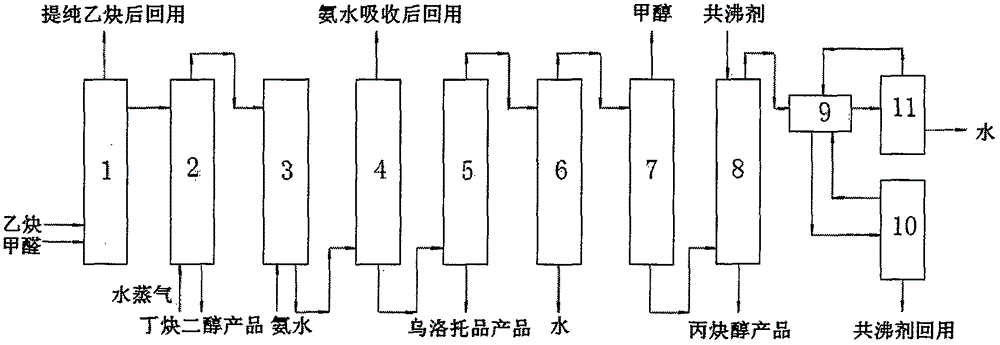

A kind of triple production continuous production method of propynyl alcohol, 1,4-butynediol and urotropine

A technology of butynediol and its production method, applied in 1, can solve problems such as micropore blockage of outlet sand core glass, influence on stable operation of reactor, micronization of catalyst, etc., so as to avoid explosion hazard, avoid reduction of catalyst activity, high Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

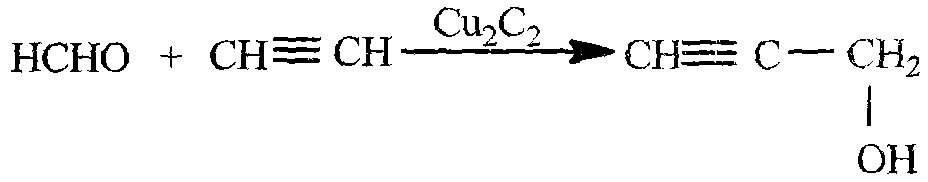

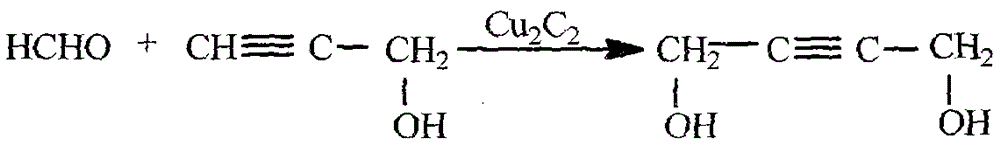

Method used

Image

Examples

Embodiment 1

[0042] The concrete steps of propynyl alcohol of the present invention, 1,4-butynediol and urotropine triple production continuous production method are as follows:

[0043] (1) Formaldehyde aqueous solution and acetylene gas enter alkyne aldehyde reactor 1 from the bottom after preheating, wherein the mass flow rate of formaldehyde solution is 1157.7kg / hr, and the mass flow rate of acetylene is 166.7kg / hr. Alkynylation reaction occurs under the condition of MPa, and the conversion rate of formaldehyde is 50%. The reacted gas phase is purified and reused, and the liquid phase enters the initial distillation column 2 for separation and purification.

[0044] (2) The initial distillation column 2 is operated under normal pressure, and the operating temperature is 110.9°C. Water vapor is introduced into the lower part of the tower for stripping. The alcohol product is produced, and the mass flow rate is 355.8kg / hr, wherein the mass content of 1,4-butynediol is 60.0%, and the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com