Waxy wheat RS5 type resistant starch and preparation method thereof

A technology of resistant starch and glutinous wheat, applied in the functions of food ingredients, fermentation, food science, etc., to achieve the effects of high production efficiency, low production cost, and improved quality and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

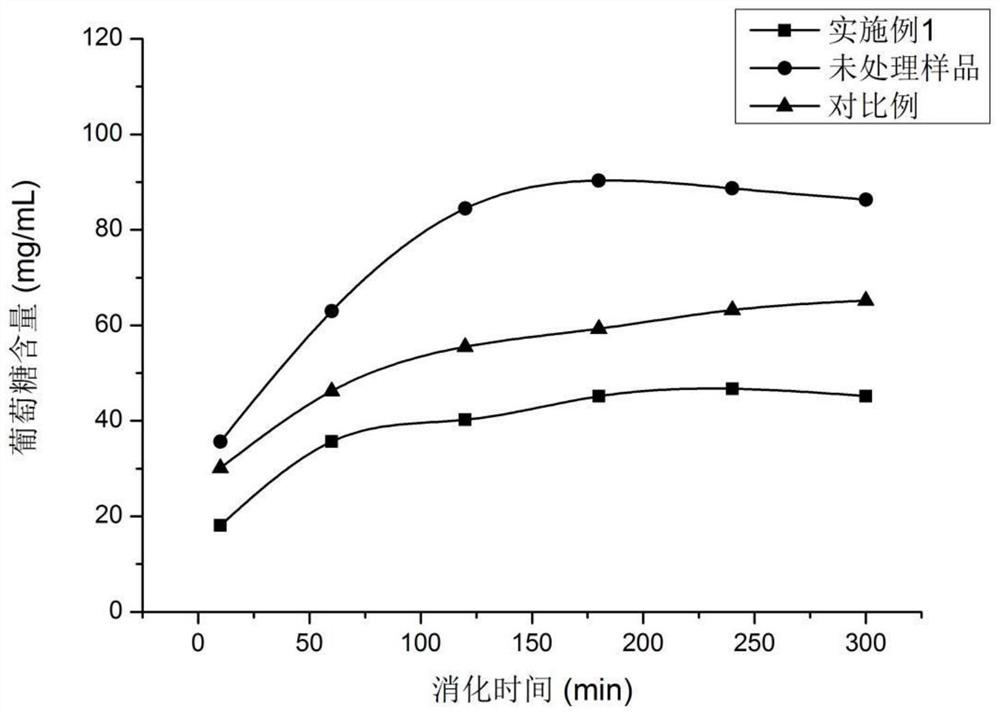

Embodiment 1

[0038] Example 1: Waxy wheat starch-lauric acid RS 5 preparation of

[0039] (1) Mix waxy wheat starch and high-amylose corn starch in a mass ratio of 2:1 (called substrate). Then add pure water to make starch milk with a concentration of 4%, adjust the pH of the system to 5.0 with 2mol / L sodium hydroxide and hydrochloric acid solution, heat and stir in a boiling water bath for 30 minutes, so that the starch is fully gelatinized, and then cool to room temperature;

[0040] (2) Add 3% pullulanase of the substrate mass, heat in a water bath, react at 53°C for 4h, heat in a boiling water bath for 10min, carry out enzyme inactivation treatment, cool to room temperature, and then use 2mol / L sodium hydroxide and hydrochloric acid The pH of the solution is adjusted to 6.5;

[0041] (3) Add 2% branching enzyme (according to 100g substrate adding 2mL branching enzyme, the same below) to the starch gelatinization solution, heat in a water bath, react at 60°C for 24h, heat in ...

