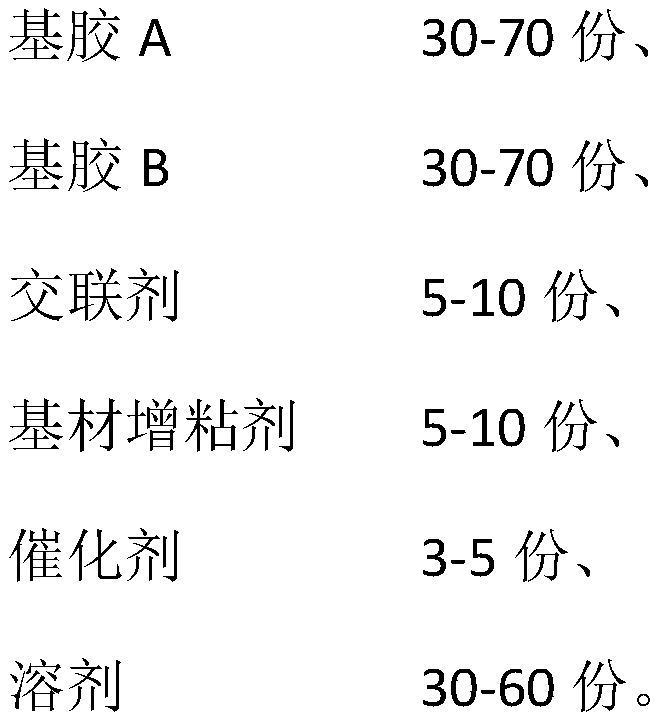

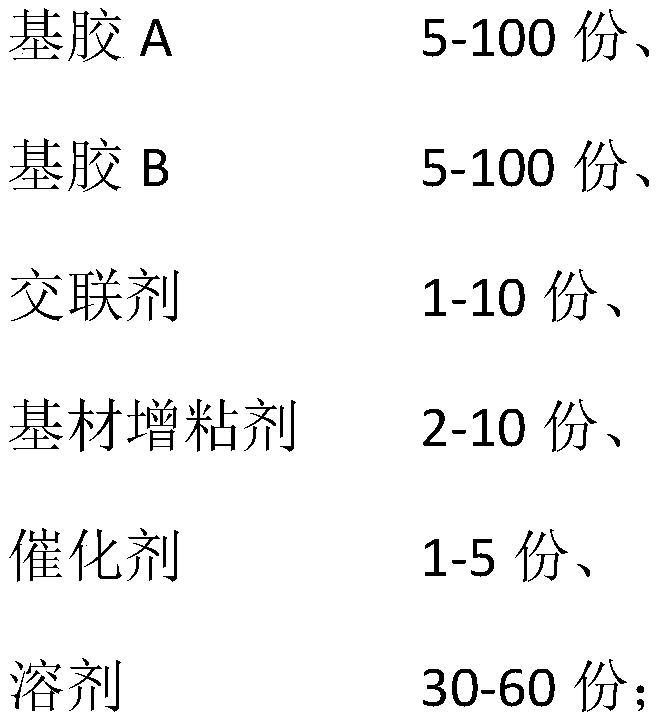

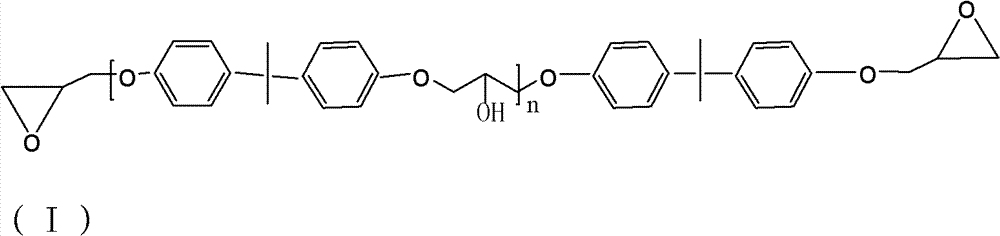

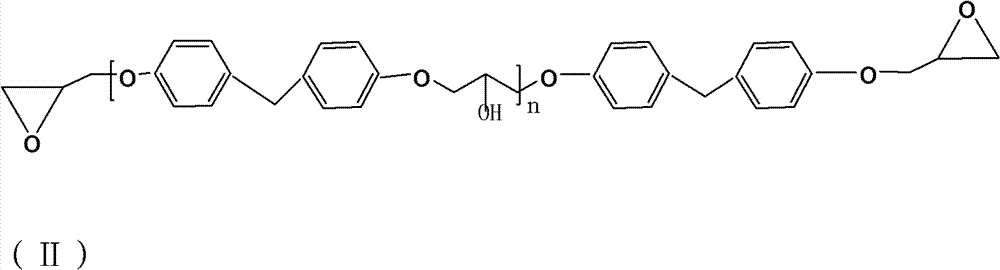

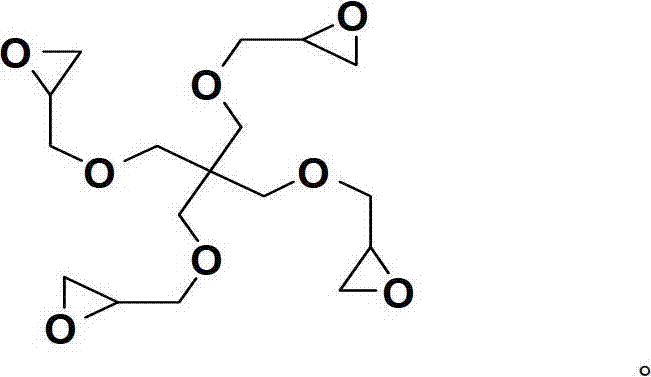

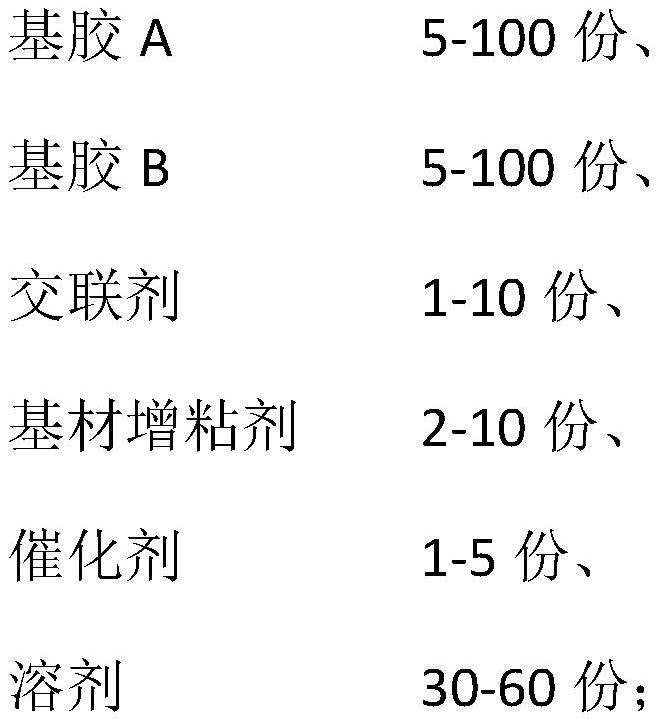

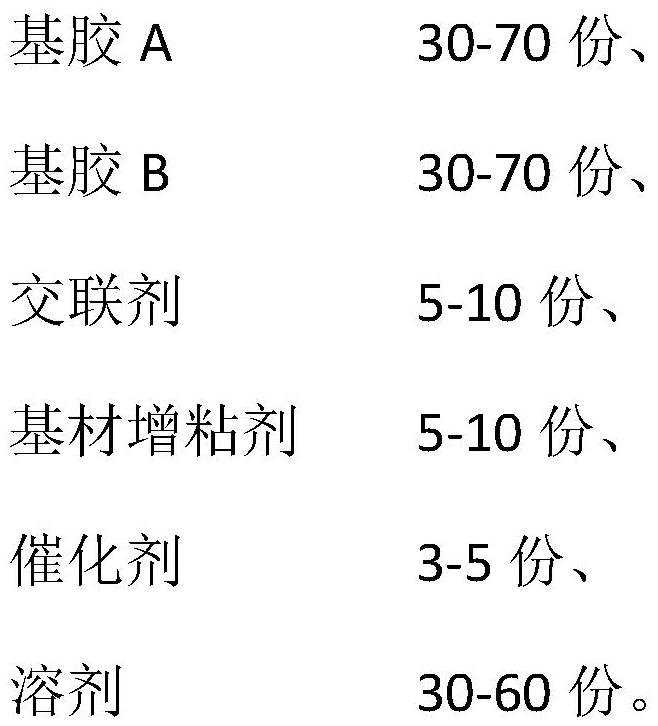

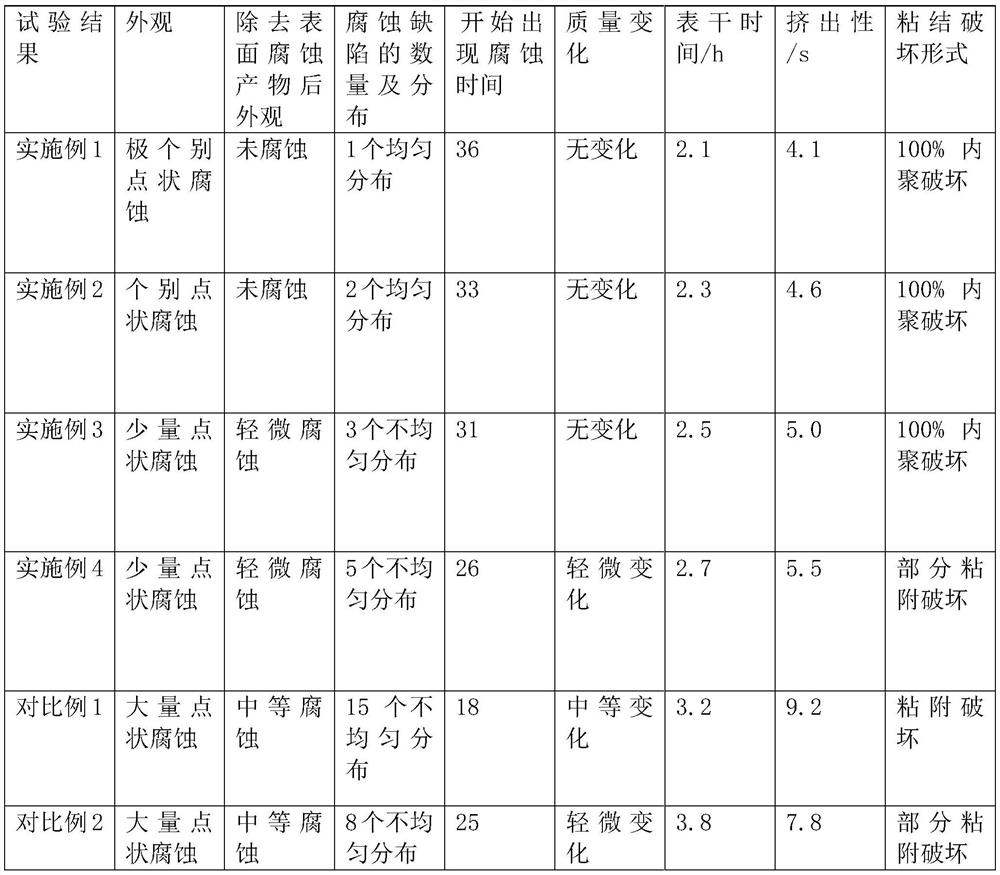

Fluorine-containing organic silicon coating adhesive and preparation method thereof

ActiveCN110698981ACuring speed can be adjustedGood chemical resistanceAdhesive processes with surface pretreatmentAnti-corrosive paintsPtru catalystMeth-

The invention relates to fluorine-containing organic silicon coating adhesive and a preparation method thereof. The fluorine-containing organic silicon coating adhesive is prepared from the followingraw materials in parts by weight: 5 to 100 parts of base adhesive A, 5 to 100 parts of base adhesive B, 1 to 10 parts of crosslinking agent, 2 to 10 parts of base material tackifier, 1 to 5 parts of catalyst and 30 to 60 parts of solvent, wherein the base adhesive A is hydroxyl terminated methyl-3,3,3-trifluoropropyl(siloxane and polysiloxane); and the base adhesive B is hydrogen-containing fluorosilicon oil. The fluorine-containing organic silicon coating adhesive is adjustable in curing speed and is oil-resistant and salt-spray resistant; the chemical corrosion resistance is greatly enhancedand the adhesive property is excellent; and the fluorine-containing organic silicon coating adhesive has three-prevention effect and excellent performance.

