Patents

Literature

59results about How to "Production process cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing titanium white

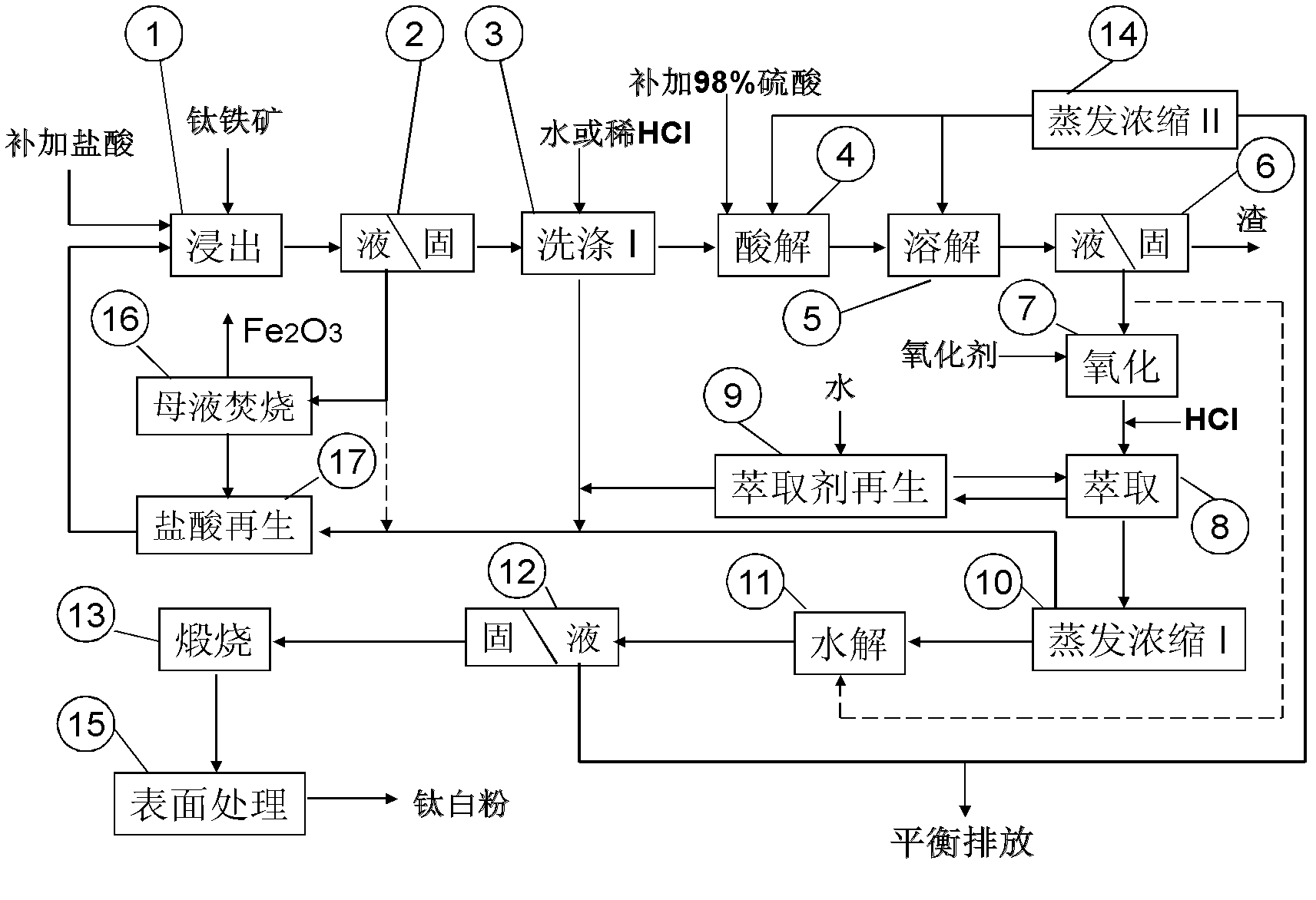

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

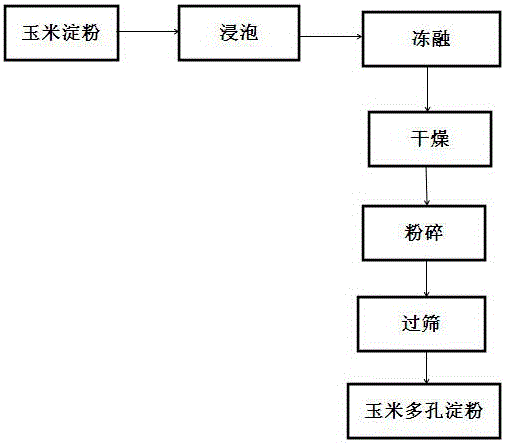

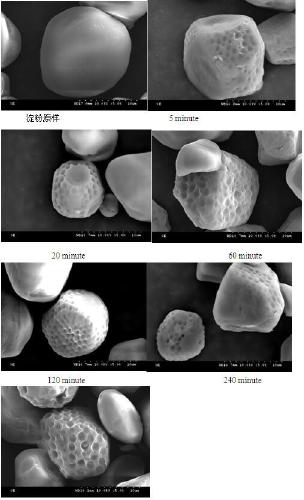

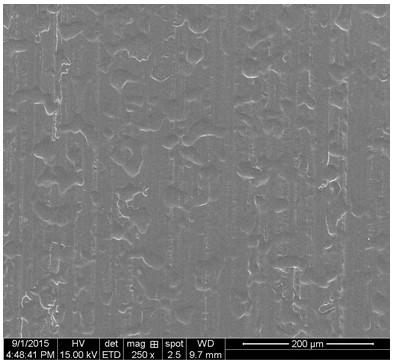

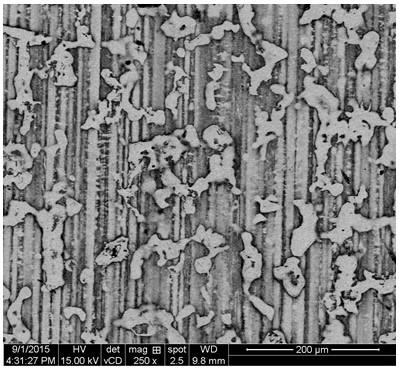

Method for producing corn porous starch by using low temperature freeze-thawing technology

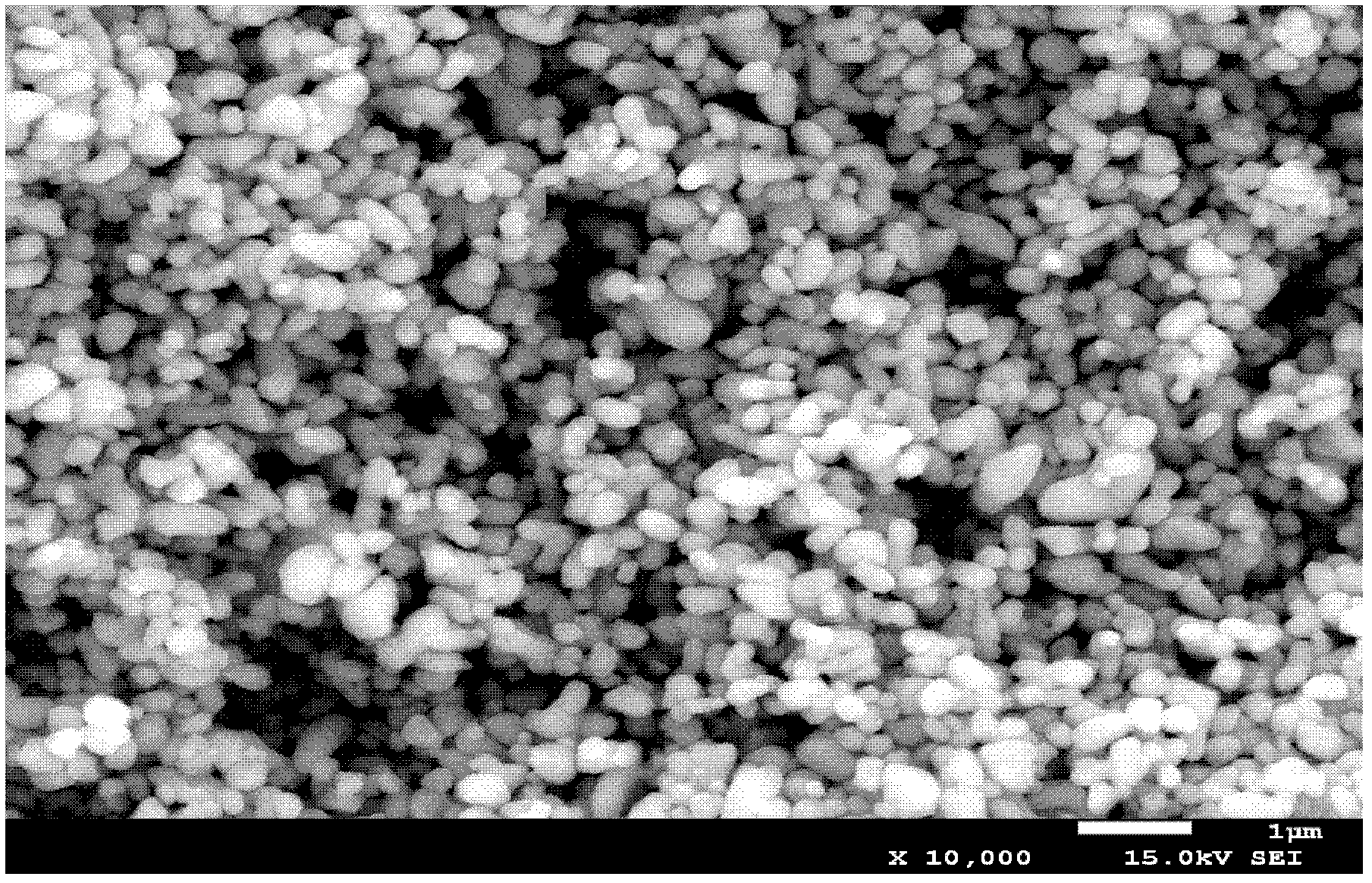

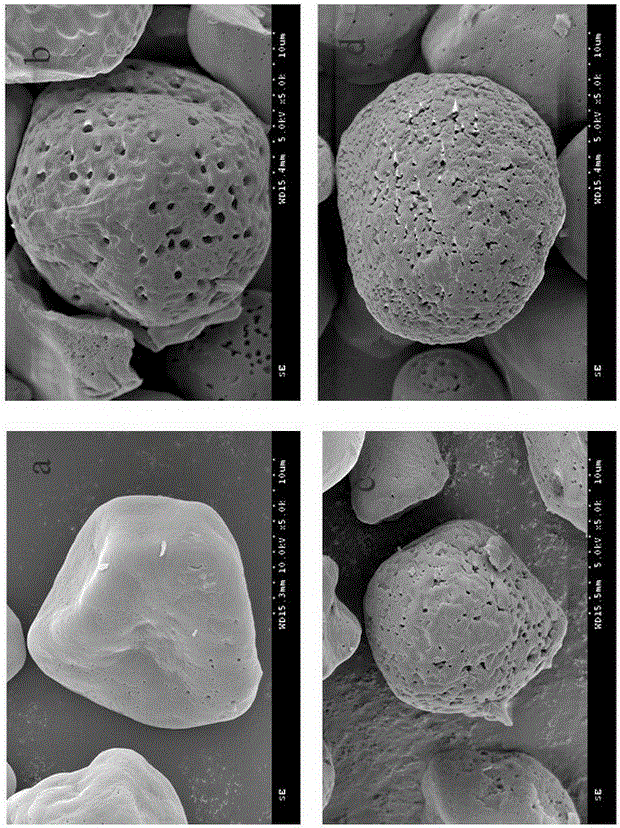

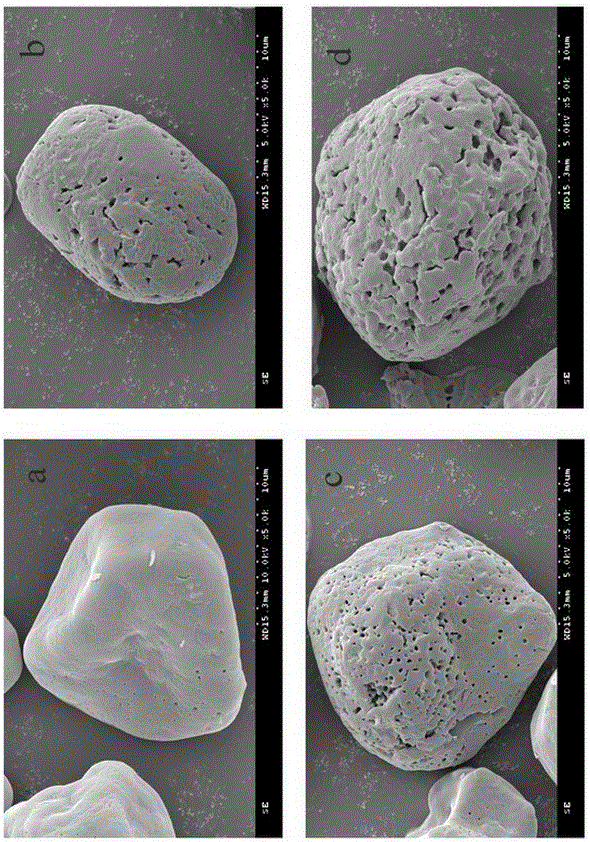

A method for producing corn porous starch by using a low temperature freeze-thawing technology comprises the following steps: 1, immersing corn starch; 2, freeze-thawing: freezing the immersed corn starch at -10 ~ -196 DEG C for 0.5-12 h, unfreezing the frozen corn starch at 20-50 DEG C for 3-8 h, and repeatedly carrying out freezing and unfreezing treatment 1-50 times. The method has the advantages of simplicity in operation, high production efficiency, clean production technology, no pollution to environment, realization of large-scale continuous production, and low production cost due to adoption of reagents and materials having common specifications; and the corn porous starch produced in the invention has the advantages of high freeze-thawing stability, strong reaction activity, good adsorptivity and good embedding property.