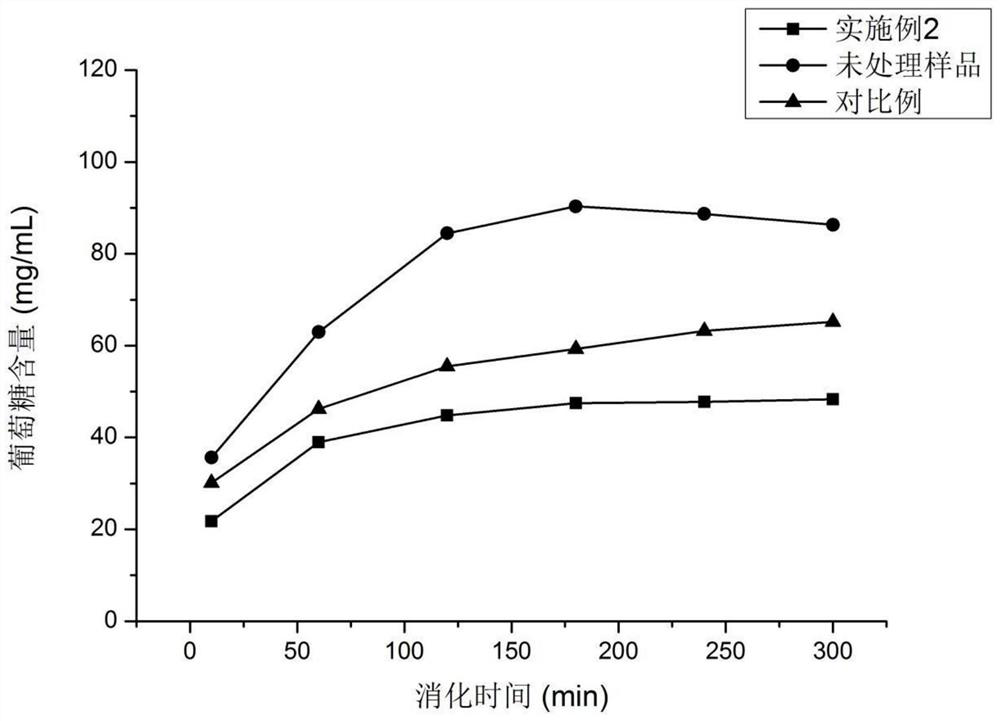

Embodiment 2

[0043] Example 2: Waxy wheat starch-myristic acid RS 5 preparation of

[0044] (1) Mix waxy wheat starch and high-amylose corn starch in a mass ratio of 2:1. Then add pure water to make starch milk with a concentration of 6%, adjust the pH of the system to 5.5 with 2mol / L sodium hydroxide and hydrochloric acid solution, heat and stir in a boiling water bath for 30 minutes, so that the starch is fully gelatinized, and then cool to room temperature;

[0045] (2) Add 3% pullulanase of substrate mass, heat in a water bath, react at 50°C for 4h, heat in a boiling water bath for 10min, carry out an enzyme-inactivating treatment, cool to room temperature, and then use 2mol / L of sodium hydroxide and The hydrochloric acid solution adjusts the pH to 6.5;

[0046] (3) Add 2% branching enzyme to the starch gelatinization solution, heat in a water bath, react at 60°C for 24 hours, heat in a boiling water bath for 10 minutes, perform enzyme inactivation treatment, and cool to roo...

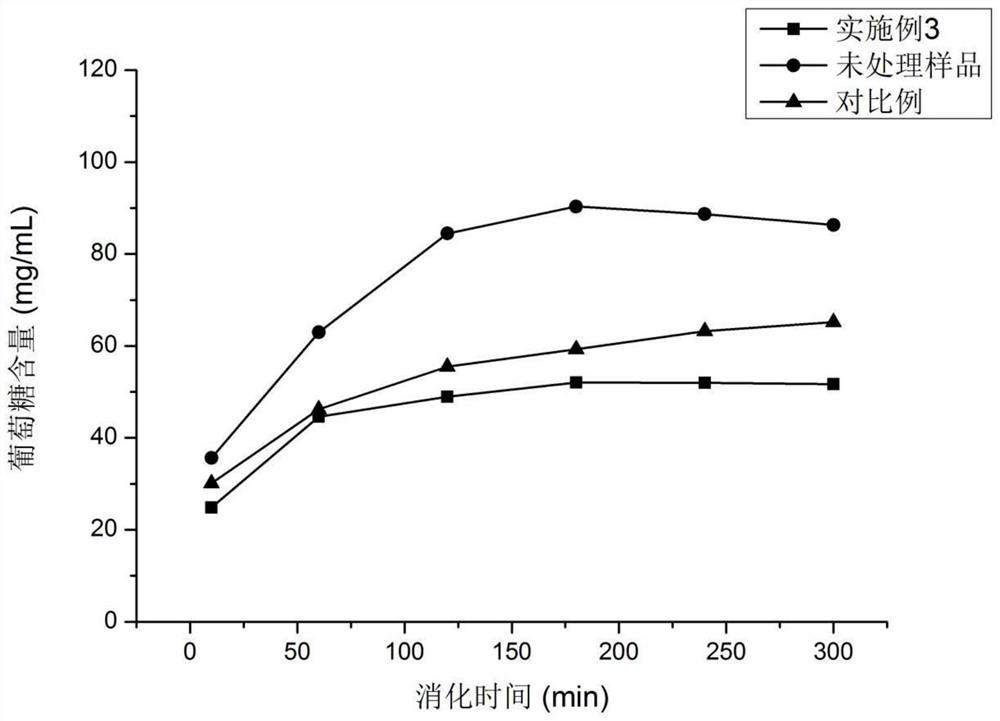

Embodiment 3

[0048] Example 3: Waxy wheat starch-palmitic acid RS 5 preparation of

[0049] (1) Mix waxy wheat starch and high-amylose corn starch in a mass ratio of 1:1. Then add pure water to make a starch emulsion with a concentration of 4%, adjust the pH of the system to 5.0 with 1mol / L sodium hydroxide and hydrochloric acid solution, heat and stir in a boiling water bath for 20 minutes, so that the starch is fully gelatinized, and then cool to room temperature;

[0050] (2) Add 4% pullulanase of the substrate mass, heat in a water bath, and react at 55°C for 3h, then heat in a boiling water bath for 10min, carry out enzyme-inactivation treatment, cool to room temperature, and then use 1mol / L sodium hydroxide and hydrochloric acid Adjust the pH of the solution to 6.0;

[0051] (3) Add 2% branching enzyme to the starch gelatinization solution, heat in a water bath, react at 60°C for 24 hours, heat in a boiling water bath for 10 minutes, perform enzyme inactivation treatment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com