Method for preparing modified starch by utilizing ozonation

A modified starch and ozone oxidation technology, applied in the field of starch deep processing, can solve problems such as limiting the value of oxidized starch, and achieve obvious economic and social benefits, clean production process, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

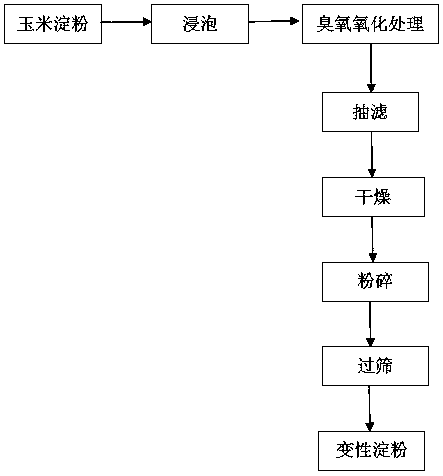

[0028] (1) Soaking: Weigh corn starch, put it in a container, add water to soak, wherein the mass ratio of starch to water is 1:5, and the soaking time is 2 hours;

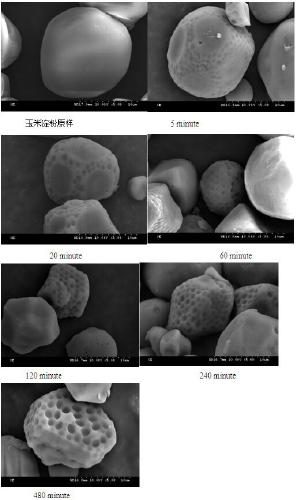

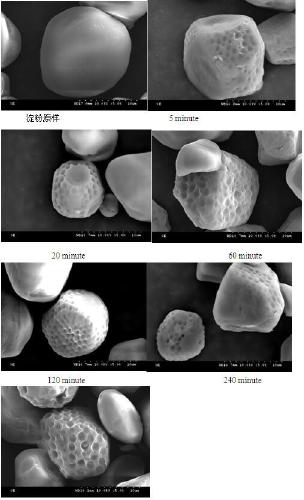

[0029] (2) Ozone oxidation of cornstarch: connect the obtained starch milk to an ozone generator, and place it under the condition that the ozone flow rate is 1L / min for oxidation, and the oxidation time is 5-480min;

[0030] (3) Suction filtration: the starch milk prepared in step (2) is subjected to suction filtration with a Buchner funnel;

[0031] (4) drying: take out the starch prepared in step (3) and dry at 40°C for 48h;

[0032] (5) pulverizing: pulverizing the dried starch in step (4);

[0033] (6) Sieving: pass the pulverized modified starch obtained in step (5) through a 100-mesh sieve to obtain the modified starch.

Embodiment 2

[0035] 1) Soaking: Weigh cornstarch, put it in a container, add water to soak, wherein the mass ratio of starch to water is 1:10, and the soaking time is 2 hours;

[0036] (2) Ozone oxidation of cornstarch: connect the obtained starch milk to an ozone generator, and place it under the condition that the ozone flow rate is 1L / min for oxidation, and the oxidation time is 5-480min;

[0037] (3) Suction filtration: the starch milk prepared in step (2) is subjected to suction filtration with a Buchner funnel;

[0038] (4) drying: take out the starch prepared in step (3) and dry at 40°C for 48h;

[0039] (5) pulverizing: pulverizing the dried starch in step (4);

[0040] (6) Sieving: pass the pulverized modified starch obtained in step (5) through a 100-mesh sieve to obtain the modified starch.

Embodiment 3

[0042] 1) Soaking: Weigh cornstarch, put it in a container, add water to soak, wherein the mass ratio of starch to water is 1:20, and the soaking time is 2 hours;

[0043] (2) Ozone oxidation of cornstarch: connect the obtained starch milk to an ozone generator, and place it under the condition that the ozone flow rate is 1L / min for oxidation, and the oxidation time is 5-480min;

[0044] (3) Suction filtration: the starch milk prepared in step (2) is subjected to suction filtration with a Buchner funnel;

[0045] (4) drying: take out the starch prepared in step (3) and dry at 40°C for 48h;

[0046] (5) pulverizing: pulverizing the dried starch in step (4);

[0047] (6) Sieving: pass the pulverized modified starch obtained in step (5) through a 100-mesh sieve to obtain the modified starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com