Owner:QIQIHAR UNIVERSITY

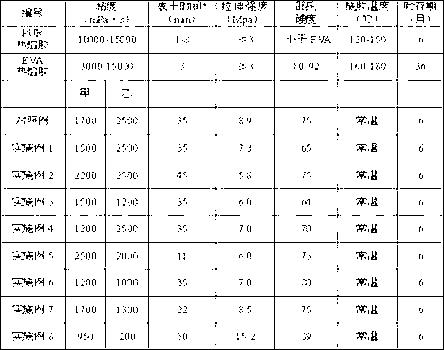

Preparation method for polyurethane adhesive for binding high-grade books

InactiveCN102703016AGood flexibilityGood mechanical propertiesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention discloses a preparation method for a polyurethane adhesive for binding high-grade books and belongs to the field of polyurethane adhesive compounding. The steps are as follows: (1) prepolymerization reaction: using hydroxy monomers and isocyanate monomers as main raw materials, and compounding to get prepolymers blocked with OH and NCO respectively; and (2) cross-linking reaction: mixing the two kinds of prepolymers by a certain proportion, and curing to obtain a transparent or semitransparent, flexible and properly hard coating. The invention adopts the two-step compounding method of prepolymerization and cross-linking to compound out a solvent-free double-component polyurethane adhesive; the production process is simple and clean and conforms to the requirement of environmental protection; and the viscosity and the molecular weight of Components A and B can be adjusted through prepolymerization so as to increase bonding strength; the adhesive can be cured in the cross-linking process so as to further improve the bonding strength. (3) The components A and B are liquid at normal temperature, and the viscosity and the curing speed are adjustable; the curing reaction is conducted at room temperature, the operation is convenient, the energy consumption is low, and product storage is stable.

Owner:CHANGZHOU UNIV

Method for producing dissolving pulp by using poplar slabs

ActiveCN102912667APento-oligosaccharide contentHigh in alpha-celluloseNatural cellulose pulp/paperPulp bleachingSteam cookingPulp and paper industry

Owner:QILU UNIV OF TECH

Method for preparing cyclic sulfate by directly oxidizing hydrogen peroxide

PendingCN111909129ALess impuritiesHigh purityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The method comprises the following steps: dropwise adding hydrogen peroxide into a mixture of cyclic sulfite, an organic solvent and a solid catalyst to carry out catalytic oxidation reaction, filtering out the solid catalyst after the reaction is finished, standing filtrate for layering, taking an organic layer, and performing distilling and concentrating to obtain a cyclic sulfate product. Cheaphydrogen peroxide is used for directly catalyzing and oxidizing cyclic sulfite to prepare cyclic sulfate, so that on one hand, the reaction is mild and easy to control, and the reaction conversion rate is high; on the other hand, no waste salt is generated, the evaporation capacity of water is small, energy consumption is low, generated waste water is little, and the production process is more environmentally friendly; the used solid catalyst contains an active component, an active auxiliary agent and an oxide carrier, and can be recycled, so that the consumption of noble metals is reduced, and the production cost is greatly reduced; the cyclic sulfate prepared by the method is few in impurities, high in purity and wide in market prospect.

Owner:CHANGSHU CHANGJI CHEM +1

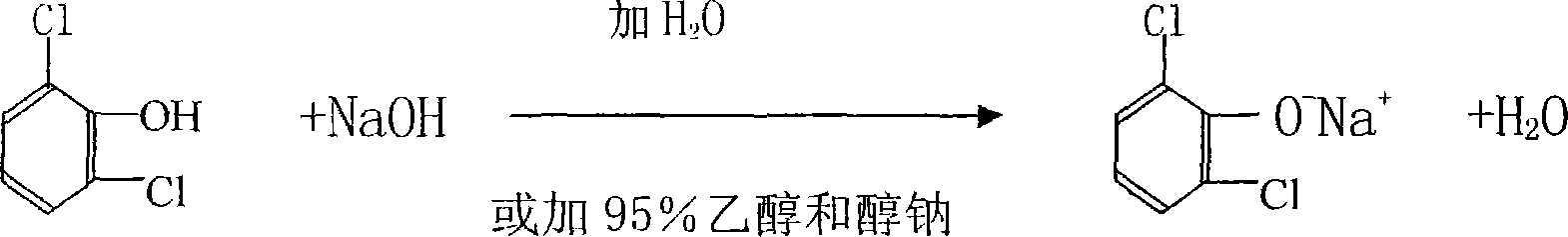

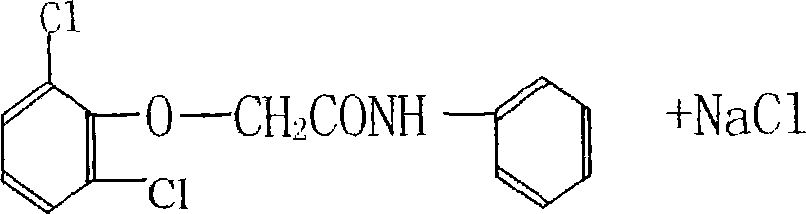

Novel technique for producing 2,6-dichloro diphenylamine

ActiveCN101230007ARelieve pressureSave moneyPreparation by rearrangement reactionsWastewaterAcetylation

The invention relates to a new process for producing 2, 6-dichloro diphenylamine, which includes a chloroacetylization step, an etherification step, rearrangement and post-processing steps; wherein, the reaction formula of the final product, 2, 6-dichloro diphenylamine, is shown as the right: The process of the invention causes no effluent, and the biproducts such as the sodium glycollate, the sodium chloride, etc during the reaction are recycled and transferred into reused resources. Moreover, the production technology is clean and environmentally friendly with no wastes and reduced total cost, and no catalyst and sodium carbonate are needed.

Owner:HENAN DONGTAI PHARM

Modified adhesive and preparation method for alumina silicate fiber paperboard

The invention relates to the technical field of an alumina silicate fiber paperboard, in particular to modified adhesive. The raw material of the alumina silicate fiber paperboard comprises sodium silicate and modifying agent, wherein the modifying agent consists of the following components at mass ratio: 1 part of sodium hydrogen phosphate, 1 part of sodium tetraborate and 1 part of silica sol; the mass ratio of the sodium silicate to the modifying agent is (8-12):(1-5). The preparation method for the alumina silicate fiber paperboard comprises the following steps of: adding the alumina silicate fiber into the modified adhesive disclosed in a patent claim 1 or 2 to obtain alumina silicate fiber slurry, wherein the mixing time is 10-30 times; and molding, finishing and drying, wherein the mass ratio of the alumina silicate fiber to the modifying agent is (1-2):(8-12). According to the invention, the alumina silicate fiber paperboard with low density and low thermal conductivity is obtained, the production technology is clean, and no wastewater is discharged.

Owner:QILU UNIV OF TECH

Clean production method of chlorinated polyethylene

ActiveCN103755845AAchieving zero emissionsEnergy saving and emission reduction effectChemistryZero emission

The invention discloses a clean production method of chlorinated polyethylene. The clean production method adopts a hydrochloric acid phase suspension process which comprises the following steps: preparation of a supernatant solution, a chlorination process, a deacidification process, a centrifugation and drying process. The deacidification process includes two stages of filtration and deacidification; a chlorinated polyethylene slurry material is subjected to a first stage of filtration, a concentrated hydrochloric acid contained in the slurry material is filtered out and put into a concentration acid storage tank, subsequently the slurry material is subjected to a second stage of filtration, the acid residue in the slurry material is washed by water and filtered out to form a diluted hydrochloric acid, and then the diluted hydrochloric acid is put into a diluted acid storage tank. The production method disclosed by the invention has the beneficial effects that by the two stages of filtration and deacidification, the concentrated hydrochloric acid in the slurry material is totally recycled and sold after the chlorination reaction, and the diluted hydrochloric acid generated by washing the slurry material after the reaction is totally recycled as well, thus zero emission of acidic water generated after the chlorination reaction and during filtration and washing is realized, the energy conservation and emission reduction effects are obvious, the production cost is further lowered, and the production process is efficient, clean and environment-friendly.

Owner:WEIFANG YAXING GRP CO LTD +1

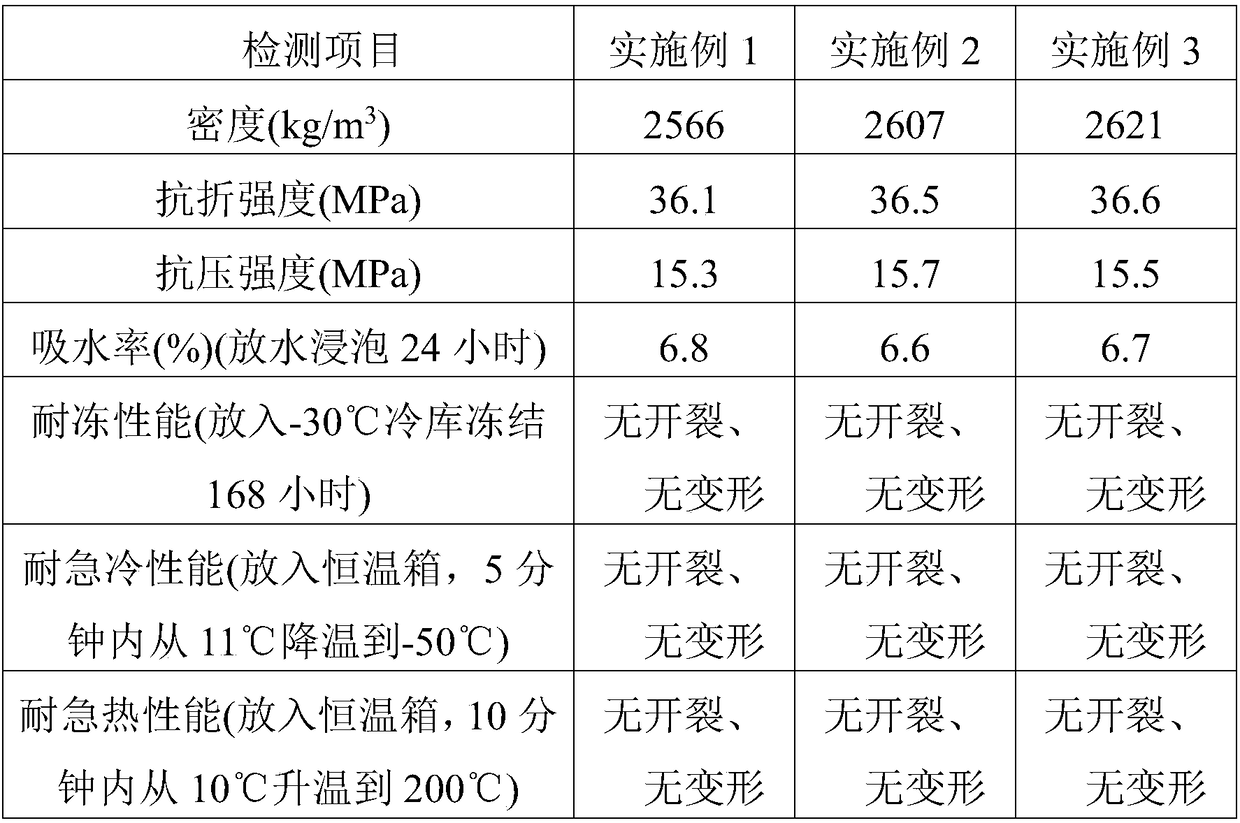

Brownish red gangue encaustic tile and preparation method thereof

InactiveCN108503337ASolve the key technical problems that reduce the service lifeIncrease consumptionCeramic extrusion diesClay mixing apparatusResource utilizationEncaustic tile

The invention belongs to the technical field of building materials, and particularly relates to a brownish red gangue encaustic tile and a preparation method thereof. Preparation materials of the gangue encaustic tile comprise gangue sand, a harmless treating agent, a glaze complexing agent and water; the harmless treating agent is composed of calcium chloride, quick lime and land plaster which are mixed; harmless treatment is carried out on the gangue, and the technical problem is solved that a gangue product separates out crystal substances during the long-term use process in a natural environment so as to reduce the service life; the invention provides a new method of gangue resource utilization, the gangue consumption is increased, the production process is clean and environmentally friendly, and the productivity is high; according to the gangue encaustic tile, the development and utilization of the gangue resources are improved, and the additional valve of products can be effectively improved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

