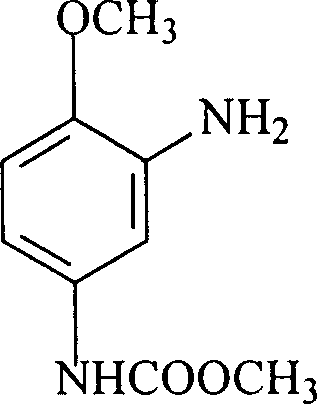

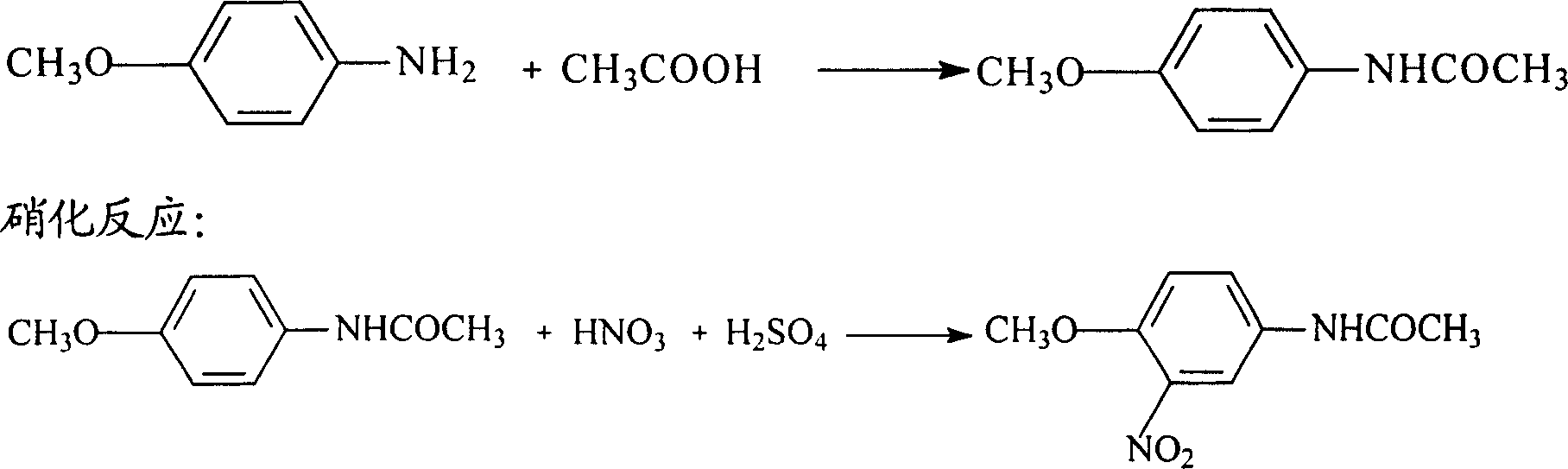

Tech. of preparing 2-amino-4-acetamido methyl-phenoxide

A technology of acetamidoanisole and amino group, applied in the field of preparing 2-amino-4-acetamidoanisole, can solve the problems of serious environmental pollution and high process cost, achieve high product purity, improve operating environment and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