Owner:GUANGZHOU DAOLIN SYNTHETIC MATERIALS CO LTD +2

Double-solidification system fast-flowing underfill and preparation method thereof

InactiveCN102010686BGuaranteed reliabilityFast flowOther chemical processesEpoxynovolac adhesivesEpoxyPolyol

The invention discloses a double-solidification system fast-flowing underfill and a preparation method thereof. The underfill comprises the following raw materials in parts by weight: 30-80% of epoxy resin, 10-50% of epoxy acrylate, 5-30% of acrylate, 2-20% of polyol, 1-20% of silane coupling agent, 0.3-4% of cationic initiator, 0.1-3% of radical initiator and 0.1-0.5% of carbon black; and the preparation method comprises the following steps of: weighing the epoxy resin and the cationic initiator in the proportion, putting in a reaction kettle and stirring into a uniform solution; weighing the epoxy acrylate, the acrylate, the polyol, the silane coupling agent, the radical initiator and the carbon black in the proportion, putting in the reaction kettle in sequence, mixing and stirring to obtain the finished product of the double-solidification system fast-flowing underfill.

Owner:YANTAI DARBOND TECH

Material for producing foamed cement, method for producing foamed cement using same, and foamed cement

ActiveCN103420654BLow thermal conductivityImprove thermal conductivitySolid waste managementCeramicwareFoaming agentThermal insulation

The invention provides a material for producing foamed cement, a method for preparing foamed cement using the same, and foamed cement, which at least include the following components in parts by weight: 100 parts of cement, 20-80 parts of solid waste materials, foam 1.2-2.5 parts of cell regulator, 0.1-0.5 parts of cell wall strengthening agent, 2.5-15 parts of foaming agent, 0.002-0.023 parts of foaming speed regulator, 0.01-0.5 parts of curing speed regulator, 62-93 parts of water . The material of the foamed cement of the present invention, under the condition of comprehensively considering the factors that may affect the performance of the foamed cement, by adjusting the raw material formula of the foamed cement material, the internal porosity and single-cell closed cell ratio of the finished foamed cement can be obtained. Higher foam cement material. Because the porosity and single-pore closed cell ratio inside the foamed cement are improved, the foamed cement prepared by the foamed cement material of the present invention has low thermal conductivity, good thermal insulation, sound insulation and other performances, and low water absorption.

Owner:CUBIC DIGITAL TECH CO LTD

Double curing encapsulating adhesive and preparation method thereof

InactiveCN102504745BImprove performanceAdjust curing speedNon-macromolecular adhesive additivesOther chemical processesEpoxyPolyol

The invention relates to a double curing encapsulating adhesive and a preparation method thereof. The double curing encapsulating adhesive comprises the following raw materials in percentage by weight: 35 to 60 percent of epoxy resin, 2 to 20 percent of polyol, 1 to 20 percent of silane coupling agent, 0.1 to 2 percent of photoinitiator, 0.1 to 2 percent of thermal initiator and 30 to 60 percent of filler. The double curing encapsulating adhesive provided by the invention with low contraction rate and high water resistance and cold and heat circulation resistance can effectively guarantee that encapsulated elements are reliable; the adhesive can cure quickly and completely under ultraviolet (UV) and heat while delivering quick positioning and excellent mechanical properties; with light smell after curing, the adhesive is environment-friendly; and with high storage stability, the adhesive is suitable to adhere electronic elements.

Owner:YANTAI DARBOND TECH

Low-viscosity and high-thermal-conductivity two-component potting silica gel

PendingCN113845875AEasy to moveGuarantee job stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a low-viscosity and high-thermal-conductivity two-component potting silica gel which is composed of a component A and a component B. The component A is composed of the following raw materials: 40-90 parts of a thermal conductive material, 20-50 parts of low-viscosity liquid silicone oil, 1-10 parts of a cross-linking agent, and 0.5-5 parts of a toner. The component B is prepared from the following raw materials in parts by weight: 40-90 parts of a heat-conducting material, 20-55 parts of low-viscosity liquid silicone oil, 0.04-1 part of a catalyst and 0.5-5 parts of a toner. The potting silica gel disclosed by the invention is good in flowability and high in thermal conductivity, the reliability and stability of an electronic device are improved, and the service life of the electronic device is prolonged.