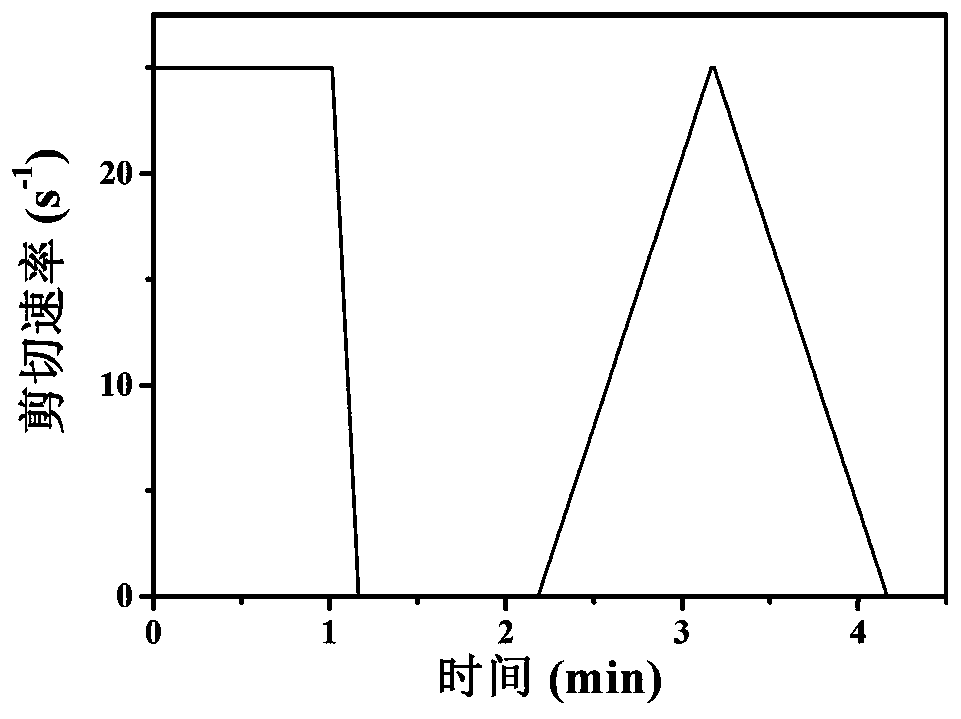

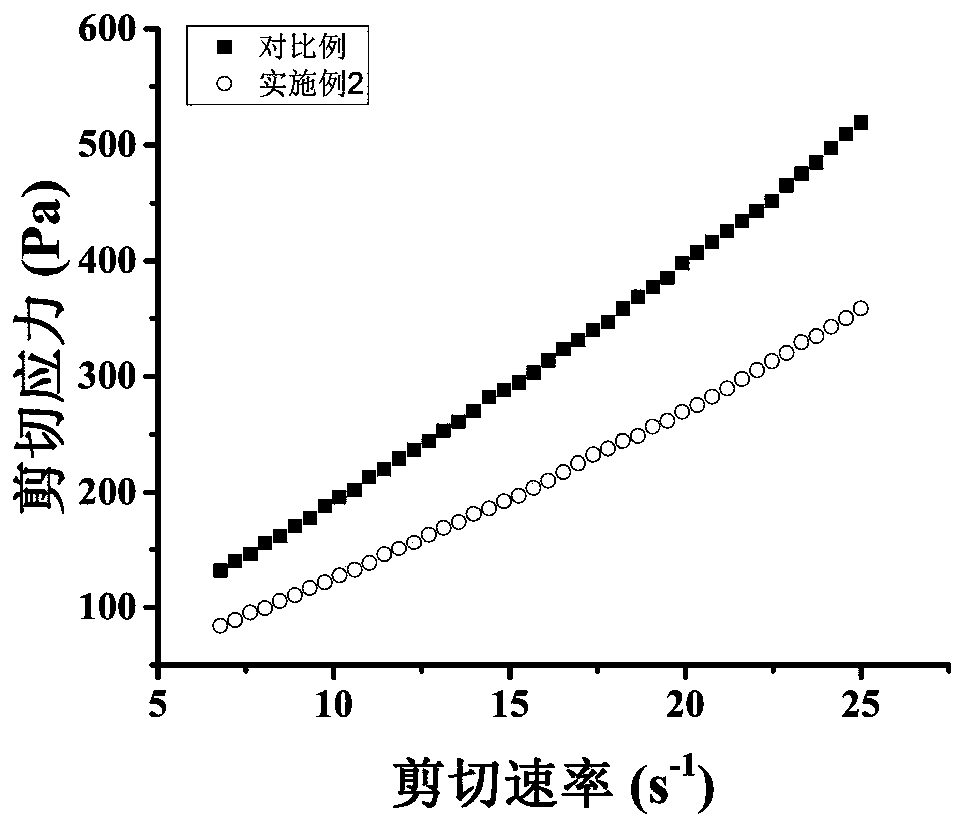

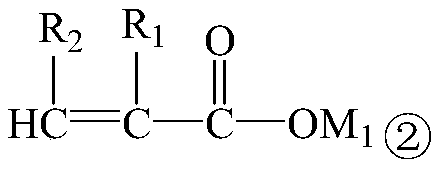

Star-shaped polycarboxylate superplasticizer with controllable molecular structure and preparation method thereof

The invention provides a star-shaped polycarboxylic acid cement dispersant with a controllable molecular structure and a preparation method of the star-shaped polycarboxylic acid cement dispersant. The star-shaped polycarboxylate superplasticizer with the controllable molecular structure is a star-shaped RAFT chain transfer agent obtained by performing amidation / imidization reaction of polyethylene polyamine and a carboxyl-containing chain transfer agent, and then carrying out reversible addition-fragmentation chain transfer polymerization with unsaturated acid, unsaturated phosphate and an unsaturated macromonomer to obtain the star-shaped polycarboxylate superplasticizer with the controllable molecular structure. The product produced by the invention has the advantages of low mixing amount, high water reducing rate, small slump loss, good cement adaptability, remarkable reduction of slurry viscosity at low water-binder ratio and the like. Reversible addition-fragmentation chain transfer polymerization is adopted, the synthesis method is simple, the production process is clean, and the production cost is low.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

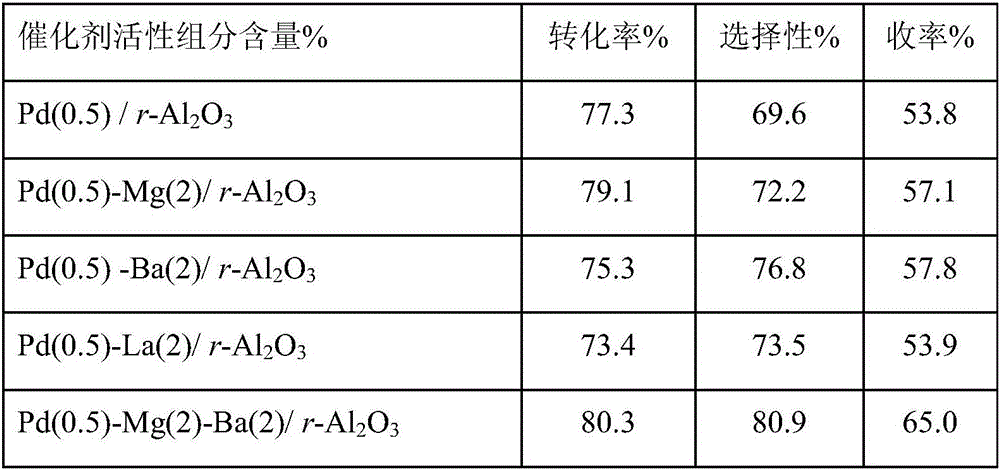

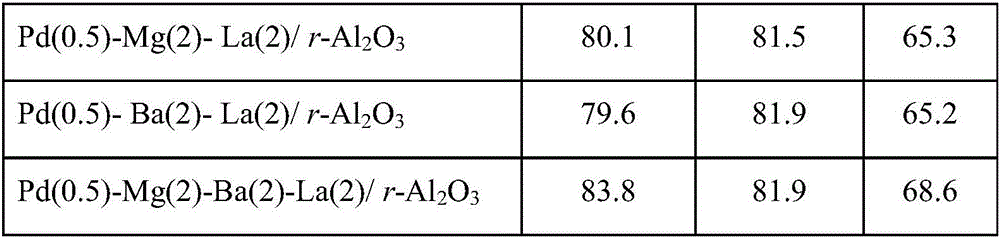

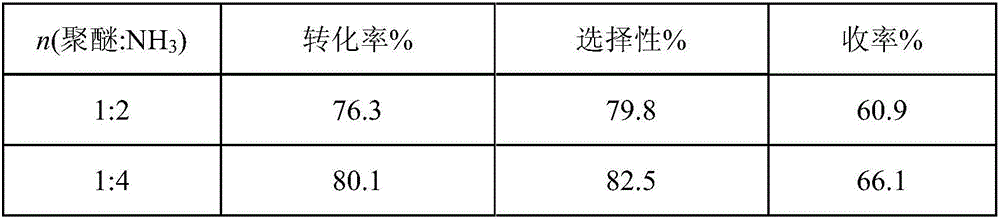

Method for preparing polyether amine through normal pressure catalysis

ActiveCN106832251AReduce difficulty of reactionSimple reaction conditionsMetal/metal-oxides/metal-hydroxide catalystsHydrogenFixed bed

The invention relates to a method for preparing polyether amine through normal pressure catalysis, and belongs to the technical field of organic high-molecular compound preparation or chemical processing. Polyoxyethylene ether, liquid ammonia and hydrogen gas are used as raw materials; the raw materials are introduced into a tubular fixed bed reactor filled with catalysts; the reaction temperature is controlled at 160 to 210 DEG C; the polyether air speed is 0.1 to 4 g / h / g / cat; the ratio of the feeding speed rate of the polyether to the feeding speed rate of liquid ammonia to the feeding speed rate of the hydrogen gas is 1:(3 to 12):(3 to 12); after the reaction is completed, filtering is performed to obtain the polyether amine product. When the method is applied to the polyether amine production, the advantages of mild reaction condition, high controllability and the like are realized.

Owner:ZHEJIANG HUANGMA TECH +3

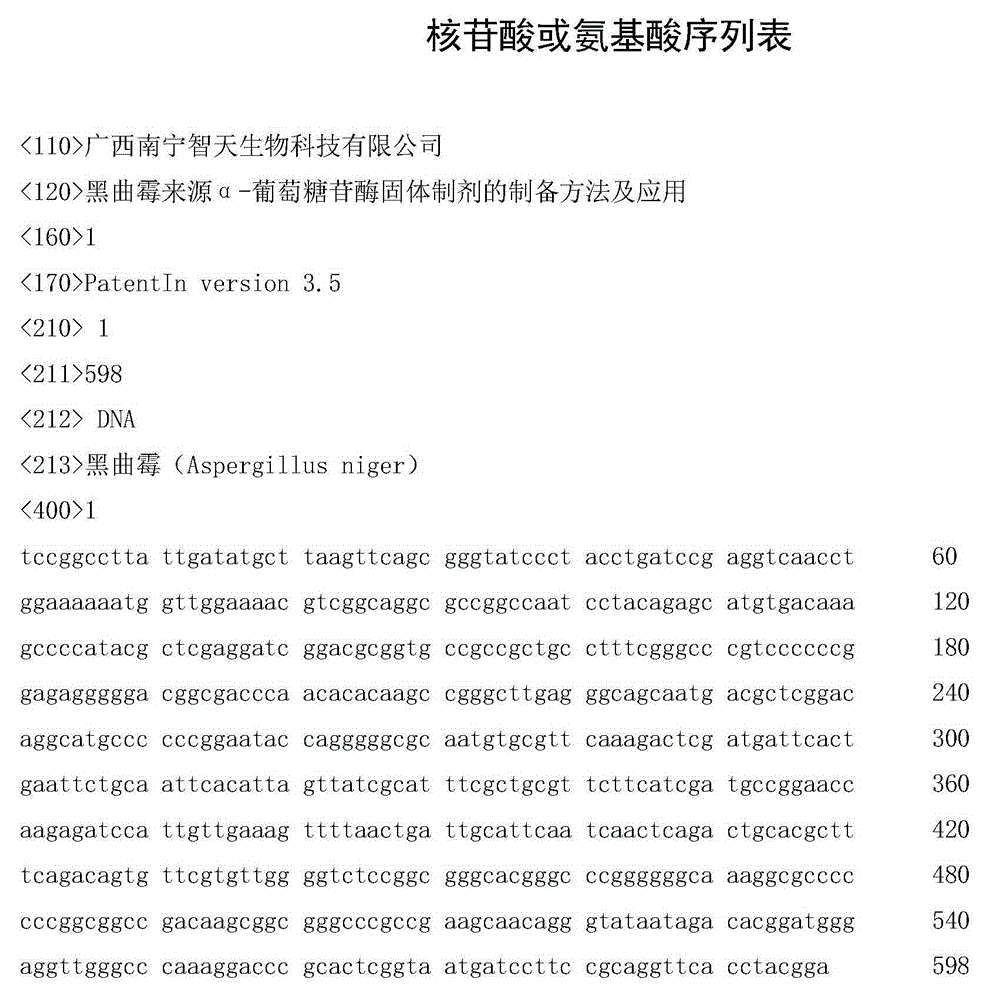

Preparation method of aspergillus niger-source alpha-glucosidase solid preparation and application thereof

ActiveCN104877978ASimple production processReduce manufacturing costMicroorganism based processesEnzymesAlgluceraseMycelium

The invention discloses a preparation method of an aspergillus niger-source alpha-glucosidase solid preparation and its application. The preparation method specifically relates to the following technological processes: (1) carrying out liquid culture of an aspergillus niger Mi strain, and collecting mycelium containing alpha-glucosidase by a centrifugation or membrane separation technique; (2) keeping the above mycelium intact or grinding to prepare cell debris or powder; and (3) freeze-drying or spray-drying the intact mycelium, cell debris or powder, metering and subpackaging to prepare the alpha-glucosidase solid preparation. The method provided by the invention has advantages of simple and clean production technology and low production cost. The alpha-glucosidase preparation is used for converting a starch saccharification solution or malt syrup to produce isomalto-oligosaccharide and can be used to greatly reduce production cost in comparison with a foreign commercial enzyme preparation.

