Low-temperature safety polyurethane injecting paste material for coal-rock mass reinforcement and preparation method thereof

A grouting material and safe technology, which is applied in the field of low-temperature safe polyurethane grouting material for coal and rock mass reinforcement and its preparation, can solve problems such as high internal reaction temperature, limited flame retardancy, and potential safety hazards, and achieve material viscosity Low cost, excellent construction performance and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

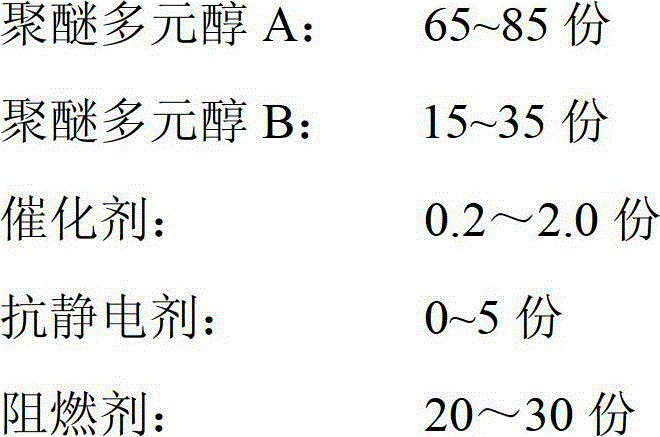

[0032] (1) Preparation of component A

[0033] Accurately metered polyether polyol A (4 functionalities, molecular weight 430) 85 parts, polyether polyol B (3 functionalities, molecular weight 170) 15 parts, catalyst dibutylene dilaurate T-12 (USA 0.5 parts of air chemical industry), 5 parts of antistatic agent AT-21 (Shanghai Qiguang) and 20 parts of flame retardant trichloropropyl phosphate TCPP (Jiangsu Yake), put them into the reaction kettle, stir and mix for 2 hours, and produce materials, sealed packaging;

[0034] (2) Preparation of component B

[0035] 80 parts of accurately metered polymethylene polyphenyl polyisocyanate PM200, 13 parts of prepolymer DT1340 (PPG / MDI series prepolymer, Shandong Dongdayi Nuowei Polyurethane Co., Ltd.), viscosity reducer DBP (Zhejiang Construction Dejianye Organic Chemical Co., Ltd.) 7 parts; put into a reaction kettle, stir and mix for 2 hours, discharge, nitrogen replacement packaging.

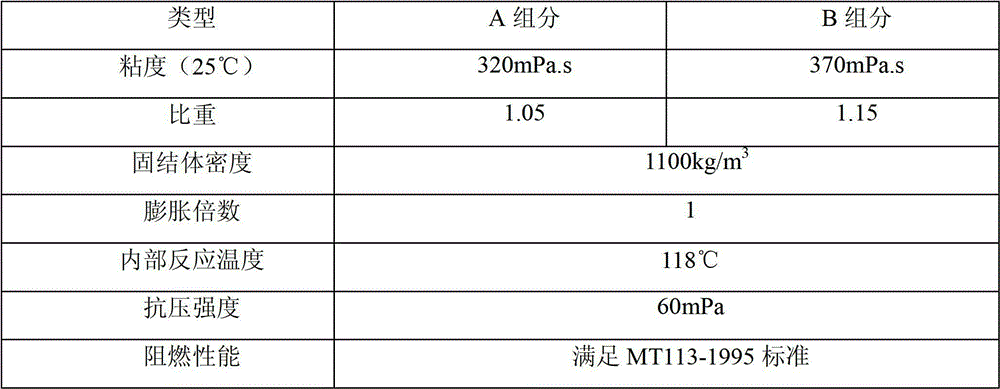

[0036] Take 100g of A and B components accor...

Embodiment 2

[0041] ①Preparation of component A

[0042] Accurately measure 65 parts of polyether polyol A (3-functionality, molecular weight 450), 35 parts of polyether polyol B (2-functionality, molecular weight 270), 0.3 parts of catalyst lead isooctanoate (10%), antistatic agent AT-21 (Shanghai Qiguang Industry and Trade) 5 parts and flame retardant trichloropropyl phosphate TCPP (Jiangsu Yake Technology Co., Ltd.) 20 parts, flame retardant dimethyl methyl phosphate DMMP (Qingdao Lianmei Chemical Co., Ltd. ) 10 parts; add in the reaction kettle, stir and mix for 1 hour, discharge and seal the package;

[0043] ②Preparation of component B

[0044] Accurately metered polymethylene polyphenyl polyisocyanate 44v2078 parts, prepolymers D1345 and DT1340 (PPG / MDI series prepolymers, Shandong Dongdayi Nuowei Polyurethane Co., Ltd.) 12 parts, viscosity reducer DBP (Zhejiang Jiande Jianye Organic Chemical Co., Ltd.) 10 parts; put into the reaction kettle, stir and mix for 2 hours, discharge, n...

Embodiment 3

[0050] ①Preparation of component A

[0051] 75 parts of polyether polyol A (4 functionalities, molecular weight 430), 25 parts of polyether polyol B (3 functionalities, molecular weight 170) and catalyst dibutylene dilaurate T-12 (U.S. Air chemical industry) 1.5 parts, flame retardant trichloropropyl phosphate TCPP (Jiangsu Yake) 20 parts, flame retardant dimethyl methyl phosphate DMMP (Qingdao Lianmei Chemical Co., Ltd.) 10 parts, put into the reaction kettle, stir and mix 2 hours, after sampling and testing, discharge and seal the package.

[0052] ②Preparation of component B

[0053] 78 parts of accurately metered polymethylene polyphenyl polyisocyanate M20S, 6 parts of prepolymer D1345 (PPG / MDI series prepolymer, Shandong Dongdayi Nuowei Polyurethane Co., Ltd.) and viscosity reducer DBP (Zhejiang Jian Dejianye Organic Chemical Co., Ltd.) 10 parts; put into a reaction kettle, stir and mix for 2 hours, discharge, nitrogen replacement packaging.

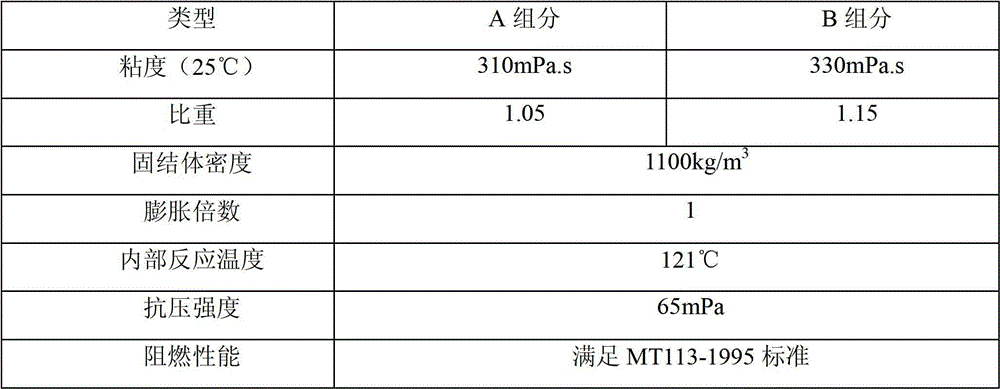

[0054] According to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com