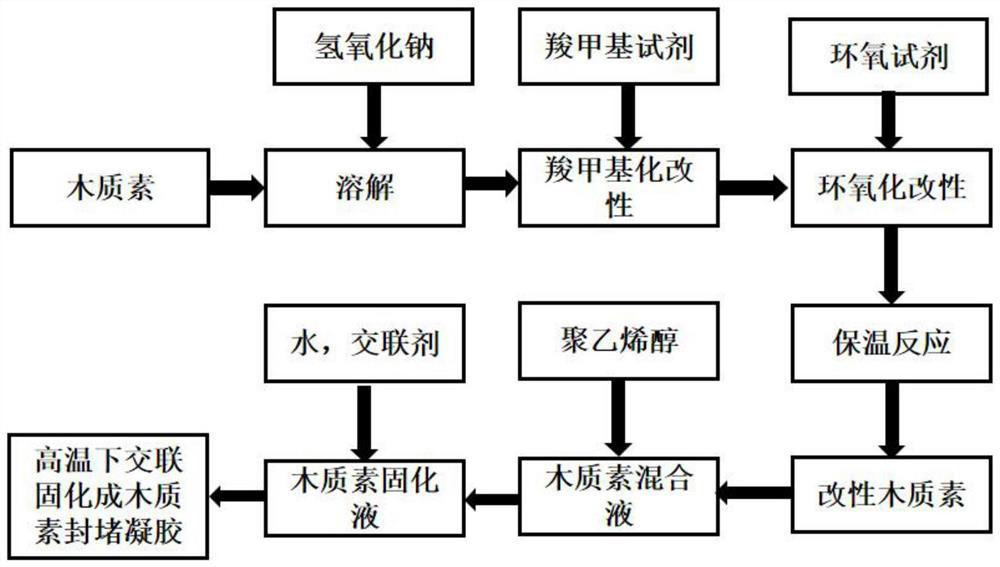

Preparation method and application of modified lignin-based gel water plugging agent

A lignin-based, water blocking agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor gelling strength, long gelling time, and high crosslinking difficulty, and achieve good temperature resistance , short gelation time and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

