Patents

Literature

42results about How to "Adjustable curing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature resistant and expediting setting dealcoholized type room temperature vulcanized silicone rubber adhesive and preparation method thereof

The invention discloses a high-temperature resistant and expediting setting dealcoholized type room temperature vulcanized silicone rubber adhesive and a preparation method thereof. The adhesive is prepared from the following components by weight: 100 parts of hydroxyl-terminated polydimethylsiloxane with the viscosity ranging from 4000 to 12000 Pa.s, 3 to 20 parts of fumed silica, 0.1 to 6 parts of viscosity increasers, 1 to 7 parts of cross-linking agents, 0.1 to 1 part of catalysts, 2 to 8 parts of titanium dioxide and 0.1 to 5 parts of hydroxy finishing agent, and is prepared by the following methods: (1) the hydroxyl-terminated polydimethylsiloxane, the fumed silica and the titanium dioxide are uniformly mixed to obtain a mixture, and the mixture is led into a vacuum drying chamber and then is dried and defoamed; and (2) under the dry environment, the hydroxy finishing agent, the viscosity increaser, the catalyst and the cross-linking agent are added to the mixture and stirred with under vacuum at room temperature, thereby preparing the adhesive. The adhesive of the invention has the advantages of high and adjustable setting speed, excellent mechanical property, favorable resistance to high temperature and strong bonding force.

Owner:TIANJIN UNIV

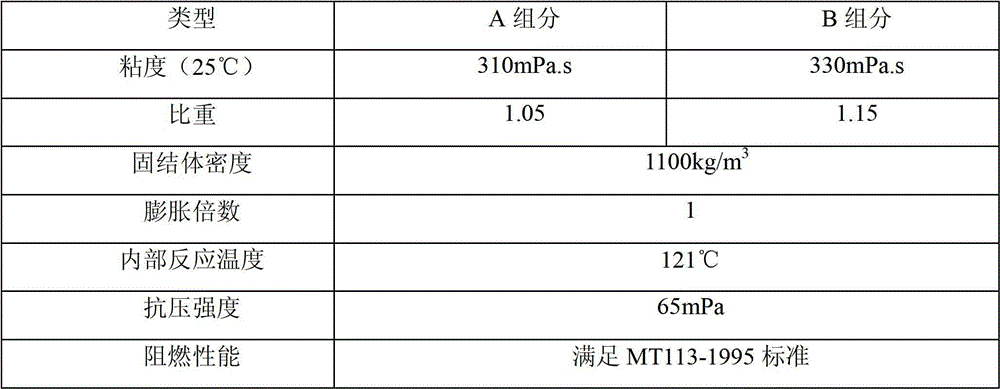

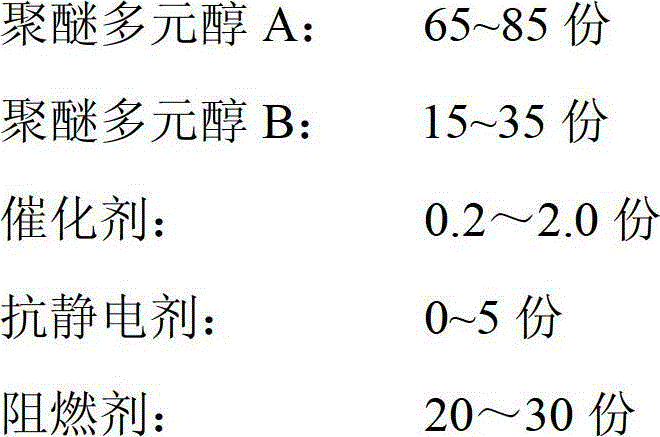

Low-temperature safety polyurethane injecting paste material for coal-rock mass reinforcement and preparation method thereof

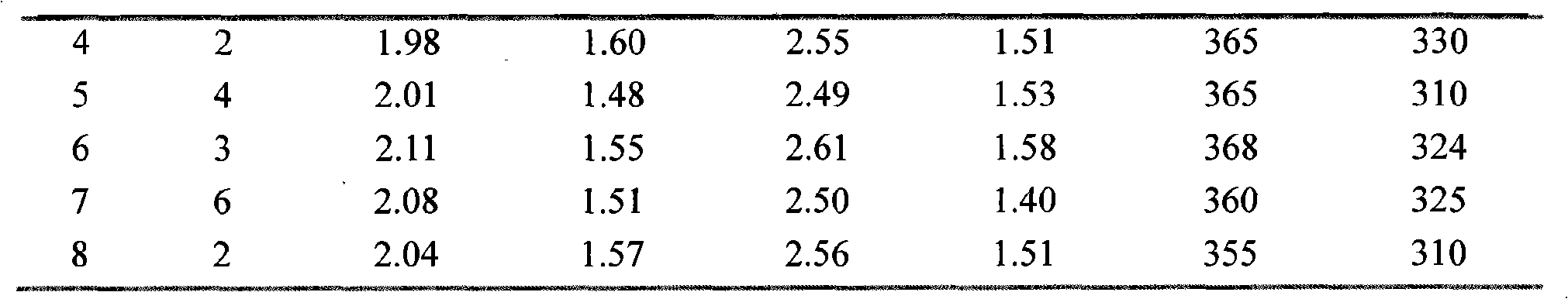

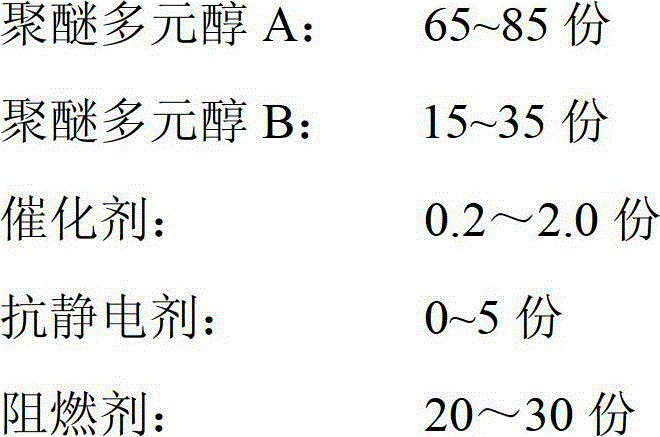

The invention provides a low-temperature safety polyurethane injecting paste material for coal-rock mass reinforcement and a preparation method thereof, and belongs to the field of polyurethane compositions. The material consists of a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 100 parts of polyether polyol, 0.2 to 2.0 parts of catalyst, 0 to 5 parts of antistatic agent, and 20 to 30 parts of flame retardant; and the component B comprises the following raw materials in parts by weight: 70 to 90 parts of polyisocyanates, 5 to 20 parts of pre-polymer, and 5 to 10 parts of viscosity reducer. The preparation method comprises the following steps of: (1) preparation of the component A, namely mixing the raw materials of the component A for later use; and (2) preparation of the component B, namely mixing the raw materials of the component B, and performing nitrogen displacement for later use. The low-temperature safety polyurethane injecting paste material has the advantages of flame retardant and antistatic performances, high adhered strength, strong shearing resistance and high toughness. The preparation method is simple and practical, has low requirements on production equipment and staff, and is short in production cycle; and according to the whole process, three wastes are not produced, and the environment and health of workers are not influenced.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

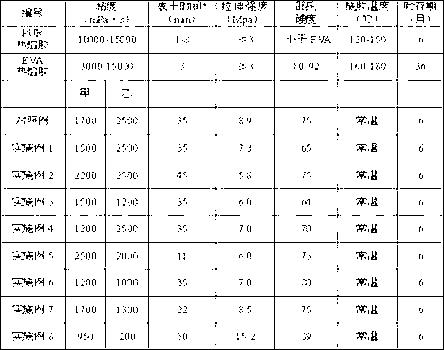

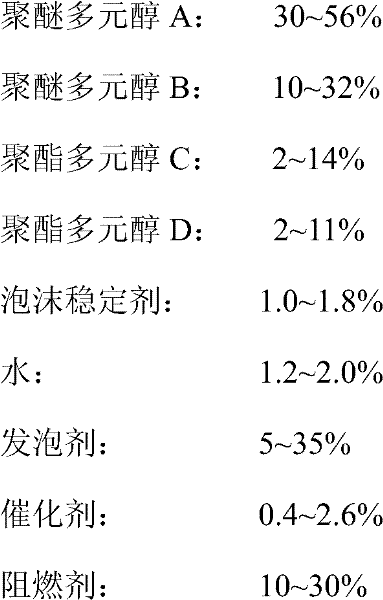

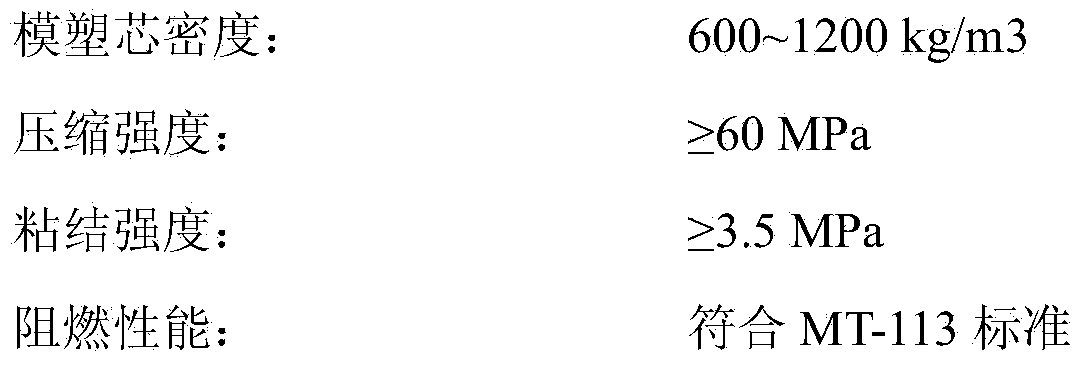

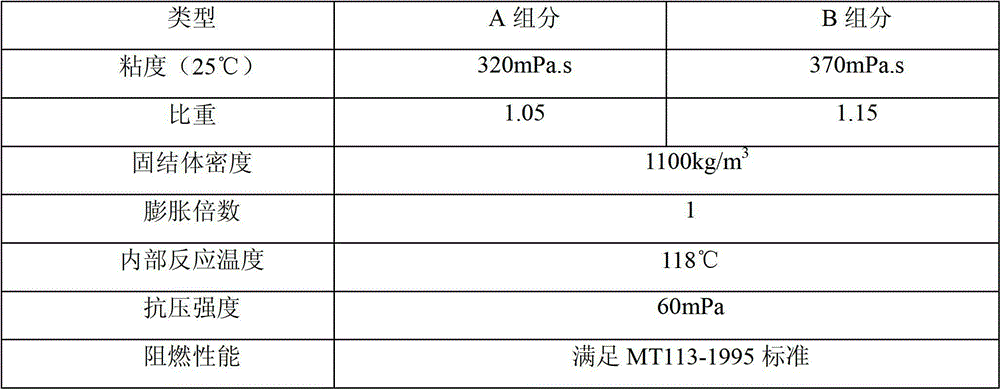

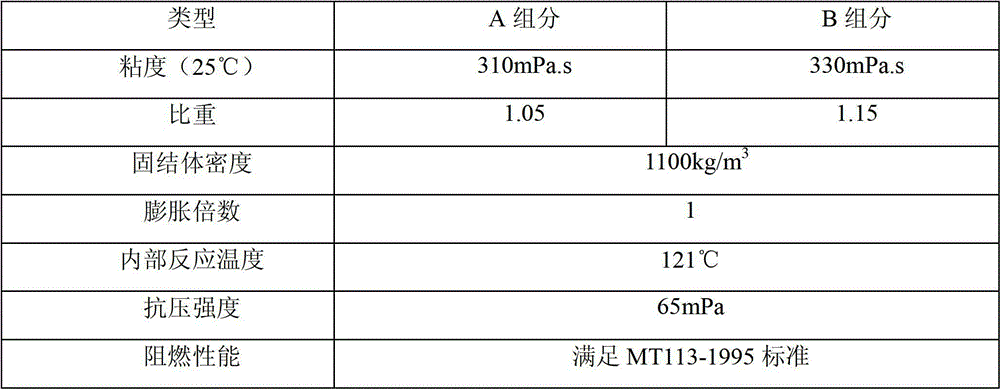

Polyurethane polymer material for coal rock mass reinforcement and preparation method thereof