Owner:YANTAI DARBOND TECH

A kind of preparation method of nano calcium carbonate special for polyurethane sealant

InactiveCN105883883BAdjust curing speedControl structureCalcium/strontium/barium carbonatesNon-macromolecular adhesive additivesCarboxylic saltSealant

The invention discloses a preparation method of special nano calcium carbonate for a polyurethane sealant. The method comprises steps as follows: A, a crystal form control agent is added to a Ca(OH)2 solution, the mixture is evenly mixed, CO2 is introduced for a bubbling carbonation reaction until the pH of the solution is 7-8, and boiled pulp is obtained; B, the boiled pulp is heated to 60-85 DEG C after being sieved, a mixture of saturated fatty acid sodium and bismuth carboxylate is added to be used as a surfactant in the stirring state, the pH value is adjusted to range from 7 to 9, and the mixture is continuously stirred for 45-60 min; C, the stirred boiled pulp in the step B is subjected to filter pressing, a filter cake is obtained, dried, crushed and further dried, and the special nano calcium carbonate is obtained. The prepared nano calcium carbonate has the higher binding force with a polyurethane system, the mechanical property of the polyurethane sealant can be significantly improved, and the tensile strength, the elongation at break and the tear strength of the polyurethane sealant can be improved after the special nano calcium carbonate is applied to the polyurethane sealant.

Owner:GUANGXI PINGNAN COUNTY HENGXIANG CALCIUM CARBONATE CO LTD

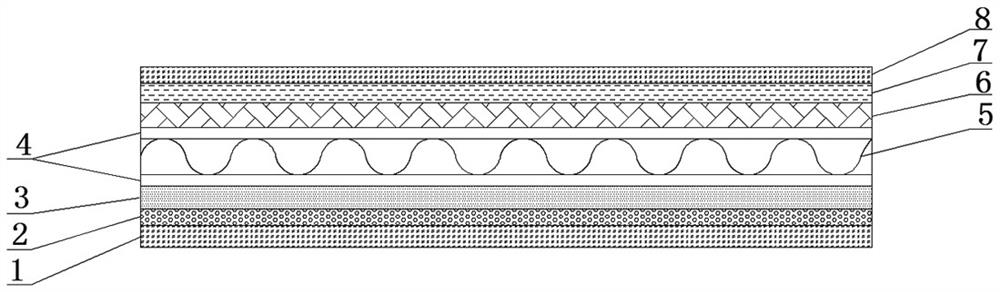

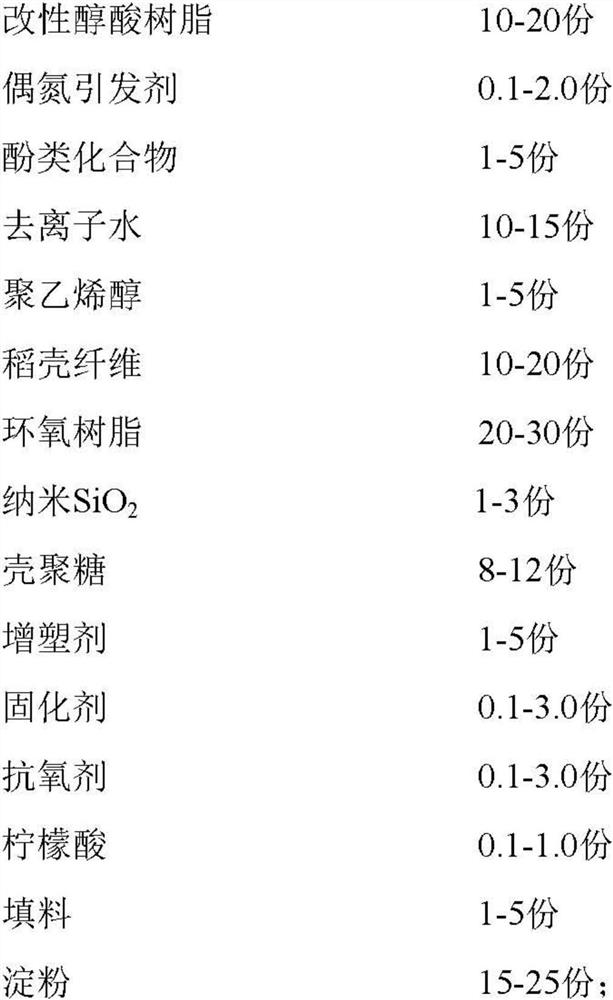

Composite corrugated paper and preparation method thereof

PendingCN112523005AHigh strengthImprove impact resistanceMechanical working/deformationWrappersFiberPolymer science