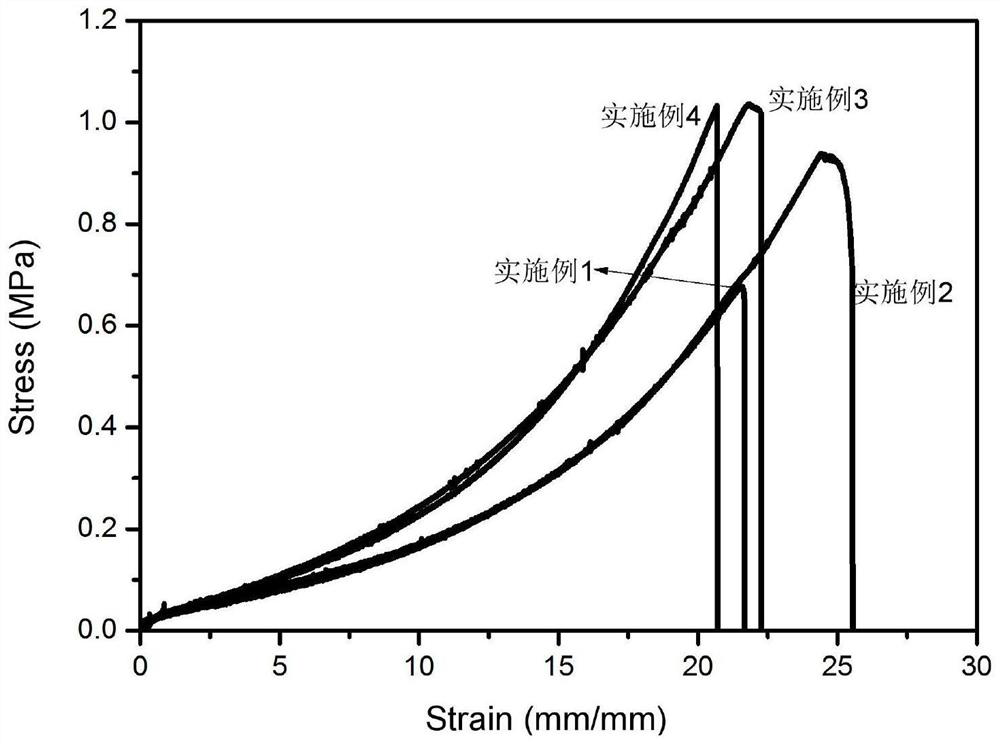

Embodiment 1

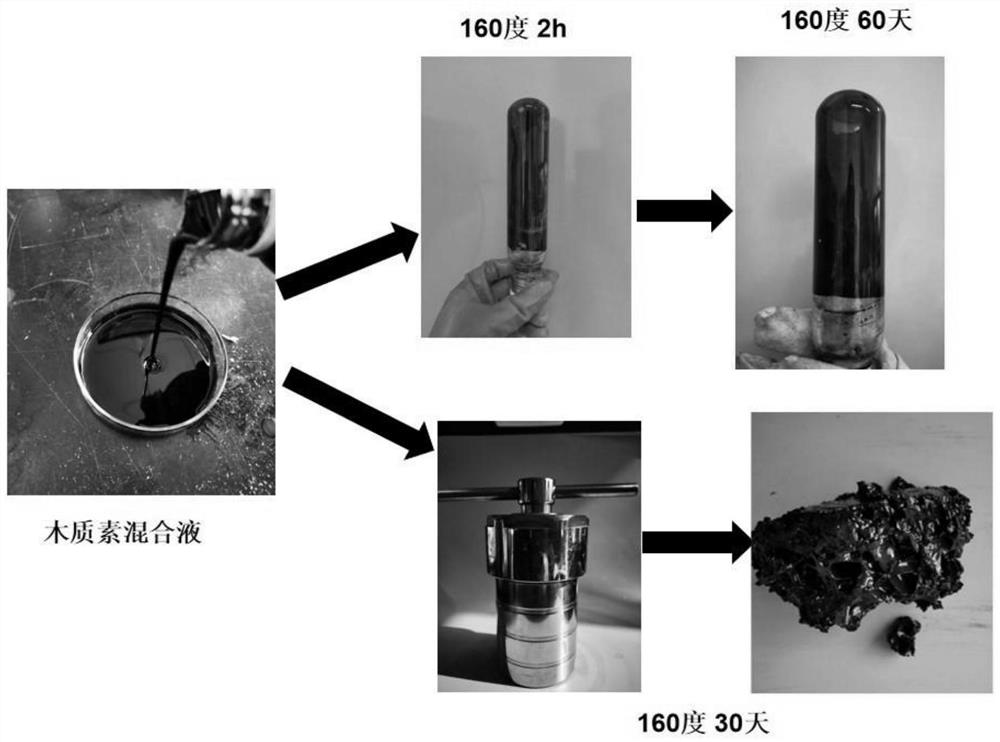

[0031] Lignin modification, weigh 200g of alkali lignin, 20g of sodium hydroxide, and 580ml of water, put them into a 1L reaction vessel, stir to dissolve the lignin, add 80g of sodium chloroacetic acid, and keep the temperature at 60°C for 2 hours; then pass The epichlorohydrin was added dropwise. The amount of epichlorohydrin added was 60 g, the dropping time was 1 h, and the temperature was kept at 60 °C for 2 hours. After the reaction, the polyvinyl alcohol dissolved in hot water was added. , 200g with a concentration of 10%, stir evenly, cool down, and finally transfer the mixture to a plastic bucket.

[0032] Lignin is cross-linked and solidified. Weigh 100 g of the above modified wood mixed solution, add 5.0 g of phthalic anhydride and 1.0 g of borax, and then dilute to 250 g with water, and stir evenly with a mixer. Environment, using pressure-resistant tube and hydrothermal reactor as reaction vessel, weighed 100mL and transferred to 100mL pressure-resistant tube and ...

Embodiment 2

[0035] Lignin modification, weigh 200g of alkali lignin, 20g of sodium hydroxide, and 580ml of water, put them into a 1L reaction vessel, stir to dissolve the lignin, add 120g of sodium chloroacetate, and keep the temperature at 55°C for 2 hours; then pass Add epichlorohydrin by dropwise addition, the amount of epichlorohydrin added is 90g, the dropwise addition time is 1h, and then the temperature is kept at 60°C for 3 hours. After the reaction is completed, polyvinyl alcohol dissolved in hot water is added. , the concentration of 100g is 10%, and the mixture is cooled down after stirring evenly, and finally the mixture is transferred to a plastic bucket.

[0036] Lignin is cross-linked and solidified. Weigh 100 g of the modified lignin mixed solution, add 0.5 g of aminophenylboronic acid and 5.0 g of dicyandiamide, dilute to 250 g with water, and stir evenly with a mixer. In order to simulate the formation curing environment, a pressure-resistant tube and a hydrothermal reac...

Embodiment 3

[0039] Lignin modification, pulping and cooking concentrated black liquor 600g (concentration 35%) through membrane filtration, sodium hydroxide 15g, put into 1L reaction vessel, add sodium chloroacetic acid 12g, keep the temperature at 70 ℃ and react for 1.5 hours; then Add epichlorohydrin by dropwise addition, the amount of epichlorohydrin added is 65g, the dropwise addition time is 1h, and then the temperature is kept at 70°C for 2 hours, and after the reaction is completed, 40g of 100-mesh powdery polyvinyl alcohol is added , stir evenly and cool down after the polyvinyl alcohol is completely dissolved, and finally transfer the mixture to a plastic bucket.

[0040] Lignin is cross-linked and cured. Weigh 90 g of the above modified wood mixed solution, add 1.0 g of borax and 5.0 g of dicyandiamide, dilute to 250 g with water, and stir evenly with a mixer. In the curing experiment, in order to simulate the formation curing environment, A pressure-resistant tube and a hydroth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com