The invention belongs to the field of chemical synthesis, and particularly relates to a polyurethane high polymer material for coal rock mass reinforcement and a preparation method of the polyurethane polymer material. The polyurethane polymer material consists of component A and component B, wherein the component A is composed of a polyalcohol, a solvent, a catalyst and a fire retardant and the component B is composed of polyaryl polymethylene polyisocyanate. The polyurethane polymer material and the preparation method, disclosed by the invention, have the advantages that: through formulation design, foaming is carried out at a normal temperature, the curing rate is adjustable, the strength of consolidation body is high, compressive strength is more than 55MPa, the coal rock support force can be obviously increased; the consolidation body has very good toughness and can bear subsequent mining influence; the raw liquid is low in viscosity and has good permeability in the coal rock mass; and the caking property of the consolidation body and the coal rock mass is good; the related raw materials in the invention are green, pollution-free and harmless to human body, contain no volatile solvent and generate no any toxic gas, therefore, the use and environmental requirements for the coal rock mass reinforcement are completely satisfied; and the material is pressed and filled by using a double liquid grouting pump, therefore, the pumpability is good and the use is convenient.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

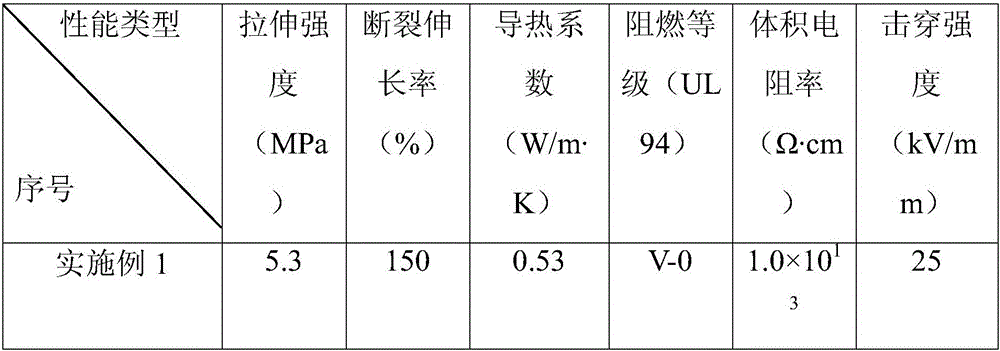

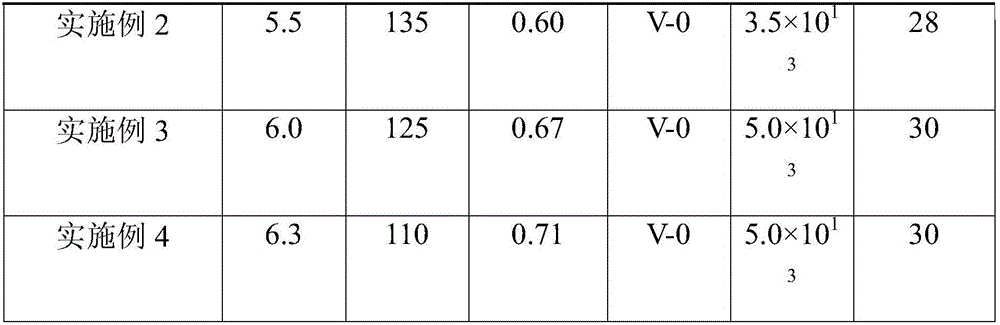

MDI-base polyurethane electronic pouring sealant as well as preparation method and application method thereof

ActiveCN105885767ASimple preparation processLow costNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane elastomerOxygen

The invention discloses an MDI-base polyurethane electronic pouring sealant as well as a preparation method and an application method thereof. The electronic pouring sealant comprises two components of A and B, wherein the component A is prepared from 50-60 parts of isocyanate, 15-20 parts of low-polymer polyalcohol and 9-30 parts of reaction type liquid flame retardant according to parts by weight; the component B is prepared from low-polymer polyalcohol, a crosslinking chain extender, a catalyst, a filler, a defoamer and an anti-oxygen according to certain proportion. The component A and the component B are mixed and cured according to certain proportion to prepare the pouring sealant. The MDI-base polyurethane electronic pouring sealant is prepared with a half-pre-polymerization method, the toxicity caused by volatilization of NCO is avoided, and synergistic flame retarding of the halogen-free reaction type liquid flame retardant and the filler avoids the influences of an addition type liquid flame retardant on the stability and performance of the polyurethane pouring sealant. A prepared polyurethane elastomer is suitable for pouring and sealing of small and medium electronic elements.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

Preparation method for polyurethane adhesive for binding high-grade books

InactiveCN102703016AGood flexibilityGood mechanical propertiesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention discloses a preparation method for a polyurethane adhesive for binding high-grade books and belongs to the field of polyurethane adhesive compounding. The steps are as follows: (1) prepolymerization reaction: using hydroxy monomers and isocyanate monomers as main raw materials, and compounding to get prepolymers blocked with OH and NCO respectively; and (2) cross-linking reaction: mixing the two kinds of prepolymers by a certain proportion, and curing to obtain a transparent or semitransparent, flexible and properly hard coating. The invention adopts the two-step compounding method of prepolymerization and cross-linking to compound out a solvent-free double-component polyurethane adhesive; the production process is simple and clean and conforms to the requirement of environmental protection; and the viscosity and the molecular weight of Components A and B can be adjusted through prepolymerization so as to increase bonding strength; the adhesive can be cured in the cross-linking process so as to further improve the bonding strength. (3) The components A and B are liquid at normal temperature, and the viscosity and the curing speed are adjustable; the curing reaction is conducted at room temperature, the operation is convenient, the energy consumption is low, and product storage is stable.

Owner:CHANGZHOU UNIV

High-flame-retardance low-temperature bicomponent filling material for coal mines and preparation method thereof

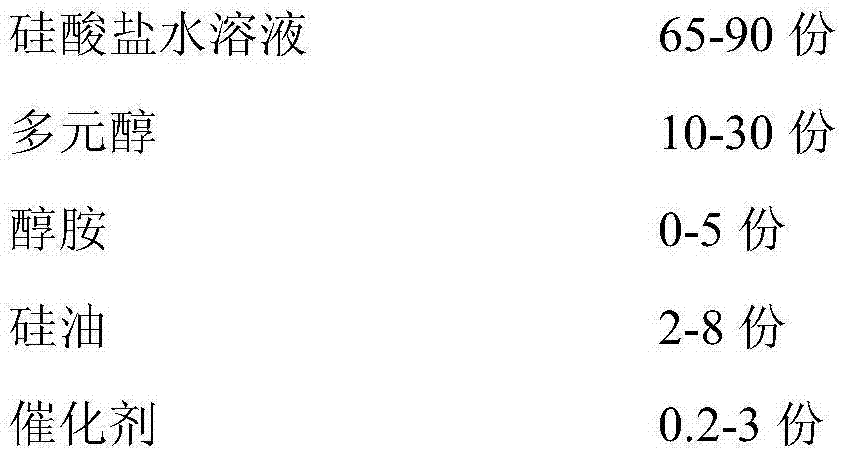

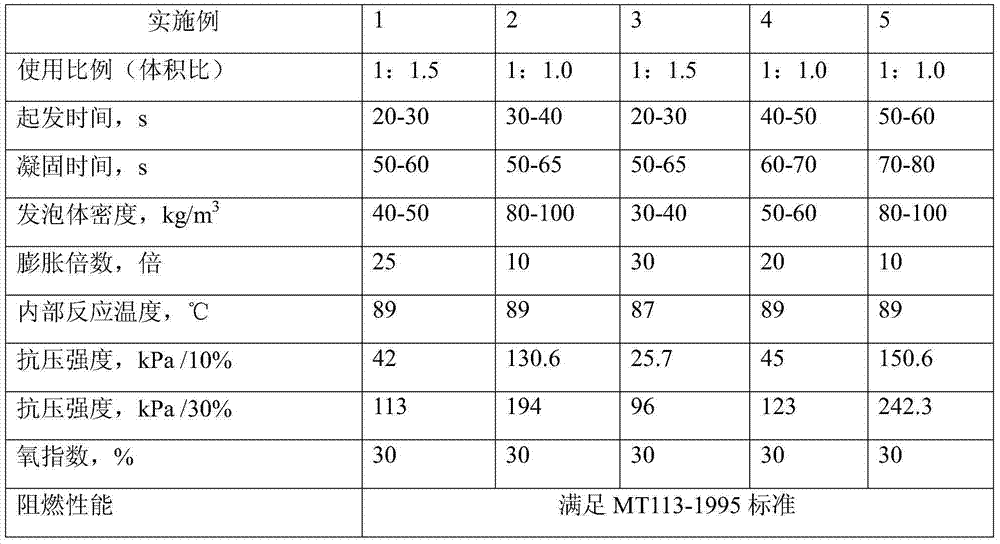

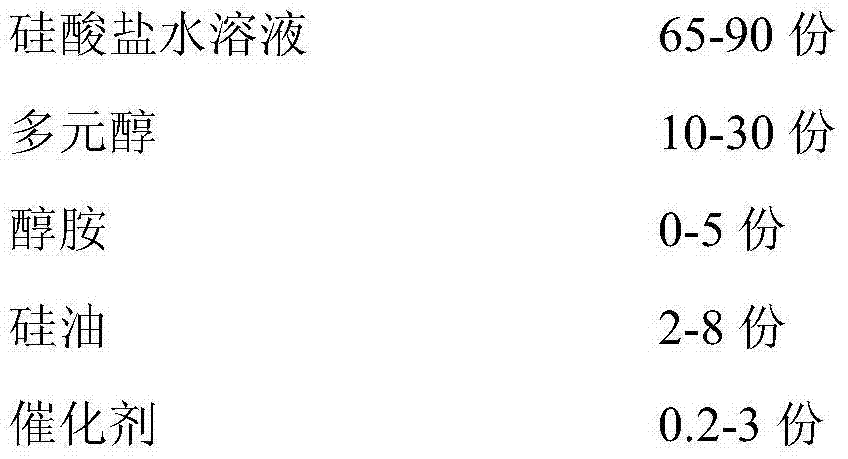

The invention belongs to the field of chemical synthesis and in particular relates to a high-flame-retardance low-temperature bicomponent filling material for coal mines and a preparation method thereof. The filling material comprises a component A and a component B, wherein when the filling material is used, the component A and the component B are mixed according to the volume ratio of 1:(1.0-1.5) and are foamed; the component A is a composition with a silicate aqueous solution as the main body; and the component B is a composition with polyisocyanate as the main body. The filling material and the preparation method have the beneficial effects that the filling material is convenient to transport and has low viscosity, fluidity and storage stability; the raw materials are free from pollution and corrosion and the filling material does not contain irritating volatile solvents; the filling material has high foaming ratio and has low internal temperature during foaming; a foaming body has good flame retardance and certain toughness; the preparation method is simple and practicable, has low requirements on production and construction personnel, is short in production cycle, is free from equipment corrosion, is free from three wastes in the whole process and does not affect the environment.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Foamable phenolic resin strengthening and filling material for coal mine