The invention relates to the technical field of corrugated paper, in particular to composite corrugated paper and a preparation method thereof. The composite corrugated paper comprises first surface paper, an antibacterial layer, a reinforcing layer, corrugated core paper, a fiber layer, a waterproof layer and second surface paper which are sequentially attached, and the upper surface of the reinforcing layer and the lower surface of the fiber layer are each coated with a composite adhesive layer. A composite adhesive is prepared from the following raw materials in parts by weight: 10-20 partsof modified alkyd resin, 0.1-2.0 parts of azo initiator, 1-5 parts of phenolic compound, 10-15 parts of deionized water, 1-5 parts of polyvinyl alcohol, 10-20 parts of rice hull fiber, 20-30 parts ofepoxy resin, 1-3 parts of nano SiO2, 8-12 parts of chitosan, 1-5 parts of plasticizer, 0.1-3.0 parts of curing agent, 0.1-3.0 parts of antioxidant, 0.1-1.0 part of citric acid, 1-5 parts of a fillerand 15-25 part of starch. The composite corrugated paper provided by the invention has good strength and mildew-proof and antibacterial effects, and is long in service life.

Owner:东莞顺裕纸业有限公司

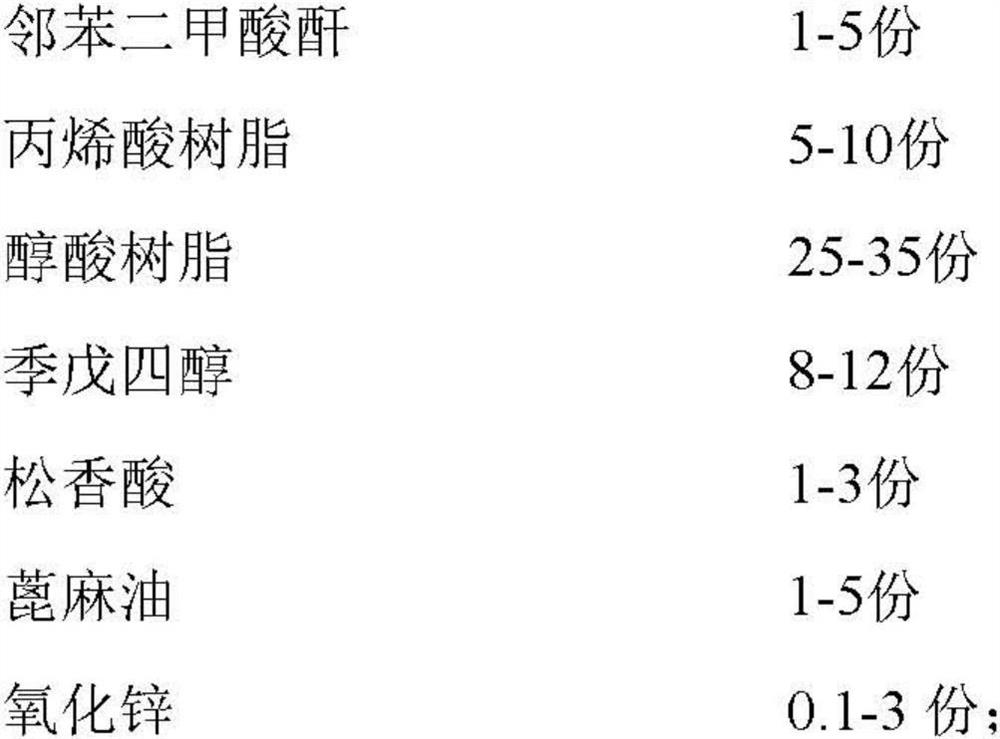

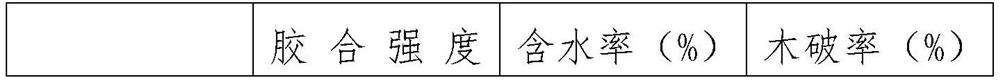

A kind of fir bark wood-based panel adhesive

ActiveCN109897596BReduce tannin contentIncrease profitNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesive cementPolymer science