Owner:GUANGXI NANNING ZHITIAN BIOTECH

Nature-identical 2,3-butanedione flavor and preparation method thereof

InactiveCN101885673AImprove conversion rateHigh degree of naturalnessCarbonyl compound preparation by condensationCarbonyl compound separation/purificationFood flavorAcetaldehyde

The invention relates to a nature-identical 2,3-butanedione flavor and a preparation method thereof. The nature-identical 2,3-butanedione flavor contains the following components in parts by weight: 1000 parts of acetaldehyde and 1-10 parts of composite catalyst. By adopting the technology of the invention, the raw materials are accessible, the conversion rate of the raw materials is high, the conditions of the two-step reaction are mild, the content of 2,3-butanedione in the product is high, the natural degree is high, the production technology is clean, mass production can be realized, the production cost is low, and three wastes can not be generated.

Owner:HENAN HUALONG SPICE

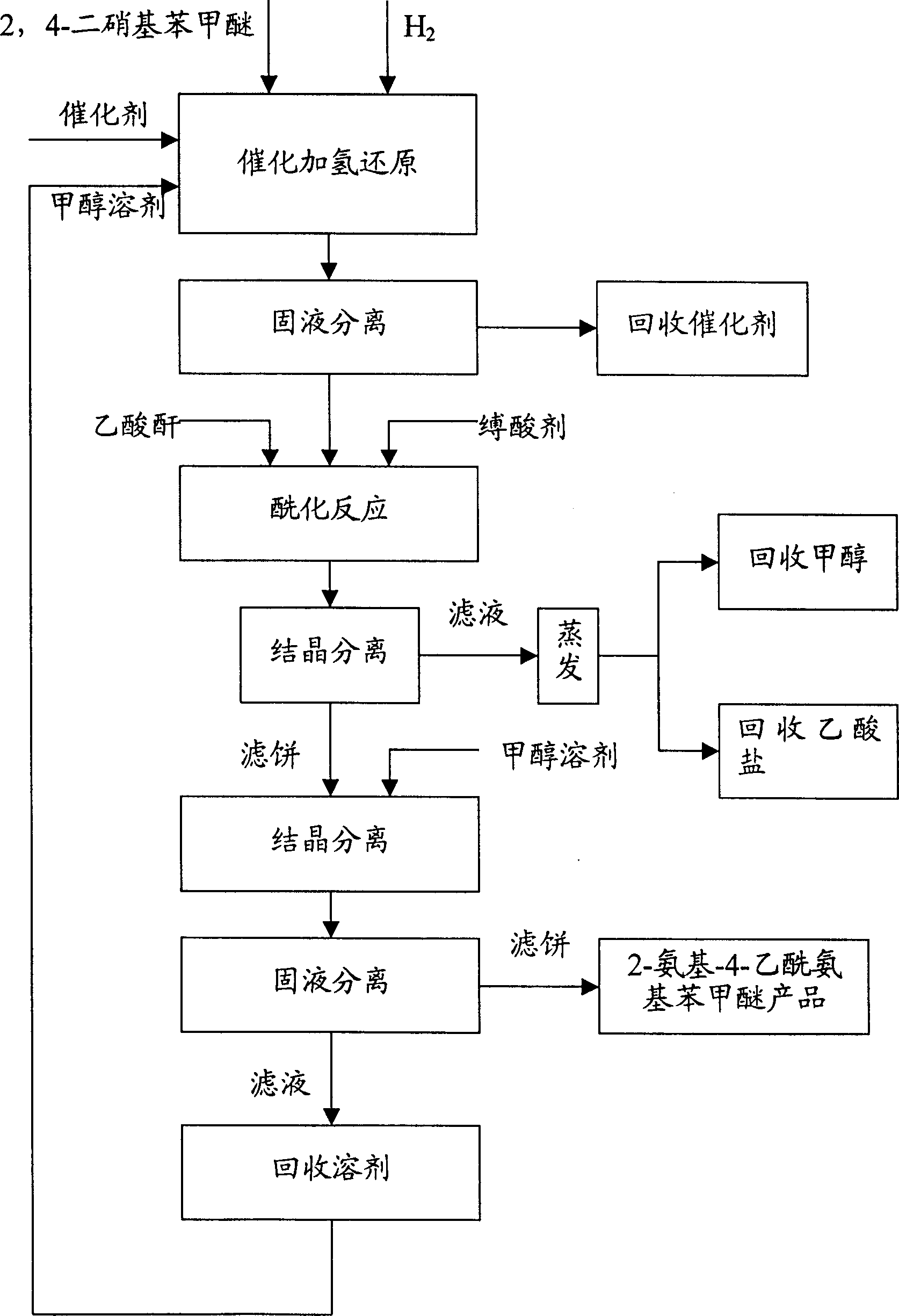

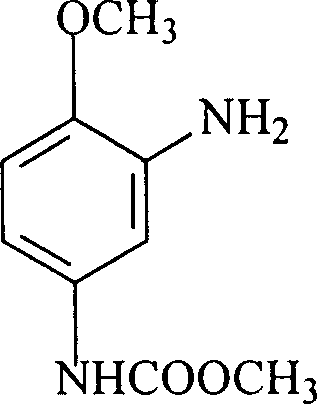

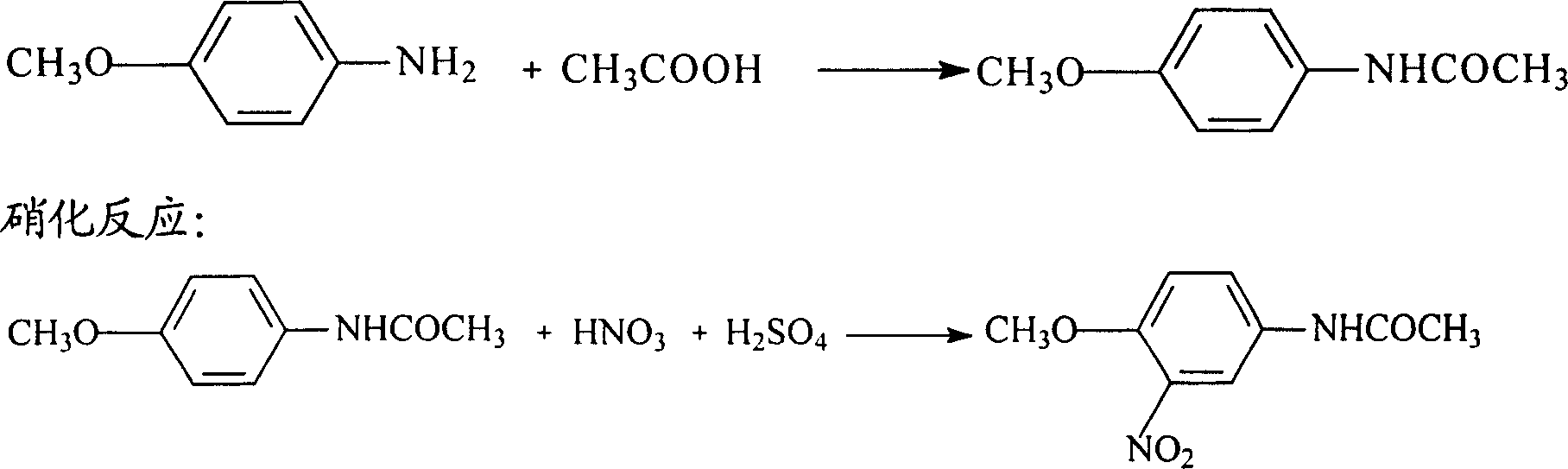

Tech. of preparing 2-amino-4-acetamido methyl-phenoxide

InactiveCN100368385CHigh purityEasy to recycleOrganic compound preparationCarboxylic acid amides preparationAcetic anhydrideSolvent

A process for preparing 2-amino-4-acetamino phenylmether includes such steps as catalytic hydroreducing reaction between methanol, 2,4-dinitro phenylmether and catalyst, solid-liquid separation, recovering catalyst, adding acid binding agent and the methanol solution of acetic anhydride, acelating reaction, cooling while crystallizing, filtering to obtain filtered cake recrystallizing in methanol, and separation.

Owner:CHANGZHOU JIASEN CHEM +1

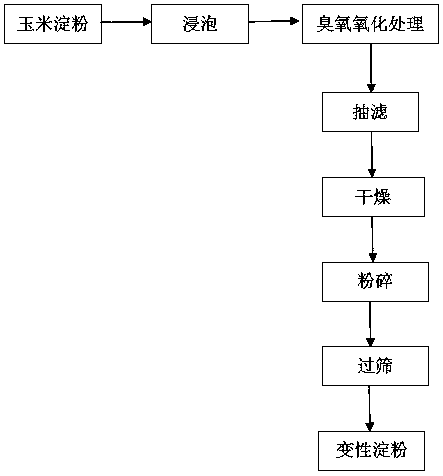

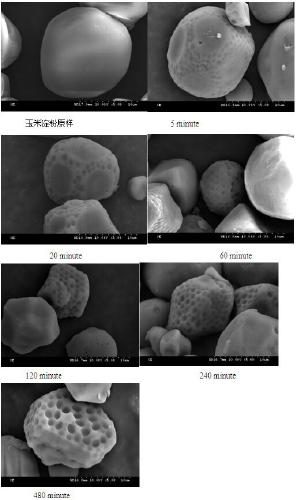

Method for preparing modified starch by utilizing ozonation

The invention relates to a method for preparing modified starch by utilizing ozonation, and belongs to the technical field of deep processing of starch. The preparation method comprises the steps of soaking of corn starch, ozonation, extraction filtration, drying, crushing and sieving so as to obtain oxidized modified starch, wherein the ozonation conditions are as follows: corn starch milk with different concentrations after soaking is oxidized under the condition of 1 L / min of ozone flow, and the oxidation time is 5 min-480 min. The method provided by the invention is easy to control and simple to operate; a production process is clean; no pollution is caused to the environment; used reagents and materials are of common specifications and the production cost is low; no residues exist during production; the modified starch prepared by the method has no chemical reagent residues, and can be better applied to the fields of food and medicine.

Owner:QIQIHAR UNIVERSITY

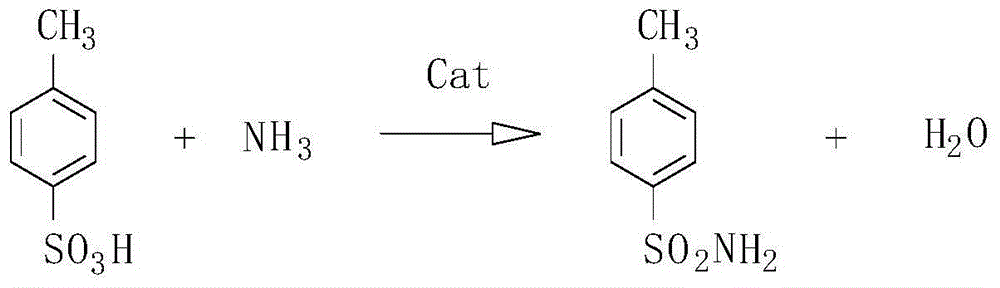

Method for preparing para toluene sulfonamide by directly amidating para-toluenesulfonic acid

ActiveCN104945288AHigh reactivityIncrease electropositivityOrganic compound preparationSulfonic acid amide preparationTosylic acidFiltration

A method for preparing para toluene sulfonamide by directly amidating para-toluenesulfonic acid comprises the following steps: (1) anhydrous para-toluenesulfonic acid is dissolved in dichloromethane, a catalyst, namely organic boronic acid, and a 5A molecular sieve are added in a mixed solution, and the mixed solution is uniformly stirred for a certain time under the condition that the temperature is controlled to be -10 to 0 DEG C; (2) an ammonia gas is introduced at the -10 to 0 DEG C for reaction; (3) after the reaction is finished, suction filtration is conducted on the reaction liquid to remove the molecular sieve, and then washing is respectively performed once with an acid solution, an alkali solution and a salt solution; (4) an organic phase is dried through anhydrous sodium sulfate, then a drying agent is removed, a dichloromethane solvent is subjected to distillation recovery, and crude para toluene sulfonamide is obtained; (5) weighing is performed after washing with distilled water and drying, and the product purity is analyzed through liquid chromatography. The complexation is generated between organic boric acid energy and oxygen on a sulfonic acid molecule, the reaction activity of the para-toluenesulfonic acid is improved, ammonia molecules are easily combined with sulfur to generate amide, the whole reaction energy consumption is low, no waste acid is discharged, and the yield of para toluene sulfonamide is about 40%.