ActiveCN102558763AAdjustable curing speedCured body with high strengthUnderground chambersTunnel liningOrganic acidUrea

The invention relates to a foamable phenolic resin strengthening and filling material for coal mine. In the foamable phenolic resin strengthening and filling material for coal mines, a component A is one of inorganic acid and organic acid or a mixture of inorganic acid and organic acid; and a component B is prepared by mixing 90 to 100 weight parts of urea modified phenolic resin with solid content of 65 to 90 weight percent, 6 to 10 weight parts of composite fire retardant, 0 to 15 weight parts of foaming agent, 1 to 5 weight parts of stabilizing agent, 1 to 15 weight parts of cosolvent, 2 to 16 weight parts of antistatic agent and 10 to 30 weight parts of plasticizer, stirring at the temperature of between 30 and 50 DEG C and reacting for 0.5 to 2 hours. When the foamable phenolic resin strengthening and filling material is used, the component A and the component B are mixed and injected into a coal (rock) layer according to the weight ratio of (1-2) : 1 and permeated into small cracks to expand and generate curing reaction for strengthening and sealing the region. According to the foamable phenolic resin strengthening and filling material for coal mines, the compressive strength is more than 40 MPa; the bonding strength is more than or equal to 3.0 MPa; and the foaming coefficient is less than or equal to two times. The foamable phenolic resin strengthening and filling material for coal mines can meet the requirement of coal mine on safety production and can be applied to the industries such as hydroelectric powder, buildings, mining, traffic and the like.

Owner:SHANXI ZHAOXIN BIO TECH

Mineral polyurethane spraying material and preparation method thereof

ActiveCN102533089AConsolidated body with high strengthGood toughnessPolyurea/polyurethane coatingsCoalChemical synthesis

The invention belongs to the field of chemical synthesis, particularly relates to a mineral polyurethane spraying material and a preparation method thereof and more particularly relates to a double-component (A and B) polyurethane material and a preparation method thereof. The material is mainly used for rapidly spraying and sealing underneath mine; and through the selection of polyol, auxiliaries and isocyanate, the spraying material has good adhesion on a rock coal body; and after adhesion is carried out, the material has good anti-shearing property and toughness and resists impact. According to the invention, the viscosity of the material is reduced so that the material can well permeate into a coal bed or a fine crack of a rock stratum, and simultaneously, the related raw materials are low in smell, do not contain volatile solvent and do not generate any toxic gases, thereby completely meeting the use and environment-friendly requirements of a coal mine reinforcement material.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Solvent-free unfoamed polyurethane structured adhesive and preparation method thereof

InactiveCN106433546AEasy to operateGood bonding performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventPolyphenyl isocyanate

The invention relates to a solvent-free unfoamed polyurethane structured adhesive which contains a component A and a component B, wherein the mass ratio of the component A to the component B is 4:1; the component A contains the following raw materials in parts by mass: 30-45 parts of polyol, 50-47 parts of packing, 8-6 parts of a water removing agent, 4-2 parts of phthalic acid bi(2-ethylhexyl) ester, 3-0 parts of xylene formaldehyde resin, 4-0 parts of lyophobic gaseous silicon and 1-0 parts of an amino curing agent; and the component B contains the following raw material in part by mass: 100 parts of polymethylene polyphenyl isocyanate. The solvent-free unfoamed polyurethane structured adhesive provided by the invention is small in moisture influence, and is barely affected by ambient humidity, a foaming phenomenon in the gluing curing process can be avoided, and later reliability can be greatly improved.

Owner:YANTAI DARBOND TECH

Preparation method of single-component polyurethane corner adhesive

InactiveCN106244085AHigh bonding strengthHigh strengthProductsNon-macromolecular adhesive additivesAging resistancePlasticizer

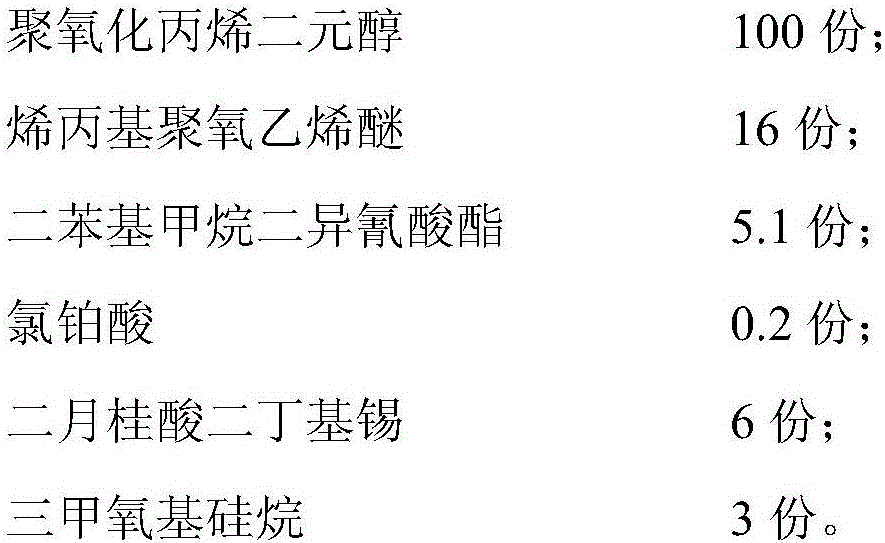

The invention belongs to the technical field of polyurethane sealant, and more specifically relates to a preparation method of a single-component polyurethane corner adhesive. The preparation method comprises following steps: tri-functionality and / or bi-functionality polyether polyols with different molecular weights, one or two ingredients selected from methylene diphenyl diisocyanate and polyaryl polymethylene isocyanate, and a plasticizer are reacted at a certain temperature; an obtained mixture is uniformly mixed with an inorganic filler and a catalyst; and an obtained mixed material is subjected to vacuum defoamation. The single-component polyurethane corner adhesive is capable of satisfying demands on both adhesive strength and sealing performance at the same time, increase the integral strength of doors and windows, and furniture effectively, realizing effective filling of gaps, and preventing leakage and corner cracking. The preparation method is simple; the single-component polyurethane corner adhesive is friendly to the environment, possesses no peculiar smell, and can be applied to assembling and bonding of door and window corner gaps and furniture; curing speed is adjustable; and aging resistance is excellent.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

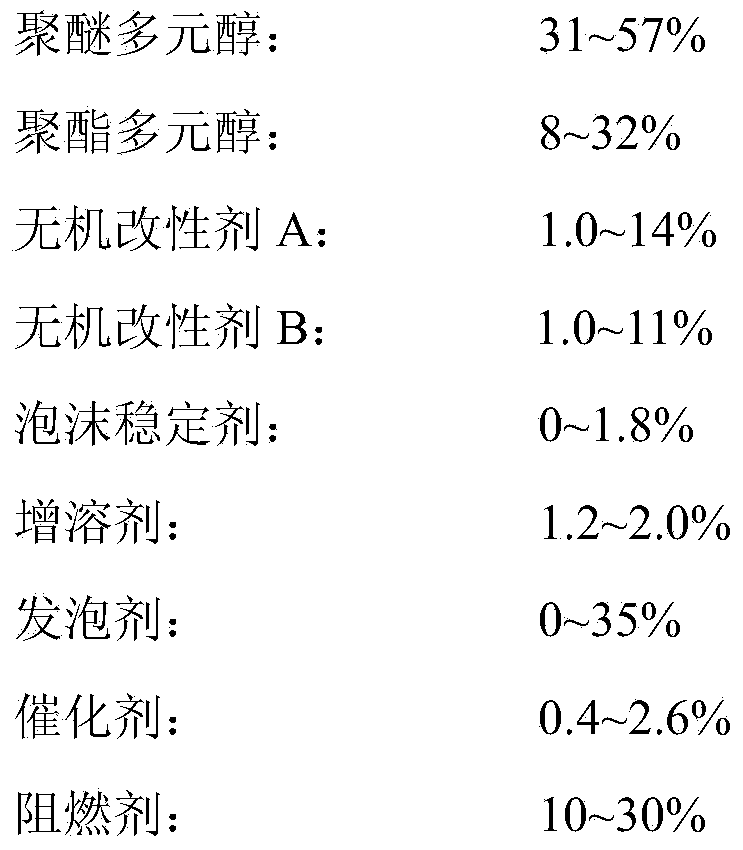

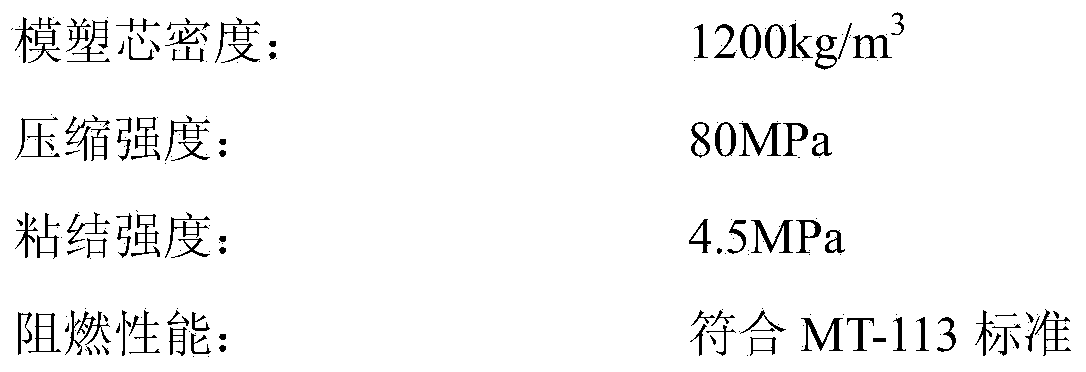

Polyurethane reinforced material for inorganic modified ores and preparation method thereof