The invention belongs to the technical field of construction materials and discloses a Chinese fir bark adhesive for artificial boards. The Chinese fir bark adhesive is prepared from, by weight, 80-100 parts of Chinese fir bark powder, 40-60 parts of urea resin, 80-85 parts of phenol, 3-5 parts of urea, 1-2 parts of mica powder, 1-2 parts of gypsum powder, 0.5-0.6 part of nano silicon oxide and 0.1-0.2 part of a siloxane surfactant. The invention further provides a preparation method of the adhesive according to components of Chinese fir bark. The preparation method includes: treating Chinesefir bark powder with sodium hydroxide solution containing H2O2, lignin peroxidase and acetylacetone; subjecting the treated Chinese fir bark powder to reaction with phenol and urea, and mixing with mica powder, gypsum powder, nano silicon oxide and the siloxane surfactant to obtain bark adhesive; mixing the bark adhesive with urea formaldehyde resin. The Chinese fir bark adhesive has advantages ofhigh adhesive strength, water resistance, weather resistance and hardness and low free formaldehyde emission.

Owner:GUIZHOU UNIV

Underfill adhesive with good compatibility and preparation method thereof

InactiveCN103436211BFast flowImprove compatibilityNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyEnvironmental resistance

The invention relates to an adhesive, and particularly relates to an underfill adhesive with good compatibility and a preparation method thereof, which are applicable to the underfilling for packaging such as chip size packaging (CSP), ball grid array (BGA) packaging and the like, and belong to the field of adhesives. The underfill adhesive is composed of the following raw materials in parts by weight: 20-50 parts of epoxy resin, 5-20 parts of rosin epoxy resin, 2-15 parts of polyols, 5-10 parts of a silane coupling agent, 0.5-1 part of a cationic initiator, 35-55 parts of silicon powder, and 0.5 part of carbon black. The underfill adhesive disclosed by the invention is high in flow speed, and meets the requirements for high density packaging; the underfill adhesive has good compatibility with a soldering flux, and the formation of defects in the processes of flowing and curing is reduced; the shrinkage rate is low, and the reliability of packaging components is effectively guaranteed; the underfill adhesive is small in smell after being cured, thereby complying with the trend of environmental protection; and the underfill adhesive is good in storage stability, and convenient to use and store.

Owner:YANTAI DARBOND TECH

High-reliability intelligent-card encapsulating glue and preparation method thereof

The invention relates to high-reliability intelligent-card encapsulating glue and a preparation method thereof. The high-reliability intelligent-card encapsulating glue comprises the following raw materials in percentage by weight: 30-50 percent of epoxy resin, 5-30 percent of functional resin, 2-20 percent of polylol, 1-20 percent of silane coupling agent, 0.3-4 percent of light trigger and 30-60 percent of filler. The high-reliability intelligent-card encapsulating compound disclosed by the invention has low shrinkage ratio and excellent water resisting property and cold-hot circulation resisting property, effectively ensures the reliability of encapsulated components, conforms to the high-efficiency tempo in modern production due to rapid ultraviolet curing, complies with the trend of environmental protection due to little odor after curing, has good storage stability and is applicable to the encapsulation of an intelligent-card module integrated circuit chip.

Owner:YANTAI DARBOND TECH

Fluorine-containing silicone coating glue and preparation method thereof

ActiveCN110698981BCuring speed can be adjustedGood chemical resistanceAdhesive processes with surface pretreatmentAnti-corrosive paintsPolymer sciencePtru catalyst

The invention relates to a fluorine-containing silicone coating glue and a preparation method thereof. The fluorine-containing silicone coating rubber is prepared from the following raw materials in parts by weight: 5-100 parts of base rubber A, 5-00 parts of base rubber B, 1-10 parts of crosslinking agent, and substrate tackifier 2-10 parts, 1-5 parts of catalyst, 30-60 parts of solvent; the base gum A is hydroxyl-terminated methyl-3,3,3-trifluoropropyl (siloxane and polysiloxane); The base gum B is a hydrofluorosilicone oil. The above-mentioned fluorine-containing silicone coating adhesive has adjustable curing speed, greatly enhanced oil resistance, salt spray resistance, chemical corrosion resistance, excellent adhesion, and three-proof effect with excellent performance.

Owner:GUANGZHOU DAOLIN SYNTHETIC MATERIALS CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com