Owner:浙江嘉福新材料科技有限公司

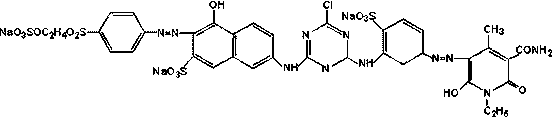

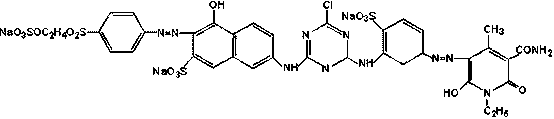

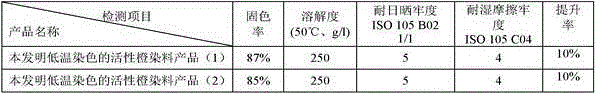

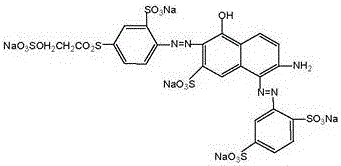

Bright orange reactive dye as well as preparation method and application thereof

InactiveCN105504872AEliminate emissionsGood dyeing depthReactive dyesDyeing processRubbingPhotochemistry

The invention discloses bright orange reactive dye as well as a preparation method and an application thereof. The bright orange reactive dye is a compound adopting the structure shown in Formula I. The bright orange reactive dye has the characteristics of good deep dyeing property, bright color, Grade 5 of light fastness, Grade 4 of fastness to wet rubbing, higher than 85% of the fixation rate, high cleaning rate and the like.

Owner:HUBEI HUALI DYESTUFF INDAL

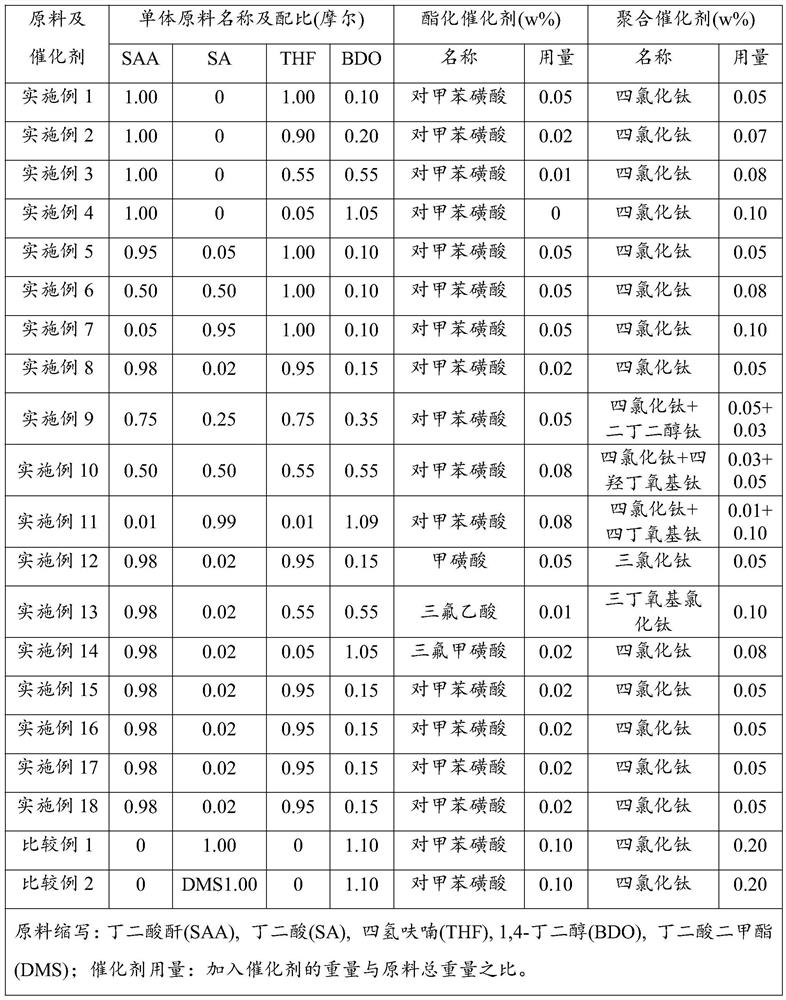

Method for synthesizing poly (1, 4-butanediol succinate) through ring-opening polymerization

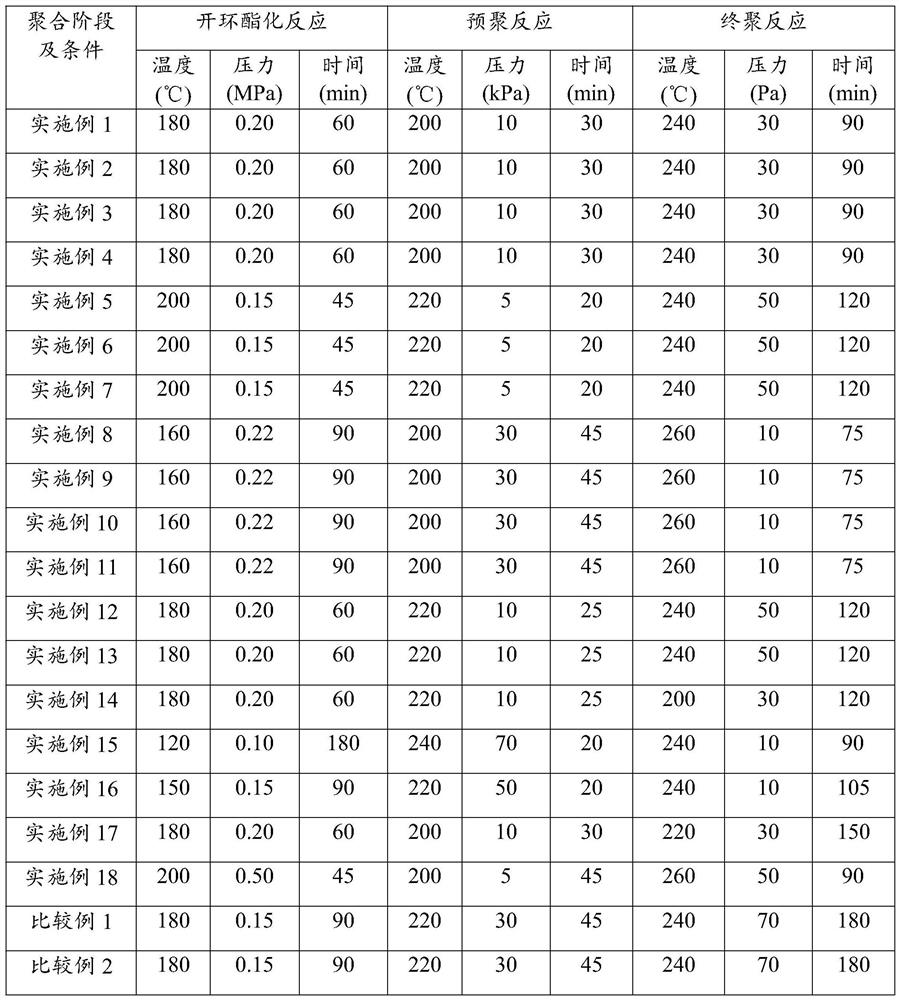

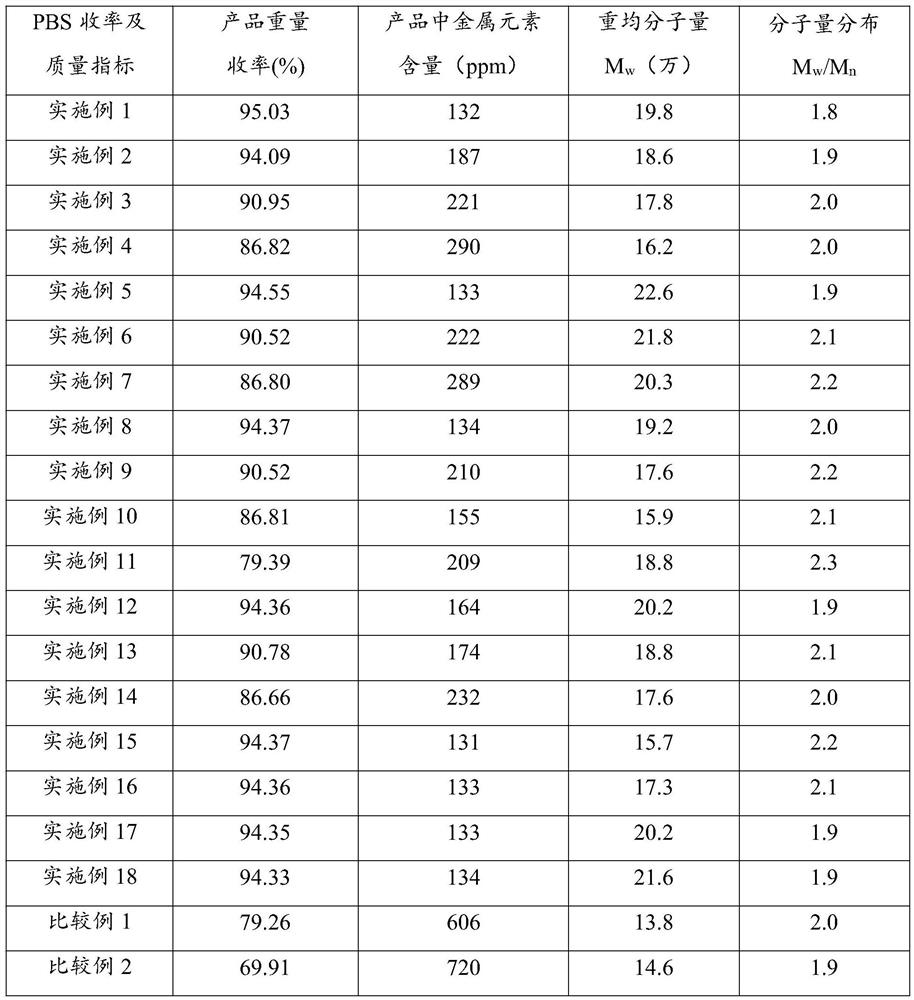

The invention provides a method for synthesizing poly (1, 4-butanediol succinate) through ring-opening polymerization, the method comprises the following steps: taking two cyclic monomers, namely succinic anhydride and tetrahydrofuran, as main raw materials and 1, 4-butanediol and / or succinic acid as auxiliary monomer raw materials, under the action of a composite catalyst, preparing the poly (1, 4-butylene succinate) (PBS) through three reaction steps of ring-opening esterification, pre-polymerization and final polymerization; essentially, transmission of active groups (hydroxyl and carboxyl) is achieved through addition-ring opening, growth of chains (alkyl and ester groups) is achieved through esterification-condensation, and finally high-molecular-weight PBS is obtained through polycondensation. Compared with the prior art, the PBS product synthesized by the method has the advantages of high polymerization degree, good chromaticity, low raw material and energy consumption and high product yield so that the quality of the PBS product can be improved, the production cost can be reduced, and the process is clean and environment-friendly.

Owner:SHANGHAI NORMAL UNIVERSITY +1

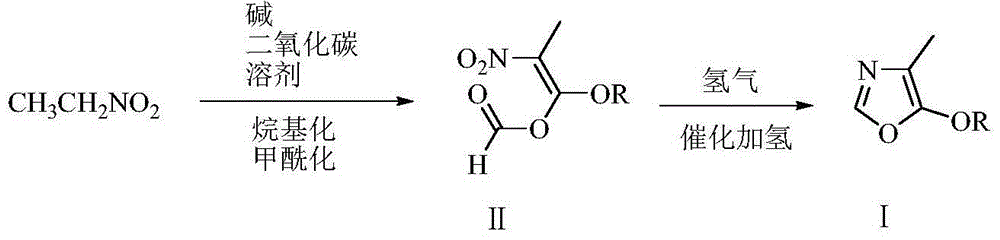

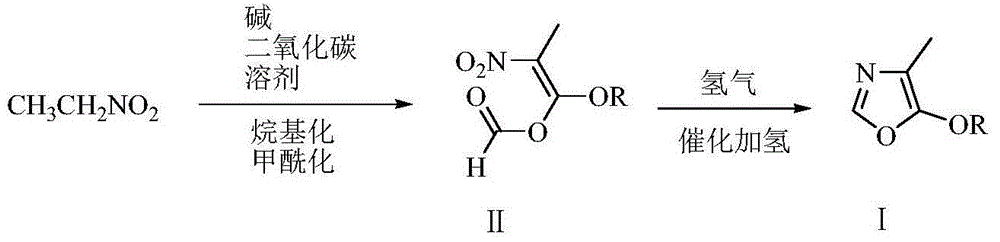

Low-cost environment-friendly preparation method of 4-methyl-5-alkoxy oxazole

The invention relates to a low-cost environment-friendly preparation method of 4-methyl-5-alkoxy oxazole. The method comprises the following steps: introducing carbon dioxide into a mixture of nitroethane, alkaline reagent and solvent, carrying out alkylation reaction and formylation reaction to generate 1-alkoxy-1-formyloxy-2-nitropropylene, and directly carrying out catalytic hydrogenation cyclization reaction without separation to obtain the 4-methyl-5-alkoxy oxazole. The method has the advantages of cheap and accessible raw materials, simple reaction operation, low product cost, no discharge of waste liquid or wastewater, high safety and environment friendliness.