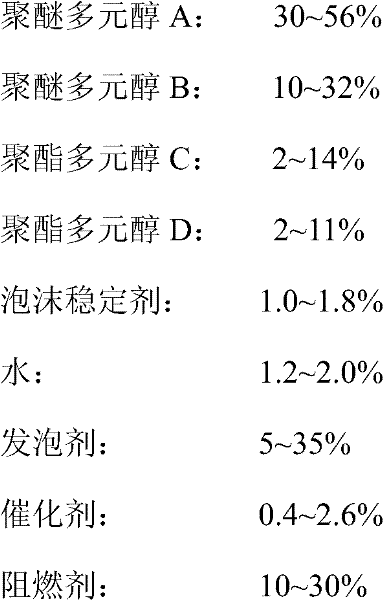

The invention aims at providing a polyurethane reinforced material for inorganic modified ores and a preparation method thereof. The material is prepared by polymerizing components A and B. The component A is prepared from the following substances in percentage by mass: 31-57% of polyether polyol, 10-32% of polyester polyol, 1.0-14% of an inorganic modifier A, 1.0-11% of an inorganic modifier B, 0-1.8% of a foam stabilizer, 1.2-2.0% of a solubilizer, 0-35% of a foaming agent, 0.4-2.6% of a catalyst and 10-30% of a flame retardant; the component B is prepared from the following substances in percentage by mass: 50-75% of polymethylene polyphenyl polyisocyanate, 10-20% of diphenyl-methane-diisocyanate and 10-30% of a compound modifier. By adding the inorganic modifiers and optimizing the formula, the flame retardance of a conventional polyurethane material is improved, the reaction temperature of the material used is greatly reduced, and the potential safety hazard of the material in the using process is eliminated.

Owner:山东润义金新材料科技股份有限公司

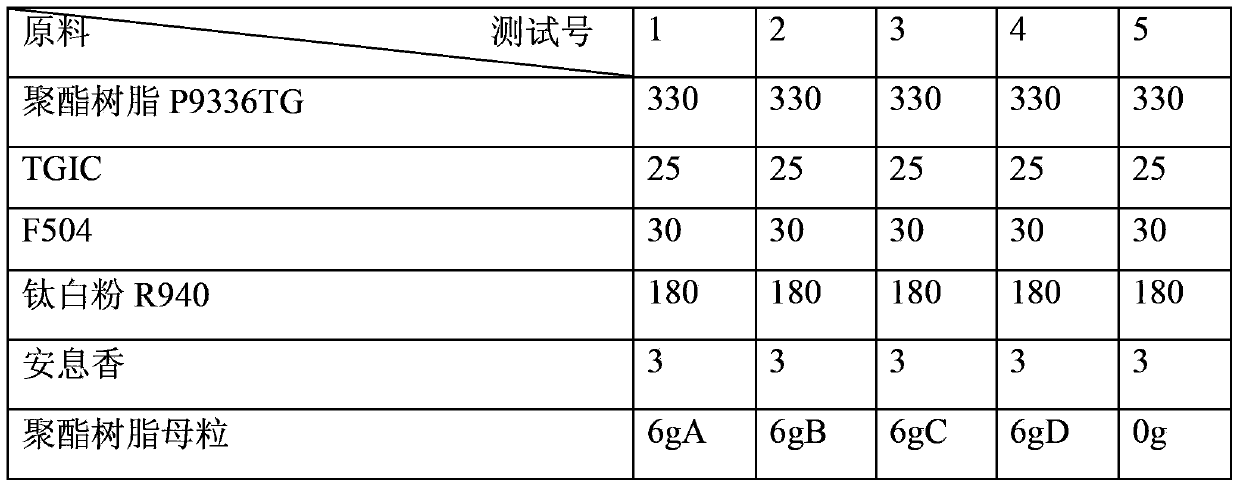

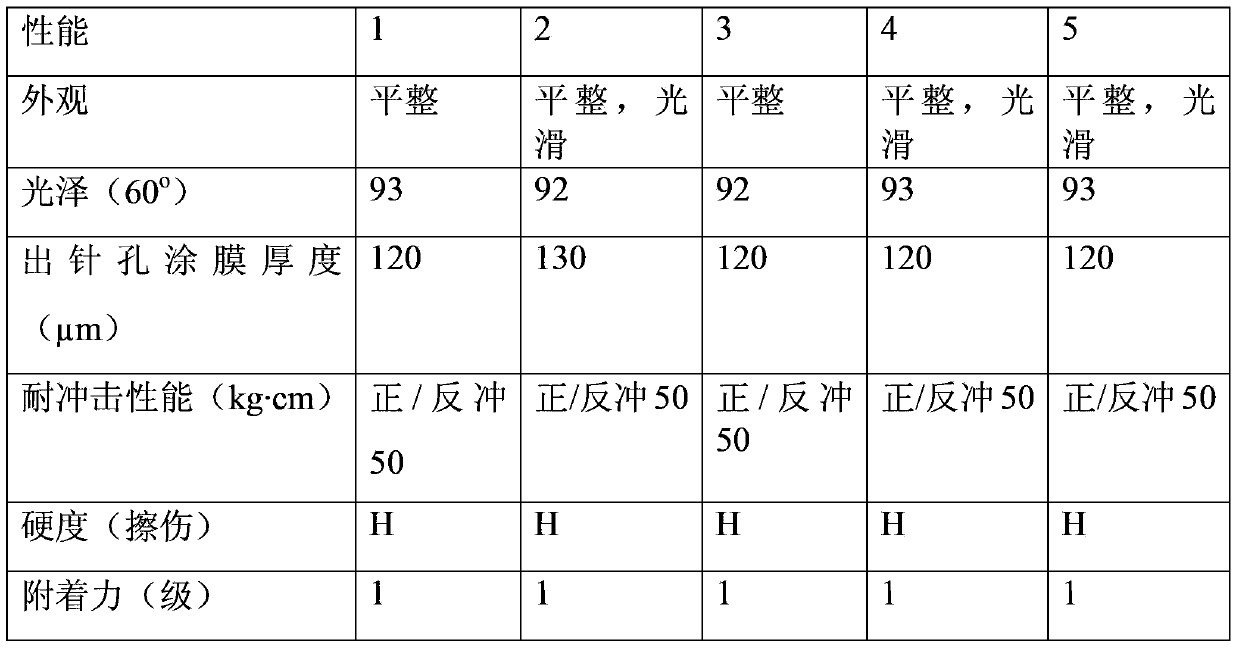

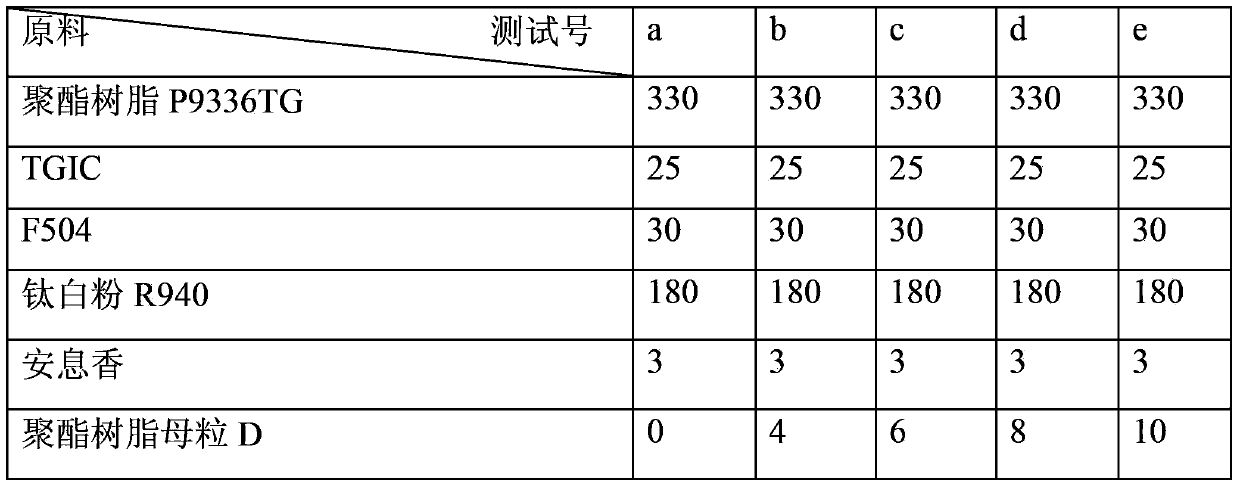

Preparation method of polyester resin master batch for regulating and controlling solidification speed of powdery coating, and application of polyester resin master batch

InactiveCN103396724AAdjustable curing speedHigh glass transition temperaturePowdery paintsPolyester coatingsAlcoholPhosphonium salt

The invention relates to the powdery coating field and discloses a preparation method of a polyester resin master batch for regulating and controlling solidification speed of a powdery coating, and application of the polyester resin master batch to powdery coating. The method provided by the invention employs alcohol and acid in a molar ratio of 1.02-1.2 / 1 to prepare the linear polyester resin master batch; and an added curing accelerator accounts for 0.2-8 wt%. The polyester resin master batch prepared according to the method has an acid value of 30-50 mg KOH / g and high glass-transition temperature; and the curing accelerator quaternary phosphonium salt and (or) quaternary ammonium salt in the weight proportion of 0.2-8% is added, so as to prepare the polyester resin master batch for regulating and controlling solidification speed of the powdery coating. The method provided by the invention can effectively shorten solidification time or reduce solidification temperature of the powdery coating, thereby reducing energy consumption and expanding scope of application of the powdery coating.