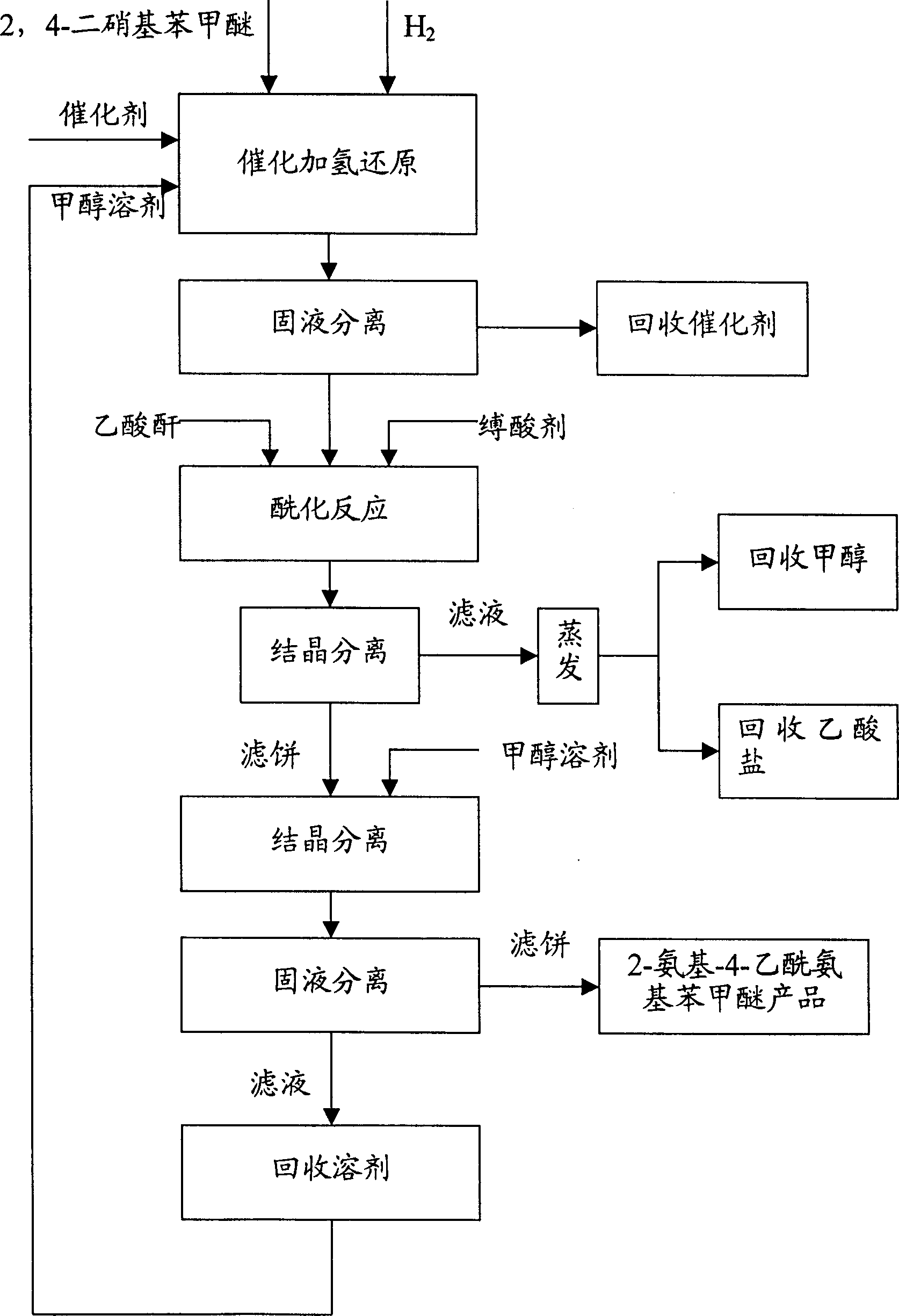

[0032] A kind of technique for preparing 2-amino-4-acetamidoanisole, described process step is as follows:

[0033] (1). Catalytic hydrogenation reduction reaction, using methanol as a solvent, add 2-4 dinitroanisole to the catalytic hydrogenation reduction reactor tank reactor with Raney-Ni as a catalyst, the amount of catalyst is nitro 2.0% of the material, the catalyst particle size is 5.0mm, and then hydrogen is introduced into the stirred tank reactor. The reactor is equipped with a supporting controller, which can display or control the reaction temperature, pressure and stirring speed. For the hydrogen reduction reaction, the temperature is controlled at 120°C, the reaction time is 4 hours, and the operating pressure is 4MPa. During the reaction, the temperature should be controlled to prevent the occurrence of overheating.

[0034] (2). Solid-liquid separation. After the catalytic hydrogenation reduction reaction is completed, solid-liquid separation is carried out aft...

Embodiment 2

[0040] A kind of technique for preparing 2-amino-4-acetamidoanisole, described process step is as follows:

[0041](1). Catalytic hydrogenation reduction reaction, using methanol as a solvent, add 2-4 dinitroanisole to the catalytic hydrogenation reduction reactor tank reactor with Raney-Ni as a catalyst, the amount of catalyst is nitro 4.8% of the material, the catalyst particle size is 9.5mm, and then hydrogen is introduced into the stirred tank reactor. The reactor is equipped with a matching controller, which can display or control the reaction temperature, pressure and stirring speed. For the hydrogen reduction reaction, the temperature is controlled at 180°C during the reaction, the reaction time is 1h, and the operating pressure is 6MPa. During the reaction, the temperature must be controlled to prevent the occurrence of overheating.

[0042] (2). Solid-liquid separation. After the catalytic hydrogenation reduction reaction is completed, solid-liquid separation is carri...

Embodiment 3

[0048] A kind of technique for preparing 2-amino-4-acetamidoanisole, described process step is as follows:

[0049] (1). Catalytic hydrogenation reduction reaction, using methanol as a solvent, add 2-4 dinitroanisole to the catalytic hydrogenation reduction reactor tank reactor with Raney-Ni as a catalyst, the amount of catalyst is nitro 0.5% of the material, the catalyst particle size is 1.0mm, and then hydrogen is introduced into the stirred tank reactor. The reactor is equipped with a supporting controller, which can display or control the reaction temperature, pressure and stirring speed. For the hydrogen reduction reaction, the temperature is controlled at 140°C, the reaction time is 9 hours, and the operating pressure is 2.4MPa. During the reaction, the temperature must be controlled to prevent the occurrence of overheating.

[0050] (2). Solid-liquid separation. After the catalytic hydrogenation reduction reaction is completed, solid-liquid separation is carried out aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com