Owner:XINFA PHARMA

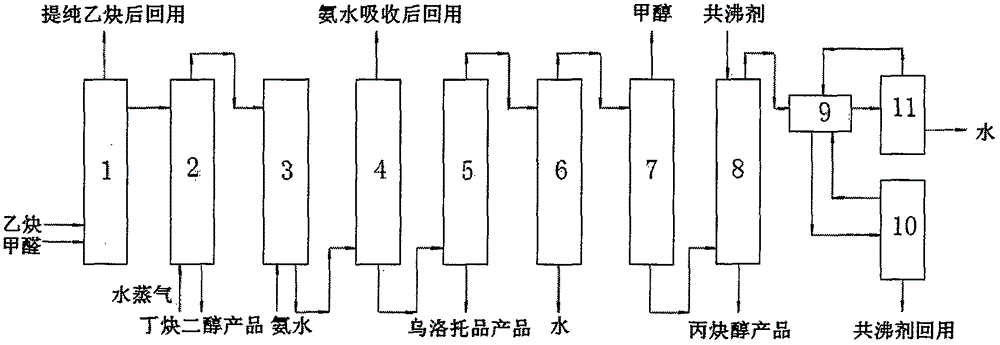

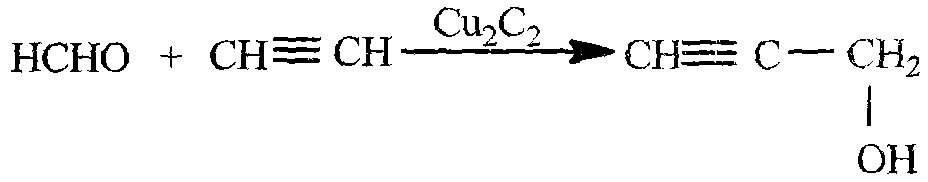

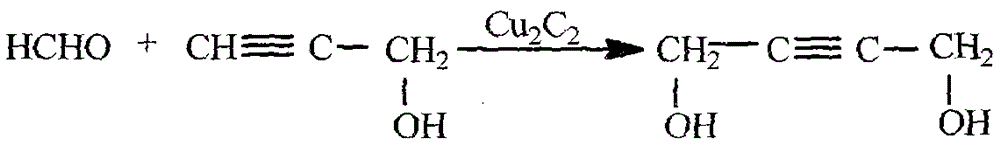

A kind of triple production continuous production method of propynyl alcohol, 1,4-butynediol and urotropine

ActiveCN104387236BAvoid wastingSolve the emission problemOrganic compound preparationHydroxy compound preparationAlcoholHexamethylenetetramine

Owner:HANGZHOU ZJU HOLLEY TECH

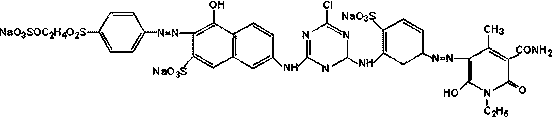

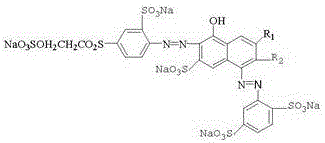

Active orange dye for low temperature dyeing and preparation method thereof

ActiveCN106065199AEmission reductionImprove responseDisazo dyesDyeing processStructural formulaEnergy consumption

The invention discloses an active orange dye for low temperature dyeing and a preparation method thereof. The structural formula of the active orange dye is as shown in the formula 1. in the formula 1, one of R1 and R2 is -NH2 and the other is H. the active orange dye is suitable for low temperature dyeing (about 40 DEG C), has stable reaction properties, good level-dyeing property and high coloring rate, and is easy to wash, and is helpful for reducing energy consumption.

Owner:HUBEI HUALI DYESTUFF INDAL

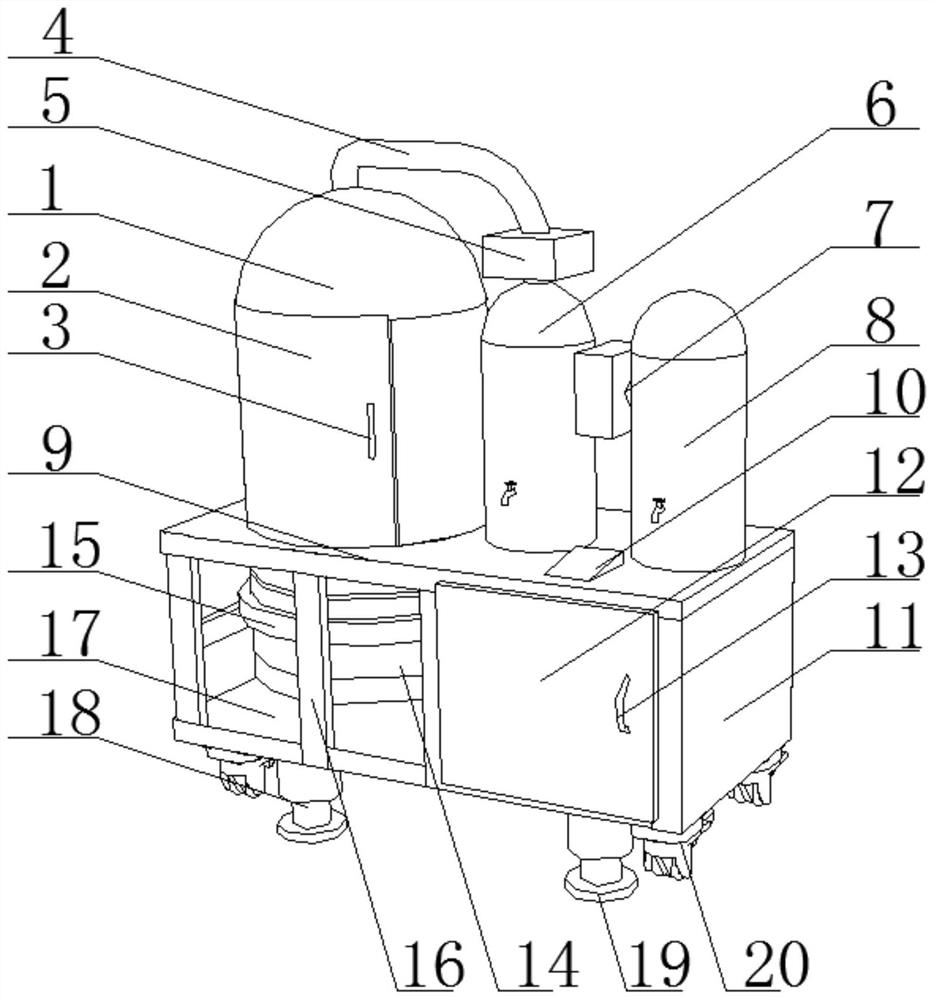

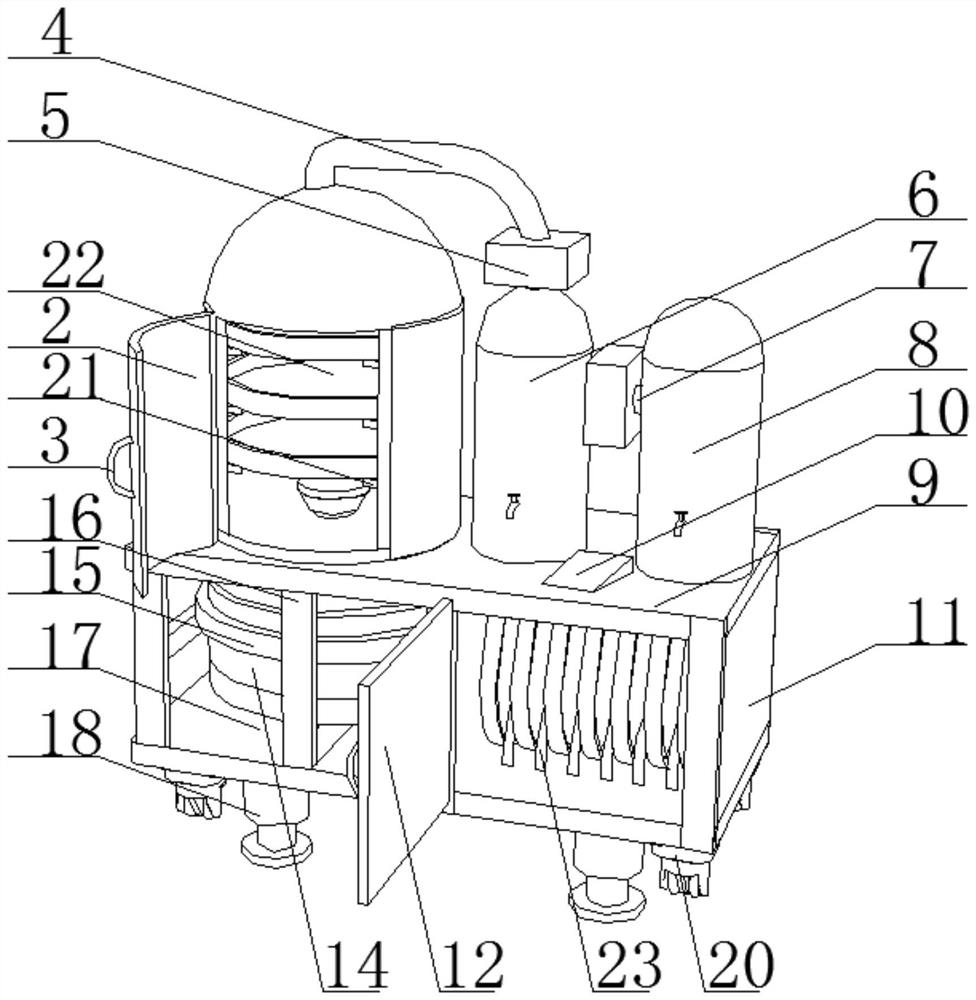

Low-pressure distillation equipment for scallion oil production and use method

PendingCN112500922AProduction process cleaningPrevent heat lossFatty-oils/fats refiningDrying gas arrangementsOil productionProcess engineering

Disclosed low-pressure distillation equipment for scallion oil production comprises a distillation bin main body, a first door is arranged on the outer surface of the side end of the distillation binmain body, a first handle is arranged on the outer surface of the front end of the first door, and a first pipeline is arranged on the outer surface of the top end of the distillation bin main body; and a condenser is arranged on the outer surface of the side end of the first pipeline, a first extraction tank is arranged on the outer surface of one side of the first pipeline, and a workbench is arranged on the outer surface of the lower end of the distillation bin main body. The low-pressure distillation equipment for scallion oil production and the use method have the advantages that in the scallion oil production process, the equipment is provided with a working table, suitable for scallion oil production process, capable of collecting extracts in a graded mode and high in utilization rate, an electric heating structure can prevent waste gas generated by combustion of mineral fuel from polluting the atmospheric environment, and the production process is cleaner; and finally, a distilled tool can be subjected to concentrated high-temperature sterilization, and is convenient to use next time.

Owner:湖南葱油哥农业发展有限公司

Planting method for organic rice

InactiveCN107711366AIncrease productionImprove qualityGrowth substratesCulture mediaFiberComposite substrate

The invention provides a planting method for organic rice. The method utilizes primary products produced by digestion of crop stalks, such as a plant growth substrate, a compound fertilizer and fiberbundles to manufacture a fertilizer fiber field membrane and a composite substrate template which are specially required by planting of the organic rice through fine preparation and deep processing production, the composite substrate template is utilized when rice seedlings are cultivated, the input costs are low, the seedlings can be raised in advance by 3-5 days, the method is soilless, has no pests or diseases, saves work and labor, and guarantees farming seasons, a pesticide does not need spraying in the process, and the cultivated seedlings are robust and have high quality; and when the rice seedlings are transplanted, the fertilizer fiber field membrane is combined, so that the rice seedlings can be saved, and the layout is reasonable. The use of the fertilizer fiber field membrane can not only block sunlight, inhibit weeds, and gradually reinforce ventilation functions, but also have functions of adjusting a temperature, preventing water and soil loss, preserving soil moisture,and cultivating land fertility, the field membrane can be degraded on schedule, and the product has no primary or secondary pollution. The planting method provided by the invention realizes all-element harmless and comprehensive development of the crop stalks, provides a pathway of fully recycling the crop stalks, and is very energy-saving and environmentally-friendly.