Owner:浙江中法新材料有限公司

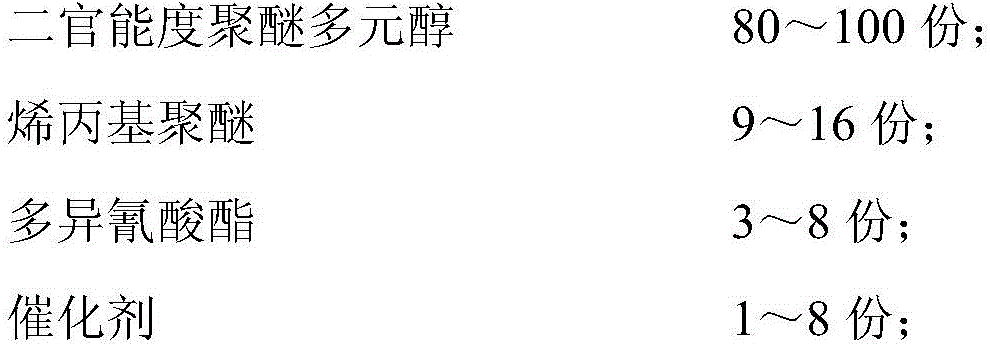

Environment-friendly organosilicone-modified polyether sealant and preparation method thereof

ActiveCN106833481AHigh bonding strengthImprove sealingOther chemical processesPolyureas/polyurethane adhesivesPolyolAging resistance

The invention relates to a sealant and particularly relates to an environment-friendly organosilicone-modified polyether sealant and a preparation method thereof. The sealant is prepared from the following raw materials: difunctional polyether polyol, allyl polyether, polyisocyanate, a catalyst and organosiloxane. The preparation method of the sealant comprises the following steps: (1) firstly adding the difunctional polyether polyol and the polyisocyanate into a reactor, increasing the temperature to 80-90 DEG C, reacting and enabling mass fraction of NCO to reach 0.8-1.05%; (2) adding the allyl polyether, keeping the temperature and reacting and enabling the mass fraction of NCO to be 0; and (3) adding part of the catalyst and part of the organosiloxane, keeping the temperature and reacting to obtain an organosilicone-modified polyether sealant prepolymer, and then adding the rest of the catalyst to prepare the environment-friendly organosilicone-modified polyether sealant. The preparation method is simple and is easy to operate; the prepared sealant is high in bonding strength, excellent in sealing effect, excellent in ageing resistance, adjustable in curing speed and free of VOC (volatile organic compound), and is environmentally friendly and odorless.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

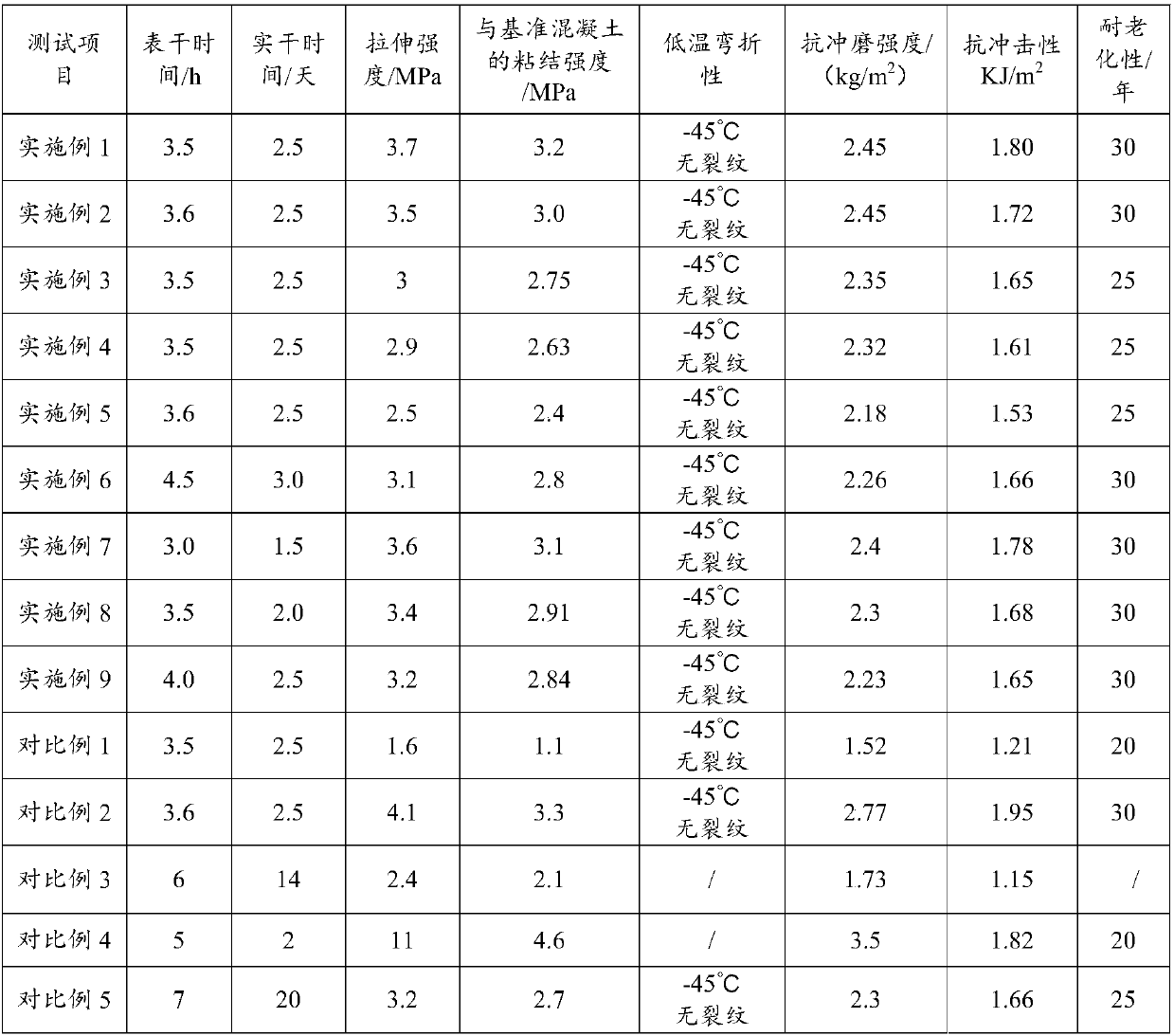

Concrete thin-layer repairing polymer mortar and preparation method thereof

ActiveCN107777922AGood wear resistance and repair abilityEasy to adjustPolyurea/polyurethane coatingsPolymer scienceThin layer

The invention provides concrete thin-layer repairing polymer mortar and a preparation method thereof and relates to the field of mortar. The concrete thin-layer repairing polymer mortar is prepared from the following raw materials in weight ratio: two-component slow reaction type polyurea waterproof coating and a sand material, wherein the weight ratio of the two-component slow reaction type polyurea waterproof coating to the sand material is 1:(1-3). By utilizing the concrete thin-layer repairing polymer mortar, the problem that polymer mortar in the prior art cannot well repair a concrete building component can be solved, and the concrete thin-layer repairing polymer mortar has the advantages of good bonding performance, corrosion resistance and scour and wear resistance.

Owner:XINJIANG KENENG WATERPROOF & PROTECTION TECH CO LTD

Foaming reinforced filling material for coal mine and preparation method thereof

PendingCN111825400AImprove recovery rateRealize room temperature foaming and curingFoaming agentMining engineering

The invention relates to a foaming reinforcing filling material for a coal mine. The foaming reinforcing filling material is prepared by mixing the following raw materials in percentage by weight: 50-60% of a quick cementing material, 35-45% of an admixture, 0.1-0.25% of a concrete admixture, 0.3-1% of a stearate foam stabilizer, 1-5% of an inorganic foaming agent and 0.5-1% of a foaming activator. After water is added into the filling material, the filling material is used for goaf backfilling and underground caving goaf filling, normal-temperature foaming and curing of the filling material can be achieved, a cured body is high in strength and has certain bonding strength, and the filling material is used for coal mine safety production and goaf treatment and can provide guarantee for mine safety and efficient production.

Owner:INNER MONGOLIA BORAN TECH CO LTD

Hydraulic structure disjoint filling silicone adhesive and preparation method thereof

InactiveCN101602918AAdjustable curing speedIncreased durabilityNon-macromolecular adhesive additivesOther chemical processesVulcanizationWater turbine

The invention discloses hydraulic structure disjoint filling silicone adhesive, which is prepared from a component A and a component B according to a weight proportion, wherein the component A comprises 100 portions of alpha, omega-dihydroxydimethylpolysiloxane and 15 to 45 portions of calcium carbonate filler; and the component B comprises 3 to 10 portions of calcium carbonate filler, 6 to 15 portions of methyl vinyl disilane, and 3 to 10 portions of linear amino polysiloxane cross linker. After stirring and mixing according to the weight proportion, the components are separately sealed and stored; and during use, the component A and the component B are mixed according to the weight proportion and vulcanized at room temperature to form the hydraulic structure disjoint filling silicone adhesive. The hydraulic structure disjoint filling silicone adhesive has the characteristics of room temperature vulcanization, double components, self leveling, adjustable curing speed, low modulus, high elasticity, high durability, free from pollution, free from erosion and the like, belongs to an environment-friendly material, and is mainly used for pouring, filling, sealing and repairing hydraulic structure disjoints of water turbine volutes, water delivery steel pipes and the like.

Owner:HOHAI UNIV

Aqueous epoxy bonding agent for carpet bituminous mixture pavement and construction method thereof

ActiveCN105694786AImprove liquidityAdjustable curing speedSingle unit pavingsEpoxy resin adhesivesEpoxyBituminous materials

The invention provides an aqueous epoxy bonding agent for a carpet bituminous mixture pavement. The aqueous epoxy bonding agent comprises a component A, a component B and water, wherein the component A contains aqueous epoxy resin with solid content of 50 to 100%, the component B is an aqueous epoxy hardener with solid content of 30 to 70%, and the weight ratios of the aqueous epoxy resin, the aqueous epoxy hardener and water are 100 parts, 100 to 200 parts and 0 to 500 parts, respectively. The aqueous epoxy bonding agent provided by the invention has the characteristics of good fluidity, adjustable curing speed and no pollution, can be prepared on a construction site and can be easily sprayed on a curled bituminous material; through controlling of appropriate process conditions during construction, the obtained bituminous pavement has the advantages of good mechanical strength and small possibility of damage; and the construction can be carried out at room temperature and a minimum construction temperature can reach 0 DEG C.

