Aqueous epoxy bonding agent for carpet bituminous mixture pavement and construction method thereof

A technology of asphalt mixture and water-based epoxy, which is applied in the direction of adhesive, epoxy glue, adhesive type, etc., can solve the problems of road rutting damage, reduce expressway transportation efficiency and service level, etc., and achieve good mechanical strength, Adjustable curing speed and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Carpet type asphalt mixture pavement water-based epoxy adhesive, composed of A component, B component and water, the weight ratio of each component is: 100 parts of water-based epoxy resin (A component), water-based epoxy 100 parts of curing agent (component B), 500 parts of water.

[0033] Components A and B are placed separately and configured at the construction site. The configuration method is: mix components A and B with water in proportion, and stir evenly for 5 to 10 minutes. The stirring temperature is 10°C and the stirring speed is 1000r / min. , at an ambient temperature of 10°C, after brushing with water-based epoxy resin, the bonding of the carpet-type asphalt mixture pavement and the base surface is completed within 60 minutes and the rolling is completed.

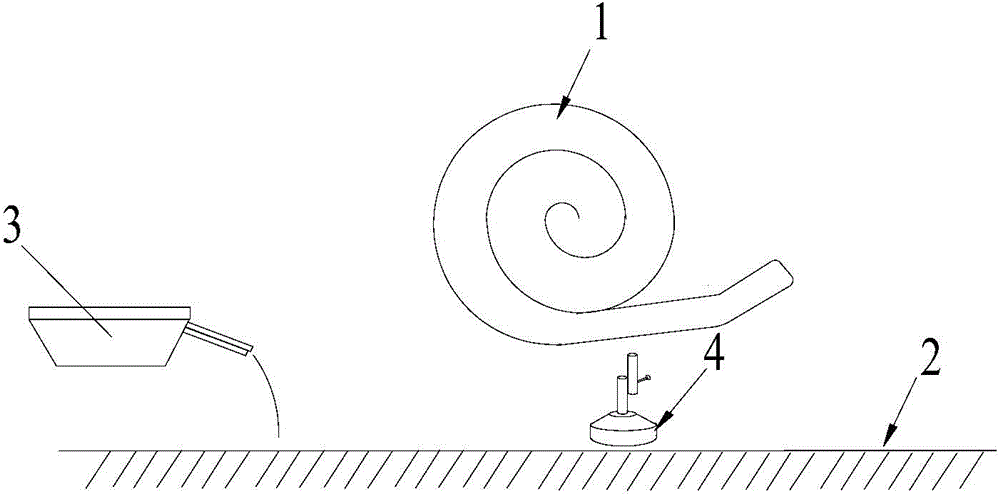

[0034] Construction methods for laying carpeted asphalt mixture pavement (see figure 1 )

[0035] Step 1: Clean the lower layer

[0036] The base surface 2 on which the asphalt pavement is to be laid ...

Embodiment 2

[0044] Carpet type asphalt mixture pavement water-based epoxy adhesive, composed of A component, B component and water, the weight ratio of each component is: 100 parts of water-based epoxy resin (A component), water-based epoxy 100 parts of curing agent (component B), 500 parts of water.

[0045] Components A, B and water are placed separately and configured at the construction site. The configuration method is: mix components A and B with water in proportion, and stir evenly for 10 minutes. The stirring temperature is 20°C and the stirring speed is 1000r / min. , At an ambient temperature of 20°C, brush or roll or spray within 60 minutes.

[0046] Construction method of laying carpet asphalt mixture pavement

[0047] Step 1: Clean the lower layer

[0048] The base surface of the asphalt pavement to be laid must be clean, dry and solid. After cleaning, ensure that the base surface is free of stones, scum, dust, oil or other surface impurities.

[0049] Step 2: In situ heatin...

Embodiment 3

[0056] Carpet type asphalt mixture pavement water-based epoxy adhesive, composed of A component, B component and water, the weight ratio of each component is: 100 parts of water-based epoxy resin (A component), water-based epoxy 100 parts of curing agent (component B), 500 parts of water.

[0057] Components A, B and water are placed separately and configured at the construction site. The configuration method is: mix components A and B with water in proportion, and stir evenly for 10 minutes. The stirring temperature is 20°C and the stirring speed is 1000r / min. , Under the condition of ambient temperature 0-30 ℃, finish by brushing, rolling or spraying within 60 minutes.

[0058] Construction method of laying carpet asphalt mixture pavement

[0059] Step 1: Clean the lower layer

[0060] The base surface of the asphalt pavement to be laid must be clean, dry and solid. After cleaning, ensure that the base surface is free of stones, scum, dust, oil or other surface impurities....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com