Method for producing acetification-grade dissolving pulp by using veneer

A technology for dissolving pulp and board skin, which is applied in the direction of pulping with organic compounds, pulping with inorganic alkalis, and cellulose treatment with microorganisms/enzymes, etc., to achieve the effect of cleaning the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

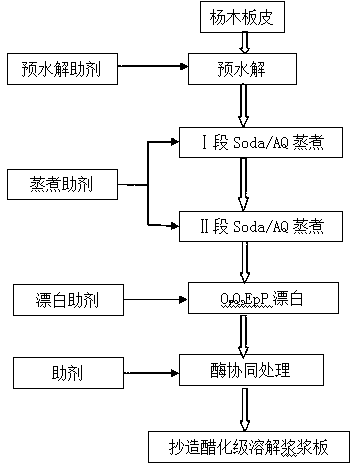

Image

Examples

Embodiment 1

[0030] Prehydrolysis with Additives - Soda / AQ Staged Cooking with Additives - O P Q D EpP-enzyme synergistic process to treat poplar veneer raw material: Take 500g of poplar veneer slices from a certain factory, 10-30mm long, with a pentosan content of 24.3% and an α-cellulose content of 43.0%.

[0031] The pre-hydrolysis process conditions for controlling the addition of additives are: liquid ratio 1: 6, additives 0.4%, maximum temperature 160°C, holding time 60 minutes, the content of pentosan after hydrolysis is 8.6%, and the hydrolysis yield is 80%;

[0032]The process conditions of Soda / AQ cooking stage I are: the amount of alkali used is 5%, the liquid ratio is 1:4, magnesium hydroxide is 0.5%, sodium sulfite is 5.0%, the amount of AQ is 0.05%, Tmax=100℃±2℃, holding time 60 minutes;

[0033] The process conditions of Soda / AQ cooking stage II are: the amount of alkali used is 18%, magnesium hydroxide is 0.5%, sodium sulfite is 3.0%, the liquid ratio is 1:7, the amount o...

Embodiment 2

[0042] Prehydrolysis with Additives - Soda / AQ Staged Cooking with Additives - O P Q D EpP-enzyme synergistic process to treat the raw material of poplar veneer, the content of pentosan in the obtained poplar veneer is 22.3%, the content of α-cellulose is 45.0%, and the process conditions are the same as in Example 1. The α-cellulose content that obtains poplar bark vinegar grade dissolving pulp is 97%, polypentose is 2.2%, degree of polymerization 1280, whiteness 90%ISO, ash content 0.01%, DCM extract content 0.02%, vinegar Chemical reaction value (PV value) 820.

[0043] Poplar veneer vinegar-grade dissolving pulp has good detection indexes and can be used to produce high-grade cellulose acetate products.

Embodiment 3

[0045] Prehydrolysis with Additives - Soda / AQ Staged Cooking with Additives - O P Q D EpP-enzyme synergistic process to treat the poplar veneer raw material, the poplar veneer obtained is the same as that in Example 1. Only the pre-hydrolysis holding time was changed to 120 minutes, the content of pentosan after hydrolysis was 8.5%, and the hydrolysis yield was 79%, and other processes remained unchanged. The α-cellulose content of the finally obtained poplar veneer vinegar grade dissolving pulp is 97%, the polypentose is 2.2%, the degree of polymerization is 1200, the whiteness is 89%ISO, the ash content is 0.01%, and the DCM extract content is 0.02%. The esterification reaction value (PV value) is 780.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aggregation | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com