Owner:BEIJING MUNICIPAL BRIDGE MAINTENANCE MANAGEMENT +2

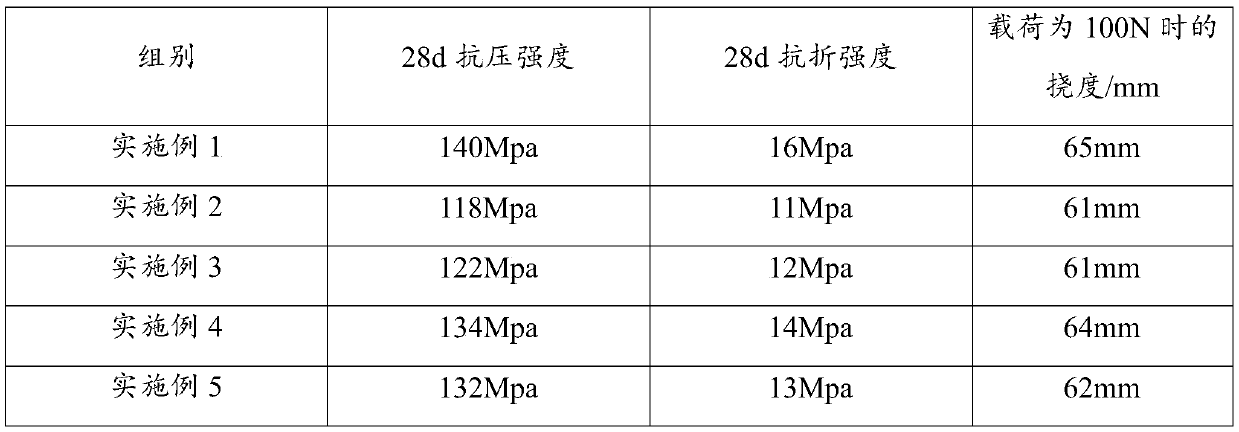

Modified urea-formaldehyde resin reinforced material used for coal mine and preparation method thereof

The invention belongs to the field of chemical synthesis, specifically relates to a modified urea-formaldehyde resin reinforced material used for coal mine and a preparation method thereof, and the material is applicable to fragmented coal body reinforcing during coal mine excavation. The modified urea-formaldehyde resin reinforced material is characterized by being composed of a composition A and a composition B, wherein the composition A is modified urea-formaldehyde resin and the composition B is a modified urea-formaldehyde resin curing agent composition. The characteristics comprise that: (1) by designing the formula of the material, the reaction is performed at normal temperature, the curing speed is adjustable, the consolidation body is high in strength and good in toughness, has the compression resistance of 30 mPa or more, and is capable of substantially improving the bracing force of loose coal; (2) the internal reaction temperature of the material is relatively low and is at 60 DEG C or less; (3) the raw material solution is low in viscosity, good in permeability in coal rocks, and the caking property between the consolidation body and the coal body is good; and (4) the material employs a special pneumatic double-liquid or three-liquid grouting pump for pressure grouting, the operation is simple and the usage is convenient.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

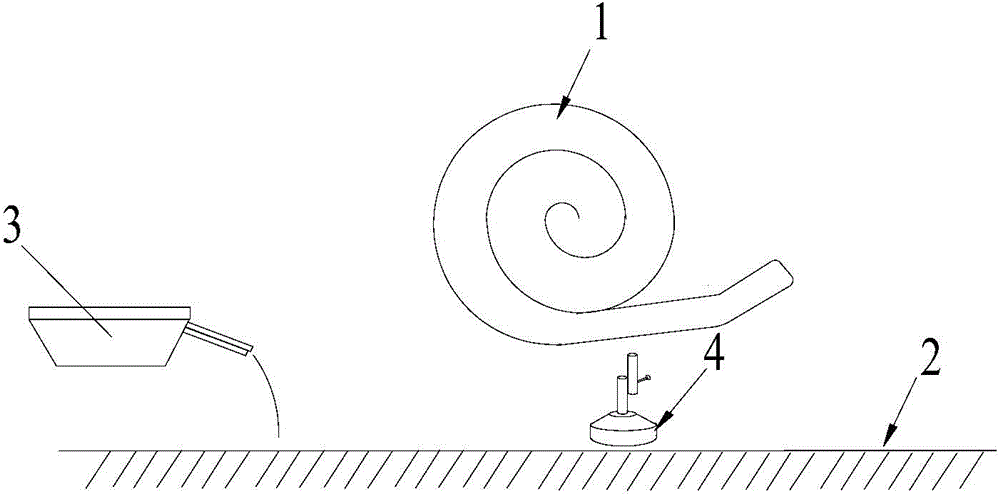

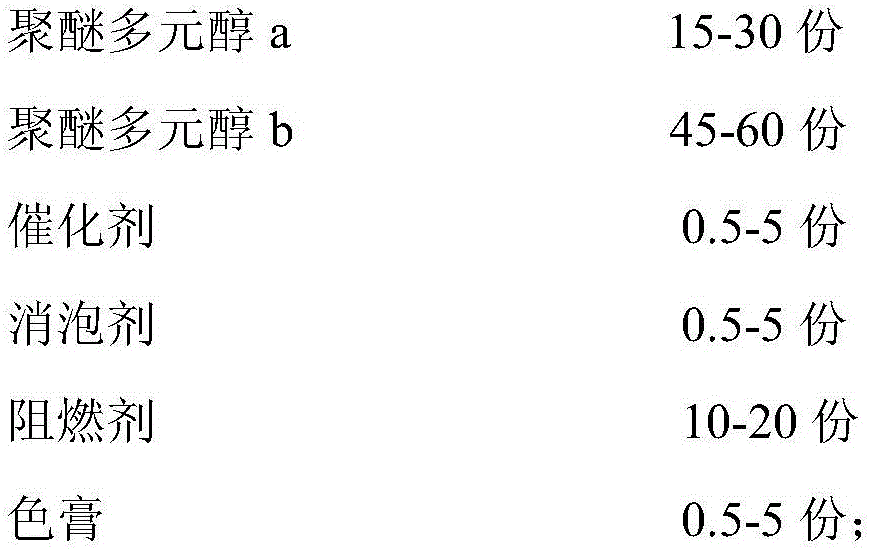

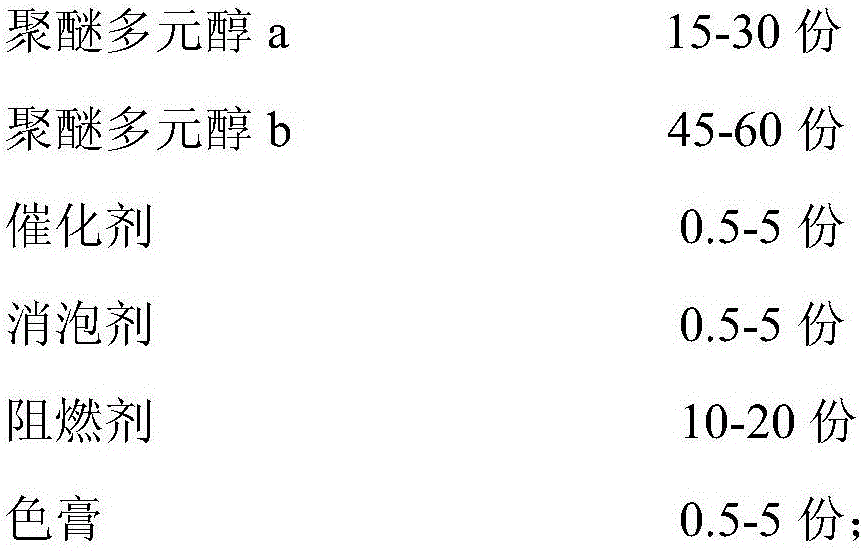

Material used for making climbing fulcra, and preparation method of material

The invention belongs to the technical field of chemical synthesis, and concretely relates to a material used for making climbing fulcra, and a preparation method of the material. The material used for making climbing fulcra comprises a component A and a component B, and the component A comprises polyether polyol a, polyether polyol b, a catalyst, an antifoaming agent, a fire retardant and a color paste; and the component B comprises polyisocyanate and a flexibilizer. The material prepared through formula design has the advantages of normal temperature reaction, adjustable curing speed, convenience in transportation of a raw material liquid, low viscosity, good fluidity and good storage stability.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Mineral polyurethane spraying material and preparation method thereof

ActiveCN102533089BLow viscosityAdjustable curing speedPolyurea/polyurethane coatingsChemical synthesisToxic gas

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Loose coal and rock foaming urea-formaldehyde resin cementing material and method for preparing same

InactiveCN1594424ARealize chemical foaming and curing at room temperatureAdjustable curing speedSilicon oxideCoal

The invention discloses a loose coal and rock foaming urea-formaldehyde resin cementing material and method for preparing same, wherein the material comprises urea aldehyde resin, polyacrylates, organic macromolecular acid, carbonates, silicon oxide and inorganic ammonium salt. The invention can realize the normal temperature chemical foaming and solidifying for the urea aldehyde resin.

Owner:淮南矿业集团兴科计量技术服务有限责任公司

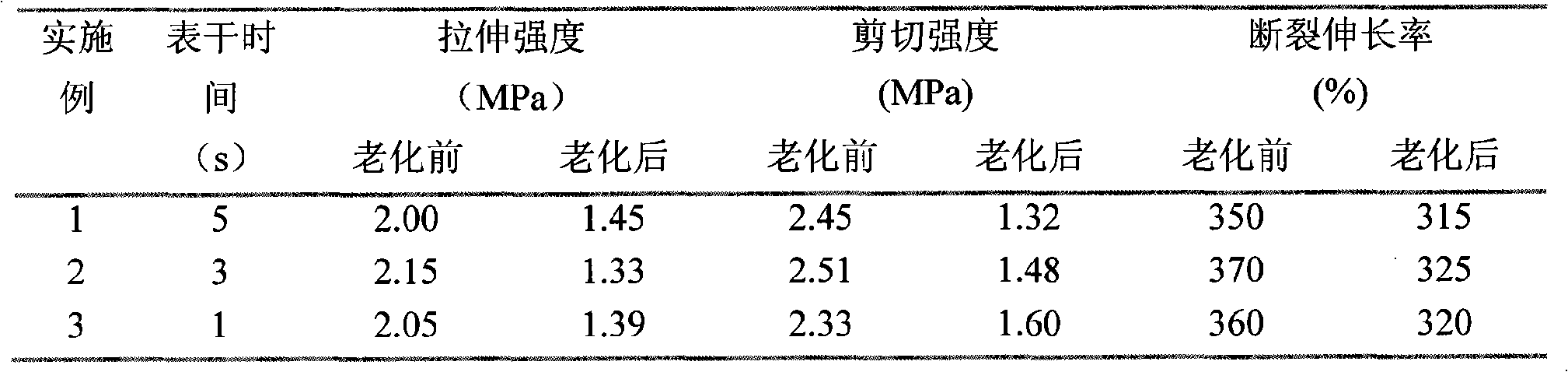

Low-temperature safety polyurethane injecting paste material for coal-rock mass reinforcement and preparation method thereof

The invention provides a low-temperature safety polyurethane injecting paste material for coal-rock mass reinforcement and a preparation method thereof, and belongs to the field of polyurethane compositions. The material consists of a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 100 parts of polyether polyol, 0.2 to 2.0 parts of catalyst, 0 to 5 parts of antistatic agent, and 20 to 30 parts of flame retardant; and the component B comprises the following raw materials in parts by weight: 70 to 90 parts of polyisocyanates, 5 to 20 parts of pre-polymer, and 5 to 10 parts of viscosity reducer. The preparation method comprises the following steps of: (1) preparation of the component A, namely mixing the raw materials of the component A for later use; and (2) preparation of the component B, namely mixing the raw materials of the component B, and performing nitrogen displacement for later use. The low-temperature safety polyurethane injecting paste material has the advantages of flame retardant and antistatic performances, high adhered strength, strong shearing resistance and high toughness. The preparation method is simple and practical, has low requirements on production equipment and staff, and is short in production cycle; and according to the whole process, three wastes are not produced, and the environment and health of workers are not influenced.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Partially blocked polyurethane curing agent and preparation method thereof

The invention discloses a partially blocked polyurethane curing agent and a preparation method thereof. The preparation method mainly comprises the following steps that end-NCO isocyanate prepolymer is obtained from the addition reaction of diphenylmethane diisocyanate and low-molecular polyol in ester solvent, and then the end-NCO isocyanate prepolymer reacts with isocyanate sealant to form the curing agent. The partially blocked polyurethane curing agent has the following characteristics that: a) according to the calculation of NCO by weight, the blocked-NCO content is between 1.0 and 5.0 percent; b) the solid content by weight of the curing agent is 75+ / -2 percent, and the percentage content of the NCO by weight is between 12.0 and 13.0 percent (according to the calculation of the effective percentage of the NCO, the percentage content of the NCO including blocked NCO radicals); and c) the viscosity of the curing agent at 25 DEG C is between 1,500 and 2,500 mPa. s. The invention has the advantages of low toxicity, good storage stability, adjustable curing speed and the like.

