Preparation method of polyester resin master batch for regulating and controlling solidification speed of powdery coating, and application of polyester resin master batch

A polyester resin, curing speed technology, used in powder coatings, polyester coatings, coatings and other directions, can solve the problems of coating surface defects, gel particles, difficult to disperse well, etc., to improve efficiency, Energy saving, simple and reasonable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

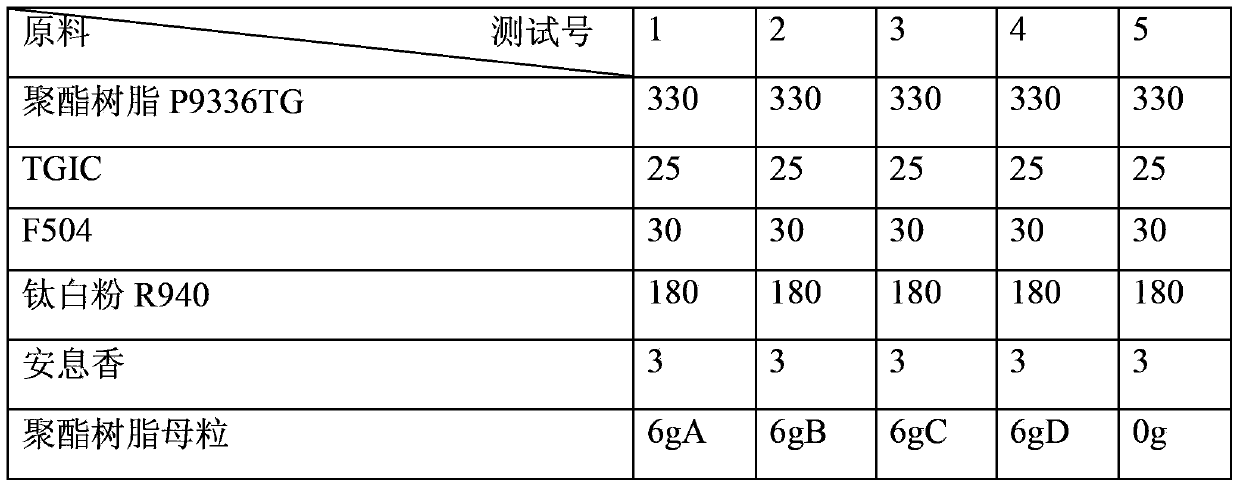

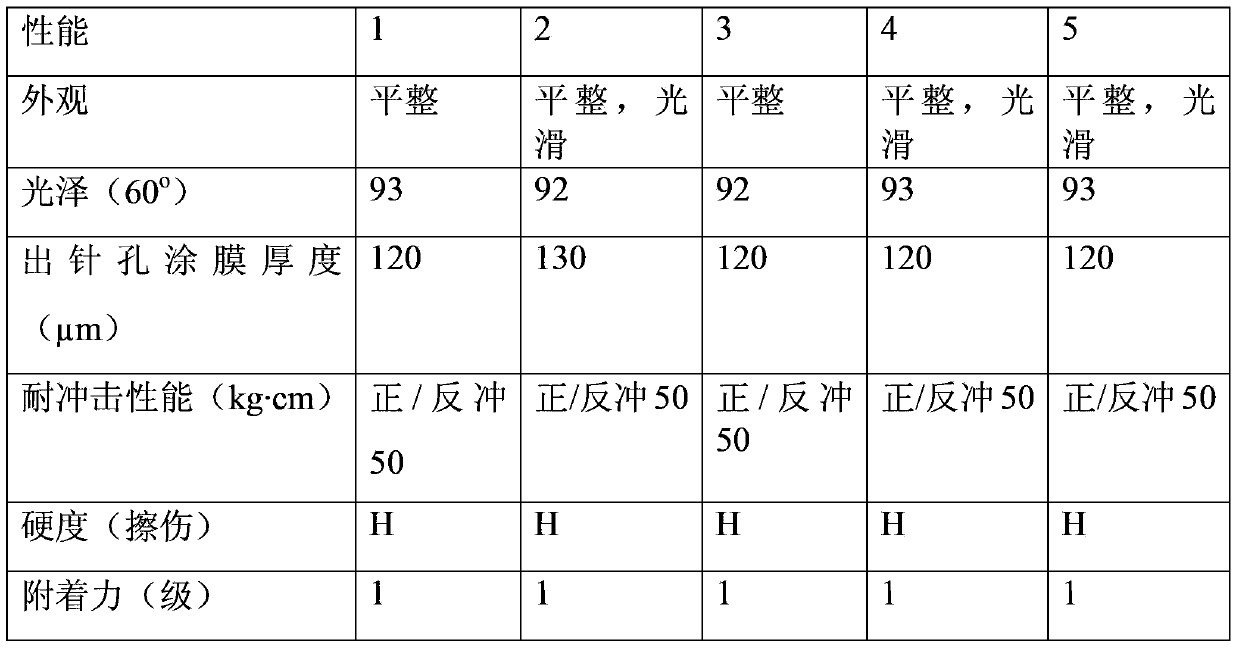

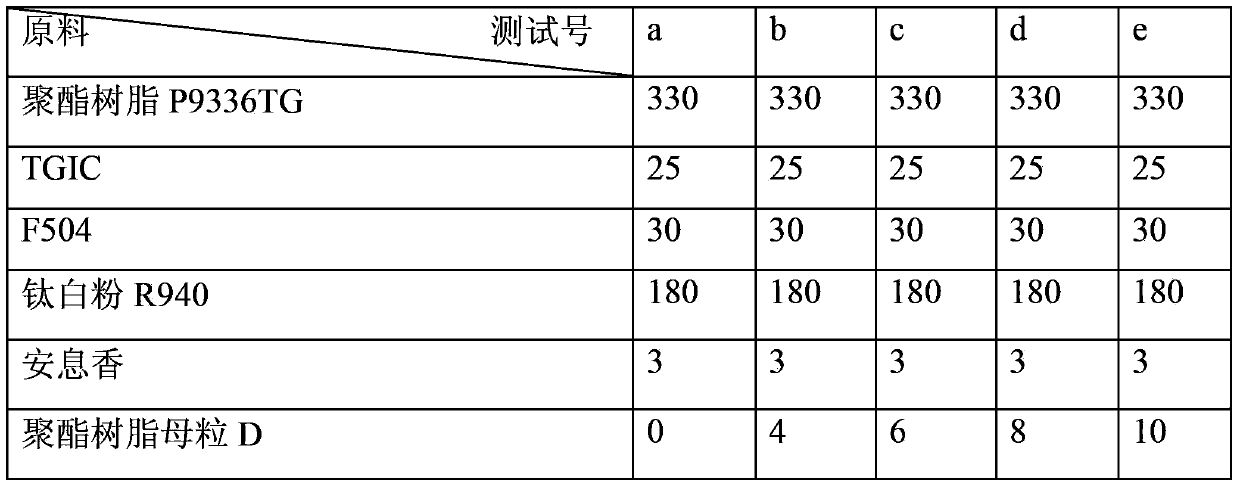

Examples

Embodiment 1

[0041] In the synthesis reaction vessel, put 160g of 2-methyl-1,3-propanediol, 210g of neopentyl glycol, 5g of trimethylolpropane, heat to melt and the temperature does not exceed 120°C; then add 540g of Terephthalic acid and 0.8g of monobutyltin oxide, while passing nitrogen gas for reaction protection; gradually heat the material to react, the temperature does not exceed 240 ° C, and maintain the temperature to continue the reaction until there is no more distillate So far, the acid value is 6-10mgKOH / g; then lower the temperature to below 220°C, add 5g of adipic acid and 130g of isophthalic acid to react, and then gradually increase the temperature without exceeding 240°C until the acid value is 43-48mgKOH / g , then vacuumize (-0.085~-0.1MPa) until the acid value is 32-40mgKOH / g; finally cool down to below 230°C, add 40g triphenylethylphosphine bromide and 30g18~16 alkyl tertiary amine, and stir for 30min After discharging, the polyester resin masterbatch A is obtained.

[...

Embodiment 2

