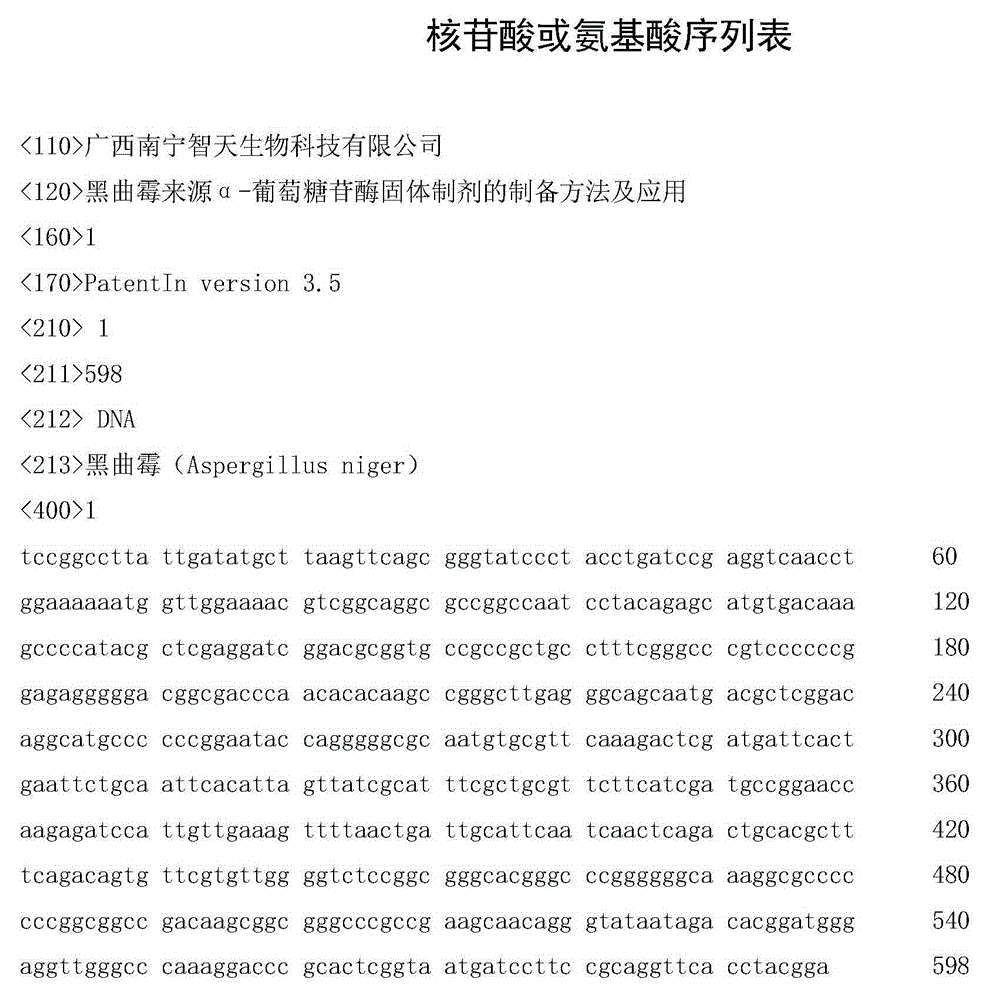

Preparation method of aspergillus niger-source alpha-glucosidase solid preparation and application thereof

A technology of glucosidase and solid preparation, which is applied in the field of preparation of solid preparation of α-glucosidase derived from Aspergillus niger, can solve the problems of low enzyme activity, difficulty in realizing industrialized production, complicated extraction process, etc., and achieves low production cost and reduced production cost. The effect of production cost and production process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: The preparation method and application of Aspergillus niger-derived α-glucosidase solid preparation 1

[0021] (1) The α-glucosidase-producing strain Aspergillus niger ( Aspergillus niger ) M1 was used as the strain, and after culturing at 32°C for 36 hours, the fermentation broth was vacuum filtered to collect mycelia.

[0022] (2) The mycelium is ground and passed through a 10-mesh sieve to make cell fragments, which are freeze-dried, measured and packaged to obtain a solid preparation of α-glucosidase.

[0023] (3) Adjust the pH to 4.5 with the maltose syrup with a solid content of 30%, add 10% (m / v) of the α-glucosidase solid preparation prepared above, and react for glycoside conversion at 55°C for 7 hours, That is, the obtained isomaltooligosaccharide syrup is determined by high-performance liquid chromatography, and the effective trisaccharide (IG+P+IG 3 ) content is 62.52%. Maltose syrup is a commercially available product, and the production com...

Embodiment 2

[0024] Embodiment 2: the preparation method and application 2 of Aspergillus niger source α-glucosidase solid preparation

[0025] (1) The α-glucosidase-producing strain Aspergillus niger ( Aspergillus niger ) M1 was used as the strain, and after culturing at 35°C for 36 hours, the fermentation broth was centrifuged to collect mycelia.

[0026] (2) Keeping the mycelium intact, after freeze-drying, measuring and dispensing, the solid preparation of α-glucosidase is obtained.

[0027] (3) Adjust the pH to 4.5 with maltose syrup with a solid content of 40%, add 15% (m / v) of the α-glucosidase solid preparation prepared above, and react for 6 hours at 55°C for glucoside conversion. That is, the obtained isomaltooligosaccharide syrup is determined by high-performance liquid chromatography, and the effective trisaccharide (IG+P+IG 3 ) content is 69.26%. Maltose syrup is a commercially available product, and the production company is Zhaoqing Huanfa Biotechnology Co., Ltd.

Embodiment 3

[0028] Embodiment 3: the preparation method and its application of Aspergillus niger source α-glucosidase solid preparation 3

[0029] (1) The α-glucosidase-producing strain Aspergillus niger ( Aspergillus niger ) M1 was used as the strain, and after culturing at 30°C for 48 hours, the fermentation broth was collected by ultrafiltration to collect mycelia.

[0030] (2) The mycelium is ground and passed through a 200-mesh sieve to make a cell powder, which is spray-dried, measured, and packaged to obtain a solid preparation of α-glucosidase.

[0031] (3) Adjust the pH to 4.5 with maltose syrup with a solid content of 10%, add 10% (m / v) of the above-prepared α-glucosidase solid preparation, and react for 8 hours at 50°C for glucoside conversion. That is, the obtained isomaltooligosaccharide syrup is determined by high-performance liquid chromatography, and the effective trisaccharide (IG+P+IG 3 ) content is 36.39%. Maltose syrup is a commercially available product, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com