Method for producing corn porous starch by using low temperature freeze-thawing technology

A technology for porous starch and corn starch, applied in the field of starch deep processing, can solve the problems affecting the reactivity, adsorption and embedding properties of corn starch, high cost of enzymatic chemical reagents, complex compound modification process, etc. Low cost and high freeze-thaw stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

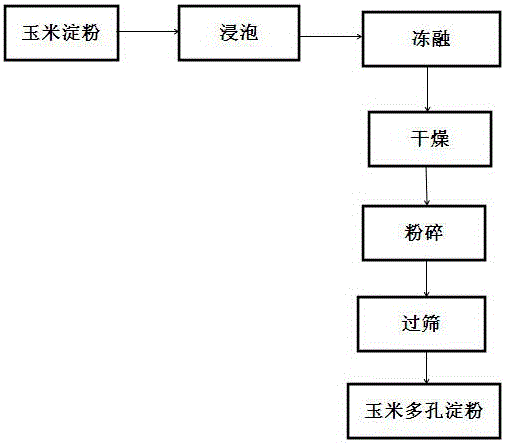

[0029] Take cornstarch, place in container, be 1:3 according to starch: water ratio, add water and soak for 6 hours;

[0030] The cornstarch obtained by soaking above was frozen at a temperature of -20°C for 12 hours. After freezing, the frozen cornstarch was thawed at a temperature of 25°C for 4 hours, and repeated freezing and thawing for 0, 5, 10, 20 times;

[0031] The cornstarch obtained after the above freeze-thawing was placed at a temperature of 40° C. for drying, and the drying time was 48 hours;

[0032] Pulverizing the dried cornstarch;

[0033] Pass the crushed corn starch through a 100-mesh sieve to obtain corn porous starch. The obtained corn porous starch has a porosity greater than 50% and a moisture content of 10% to 14%.

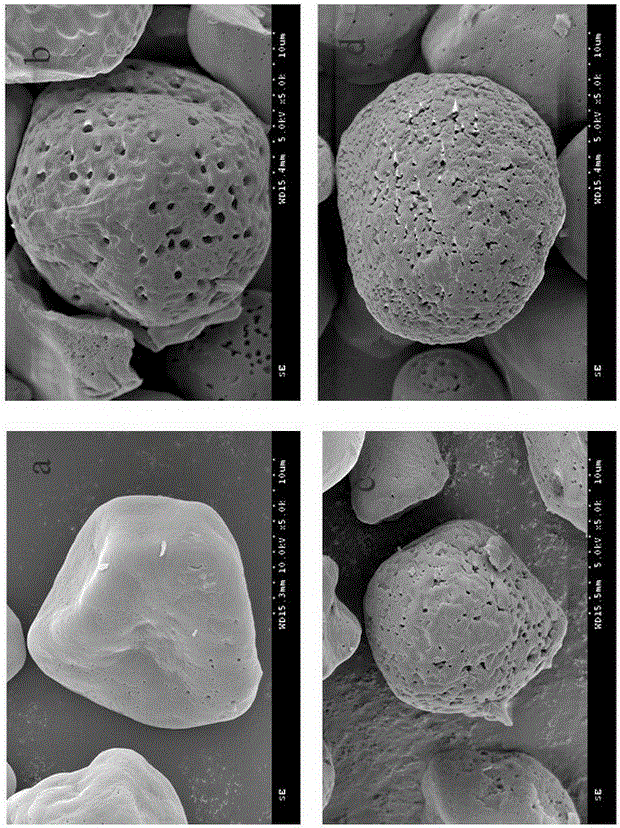

[0034] figure 2 Electron microscope of the corn porous starch obtained by freezing and thawing at a freezing temperature of -20°C and a thawing temperature of 25°C (a: 0 times, b: 5 times, c: 10 times, d: 20 times) scan diagram.

Embodiment 2

[0036] Take cornstarch, place in container, be 1:3 according to starch: water ratio, add water and soak for 6 hours;

[0037] The cornstarch obtained by soaking above was frozen at a temperature of -196°C for 12 hours. After freezing, the frozen cornstarch was thawed at a temperature of 25°C for 4 hours, and repeated freezing and thawing 0, 5, 10, 20 times;

[0038] The cornstarch obtained after the above freeze-thawing was placed at a temperature of 40° C. for drying, and the drying time was 48 hours;

[0039] Pulverizing the dried cornstarch;

[0040] Pass the crushed corn starch through a 100-mesh sieve to obtain corn porous starch. The obtained corn porous starch has a porosity greater than 50% and a moisture content of 10% to 14%.

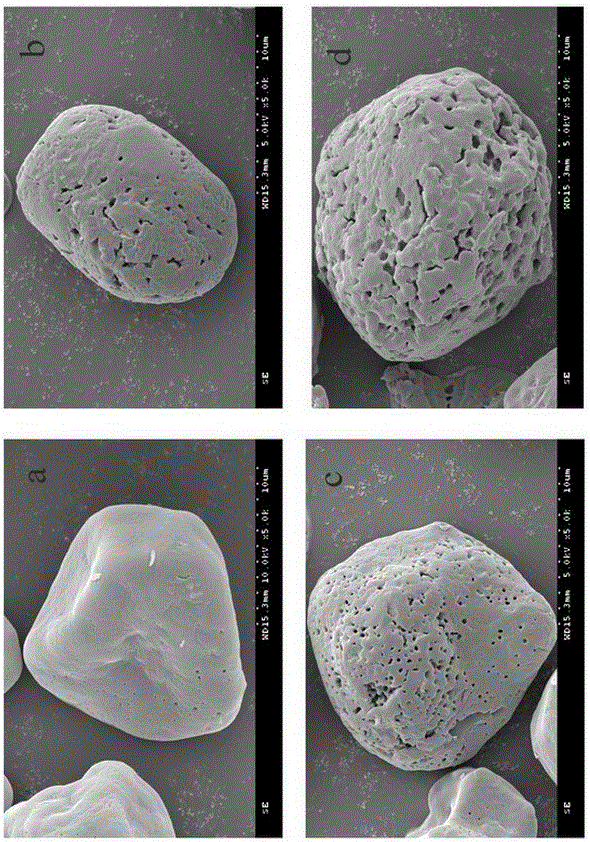

[0041] image 3 Electron microscope of the corn porous starch obtained by freezing and thawing at a freezing temperature of -196°C and a thawing temperature of 25°C (a: 0 times, b: 5 times, c: 10 times, d: 20 times) scan diagram.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com