Brownish red gangue encaustic tile and preparation method thereof

A technology of coal gangue and glazed tile, applied in the field of brown-red coal gangue glazed tile and its preparation, can solve the problems of loss of life and property, low added value, cost of capital, etc., and achieves increased development and utilization, clean production process and high product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

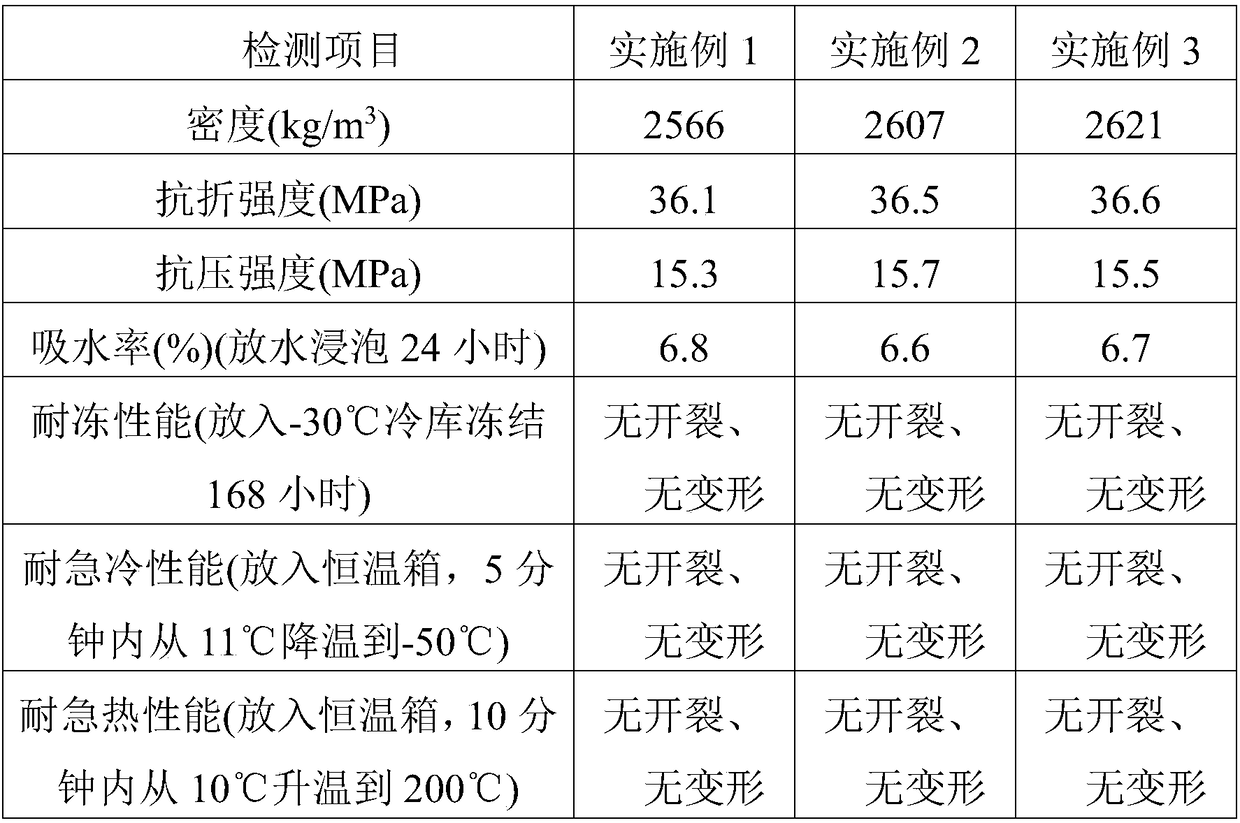

Examples

preparation example Construction

[0040] The raw materials for preparing the gangue glazed tile include 70%-75% of gangue sand, 2%-3% of harmless treatment agent, 3%-5% of glaze compounding agent, and 16%-22% of water. The content is percentage by weight;

[0041] The harmless treatment agent includes 5% to 10% of calcium chloride, 70% to 75% of quicklime, and 20% to 25% of gypsum powder, and the percentage is by weight;

[0042] The glaze compounding agent comprises 84% of lead frit, 10% of iron powder, and 6.0% of kaolin, and the percentages are percentages by weight;

[0043] Further, in the harmless treatment agent, the fineness of the calcium chloride, quicklime and gypsum powder is 100 mesh.

[0044] The present invention also provides a method for preparing the above-mentioned brown-red coal gangue glazed tile, comprising the following steps:

[0045] (1) After screening the gangue sand, air it in the air, so that its water content is lower than 5%;

[0046] (2) Adopt Raymond pulverizer to pulveriz...

Embodiment 1

[0066] A brown-red coal gangue glazed tile, comprising 146kg of gangue sand, 6kg of harmless treatment agent, 8kg of glaze compounding agent, and 40kg of water;

[0067] Wherein, the harmless treatment agent includes 0.48 kg of calcium chloride with a fineness of 100 mesh, 4.32 kg of quicklime, and 1.2 kg of gypsum powder;

[0068] Described glaze composite agent comprises lead frit 6.72kg, iron powder 0.8kg, kaolin 0.48kg;

[0069] The preparation method of above-mentioned brown-red coal gangue glazed tile comprises:

[0070] (1) After screening the gangue sand, air it in the air, so that its water content is lower than 5%;

[0071] (2) Pulverize the dried coal gangue sand, and pass through a 190-mesh sieve to obtain coal gangue powder, with a sieve residue of less than 3%;

[0072] (3) Mix the finely screened coal gangue powder with water and harmless treatment agent, stir evenly to make its humidity 18% to 20%, and then carry out stuffing, that is, harmless treatment for ...

Embodiment 2

[0090] A brown-red coal gangue glazed tile, comprising 140kg of gangue sand, 6kg of harmless treatment agent, 10kg of glaze compounding agent, and 44kg of water;

[0091] Wherein, the harmless treatment agent includes 0.3 kg of calcium chloride with a fineness of 100 mesh, 4.2 kg of quicklime, and 1.5 kg of gypsum powder;

[0092] Described glaze composite agent comprises lead frit 8.4kg, iron powder 1kg, kaolin 0.6kg;

[0093] The preparation method of above-mentioned brown-red coal gangue glazed tile comprises:

[0094] (1) After screening the gangue sand, air it in the air, so that its water content is lower than 5%;

[0095] (2) Pulverize the dried coal gangue sand, and pass through a 180-mesh sieve to obtain coal gangue powder, with a residue less than 3%;

[0096] (3) Mix the finely screened coal gangue powder with water and harmless treatment agent, stir evenly to make its humidity 18% to 20%, and then carry out stuffing, that is, harmless treatment for 4 days to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com