Medical composite chitosan functional dressing and preparation method thereof

A technology of chitosan and water-soluble chitosan, which is applied in the field of medical supplies, can solve problems such as toxicity, achieve softness and plasticity, reduce the use of cross-linking agents, and avoid residual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

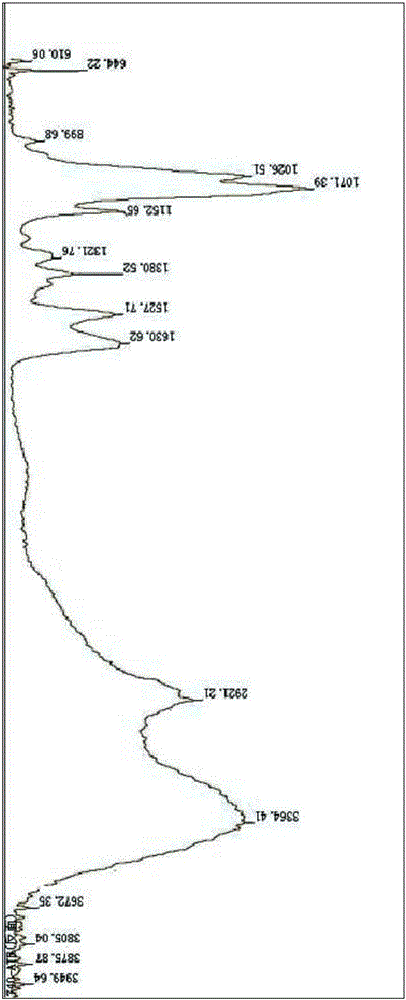

Image

Examples

Embodiment 1

[0047] A medical composite chitosan functional dressing, which includes water-soluble chitosan or its salt, and carboxymethyl starch or sodium carboxymethyl starch, specifically, includes the following components in parts by mass: carboxymethyl starch Base chitosan 1g, carboxymethyl starch 3g.

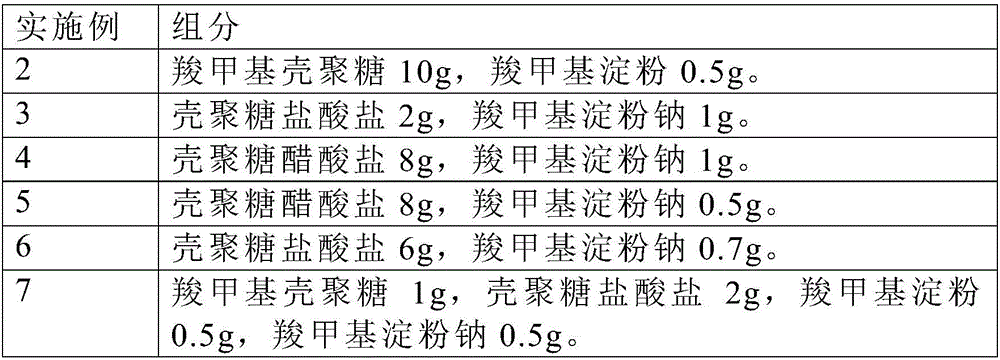

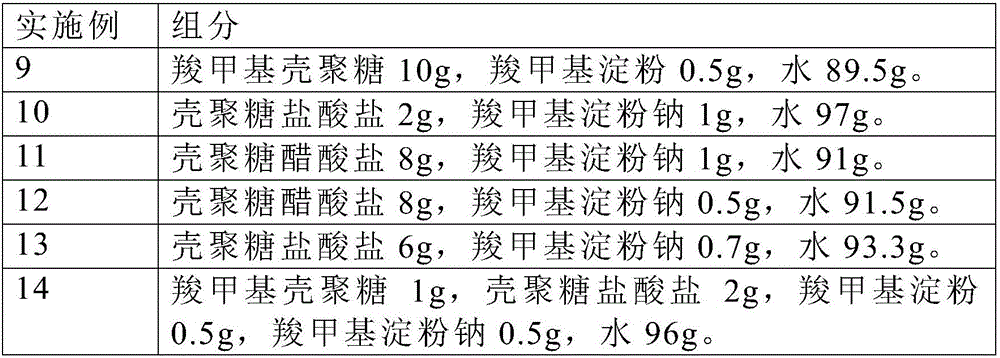

Embodiment 2-7

[0049]

[0050] The molecular weight of chitosan hydrochloride is 20000-300000, the degree of deacetylation is 80-95%, the viscosity is 10-120mpa·s, the pH value is 4.0-6.0, and the pH value of the sodium carboxymethyl starch is 5.5-7.5 .

Embodiment 8

[0052] A preparation method of medical composite chitosan functional dressing, is characterized in that, comprises the following steps:

[0053] A. Weigh a certain amount of water-soluble chitosan or its salt and carboxymethyl starch or sodium carboxymethyl starch, put it in a stirrer, add a certain amount of water, stir to make the solution foam and expand, and obtain the prepared solution ,

[0054]B. Weigh the above preparation solution, pour it into a silicone mold tray, put the lid closed and place it in a -20°C refrigerator for quick freezing. The silicone mold tray can be of different specifications, specifically 5cm×5cm, 5cm×10cm, 10cm×10cm , 10cm×20cm, 20cm×20cm, 20cm×30cm, 30cm×30cm, 12.5cm×7.5cm, etc.,

[0055] C, place the quick-frozen molded product in step B to freeze-dry in a vacuum freeze dryer, sterilize and pack after demoulding, and make a composite chitosan functional dressing, and the sterilization can be specifically ethylene oxide sterilization, cobalt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com