Owner:李利恒

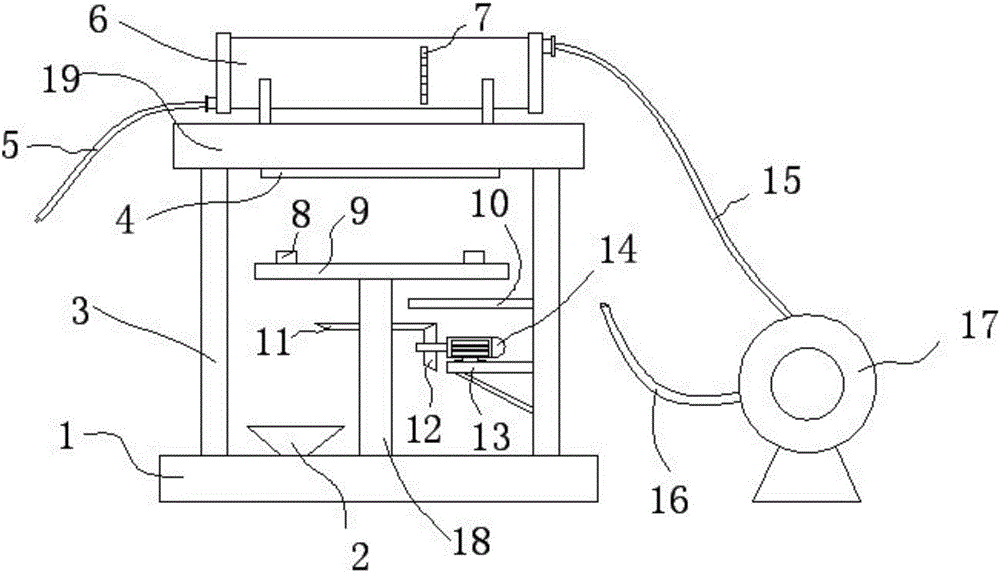

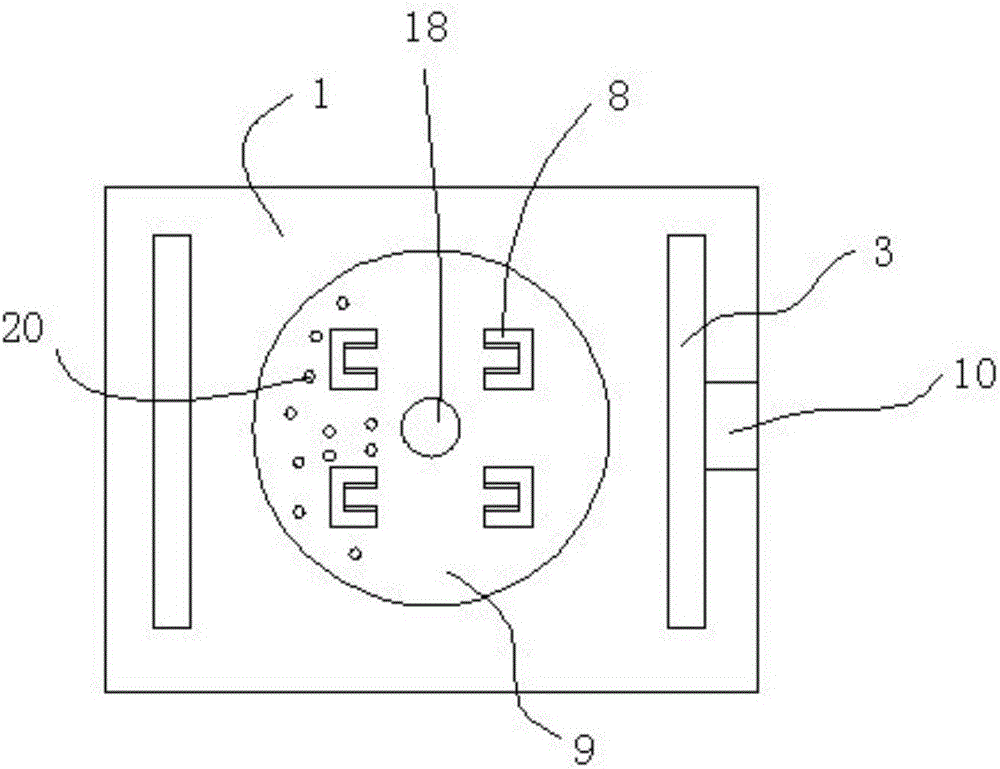

Heating radiator set inner wall anticorrosion layer generating device

InactiveCN105750166AProduction process cleaningEnergy savingPretreated surfacesCoatingsEngineeringBevel gear

The invention provides a heating radiator set inner wall anticorrosion layer generating device which comprises a rotating table, a paint barrel and an upper beam for supporting the paint barrel.The rotating table is located below the upper beam.A clamp for clamping a heating radiator set is welded to the rotating table.A shaft is welded to the lower end of the rotating table and provided with a driven bevel gear.The diameter of the driven bevel gear is smaller than that of the rotating table.A through hole for paint to fall therein is formed in the left half portion of the rotating table.A filter screen is arranged in the paint barrel.By means of the device, an anticorrosion layer of the inner wall of the heating radiator set can be rapidly generated and dried, production process is clean, paint is used in a circulating mode, energy is saved, production efficiency is improved, and cost is saved for enterprises.

Owner:TIANJIN JULONG HVAC EQUIP DEV

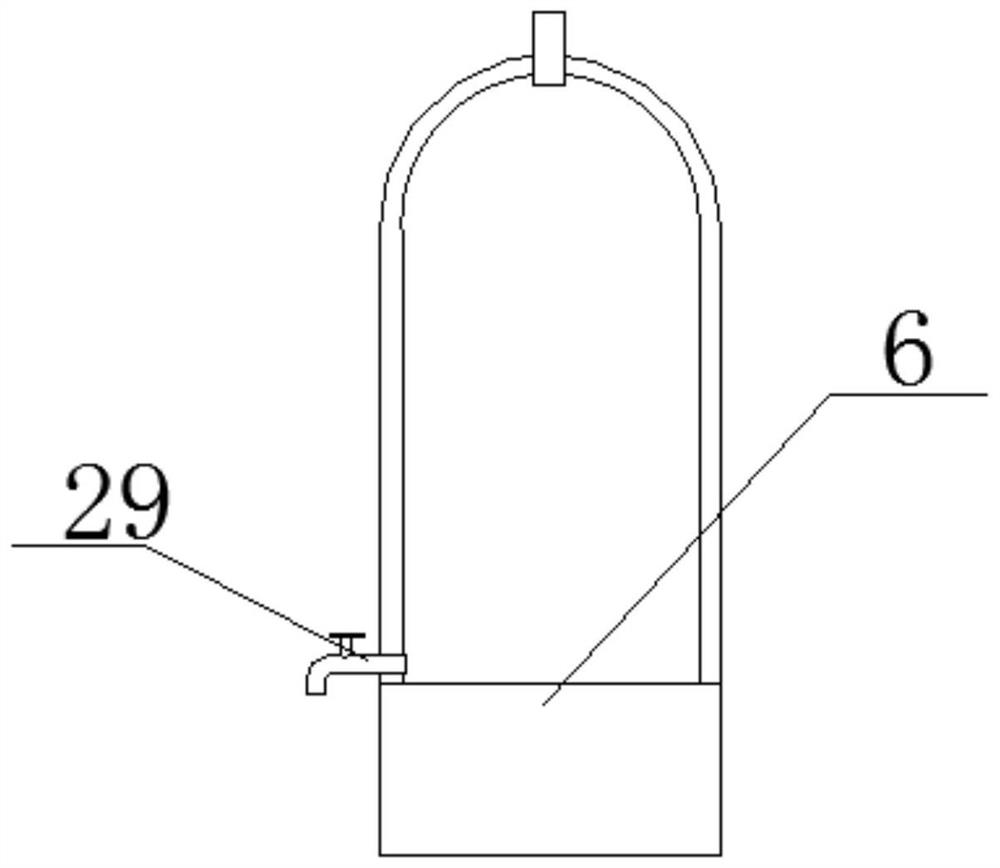

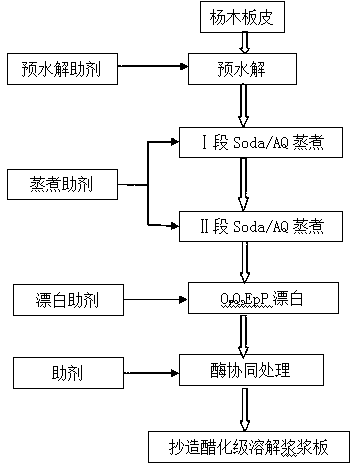

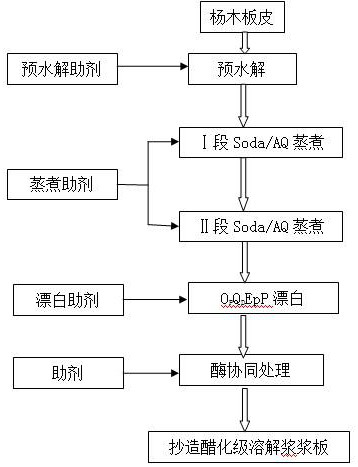

Method for producing acetification-grade dissolving pulp by using veneer

InactiveCN109403115AHigh purityImprove responsePretreatment with water/steamPulping with organic compoundsDissolving pulpStage ii

The invention relates to the technical field of dissolving pulp preparation and particularly relates to a method for producing acetification-grade dissolving pulp by using veneer. The method comprisesthe following steps: adding auxiliaries for prehydrolysis; Soda / AQ cooking stage I; Soda / AQ cooking stage II; OPDQEPP bleaching; enzyme collaborative treatment. The veneer acetification-grade dissolving pulp with high purity and high reaction activity is prepared; the applied chemicals are clean and environmentally friendly, and the production technology is clean.

Owner:QILU UNIV OF TECH

Tin-plated steel plate printed on one side and coated with baking-resistant floral frame printing and its manufacturing method