[0044] In the synthesis reaction vessel, put 145g of 2-methyl-1,3-propanediol, 235g of neopentyl glycol, and 7.5g of trimethylolpropane, heat to melt and the temperature does not exceed 120°C; then, under stirring, add 560g of terephthalic acid and 0.8g of monobutyltin oxide, while passing nitrogen gas for reaction protection; gradually heat the materials for reaction, the temperature does not exceed 240°C, and maintain the temperature to continue the reaction until there is no more lutetization until the acid value is 6-10mgKOH / g; then lower the temperature to below 220°C, add 135g of isophthalic acid to react, then gradually increase the temperature and not exceed 240°C until the acid value is 43-48mgKOH / g, and then vacuumize (-0.085~-0.1MPa) until the acid value is 32-40mgKOH / g; finally lower the temperature to below 230°C, add 70g of triphenylethylphosphine bromide, stir for 30min, and discharge to obtain polyester resin masterbatch B .

[0045] After testing, the acid va...

Embodiment 3

[0047] In the synthesis reaction vessel, put 130g of 2-methyl-1,3-propanediol, 255g of neopentyl glycol, and 8g of trimethylolpropane, heat to melt and the temperature does not exceed 120°C; then add 548g of Terephthalic acid and 0.8g of monobutyltin oxide, while passing nitrogen gas for reaction protection; gradually heat the material to react, the temperature does not exceed 240 ° C, and maintain the temperature to continue the reaction until there is no more distillate So far, the acid value is 6-10mgKOH / g; then lower the temperature to below 220°C, add 5g of adipic acid and 140g of isophthalic acid to react, and then gradually increase the temperature and not exceed 240°C until the acid value is 43-48mgKOH / g , then vacuumize (-0.085~-0.1MPa) until the acid value is 32-40mgKOH / g; finally cool down to below 230°C, add 70g of 18-16 alkyl tertiary amine, stir for 30min and discharge to obtain polyester resin master grain C.

[0048] After testing, the acid value of polyester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com