Owner:WANHUA CHEM BEIJING +1

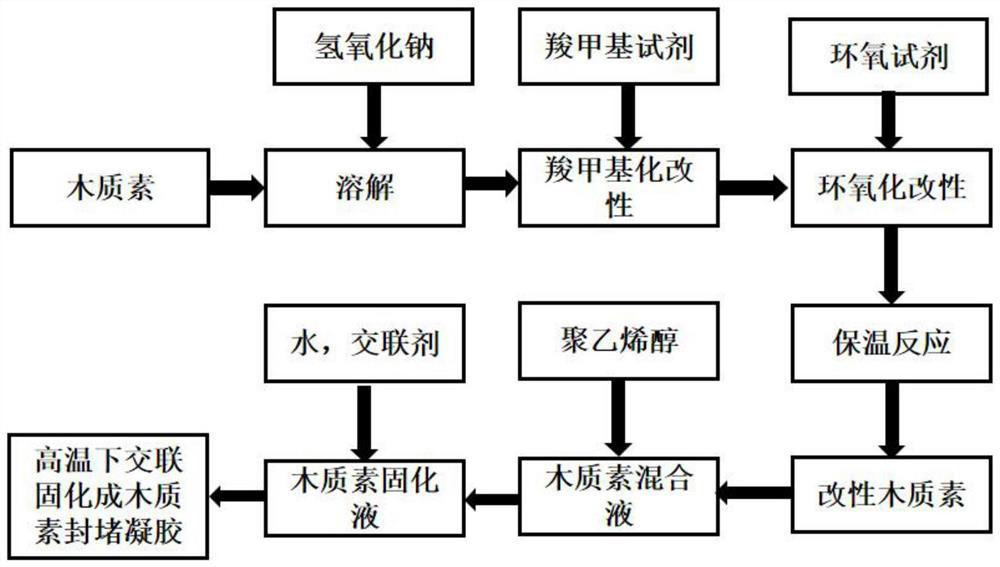

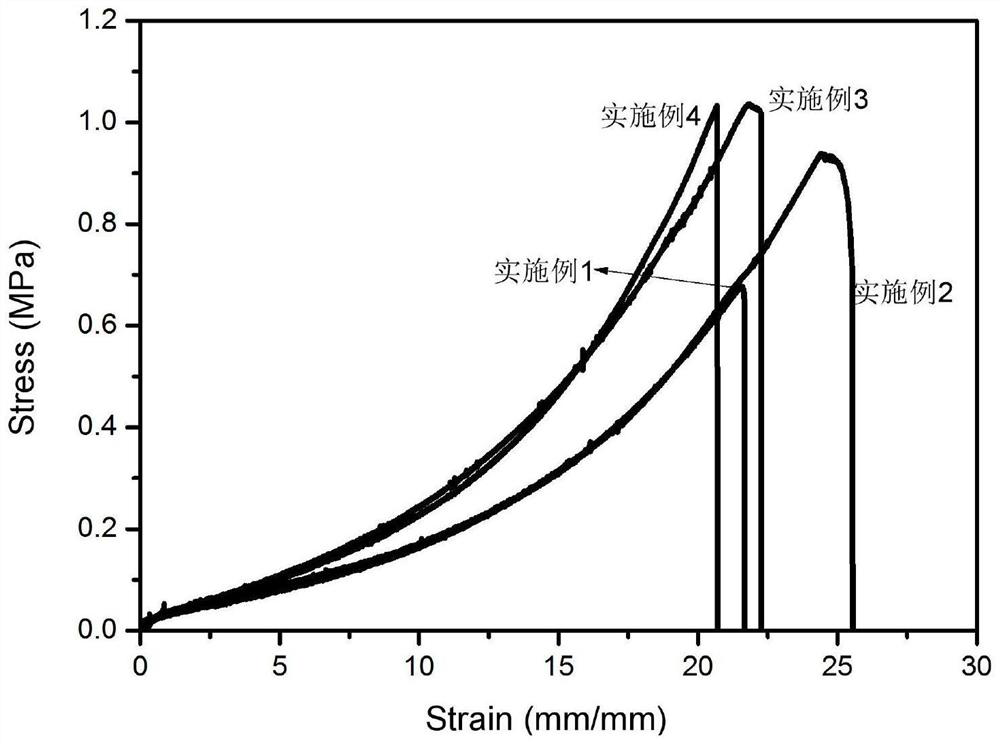

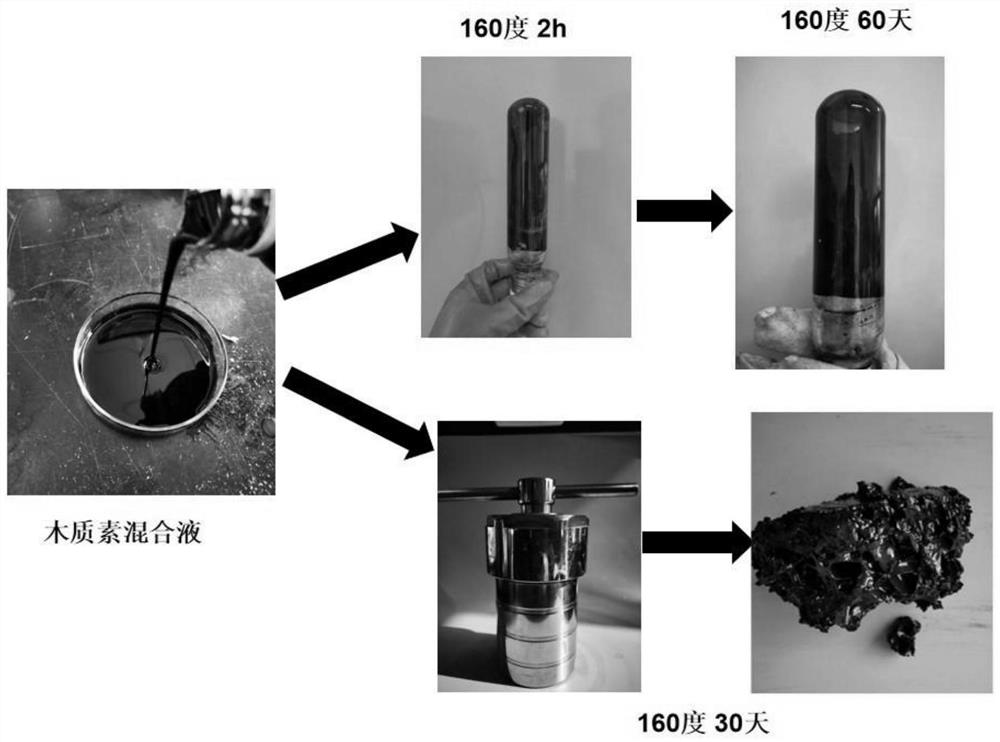

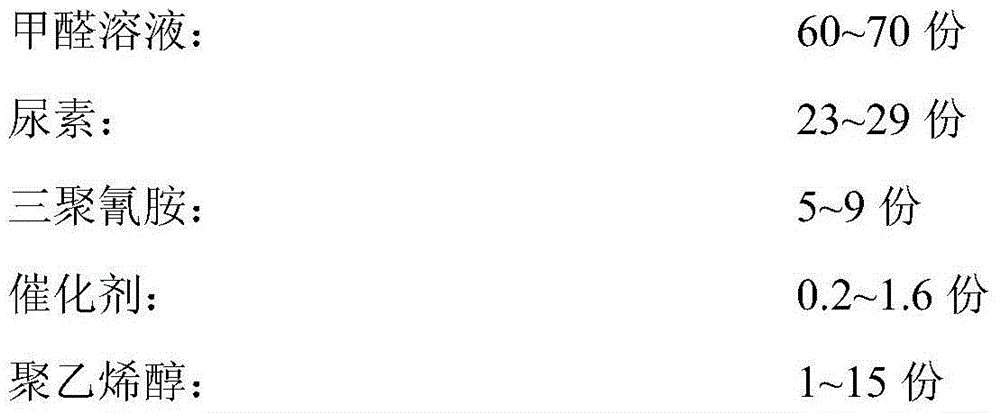

Preparation method and application of modified lignin-based gel water plugging agent

PendingCN114716701AEasy to crosslinkImprove temperature resistanceDrilling compositionCarboxyl radicalPolyvinyl alcohol

The invention discloses a preparation method and application of a modified lignin-based gel water shutoff agent, and the preparation method comprises the following preparation steps: step A, putting a lignin raw material into a reaction container, uniformly stirring, adding a carboxymethylation modification reagent, and reacting for a period of time at a certain temperature; step B, adding an epoxy modification reagent, and reacting for a period of time at a certain temperature; c, adding a polyvinyl alcohol solution, uniformly stirring, and cooling; and D, adding a cross-linking agent to adjust the concentration, uniformly stirring, transferring into a high-temperature-resistant pipe or a high-temperature-resistant tank, putting into an electrothermal blowing dry box, and reacting at 100-200 DEG C to form gel, thereby obtaining the modified lignin-based gel water plugging agent. The lignin is subjected to chemical modification, the modified lignin contains carboxyl and epoxy groups at the same time and then acts with the cross-linking agent and the like, the lignin is cured into gel at high temperature, the temperature-resistant and salt-resistant water shutoff agent is formed, the modified lignin is easy to cross-link, the strength after cross-linking and curing is high, and a cured product is good in temperature resistance.

Owner:湖南骏泰新材料科技有限责任公司

Acrylate adhesive and preparation method thereof

InactiveCN1670103ACuring is smooth and slowCuring is achieved smoothly and slowlyNitrile polymer adhesivesOrganic non-macromolecular adhesiveBenzoyl peroxideDetonation

The invention discloses a new acrylic ester adhesive agent, which comprises the following two components A and B in the weight proportion of A of 90-120 shears and of B of 2-40 shears, wherein, the said component A is made of the following raw materials in weight proportion of methyl methacrylate of 80-120 shears, acrylonitrile-butadiene-styrene of 20-35 shears and modified arylamine of 1-4 shears, the said component B is made of the following raw materials in weight proportion of benzoyl peroxide of 5-15 shears, methacrylic acid of 5-15 shears and talcum powder of 10-30 shears. The acrylic ester adhesive agent in the invention cures mildly and stably in room temperature and disappears the phenomenons vigorous heat release or imploding detonation when the curing time in room temperature is controlled in 10-90 min and the one-time dosage is lass than 10 g. The shelf life of the said acrylic ester adhesive agent in room temperature can reach more than half a year.