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

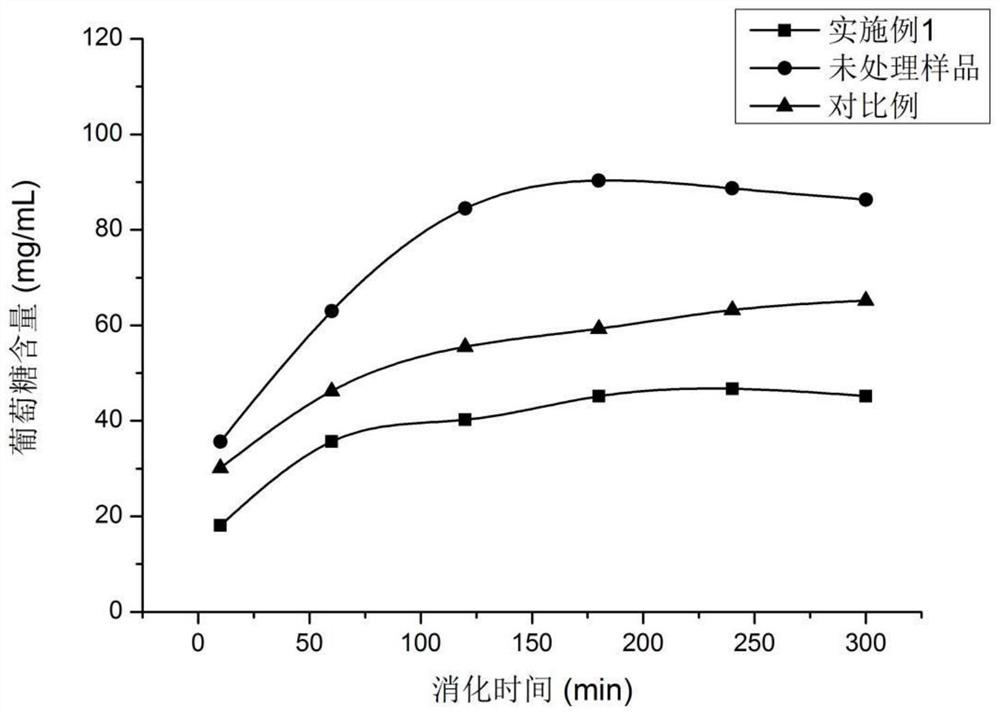

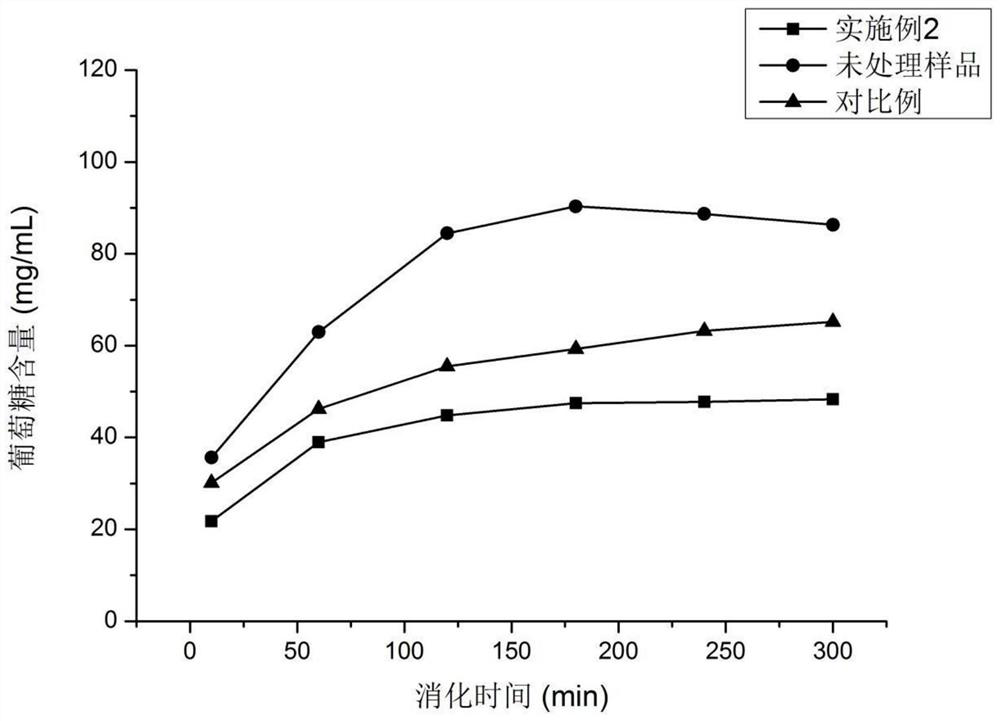

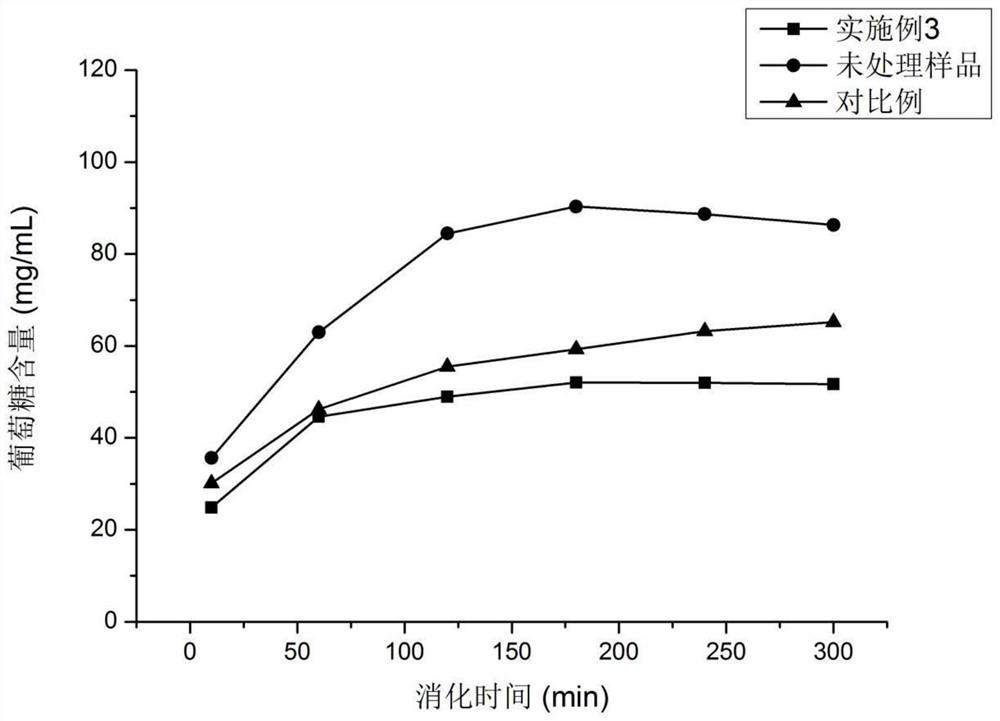

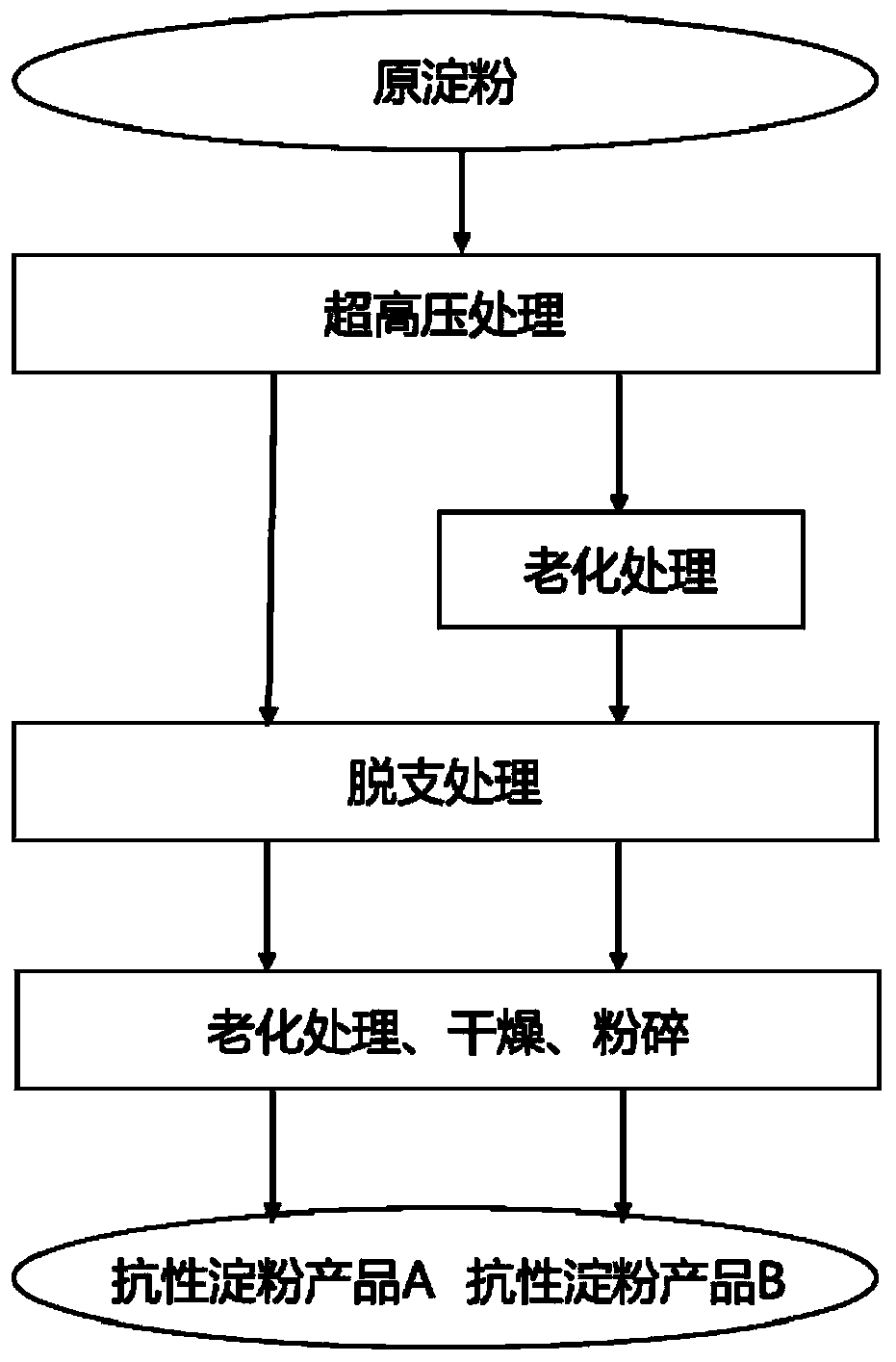

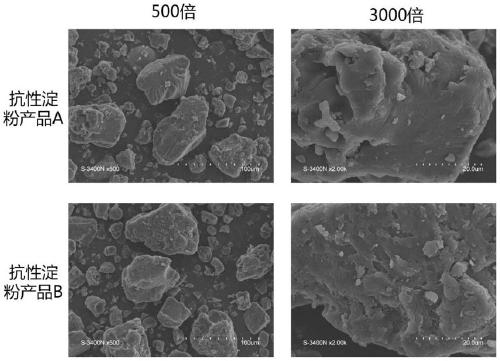

Waxy wheat RS5 type resistant starch and preparation method thereof

PendingCN114451556AHigh composite indexPrevent Type 2 DiabetesFermentationFood ingredient functionsResistant starchPullulanase

The invention belongs to the technical field of resistant starch processing, and particularly relates to waxy wheat RS5 type resistant starch and a preparation method thereof. Waxy wheat starch and high-amylose corn starch are taken as substrates, pullulanase is adopted for debranching, then branching enzyme is adopted for high branching treatment, and then the treated materials react with lipid to obtain the waxy wheat RS5 type resistant starch. The novel RS5-type resistant starch can be obtained, and the resistant starch is high in composite index and low in GI value.

Owner:河南省农业科学院农副产品加工研究中心

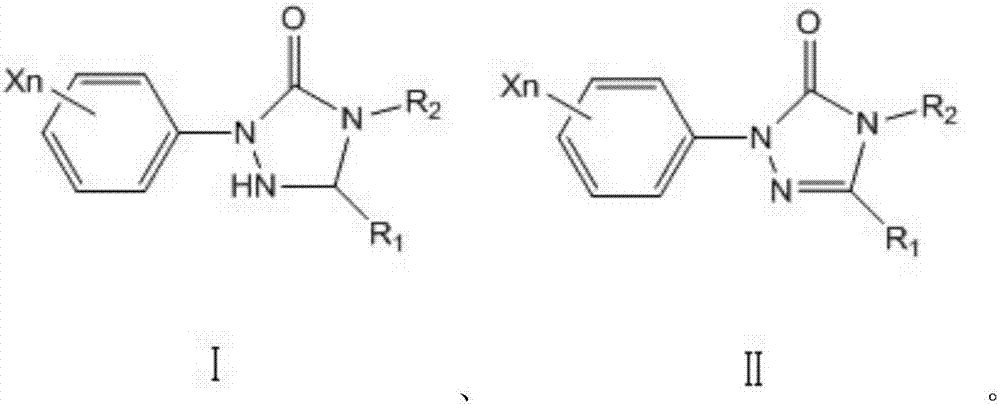

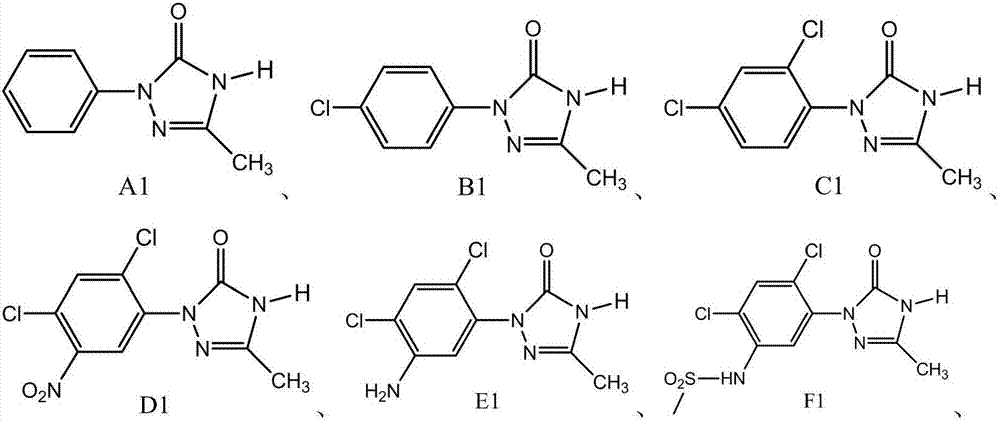

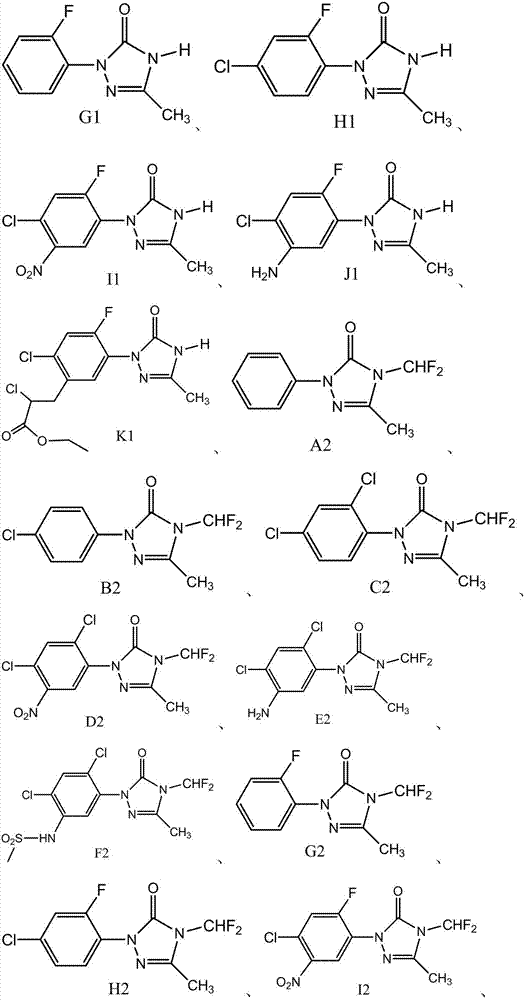

A kind of preparation method of aryl triazolone

The invention discloses a method for preparing aryl triazolinone. The method comprises the following steps: by taking aryl triazolinone as a raw material, taking an oxygen-containing gas or hydrogen peroxide water solution as an oxidant, and taking active carbon as a catalyst, performing oxidation reaction to obtain aryl triazolinone. By adopting the method, a new concept for the synthesis of the aryl triazolinone compound is provided, the hydrogen peroxide solution or the oxygen-containing gas is taken as the oxidant, the active carbon is taken as the catalyst, and the traditional processing modes of hypohalous acid and salt thereof, halogen oxidant or metal compound catalyst are substituted; the halogen and the metal compound are not contained in the wastewater, so that the environment is not polluted; when the optimized active carbon is adopted, the purity and the yield of the product are high. The environment pollution caused by the halogen-containing oxidant and the metal compound is avoided, the production process is clean, the reaction process is environmentally friendly, the product content and the yield are high and the economic and environmental protection benefits are obvious, so that the method is a scientific and environment-friendly novel method for producing the aryl triazolinone compound.

Owner:SHANDONG WEIFANG RAINBOW CHEM

A method of producing vinegar grade dissolving pulp by using poplar veneer

InactiveCN109403115BHigh purityImprove responsePretreatment with water/steamPulping with organic compoundsPulp and paper industryDissolving pulp

The disclosure relates to the technical field of dissolving pulp preparation, and particularly relates to a method for producing acetate grade dissolving pulp utilizing poplar residual slabs. The method comprises the following steps: adding an auxiliary agent for prehydrolysis, performing a Soda / AQ cooking I segment, performing a Soda / AQ cooking II segment, performing OpDQEPP bleaching and performing enzyme coprocessing, thereby preparing high-purity high-reactivity poplar residual slab acetate grade dissolving pulp. In the method, used chemicals are clean and environmental friendly, and production process is clean.

Owner:QILU UNIV OF TECH

A product with high resistant starch content prepared by ultra-high pressure synergistic enzymes and its preparation method

The invention relates to a high-resistant-starch-content product prepared by ultrahigh-pressure coordinated enzyme and a preparation method of the product. The preparation method includes: 1), mixing starch with distilled water to obtain starch suspension, and performing ultrahigh pressure treatment; 2), cooling, adjusting pH, and adding enzyme for debranching; or aging after cooling, adjusting pH, and adding enzyme for debranching; 3), subjecting a sample to enzyme deactivation, aging, drying and grinding to obtain the product. Currently, starched modified products with functional or healthcare effect are still few in type on the market; the modified starch product is high in resistant-starch content and can be expected to be added into low-sugar food that diabetic patients can eat to play a role in assisted treatment or regulating blood sugar.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com