Preparation method for polyurethane adhesive for binding high-grade books

A technology of polyurethane adhesives and books, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of high rigidity, poor flexibility, and high glass transition temperature, and achieve convenient operation and flexibility Good, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

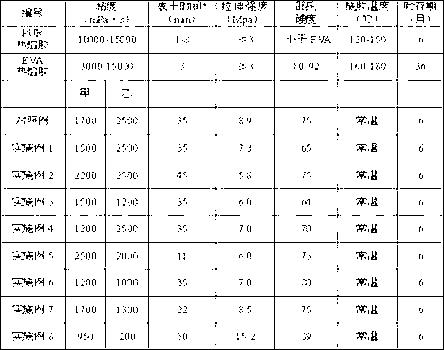

Image

Examples

Embodiment 1

[0029] Under the reaction conditions of the comparative example, 100 g of trihydroxypolyoxypropylene ether was added to component A, and a light yellow, fluid, and almost transparent viscous liquid was obtained; trihydroxypolyoxypropylene ether in component B And the amount of glycerol becomes 105g and 17g respectively, obtains transparent, pale yellow viscous liquid, and A, B two components are mixed and stirred according to R=1.1.

Embodiment 2

[0031]Under the reaction conditions of the control example, replace the toluene diisocyanate (TDI) in the component A with 10g 4,4'-diphenylmethane diisocyanate (MDI), and the light yellow, fluidity, and transparent viscous Thick liquid, and mix A and B according to R=1.2.

Embodiment 3

[0033] Under the reaction conditions of the comparative example, the hydroxyl monomer in component A was converted into 160g castor oil, 20g polyethylene adipate, and the isocyanate monomer was converted into 10g isophorone diisocyanate (IPDI), to obtain Light yellow, high viscosity, transparent viscous liquid; the hydroxyl monomer in component B is converted into 45g castor oil and 5g glycerol to obtain a light yellow transparent, relatively viscous liquid, and the two groups of A and B Parts are mixed according to R=1.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com