Modified urea-formaldehyde resin reinforced material used for coal mine and preparation method thereof

A technology of urea-formaldehyde resin and reinforcing material is applied in the field of modified urea-formaldehyde resin reinforcing material for coal mines and its preparation field, which can solve the problems of easy foaming compressive strength, roof collapse of the sheet, and fire, so as to improve the supporting force and bonding The effect of good sex and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

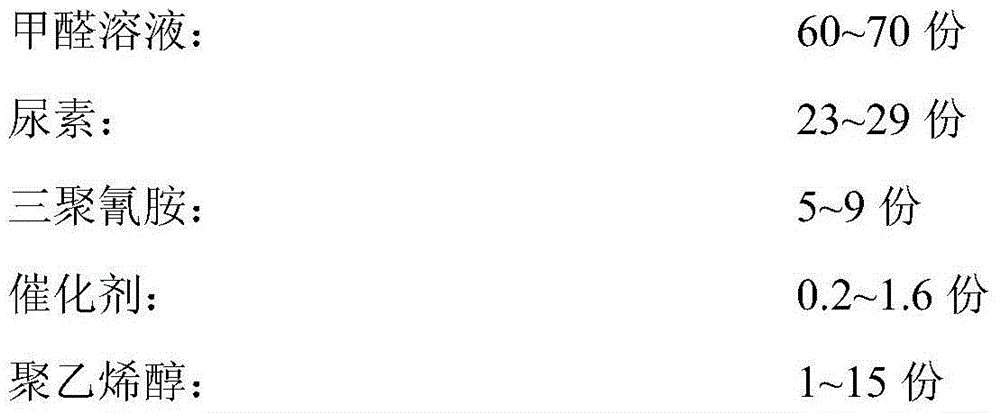

Method used

Image

Examples

Embodiment 1

[0034] Preparation of Component A:

[0035] a. Add 64kg of 37% industrial formaldehyde, 26kg of urea and 0.8kg of triethanolamine into the reaction kettle, start stirring, slowly raise the temperature of the material to 75°C, and keep the temperature at 75°C for 40 minutes;

[0036] b. Put 7.2kg of melamine into the reaction kettle again, and raise the temperature of the material to 80°C, and keep it warm for 60 minutes;

[0037] c. Add 3kg of polyvinyl alcohol into the reactor, raise the temperature of the material to 85°C, and keep the temperature at 85°C for 30 minutes;

[0038] d. Lower the temperature of the material to below 40°C, and discharge the material into barrels.

[0039] Preparation of Component B: Preparation of Component B: Add 50kg of p-toluenesulfonic acid, 2.5kg of concentrated hydrochloric acid, and 47.5kg of water into the reaction kettle, mix for 1 hour at room temperature, and discharge after sampling and testing.

[0040] Component A and component B ...

Embodiment 2

[0044] Preparation of Component A:

[0045] a. Add 70kg of 35% industrial formaldehyde, 24kg of urea, 0.3kg of diethanolamine and 0.3kg of monoethanolamine into the reaction kettle, start stirring, slowly raise the temperature of the material to 75°C, and keep the temperature at 80°C for 40 minutes. ;

[0046] b. Put 8.6kg of melamine into the reaction kettle again, and raise the temperature of the material to 85°C, and keep it warm for 65 minutes;

[0047] c. Add 6kg of polyvinyl alcohol into the reactor, raise the temperature of the material to 85°C, and keep the temperature at 85-90°C for 35 minutes;

[0048] d. Lower the temperature of the material to below 40°C, and discharge the material into barrels.

[0049] Preparation of component B: 30kg of citric acid, 30kg of malic acid, 1.5kg of sulfuric acid, 3kg of phosphoric acid, and 36.5kg of water were added to the reaction kettle, mixed for 2 hours at room temperature, and discharged after passing the sampling test.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com