Tin-plated steel plate printed on one side and coated with baking-resistant floral frame printing and its manufacturing method

A technology of a tin-plated steel sheet and a manufacturing method, which is applied in the field of iron-based alloys, can solve the problems of large fluctuations and attenuation of the roughness of the scalded print of the flower stand, and achieves the effects of small fluctuations, reduced contact point area, and reduced production difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0037] The invention discloses a method for manufacturing a tin-plated steel plate printed and coated with a baking-resistant floral print on one side. The method includes:

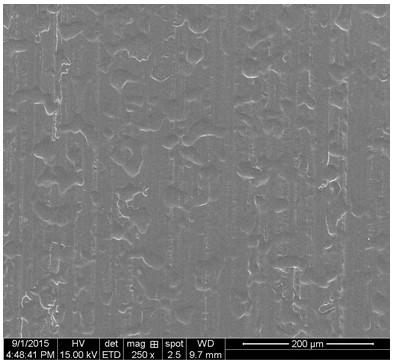

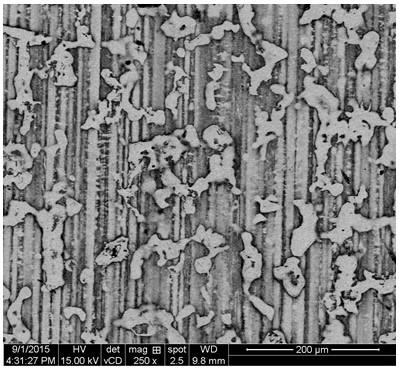

[0038] Pickling, cold continuous rolling, annealing, and leveling of hot-rolled steel sheets with a thickness of 2.0-2.5 mm to obtain cold-rolled steel strips with a thickness of 0.18-0.30 mm; , passivation, and the finished tin-plated steel coil obtained after coiling, wherein,

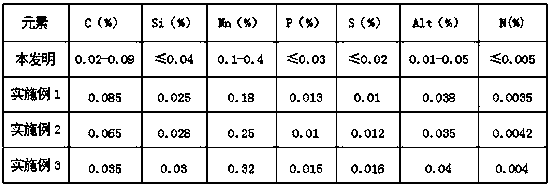

[0039] The chemical composition weight percentage of the hot-rolled steel sheet is: C: 0.02%-0.09%, Si≤0.04%, Mn: 0.1%-0.4%, P≤0.03%, S≤0.02%, Alt: 0.01%-0.05% , N≤0.005%, the balance is Fe and unavoidable impurity elements, the yield strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com