Owner:张恩天

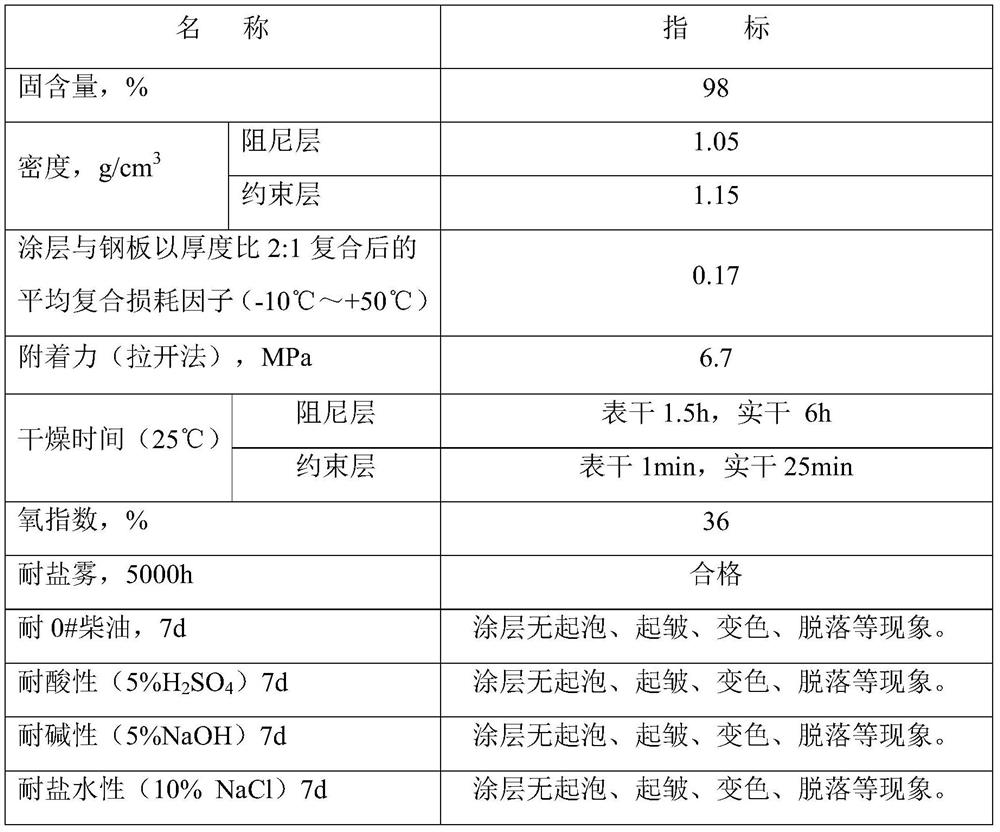

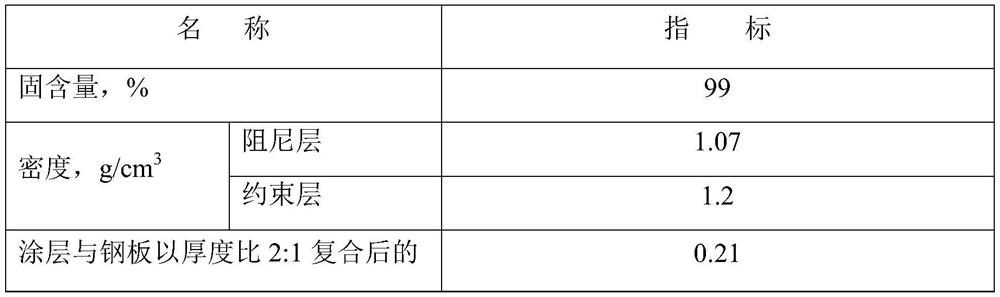

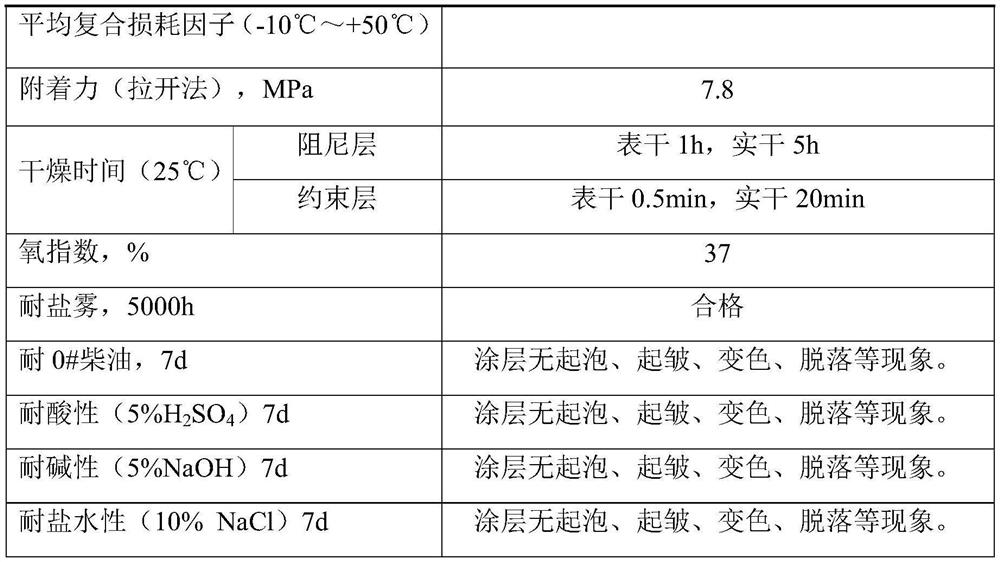

A fast-curing constrained structural damping coating and its preparation method

ActiveCN111635695BLittle influence of temperature and humidityImprove construction qualityFireproof paintsAnti-corrosive paintsPolymer sciencePtru catalyst

The invention proposes a fast-curing constrained structure damping coating and a preparation method thereof, which belong to the technical field of special functional materials. Chain agent, glycol, dispersant, defoamer, substrate wetting agent, adhesion promoter, first catalyst, damping pigment and filler; constraining layer is two-component solvent-free polyurethane coating, including component A: isocyanate , polyol, liquid flame retardant; B component: amino-terminated polyether, polyether polyol, flame retardant pigments and fillers, hollow microspheres, chain extender, second catalyst, antioxidant, dispersant, water remover , Color paste. The damping paint of the present invention, the curing speed of the damping layer and the constraining layer can be adjusted, and can be quickly cured in winter construction without sagging. The material can not only be applied to the vibration and noise protection in the field of ships, but also can be widely used in rail transit, automobiles, etc. , construction machinery and other fields.

Owner:QINGDAO AIR NEW MATERIALS

Loose coal and rock foaming urea-formaldehyde resin cementing material and method for preparing same

InactiveCN1241985CRealize chemical foaming and curing at room temperatureAdjustable curing speedSilicon oxideCoal

The invention discloses a loose coal and rock foaming urea-formaldehyde resin cementing material and method for preparing same, wherein the material comprises urea aldehyde resin, polyacrylates, organic macromolecular acid, carbonates, silicon oxide and inorganic ammonium salt. The invention can realize the normal temperature chemical foaming and solidifying for the urea aldehyde resin.

Owner:淮南矿业集团兴科计量技术服务有限责任公司

Modified urea-formaldehyde resin reinforced material used for coal mine and preparation method thereof

The invention belongs to the field of chemical synthesis, specifically relates to a modified urea-formaldehyde resin reinforced material used for coal mine and a preparation method thereof, and the material is applicable to fragmented coal body reinforcing during coal mine excavation. The modified urea-formaldehyde resin reinforced material is characterized by being composed of a composition A and a composition B, wherein the composition A is modified urea-formaldehyde resin and the composition B is a modified urea-formaldehyde resin curing agent composition. The characteristics comprise that: (1) by designing the formula of the material, the reaction is performed at normal temperature, the curing speed is adjustable, the consolidation body is high in strength and good in toughness, has the compression resistance of 30 mPa or more, and is capable of substantially improving the bracing force of loose coal; (2) the internal reaction temperature of the material is relatively low and is at 60 DEG C or less; (3) the raw material solution is low in viscosity, good in permeability in coal rocks, and the caking property between the consolidation body and the coal body is good; and (4) the material employs a special pneumatic double-liquid or three-liquid grouting pump for pressure grouting, the operation is simple and the usage is convenient.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Gypsum powder, preparation method thereof, and application of gypsum powder in sculptures and unfired pottery clay

The invention discloses gypsum powder, a preparation method of the gypsum powder and application of the gypsum powder in sculptures and unfired pottery clay. The gypsum powder comprises the followingcomponents in parts by weight: 70-80 parts of gypsum powder, 15-20 parts of a filler, 0.2-0.5 part of a dispersing agent, 2-5 parts of dispersible latex powder, 5-10 parts of a retarder, 5-10 parts ofmodified starch, 8-12 parts of polyvinyl alcohol (PVA) powder, 1-10 parts of cellulose ether, and 1-2 parts of short glass fibers or 0.1-0.2 part of short chemical fibers. The gypsum powder providedby the invention is slow and adjustable in curing speed, and can be cured in 5-15 days; the cured gypsum powder still has high strength, can be used for shaping, and has good weather resistance and good compatibility with other materials; and the gypsum powder is used for sculptures and unfired clay, replaces sculpture clay and argil, is directly cured, does not need mold turnover, casting and high-temperature firing, protects the environment, reduces sculpture shaping procedures, greatly reduces process steps, shortens a sculpturing period and reduces sculpturing cost.

Owner:JINGMEN QIAN NIAN JIAN HEALTH CARE TECH

Polyurethane polymer material for coal rock mass reinforcement and preparation method thereof

The invention belongs to the field of chemical synthesis, and particularly relates to a polyurethane high polymer material for coal rock mass reinforcement and a preparation method of the polyurethane polymer material. The polyurethane polymer material consists of component A and component B, wherein the component A is composed of a polyalcohol, a solvent, a catalyst and a fire retardant and the component B is composed of polyaryl polymethylene polyisocyanate. The polyurethane polymer material and the preparation method, disclosed by the invention, have the advantages that: through formulation design, foaming is carried out at a normal temperature, the curing rate is adjustable, the strength of consolidation body is high, compressive strength is more than 55mpa, the coal rock support force can be obviously increased; the consolidation body has very good toughness and can bear subsequent mining influence; the raw liquid is low in viscosity and has good permeability in the coal rock mass; and the caking property of the consolidation body and the coal rock mass is good; the related raw materials in the invention are green, pollution-free and harmless to human body, contain no volatile solvent and generate no any toxic gas, therefore, the use and environmental requirements for the coal rock mass reinforcement are completely satisfied; and the material is pressed and filled by using a double liquid grouting pump, therefore, the pumpability is good and the use is convenient.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com