Environment-friendly organosilicone-modified polyether sealant and preparation method thereof

A silicone, environmentally friendly technology, applied in the field of sealants, to improve the bonding strength, the preparation method is simple and easy to operate, and the sealing effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

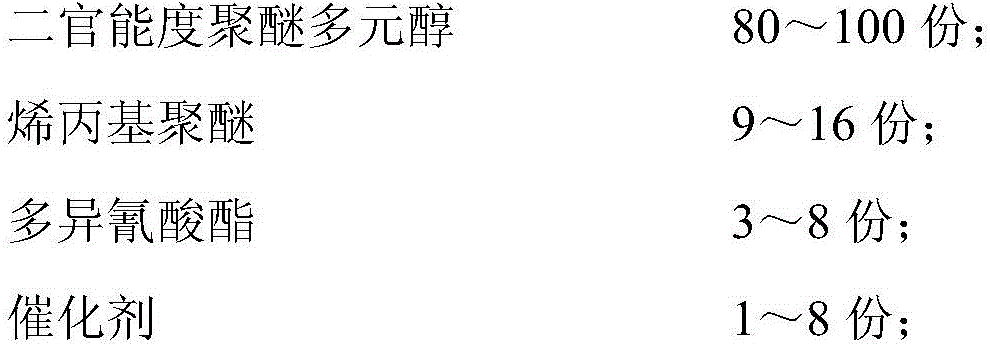

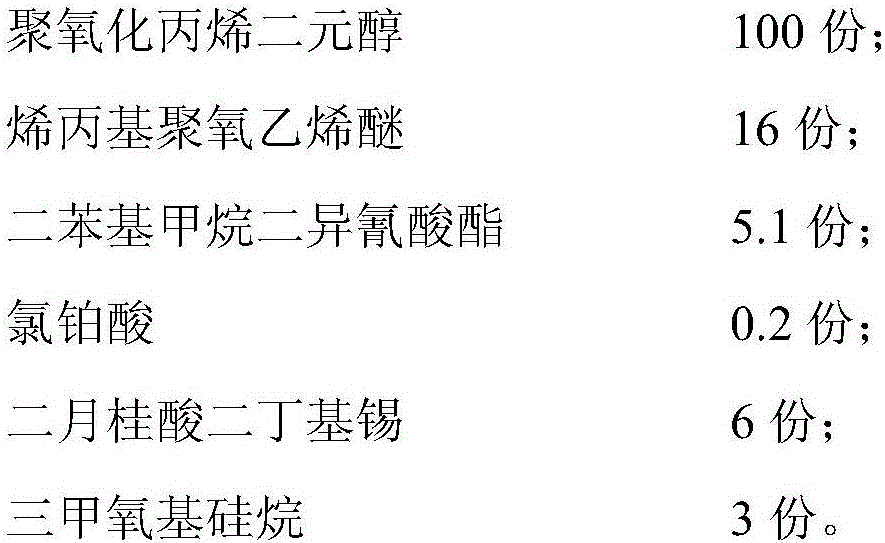

[0029] The environment-friendly silicone modified polyether sealant is made of the following raw materials in parts by weight:

[0030]

[0031] The number average molecular weight of the polyoxypropylene glycol is 10000.

[0032] The number average molecular weight of the allyl polyoxyethylene ether is 700.

[0033] The preparation method is as follows:

[0034] (1) First, add polyoxypropylene glycol and diphenylmethane diisocyanate into a reaction kettle equipped with a stirring device, a nitrogen inlet, and a thermometer, raise the temperature to 85°C, and stop the reaction until the NCO mass fraction drops to 0.83%. Reaction, get product one;

[0035] (2) Allyl polyoxyethylene ether was added to product 1, and reacted at 85°C until the mass fraction of NCO was reduced to 0 to obtain product 2;

[0036] (3) Add chloroplatinic acid and trimethoxysilane to the product 2, and heat it at 85°C for 5 hours to obtain a silicone-modified polyether sealant prepolymer, and then...

Embodiment 2

[0038] The environment-friendly silicone modified polyether sealant is made of the following raw materials in parts by weight:

[0039]

[0040] The number average molecular weight of the polyoxypropylene glycol is 8000.

[0041] The number average molecular weight of the allyl polyoxyethylene ether is 500.

[0042] The preparation method is as follows:

[0043] (1) At first, polyoxypropylene glycol and toluene diisocyanate are added in the reactor that stirring device, nitrogen inlet, thermometer are housed, be warmed up to 80 ℃, when reacting to NCO mass fraction and drop to 1.05%, stop reaction, obtain product one;

[0044] (2) Allyl polyoxyethylene ether was added to product 1, and reacted at 80°C until the mass fraction of NCO was reduced to 0 to obtain product 2;

[0045] (3) Add chloroplatinic acid and trimethoxysilane to the product 2, and keep warm at 80°C for 5 hours to obtain a silicone-modified polyether sealant prepolymer, and then add dibutyltin dilaurate t...

Embodiment 3

[0047] The environment-friendly silicone modified polyether sealant is made of the following raw materials in parts by weight:

[0048]

[0049] The number average molecular weight of the polyoxypropylene glycol is 10000.

[0050] The number average molecular weight of the allyl polyoxyethylene ether is 500.

[0051] The preparation method is as follows:

[0052] (1) First, add polyoxypropylene glycol and diphenylmethane diisocyanate into a reaction kettle equipped with a stirring device, nitrogen inlet, and thermometer, raise the temperature to 90°C, and stop the reaction until the NCO mass fraction drops to 0.83%. Reaction, get product one;

[0053] (2) Allyl polyoxyethylene ether was added to product 1, and reacted at 90°C until the mass fraction of NCO was reduced to 0 to obtain product 2;

[0054] (3) Add chloroplatinic acid and triethoxysilane to the product 2, and keep warm at 90°C for 5 hours to obtain a silicone-modified polyether sealant prepolymer, and then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com