Material used for making climbing fulcra, and preparation method of material

A rock climbing fulcrum and toughening agent technology, applied in the field of chemical synthesis, can solve the problems of unenvironmental protection, high odor, volatile solvent, etc., and achieve the effects of convenient transportation, low viscosity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

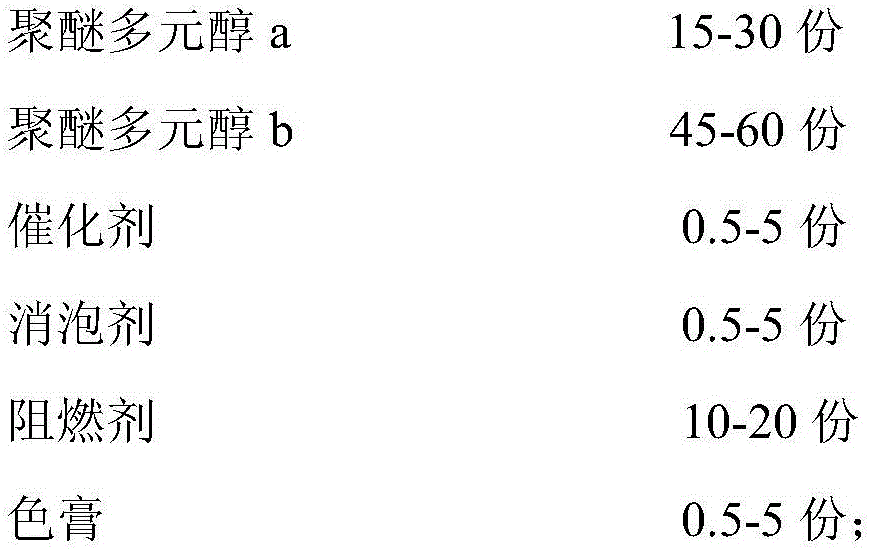

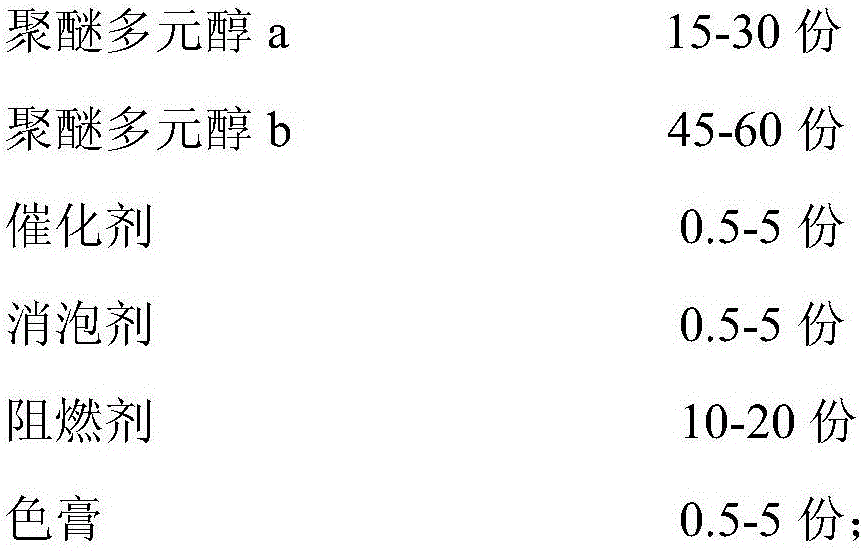

[0028] (1) prepare 100 kilograms of component A, weigh respectively 20.6 kilograms of polyether polyol a (2 functionalities, molecular weight 2000), 55.6 kilograms of polyether polyols b (6 functionalities, molecular weight 730), catalyst (February silicon Dibutyltin dibutyltin) 2.2 kg, 0.6 kg of defoamer (GEP50), 19 kg of flame retardant TCPP, 2 kg of red paste, weighed polyether polyol a, polyether polyol b, catalyst, defoamer , flame retardant, and color paste are put into the mixing kettle and stirred evenly. After the sampling test is qualified, it can be loaded into barrels.

[0029] (2) Prepare 100 kg of component B, put 80 kg of accurately measured polymethylene polyphenyl polyisocyanate 44V20 (Bayer) and 20 kg of toughening agent DBP into the reactor in order, stir and mix for 1 hour, and the sampling test is qualified After the material is discharged, the nitrogen is replaced with a sealed package.

[0030] (3) Mix components A and B according to the weight ratio of...

Embodiment 2

[0032] (1) Prepare 100 kilograms of component A, weigh respectively 29.5 kilograms of polyether polyol a (3 functionality, molecular weight 1000), 48.6 kilograms of polyether polyol b (4.8 functionality, molecular weight 700), catalyst (bismuth isooctanoate ) 2.3 kg, defoamer (GEP20) 2.6 kg, flame retardant TEP 14.3 kg, green paste 2.7 kg, weighed polyether polyol a, polyether polyol b, catalyst, defoamer, flame retardant Put the agent and color paste into the mixing kettle and stir evenly. After the sampling test is qualified, it can be loaded into barrels.

[0033] (2) To prepare 100 kg of component B, put 65 kg of accurately measured polymethylene polyphenyl polyisocyanate PM200 (Wanhua) and 35 kg of toughening agent DOP into the reaction kettle in order, stir and mix for 1 hour, and sample and test After qualified, the material is discharged, and the nitrogen is replaced with a sealed package.

[0034] (3) Mix components A and B according to the weight ratio of A:B=100:10...

Embodiment 3

[0036] (1) Prepare 100 kilograms of component A, weigh 15 kilograms of polyether polyol a (2 functionality, molecular weight 2000) respectively, polyether polyol b (5.2 functionality, molecular weight 650) 60 kilograms, catalyst (February silicon Dibutyltin dibutyltin) 1.2 kg, 1.6 kg of defoamer (GEP30), 20 kg of flame retardant TEP, 2.2 kg of yellow paste, polyether polyol a, polyether polyol b, catalyst, defoamer, Put the flame retardant and color paste into the mixing kettle and stir evenly. After the sampling test is qualified, it can be loaded into barrels.

[0037] (2) Prepare 100 kg of component B, put 60 kg of accurately measured polymethylene polyphenyl polyisocyanate 44V20 (Bayer) and 40 kg of toughening agent DBP into the reactor in order, stir and mix for 1 hour, and the sampling test is qualified After the material is discharged, the nitrogen is replaced with a sealed package.

[0038] (3) Mix components A and B according to the weight ratio of A:B=100:100 and po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com